Professional Documents

Culture Documents

Road Structures Design Manual - DOT

Uploaded by

Abdullah MansoorOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Road Structures Design Manual - DOT

Uploaded by

Abdullah MansoorCopyright:

Available Formats

ROAD STRUCTURES DESIGN MANUAL

DOCUMENT NO: AD-D-06

SIXTH EDITION (DRAFT)

2013

Document No: AD-D-06

Sixth Edition (Draft)

2013

Department of Transport

PO Box 20

Abu Dhabi, United Arab Emirates

Copyright 2013, by the Department of Transport. All Rights Reserved. This document, or parts

thereof, may not be reproduced in any form without written permission of the publisher.

Page i

TABLE OF CONTENTS

Table of Contents........................................................................................................................... i

List of Figures .............................................................................................................................. xi

List of Tables ............................................................................................................................... xii

1 INTRODUCTION ................................................................................................................. 1

1.1 Overview .......................................................................................................................... 1

1.2 Purpose and Scope .......................................................................................................... 1

1.2.1 General ...................................................................................................................... 1

1.2.2 AASHTO LRFD Bridge Design Specifications ............................................................ 2

1.3 Application of this Manual ................................................................................................. 2

1.3.1 Definition of Road Structures ..................................................................................... 2

1.3.2 Hierarchy of Priority ................................................................................................... 2

1.4 Design Objectives ............................................................................................................. 3

1.4.1 Serviceability ............................................................................................................. 3

1.4.2 Constructability .......................................................................................................... 3

1.4.3 Maintenance of Traffic ............................................................................................... 3

1.4.4 Sustainability ............................................................................................................. 3

1.4.5 Aesthetics .................................................................................................................. 4

1.5 Design Approval Procedures ............................................................................................ 4

1.5.1 Objectives .................................................................................................................. 4

1.5.2 Reference .................................................................................................................. 4

1.6 Bridge Design Checklists .................................................................................................. 4

2 LOADS AND LOAD FACTORS .......................................................................................... 5

2.1 General ............................................................................................................................. 5

2.1.1 Limit States ................................................................................................................ 5

2.1.2 Load Factors and Combinations ................................................................................ 6

2.2 Permanent Loads ............................................................................................................. 9

2.2.1 General ...................................................................................................................... 9

2.2.2 Downdrag (DD) on Deep Foundations ..................................................................... 10

2.2.3 Differential Settlement (SE) ..................................................................................... 10

2.3 Transient Loads .............................................................................................................. 10

2.3.1 General .................................................................................................................... 10

2.3.2 Abu Dhabi Vehicular Load (ADVL) ........................................................................... 10

2.3.3 Wind Loads (WS and WL) ....................................................................................... 12

2.3.4 Earthquake Effects (EQ) .......................................................................................... 13

Page ii

2.3.5 Uniform Temperature (TU) ....................................................................................... 14

2.3.6 Temperature Gradient (TG) ..................................................................................... 14

2.3.7 Live-Load Surcharge (LS) ........................................................................................ 15

2.3.8 Ground Water Levels ............................................................................................... 15

3 STRUCTURAL ANALYSIS ............................................................................................... 16

3.1 Acceptable Methods ....................................................................................................... 16

3.1.1 General .................................................................................................................... 16

3.1.2 Exceptions ............................................................................................................... 16

3.2 Static Analysis ................................................................................................................ 16

3.2.1 Refined Analysis ...................................................................................................... 16

3.2.2 Approximate Analysis .............................................................................................. 16

3.2.3 Lateral Wind-Load Distribution in Multi-Beam Bridges ............................................. 19

3.3 Dynamic Analysis ........................................................................................................... 19

3.3.1 Seismic Analysis ...................................................................................................... 19

3.3.2 Wind-Induced Vibration ........................................................................................... 21

4 CONCRETE STRUCTURES ............................................................................................. 22

4.1 Structural Concrete Design ............................................................................................. 22

4.1.1 Member Design Models ........................................................................................... 22

4.1.2 Sectional Design Model ........................................................................................... 22

4.1.3 Strut-and-Tie Model ................................................................................................. 24

4.1.4 Fatigue .................................................................................................................... 25

4.1.5 Torsion .................................................................................................................... 25

4.2 Materials ......................................................................................................................... 26

4.2.1 Structural Concrete .................................................................................................. 26

4.2.2 Reinforcing Steel ..................................................................................................... 26

4.2.3 Prestressing Strand ................................................................................................. 26

4.2.4 Prestressing Bars .................................................................................................... 27

4.3 Reinforcement ................................................................................................................ 27

4.3.1 Reinforcing-Steel Details ......................................................................................... 27

4.3.2 Prestressing Strands and Tendons .......................................................................... 34

4.4 Prestressed Concrete Superstructures ........................................................................... 36

4.4.1 Basic Criteria ........................................................................................................... 36

4.4.2 Post-Tensioned Bridges........................................................................................... 36

4.4.3 Precast, Prestressed Concrete Girders .................................................................... 49

4.4.4 Pretensioned/Post-Tensioned Beams ...................................................................... 55

4.4.5 Camber Diagram ..................................................................................................... 55

Page iii

4.4.6 Responsibilities ........................................................................................................ 55

5 STEEL STRUCTURES ..................................................................................................... 57

5.1 General ........................................................................................................................... 57

5.1.1 Economical Steel Superstructure Design ................................................................. 57

5.1.2 Rolled Beams vs Welded Plate Girders ................................................................... 58

5.1.3 Economical Plate Girder Proportioning .................................................................... 58

5.1.4 Falsework ................................................................................................................ 62

5.2 Materials ......................................................................................................................... 62

5.2.1 Structural Steel ........................................................................................................ 62

5.2.2 Bolts ........................................................................................................................ 64

5.2.3 Splice Plates ............................................................................................................ 65

5.3 Horizontally Curved Members ......................................................................................... 65

5.3.1 General .................................................................................................................... 65

5.3.2 Diaphragms, Bearings, and Field Splices ................................................................ 65

5.4 Fatigue Considerations ................................................................................................... 66

5.4.1 Load-Induced Fatigue .............................................................................................. 66

5.4.2 Other Fatigue Considerations .................................................................................. 67

5.5 General Dimension and Detail Requirements ................................................................. 67

5.5.1 Deck Haunches ....................................................................................................... 67

5.5.2 Sacrificial Metal Thickness ....................................................................................... 67

5.5.3 Minimum Thickness of Steel Plates ......................................................................... 67

5.5.4 Camber .................................................................................................................... 68

5.5.5 Diaphragms and Cross Frames ............................................................................... 68

5.5.6 Jacking .................................................................................................................... 70

5.5.7 Lateral Bracing ........................................................................................................ 73

5.5.8 Inspection Access (Tub Girders) .............................................................................. 73

5.6 I-Sections in Flexure ....................................................................................................... 73

5.6.1 General .................................................................................................................... 73

5.6.2 Shear Connectors .................................................................................................... 74

5.6.3 Stiffeners ................................................................................................................. 74

5.6.4 Deck-Overhang Cantilever Brackets ........................................................................ 76

5.7 Connections and Splices ................................................................................................ 76

5.7.1 Bolted Connections .................................................................................................. 76

5.7.2 Welded Connections ................................................................................................ 77

5.7.3 Splices ..................................................................................................................... 78

6 DECKS AND DECK SYSTEMS ........................................................................................ 80

Page iv

6.1 Concrete Decks .............................................................................................................. 80

6.1.1 Protection of Reinforcing Steel................................................................................. 80

6.1.2 Empirical Design ...................................................................................................... 80

6.1.3 Traditional Design Using the Strip Method............................................................. 80

6.1.4 Precast Concrete Deck Panels ................................................................................ 81

6.2 Metal Decks .................................................................................................................... 81

6.2.1 Grid Decks ............................................................................................................... 81

6.2.2 Orthotropic Steel Decks ........................................................................................... 81

6.3 Design Details for Concrete Bridge Decks ...................................................................... 82

6.3.1 General .................................................................................................................... 82

6.3.2 Detailing Requirements for Concrete-Deck Haunches ............................................. 83

6.3.3 Reinforcing Steel Over Intermediate Piers or Bents ................................................. 84

6.3.4 Minimum Negative Flexure Slab Reinforcement ...................................................... 84

6.3.5 Crack Control in Continuous Decks ......................................................................... 84

6.3.6 Skewed Decks ......................................................................................................... 87

6.3.7 Temperature and Shrinkage Reinforcement ............................................................ 88

6.3.8 Thickened Slab End Requirements .......................................................................... 88

6.3.9 Phase Constructed Decks ....................................................................................... 88

6.3.10 Stay-in-Place Forms ................................................................................................ 89

6.3.11 Concrete Deck Pouring Sequence for Decks Constructed Compositely in Conjunction

with Concrete and Steel Girders .............................................................................. 89

6.3.12 Longitudinal Construction Joints .............................................................................. 90

6.3.13 Longitudinal Concrete Deck Joints ........................................................................... 92

6.3.14 Transverse Edge Beam for Steel Girder Bridges ..................................................... 94

6.3.15 Concrete Deck Overhang/Bridge Rail ...................................................................... 94

6.4 Approach Slabs .............................................................................................................. 96

6.4.1 Usage ...................................................................................................................... 96

6.4.2 Design Criteria ......................................................................................................... 96

7 FOUNDATIONS ................................................................................................................ 97

7.1 General ........................................................................................................................... 97

7.1.1 Scope ...................................................................................................................... 97

7.1.2 Design Methodology ................................................................................................ 97

7.1.3 Bridge Foundation Design Process .......................................................................... 97

7.1.4 Bridge Design/Geotechnical Design Interaction ....................................................... 98

7.2 Spread Footings and Pile Caps .................................................................................... 101

7.2.1 Usage .................................................................................................................... 101

Page v

7.2.2 Dynamic Load Allowance (Impact Modifier, IM) ..................................................... 102

7.2.3 Thickness .............................................................................................................. 102

7.2.4 Depth ..................................................................................................................... 102

7.2.5 Bearing Resistance and Eccentricity ...................................................................... 102

7.2.6 Sliding Resistance ................................................................................................. 102

7.2.7 Differential Settlement ........................................................................................... 103

7.2.8 Reinforcement ....................................................................................................... 104

7.2.9 Miscellaneous ........................................................................................................ 104

7.3 Deep Foundations ........................................................................................................ 105

7.3.1 General .................................................................................................................. 105

7.3.2 Component Spacing .............................................................................................. 105

7.3.3 Drilled Shafts ......................................................................................................... 105

7.3.4 Driven Piles ........................................................................................................... 111

7.3.5 Pile/Shaft Testing................................................................................................... 114

7.4 Modelling for Lateral Loading ........................................................................................ 116

7.5 Mass Concrete ............................................................................................................. 117

8 ABUTMENTS, PIERS, AND WALLS .............................................................................. 118

8.1 Abutments/Wingwalls ................................................................................................... 118

8.1.1 General .................................................................................................................. 118

8.1.2 General Abutment/Wingwall Design and Detailing Criteria ..................................... 119

8.1.3 Seat Abutments ..................................................................................................... 119

8.1.4 Integral Abutments ................................................................................................. 120

8.1.5 Semi-Integral Abutments ....................................................................................... 120

8.1.6 MSE Wall Abutments ............................................................................................. 121

8.1.7 Wingwalls .............................................................................................................. 121

8.1.8 Abutment Construction Joints ................................................................................ 122

8.2 Piers ............................................................................................................................. 122

8.2.1 Design Preferences ............................................................................................... 122

8.2.2 Pier Caps ............................................................................................................... 122

8.2.3 Column Cross Sections ......................................................................................... 123

8.2.4 Column Reinforcement .......................................................................................... 123

8.2.5 Column Construction Joints ................................................................................... 125

8.2.6 Multi-Column Piers ................................................................................................ 125

8.2.7 Single-Column Piers .............................................................................................. 125

8.2.8 Pier Walls .............................................................................................................. 125

8.2.9 Dynamic Load Allowance (DLA) ............................................................................ 125

Page vi

8.2.10 Moment-Magnification ........................................................................................... 125

8.2.11 Crack Control ......................................................................................................... 126

8.3 Walls (Earth Retaining Systems) .................................................................................. 126

8.3.1 General .................................................................................................................. 126

8.3.2 Responsibilities ...................................................................................................... 127

8.3.3 Types of Earth Retaining Systems ......................................................................... 129

8.3.4 Mechanically-Stabilized Earth (MSE) Walls ........................................................... 131

8.4 Geosynthetic Reinforced Soil (GRS) Walls and Abutments .......................................... 139

8.5 Pier, Column, and Footing Design ................................................................................ 140

9 EXPANSION JOINTS ..................................................................................................... 143

9.1 Design Requirements: Movement and Loads ............................................................... 143

9.1.1 General .................................................................................................................. 143

9.1.2 Estimation of General Design Thermal Movement, A

T

........................................... 144

9.1.3 Estimation of Design Movement ............................................................................ 144

9.1.4 Setting Temperature .............................................................................................. 144

9.2 Expansion Joint Selection and Design .......................................................................... 145

9.2.1 General .................................................................................................................. 145

9.2.2 Strip Seal Joint ...................................................................................................... 145

9.2.3 Modular Expansion Joint........................................................................................ 146

9.2.4 Silicone Joint Sealant ............................................................................................ 146

9.2.5 Closed-Cell Compression Seal .............................................................................. 146

9.2.6 Asphaltic Plug Joint ............................................................................................... 146

9.2.7 Steel Finger Joints ................................................................................................. 147

9.2.8 Nosing Joint ........................................................................................................... 147

9.2.9 Expansion Joints for Asphaltic Overlays ................................................................ 147

9.3 Expansion Joints for Post-Tensioned Bridges ............................................................... 147

9.4 Expansion Joint Design ................................................................................................ 148

10 BEARINGS ..................................................................................................................... 149

10.1 General ......................................................................................................................... 149

10.1.1 Movements and Loads .......................................................................................... 149

10.1.2 Effect of Camber and Construction Procedures ..................................................... 149

10.1.3 Design Thermal Movements .................................................................................. 149

10.1.4 Estimation of Total Design Movement .................................................................... 150

10.1.5 Serviceability, Maintenance, and Protection Requirements .................................... 150

10.1.6 Anchor Bolts .......................................................................................................... 150

10.1.7 Bearing Plate Details ............................................................................................. 151

Page vii

10.1.8 Levelling Pad at Integral Abutments ...................................................................... 151

10.1.9 Lateral Restraint .................................................................................................... 151

10.2 Bearing Types and Selection ........................................................................................ 152

10.2.1 General .................................................................................................................. 152

10.2.2 Steel-Reinforced Elastomeric Bearings .................................................................. 152

10.2.3 Plain Elastomeric Bearing Pads ............................................................................. 153

10.2.4 High-Load, Multi-Rotational (HLMR) Bearings ....................................................... 153

10.2.5 Polytetrafluoroethyl (PTFE) Sliding Surfaces ......................................................... 154

10.2.6 Seismic Isolation Bearings ..................................................................................... 154

10.3 Plain Elastomeric Bearing Pads and Steel-Reinforced Elastomeric Bearings ............... 154

10.3.1 General .................................................................................................................. 154

10.3.2 Holes in Elastomer ................................................................................................. 154

10.3.3 Edge Distance ....................................................................................................... 154

10.3.4 Steel-Reinforced Elastomeric Bearings .................................................................. 155

10.3.5 Design of Plain Elastomeric Bearing Pads ............................................................. 155

10.3.6 Design of Steel-Reinforced Elastomeric Bearings .................................................. 155

11 PEDESTRIAN BRIDGES ................................................................................................ 157

11.1 Live Load ...................................................................................................................... 157

11.1.1 Pedestrian Load (PL) ............................................................................................. 157

11.1.2 Vehicle Load (LL) .................................................................................................. 157

11.2 Wind Load (WS) ........................................................................................................... 157

11.3 Vibrations ..................................................................................................................... 157

11.4 Design .......................................................................................................................... 157

11.4.1 General .................................................................................................................. 157

11.4.2 Geometrics ............................................................................................................ 158

11.4.3 Structure Type ....................................................................................................... 158

11.4.4 Seismic .................................................................................................................. 158

11.4.5 Fatigue .................................................................................................................. 158

11.4.6 Design ................................................................................................................... 158

11.4.7 Deflections ............................................................................................................. 159

11.4.8 Steel Connections.................................................................................................. 159

11.4.9 Charpy V-Notch Testing......................................................................................... 159

11.4.10 Painting/Galvanizing .............................................................................................. 160

11.4.11 Erection ................................................................................................................. 160

11.4.12 Railings/Enclosures ............................................................................................... 160

11.4.13 Drainage ................................................................................................................ 161

Page viii

11.4.14 Corrosion Resistant Details ................................................................................... 161

11.4.15 Lighting/Attachments ............................................................................................. 161

11.4.16 Maintenance and Inspection Attachments ............................................................. 161

12 CULVERTS ..................................................................................................................... 162

12.1 Reinforced Concrete Boxes .......................................................................................... 162

12.1.1 General .................................................................................................................. 162

12.1.2 Analysis ................................................................................................................. 162

12.1.3 Span-to-Rise Ratios ............................................................................................... 162

12.1.4 Deformations ......................................................................................................... 163

12.1.5 Design Method ...................................................................................................... 163

12.1.6 Load Modifiers and Load Factors ........................................................................... 163

12.1.7 Dead Loads and Earth Pressure ............................................................................ 163

12.1.8 Live Load ............................................................................................................... 164

12.1.9 Wall Thickness Requirements ............................................................................... 164

12.1.10 Reinforcement Details ........................................................................................... 164

12.1.11 Skewed Culverts .................................................................................................... 164

12.2 Concrete Arch Culverts ................................................................................................. 165

12.3 Concrete Pipe Culverts ................................................................................................. 165

12.3.1 General .................................................................................................................. 165

12.3.2 Materials ................................................................................................................ 165

12.3.3 Design ................................................................................................................... 166

13 SOUND BARRIERS ........................................................................................................ 167

13.1 Sound Barrier Design ................................................................................................... 167

13.1.1 General Features Panel Height and Post Spacing .............................................. 167

13.1.2 Wind Loads............................................................................................................ 167

13.1.3 Lateral Earth Pressure ........................................................................................... 167

14 SIGN AND LUMINAIRE SUPPORTS .............................................................................. 168

14.1 General ......................................................................................................................... 168

14.2 Deformations ................................................................................................................ 168

14.3 Basic Wind Speed ........................................................................................................ 168

14.4 Steel Design ................................................................................................................. 168

14.4.1 Base-Plate Thickness ............................................................................................ 168

14.4.2 Welded Connections .............................................................................................. 168

14.4.3 Bolted Connections ................................................................................................ 169

14.4.4 Anchor Bolt Connections ....................................................................................... 169

14.4.5 Bolt Types ............................................................................................................. 169

Page ix

14.5 Aluminium Design ......................................................................................................... 169

14.6 Prestressed-Concrete Poles ......................................................................................... 169

14.7 Foundation Design ........................................................................................................ 170

14.7.1 Geotechnical Design of Drilled Shaft Foundations ................................................. 170

14.7.2 Structural Design of Drilled Shaft Foundations ....................................................... 170

14.8 Design Loads for Vertical Supports ............................................................................... 170

15 ROAD TUNNELS ............................................................................................................ 171

15.1 General ......................................................................................................................... 171

15.2 Definition of Road Tunnels ............................................................................................ 171

15.3 Geotechnical Site Investigations ................................................................................... 172

15.4 Fire Protection .............................................................................................................. 172

15.5 Constructability ............................................................................................................. 172

15.6 Design Life.................................................................................................................... 172

15.7 Design Considerations .................................................................................................. 173

15.7.1 Design Elements ................................................................................................... 173

15.7.2 Live Load ............................................................................................................... 173

15.7.3 Seismic Considerations ......................................................................................... 174

15.8 Tunnel Types ................................................................................................................ 174

15.8.1 Cut-and-Cover Tunnels ......................................................................................... 174

15.8.2 Mined or Bored Tunnels......................................................................................... 175

15.8.3 Immersed Tunnels ................................................................................................. 176

15.9 Tunnel Lining ................................................................................................................ 176

16 BRIDGE EVALUATION .................................................................................................. 177

16.1 Load Rating .................................................................................................................. 177

16.1.1 General .................................................................................................................. 177

16.1.2 Importance of Load Rating ..................................................................................... 177

16.1.3 Methodology .......................................................................................................... 177

16.1.4 Thresholds for Re-Rating Existing Bridges ............................................................ 177

16.1.5 Limit States for Load Rating ................................................................................... 177

16.1.6 Dimensions ............................................................................................................ 177

16.1.7 The LRFR Load-Rating Equation ........................................................................... 178

16.1.8 Analytical Methods for the Load Rating of Post-Tensioned Box Girder Bridges ..... 179

16.2 Design Load Rating ...................................................................................................... 179

16.3 Legal-Load Rating and Load Posting ............................................................................ 179

16.3.1 Legal-Load Rating ................................................................................................. 179

16.3.2 Load Posting .......................................................................................................... 179

Page x

16.4 Permitting and Permit-Load Rating ............................................................................... 180

16.4.1 Permitting .............................................................................................................. 180

16.4.2 Permit-Load Rating ................................................................................................ 180

16.5 Load Testing of Bridges ................................................................................................ 180

16.5.1 General .................................................................................................................. 180

16.5.2 Load Testing Calculations ...................................................................................... 181

16.5.3 Load Testing Method Statement ............................................................................ 181

16.5.4 Load Testing Analysis Report ................................................................................ 182

17 REFERENCES ................................................................................................................ 184

APPENDIX A BRIDGE DESIGN CHECKLIST ........................................................................... 188

Page xi

LIST OF FIGURES

Figure 2.1: Characteristics of the Design Truck ............................................................................. 11

Figure 2.2: Permit Design Live Loads (for P-13 Vehicle) ............................................................... 12

Figure 2.3: Design Response Spectrum........................................................................................ 13

Figure 2.4: Positive Vertical Temperature Gradient in Concrete and Steel Superstructures .......... 15

Figure 3.1: Common Deck Superstructures Covered .................................................................... 18

Figure 4.1: Flowchart for Environmental Classification of Structures ............................................. 28

Figure 4.2: Deviator Diaphragm Detail .......................................................................................... 40

Figure 4.3: Inside Corner Detail at Pier ......................................................................................... 40

Figure 4.4: Details at Expansion Joints ......................................................................................... 40

Figure 5.1: Grouping Flanges for Efficient Fabrication (from the AASHTO/NSBA Steel Bridge

Collaboration (18)) ........................................................................................................................ 60

Figure 5.2: Flange Width Transition (Plan View) ........................................................................... 61

Figure 5.3: Drip Plate Detail .......................................................................................................... 65

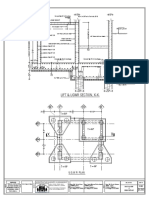

Figure 5.4: Typical Pier and Intermediate Diaphragm Connection (Rolled Beams) ....................... 70

Figure 5.5: Typical Abutment Diaphragm Connection (Skewed Diaphragm with Rolled Beams) .. 71

Figure 5.6: Typical Pier and Intermediate Cross Frames (Plate Girder Web > 1200 mm) ............ 72

Figure 5.7: Typical Abutment Cross Frames (Plate Girder Web > 1200 mm) ................................ 72

Figure 5.8: Schematic of Location for Deck Overhang Bracket ..................................................... 76

Figure 5.9: Typical Welded Splice Details ..................................................................................... 78

Figure 6.1: Haunch Dimension for Steel Plate Girders .................................................................. 85

Figure 6.2: Haunch Dimension for Steel Rolled Beams ................................................................. 85

Figure 6.3: Haunch Dimension for Concrete ................................................................................. 86

Figure 6.4: Skew Angle and Length/Bridge Width Ratios .............................................................. 88

Figure 6.5: Typical Pour Diagram (Continuous Steel and Precast Girders) ................................... 91

Figure 6.6: Support for Finishing Machine ..................................................................................... 93

Figure 6.7: Transverse Edge Beam .............................................................................................. 95

Figure 7.1: Concrete Backfill Under Stepped Footing .................................................................. 105

Figure 7.2: Drilled Shaft Detail (With Permanent Corrugated Metal Pipe for Shafts Larger Than

Columns) .................................................................................................................................... 108

Figure 7.3: Drilled Shaft Detail (For Shafts Larger Than Columns Without Corrugated Metal Pipe)

................................................................................................................................................... 109

Figure 7.4: Drilled Shaft Detail (With Equal Diameter Shaft and Column) .................................. 110

Figure 7.5: Method of Modelling Deep Foundation Stiffness ....................................................... 117

Figure 8.1: Tops of Drop Caps .................................................................................................... 123

Figure 8.2: Design Criteria for Acute Corners of MSE Bin Walls ................................................. 132

Figure 8.3: MSE Wall Minimum Front Face Embedment ............................................................. 133

Figure 8.4: Broken Backfill with Traffic Surcharge ....................................................................... 135

Figure 8.5: Broken Backfill without Traffic Surcharge .................................................................. 135

Figure 8.6: Proprietary Retaining Walls ....................................................................................... 136

Figure 11.1: Tubular Truss Splice Detail ..................................................................................... 160

Page xii

LIST OF TABLES

Table 2.1: Load Combinations and Load Factors ............................................................................ 6

Table 2.2: Load Factors for Permanent Loads,

p

........................................................................... 8

Table 2.3: Spectral Response Accelerations for the Abu Dhabi Emirate ....................................... 13

Table 2.4: BDS Procedure A Temperature Ranges .................................................................... 14

Table 4.1: Compressive Strength of Concrete............................................................................... 26

Table 4.2: Criteria for Substructure Environmental Classifications ................................................ 29

Table 4.3: Chloride Intrusion Rate/Environmental Classifications .................................................. 30

Table 4.4: Concrete Cover ............................................................................................................ 31

Table 4.5: Minimum Centre-to-Centre Duct Spacing ..................................................................... 38

Table 4.6: Minimum Tendon Radius ............................................................................................. 38

Table 4.7: Minimum Tendons Required for Critical Post-Tensioned Sections .............................. 43

Table 4.8: Minimum Duct Radius .................................................................................................. 43

Table 6.1: Orthotropic-Deck Panel Proportions ............................................................................ 82

Table 7.1: Resistance Factors for Drilled Shafts (Bridge Foundations)........................................ 111

Table 7.2: Driven Pile Selection Guide ........................................................................................ 112

Table 7.3: Table of Additional Sacrificial Steel Thickness Required (mm) ................................... 115

Table 8.1: Required Tendons for Post-Tensioned Substructure Elements .................................. 141

Table 8.2: Minimum Centre-to-Centre Duct Spacing ................................................................... 142

Table 9.1: BDS Procedure A Temperature Changes ................................................................ 143

Table 9.2: Expansion Joint Selection ......................................................................................... 145

Table 10.1: Summary of Bearing Capabilities ............................................................................. 153

Table 15.1: Spectral Response Accelerations Based Upon a 475-Year Return Period for the Abu

Dhabi Emirate ............................................................................................................................. 174

Page 1

1 INTRODUCTION

1.1 Overview

In 2010, the Abu Dhabi Department of Transport commenced with the Unifying and Standardizing

of Road Engineering Practices Project. The objective of the project was to enhance the

management, planning, design, construction, maintenance and operation of all roads and related

infrastructures in the Emirate and ensure a safe and uniform operational and structural capacity

throughout the road network.

To achieve this objective a set of standards, specifications, guidelines and manuals were

developed in consultation with all relevant authorities in the Abu Dhabi Emirate including the

Department of Municipal Affairs (DMA) and Urban Planning Council (UPC). In the future, all

authorities or agencies involved in roads and road infrastructures in the Emirate shall exercise their

functions and responsibilities in accordance with these documents. The purpose, scope and

applicability of each document are clearly indicated in each document.

It is recognized that there are already published documents with similar objectives and contents

prepared by other authorities. Such related publications are mentioned in each new document and

are being superseded by the publication of the new document, except in cases where previously

published documents are recognized and referenced in the new document.

1.2 Purpose and Scope

1.2.1 General

The basic purpose and scope for the Abu Dhabi Road Structures Design Manual (RSDM, the

Manual) is as follows:

1. Objective. The Manual is an application-oriented document.

2. Theory. The Manual is not a structural design theory resource or a research document. The

Manual provides background information for bridge design criteria and application.

3. Details. Where beneficial, the Manual provides design details for various structural

elements.

4. Coordination with AASHTO LRFD Bridge Design Specifications (BDS). Chapters 2 through

12 of the Manual are basically a Supplement to the AASHTO LRFD Bridge Design

Specifications, 6

th

Edition, 2012 (1) (BDS) that:

- in general, does not duplicate information in the BDS, unless necessary for clarity;

- elaborates on specific articles of the BDS;

- presents interpretative information and commentary on some provisions, where

required; these texts are shown as highlighted in the RSDM;

- modifies sections from the BDS where required due to local conditions or because the

bridge owner has adopted a different practice;

- indicates owners preference where the BDS presents multiple options; and

Page 2

- indicates bridge design applications presented in the BDS which are not typically used

in the Abu Dhabi Emirate.

In addition, the Manual discusses, for selected applications, the intent of the BDS to assist

the bridge designer in proper application.

The RSDM will be revised periodically as newer editions of the BDS are published. If newer

editions of the BDS (and any Interims) become available before the RSDM is revised, then

the more recent editions of the BDS shall govern.

5. Audience. The primary audience for the Manual is the owners employees, other relevant

authorities, consultants and contractors for the design and construction of road structures in

the Abu Dhabi Emirate.

1.2.2 AASHTO LRFD Bridge Design Specifications

1.2.2.1 General

The BDS establishes minimum requirements that apply to common road bridges and other

structures such as retaining walls and culverts; long-span or unique structures may require design

provisions in addition to those presented in the BDS. AASHTO issues interim revisions annually

and, periodically, AASHTO publishes a completely updated edition. The BDS serves as a standard

for use by bridge designers. Many agencies also have used it for the development of their own

structural specifications.

1.2.2.2 LRFD Methodology

The BDS presents a load-and-resistance-factor design (LRFD) methodology for the structural

design of bridges. Basically, the LRFD methodology requires that bridge components be designed

to satisfy four sets of limit states: Strength, Service, Fatigue-and-Fracture and Extreme-Event.

Through the use of reliability indices derived through statistical analyses, the Strength limit-state

provisions of the BDS reflect a uniform level of safety for all structural elements, components, and

systems.

1.3 Application of this Manual

1.3.1 Definition of Road Structures

Road structures are part of the roadway infrastructure including bridges, culverts, tunnels, and

retaining walls. Road structures also include pedestrian bridges, sound barriers, and structural

supports for signs and luminaires.

1.3.2 Hierarchy of Priority

Where conflicts are observed in publications and documents for structural design, the following

hierarchy of priority should be used to determine the appropriate application:

- Structural Design Memoranda issued by the owner,

- this Manual,

- BDS, and

- all other generally recognised structure-related publications (e.g. research studies).

Page 3

1.4 Design Objectives

Reference: BDS Article 2.5

In addition to the design objectives outlined in the BDS, the following emphasizes objectives of

special importance to the Abu Dhabi Emirate.

1.4.1 Serviceability

1.4.1.1 Durability

Reference: BDS Article 2.5.2.1

Provide special attention to durability issues during design and construction. In consideration of

local conditions, this Manual specifies material and protective measures to enhance the durability

provisions already included in the BDS.

1.4.1.2 Inspectability and Maintainability

Reference: BDS Articles 2.5.2.2 and 2.5.2.3

Provide access to different parts of structures for inspection, maintenance, rehabilitation, and

replacement where and when necessary (e.g. bearings, expansion joints, future post-tensioning

tendons). Provide all required jacking points.

1.4.1.3 Adjacent Structures

As practical, the bridge design should not affect, nor have any negative impact on adjacent existing

buildings and structures (if any) or any planned construction in the area. Therefore, due

consideration shall be given to existing structures during the design process.

1.4.1.4 Utilities

Reference: BDS Article 2.5.2.5

Provide service provisions as required by the interested authorities. Design protection culverts for

oil, water, sewer, and electricity in coordination with the authorities requirements.

1.4.2 Constructability

Reference: BDS Article 2.5.3

1.4.3 Maintenance of Traffic

Minimize the disturbance to traffic flow on the existing roads during construction. (Refer to the

Work Zone Management Manual (under development)).

1.4.4 Sustainability

A sustainable bridge project must satisfy transportation requirements and improve the economy,

environment, and social aspects. Although the concept of sustainable bridge design is still in

development, and clear standards have not been formalized, all bridges in the Abu Dhabi Emirate

shall be designed with sustainability as a major design objective.

Page 4

1.4.5 Aesthetics

Reference: BDS Article 2.5.5

Every effort shall be made in the treatment of structures to respect the local aesthetic design and

culture. Design concepts should be easily implementable. Also, construction considerations shall

be considered in the architectural treatment concepts. Architectural elements should be functional,

durable, and easily maintainable. Each structure should have individuality; however, a completely

different aesthetic treatment is not required for every structure. Desirably, maintain a sense of

continuity throughout the entire highway corridor.

Architectural treatment should be continuous throughout an interchange. Underpasses spanning a

given roadway should have a similar treatment to establish continuity. Decorative and median

lighting should be similar on overpasses along a given route, unless special lighting is requested

by the client over the structure.

1.5 Design Approval Procedures

1.5.1 Objectives

The fundamental objectives of the design approval procedures are to provide increased assurance

for the required construction, rehabilitation, or demolition so that the proposed projects are safe to

implement. The procedures also ensure that any new structures are:

- safely serviceable in use,

- constructable,

- durable,

- economic to build and maintain,

- comply with the objectives of sustainability,

- have due regard for the environment, and

- satisfactorily perform their intended functions.

The design check shall also ensure that the road users and others who may be affected are

protected from any adverse effects resulting from any work to the structure, and that there is

always adequate provision for safety.

1.5.2 Reference

The design approval procedures for different types of structures should be according to BD 2/05

Technical Approval of Highway Structures (2).

1.6 Bridge Design Checklists

Check the bridge design documents (calculations and drawings) according to the Bridge Design

Checklists for the various stages of design presented in Appendix 1.

Page 5

2 LOADS AND LOAD FACTORS

Sections 1 and 3 of the BDS discuss various aspects of loads and load factors. Unless noted

otherwise in Chapter 2, the BDS loads and load factors shall be followed.

2.1 General

2.1.1 Limit States

Reference: BDS Articles 1.3.2 and 3.4.1

All of the limit-state load combinations as specified in BDS Table 3.4.1-1 shall be followed, except

as modified herein.

The BDS groups the design criteria together within groups termed as limit states to which

different load combinations are assigned.

2.1.1.1 BDS Total Factored Force Effect Equation

All structure components and connections shall be designed to satisfy the basic BDS equation for

the total factored force effects for all limit states:

Equation 2.1

where:

i

= load factor

Q

i

= load or force effect

= resistance factor

R

n

= nominal resistance

i

= load modifier as defined in BDS Equations 1.3.2.1-2 and 1.3.2.1-3

The left-hand side of BDS Equation 1.3.2.1-1 (Equation 2.1 above) is the sum of the factored load

(force) effects acting on a component; the right-hand side is the factored nominal resistance of the

component. The equation must be considered for all applicable limit state load combinations.

Similarly, the equation is applicable to superstructures, substructures, and foundations.

For the Strength limit states, the BDS is basically a hybrid design code in that the force effect on

the left-hand side of the BDS equation is based upon elastic structural response, while resistance

on the right-hand side of the equation is determined predominantly by applying inelastic response

principles. The BDS has adopted the hybrid nature of strength design on the assumption that the

inelastic component of structural performance will always remain relatively small because of non-

critical redistribution of force effects. This non-criticality is assured by providing adequate

redundancy and ductility of the structures, which is the general policy for the design of bridges.

2.1.1.2 Load Modifier

Use

i

values of 1.00 for all limit states, because bridges designed in accordance with this Manual

will demonstrate traditional levels of redundancy and ductility. Rather than penalize less redundant

or less ductile bridges, such bridges are not encouraged. The designer may on a case-by-case

basis designate a bridge to be of special operational importance and specify an appropriate value

of

i

.

n i i i R Q | s q

Page 6

The load modifier

i

relates to ductility, redundancy, operational importance, and is a function of

the factors

D

,

R

, and

I

. The location of

i

on the load side of Equation 2.1 may appear

counterintuitive because it appears to be more related to resistance than to load.

i

is on the load

side for a logistical reason. When

i

modifies a maximum load factor, it is the product of the factors

as indicated in BDS Equation 1.3.2.1-2; when

i

modifies a minimum load factor, it is the reciprocal

of the product as indicated in BDS Equation 1.3.2.1-3. These factors are somewhat arbitrary; their

significance is in their presence in the BDS and not necessarily in the accuracy of their magnitude.

The BDS factors reflect the desire to promote redundant and ductile bridges.

The load modifier accounting for importance of BDS Article 1.3.5,

I

, should not be confused with

the importance categories for seismic design of BDS Articles 3.10.3 and 4.7.4.3. The importance

load modifier is used in the basic BDS Equation, but the importance categories are used to

determine the minimum seismic analysis requirements.

2.1.2 Load Factors and Combinations

Reference: BDS Article 3.4.1

Table 2.1 (BDS Table 3.4.1-1) provides the load factors for all of the load combinations of the BDS.

Table 2.1: Load Combinations and Load Factors

Load Combination

Limit State

DC

DD

DW

EH

EV

ES

EL

PS

CR

SH

LL

IM

CE

BR

PL

LS WA WS WL FR TU TG SE

Use One of These

at a Time

EQ IC CT CV

Strength I (unless noted) p 1.75 1.00 1.00 0.50/1.20 TG SE

Strength II p 1.35 1.00 1.00 0.50/1.20 TG SE

Strength III p 1.00 1.40 1.00 0.50/1.20 TG SE

Strength IV p 1.00 1.00 0.50/1.20

Strength V p 1.35 1.00 0.40 1.0 1.00 0.50/1.20 TG SE

Extreme Event I p EQ 1.00 1.00 1.00

Extreme Event II p 0.50 1.00 1.00 1.00 1.00 1.00

Service I 1.00 1.00 1.00 0.30 1.0 1.00 1.00/1.20 TG SE

Service II 1.00 1.30 1.00 1.00 1.00/1.20

Service III 1.00 0.80 1.00 1.00 1.00/1.20 TG SE

Service IV 1.00 1.00 0.70 1.00 1.00/1.20 1.0

Fatigue ILL, IM & CE only 1.50

Fatigue IILL, IM & CE only 0.75

2.1.2.1 Strength Load Combinations

The load factors for the Strength load combinations are calibrated based upon structural reliability

theory and represent the uncertainty of their associated loads. The significance of the Strength

load combinations can be simplified as follows:

1. Strength I Load Combination. This load combination represents random traffic and the

heaviest truck to cross the bridge in its design life. During this live-load event, a significant

wind is not considered probable.

2. Strength II Load Combination. In the BDS, this load combination represents an owner-

specified permit load model. This live-load event has less uncertainty than random traffic

Page 7

and, thus, a lower live-load load factor. This load combination is used for design in

conjunction with the permit live load design vehicle (P-13 load) discussed in Section

2.3.2.2.

3. Strength III Load Combination. This load combination represents the most severe wind

during the bridges design life. During this severe wind event, no significant live load is

assumed to cross the bridge.

4. Strength IV Load Combination. This load combination represents an extra safeguard for

bridge superstructures where the unfactored dead load exceeds seven times the

unfactored live load. Thus, the only significant load factor would be the 1.25 dead-load

maximum load factor. For additional safety, and based solely on engineering judgment, the

BDS has arbitrarily increased the load factor for DC to 1.5. This load combination need not

be considered for any component except a superstructure component, and never where the

unfactored dead-load force effect is less than seven times the unfactored live-load force

effect. This load combination typically governs only for longer spans, approximately greater

than 60 m in length. Thus, this load combination will only be necessary in relatively rare

cases.

5. Strength V Load Combination. This load combination represents the simultaneous

occurrence of a normal live-load event and a wind event with load factors of 1.35 and 0.4,

respectively.

For components not traditionally governed by wind force effects, the Strength III and Strength V

load combinations should not govern. Generally, the Strength I and Strength II load combinations

will govern for a typical multi-girder highway bridge.

2.1.2.2 Service Load Combinations

Unlike the strength load combinations, the service load combinations are material dependent. The

following applies:

1. Service I Load Combination. Apply this load combination to control cracking in reinforced

concrete components and compressive stresses in prestressed concrete components.

Also, use this load combination to calculate deflections and settlements of superstructure

and substructure components.

2. Service II Load Combination. Apply this load combination to control permanent

deformations of compact steel sections and the slip of slip-critical (i.e. friction-type) bolted

steel connections.

3. Service III Load Combination. Apply this load combination to control tensile stresses in

prestressed concrete superstructure components under vehicular traffic loads. The Service

III load combination need not apply to the design permit live load design vehicle.

4. Service IV Load Combination. Apply this load combination to control tensile stresses in

prestressed concrete substructure components under wind loads. For components not

traditionally governed by wind effects, this load combination should not govern.

2.1.2.3 Extreme-Event Load Combinations

The extreme-event limit states differ from the strength limit states, because the event for which the

bridge and its components are designed has a greater return period than the design life of the

Page 8

bridge (or a much lower frequency of occurrence than the loads of the strength limit state). The

following applies:

1. Extreme-Event I Load Combination. This load combination is applied to earthquakes. Use a

load factor of 0.5 for

EQ

for all live-load related forces in BDS Table 3.4.1-1. Earthquakes in

conjunction with scour (which is considered a change in foundation condition, not a load)

can result in a very costly design solution if severe scour is anticipated. In this case, typical

practice is to combine one-half of the total design scour (sum of contraction, local, and

long-term scour) with the full seismic loading.

2. Extreme-Event II Load Combination. This load combination is applied to various types of

collisions (vessel or vehicular) applied individually.

2.1.2.4 Fatigue-and-Fracture Load Combination

The Fatigue-and-Fracture load combination, although strictly applicable to all types of

superstructures, only affects the steel elements, components, and connections of a limited number

of steel superstructures. Chapter 5 discusses fatigue and fracture for steel.

2.1.2.5 Application of Multiple-Valued Load Factors

Maximum and Minimum Permanent-Load Load Factors

In Table 2.1, the variable

P

represents load factors for all of the permanent loads, shown in the

first column of load factors. This variable reflects that the Strength and Extreme-Event limit state

load factors for the various permanent loads are not single constants, but they can have two

extreme values. Table 2.2 (BDS Table 3.4.1-2) provides these two extreme values for the various

permanent load factors, maximum and minimum. Permanent loads are always present on the

bridge, but the nature of uncertainty is that the actual loads may be more or less than the nominal

specified design values. Therefore, maximum and minimum load factors reflect this uncertainty.

Table 2.2: Load Factors for Permanent Loads,

p

Type of Load, Foundation Type, and

Method Used to Calculate Downdrag

Load Factor

Maximum Minimum

DC: Component and attachments

DC: Strength IV only

1.25

1.50

0.90

0.90

DD: Downdrag Piles, o Tomlinson method

Piles, method

Drilled shafts, ONeill and Reese (1999) Method

1.40

1.05

1.25

0.25

0.30

0.35

DW: Wearing surfaces and utilities 1.50 0.65

EH: Horizontal earth pressure

Active

At-Rest

AEP for anchored walls

1.50

1.35

1.35

0.90

0.90

N/A

EL: Locked-in construction stresses 1.00 1.00

EV: Vertical earth pressure

Overall stability

Retaining walls and abutments

Rigid buried structure

Rigid frames

Flexible buried structures other than metal box culverts

Flexible metal box culverts and structural plate culverts with

deep corrugations

1.00

1.35

1.30

1.35

1.95

1.50

N/A

1.00

0.90

0.90

0.90

0.90

ES: Earth surcharge 1.50 0.75

Page 9

Select the appropriate maximum or minimum permanent-load load factors to produce the more

critical load effect. For example, in continuous superstructures with relatively short end spans,

transient live load in the end span causes the bearing to be more compressed, while transient live

load in the second span causes the bearing to be less compressed and perhaps lift up. To check

the maximum compression force in the bearing, place the live load in the end span and use the

maximum DC load factor of 1.25 for all spans. To check possible uplift of the bearing, place the live

load in the second span and use the minimum DC load factor of 0.90 for all spans.

Superstructure design uses the maximum permanent-load load factors almost exclusively, with the

most common exception being uplift of a bearing as discussed above. The BDS has generalized

load situations such as uplift where a permanent load (in this case a dead load) reduces the overall

force effect (in this case a reaction). Permanent load factors, either maximum or minimum, must be

selected for each load combination to produce extreme force effects.

Substructure design routinely uses the maximum and minimum permanent-load load factors from

Table 2.2. An illustrative yet simple example is a spread footing supporting a cantilever retaining

wall. When checking bearing, the weight of the soil (EV) over the heel is factored up by the

maximum load factor, 1.35, because greater EV increases the bearing pressure, q

ult

, making the

limit state more critical. When checking sliding, EV is factored by the minimum load factor, 1.00,

because lesser EV decreases the resistance to sliding, Q

t

, again making the limit state more

critical. The application of these maximum and minimum load factors is required for foundation and

substructure design; see Chapters 7 and 8.

Load Factors for Superimposed Deformations

The load factors for the superimposed deformations (TU, CR, SH) for the strength limit states also

have two specified values a load factor of 0.5 for the calculation of stress, and a load factor of

1.2 for the calculation of deformation. Use the greater value of 1.2 to calculate unrestrained

deformations (e.g. a simple span expanding freely with rising temperature). The lower value of 0.5

for the elastic calculation of stress reflects the inelastic response of the structure due to restrained

deformations. For example, use one-half of the temperature rise to elastically calculate the

stresses in a constrained structure. Using 1.2 times the temperature rise in an elastic calculation

would overestimate the stresses in the structure. The structure resists the temperature inelastically

through redistribution of the elastic stresses.

2.2 Permanent Loads

2.2.1 General

Reference: BDS Article 3.5

The BDS specifies seven components of permanent loads, which are either direct gravity loads or

caused by gravity loads. The primary forces from prestressing are considered to be part of the

resistance of a component and has been omitted from the list of permanent loads in Section 3 of

the BDS. However, when designing anchorages for prestressing tendons, the prestressing force is

the only load effect, and it should appear on the load side of Equation 2.1. The permanent load EL

includes secondary forces from pre-tensioning or post-tensioning.

As discussed in Section 2.1.2.5, the permanent force effects in superstructure design are factored

by the maximum permanent-load load factors almost exclusively, with the most common exception

being the check for uplift of a bearing. In substructure design, the permanent force effects are

Page 10

routinely factored by the maximum or minimum permanent-load load factors from BDS Table 3.4.1-

2 as appropriate.

The following lists additional minimum loads that are usually applicable to Abu Dhabi structures:

- Unit weight of reinforced and prestressed concrete: 25 kn/m

3

.

- 110 mm of asphalt wearing course shall be considered. Unit weight of wearing course: 23

kn/m

3

.

- The actual weight and position of all known utilities; otherwise, an additional dead load

(curb to curb) of 0.85 kn/m

2

shall be considered.

2.2.2 Downdrag (DD) on Deep Foundations

Reference: BDS Article 3.11

Deep foundations (i.e. drilled shafts and driven piles) through unconsolidated soil layers may be

subject to downdrag, DD. Downdrag is a load developed along the vertical sides of a deep-