Professional Documents

Culture Documents

Nitocote EP410: Epoxy Resin Tank and Surface Lining Material

Uploaded by

Venkata Raju KalidindiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nitocote EP410: Epoxy Resin Tank and Surface Lining Material

Uploaded by

Venkata Raju KalidindiCopyright:

Available Formats

Nitocote EP410

Epoxy resin tank and surface lining material

Uses A hygienic and chemical resistant coating for brick and concrete walls, concrete and metal tanks, sluices and ducts. Advantages Excellent adhesion - Compatible with all substrates. Can be applied directly on to mild steel and concrete Hygienic & Aesthetic Forms a smooth, glossy and easy to clean surface on curing Abrasion resistant Exceptional resistance to abrasion and to a wide range of chemicals Chemical resistant Proven against a wide range of industrial chemicals Description Nitocote EP410 high build surface protective coating is based on solvent free epoxy resins specially formulated to provide a thixotropic coating suitable for application to vertical surfaces. It cures to form a smooth hygienic film with good resistance to a wide range of mineral and organic acids, alkalis, fats and oils. Colour : Green ( Non-stable). Technical support The company provides a technical advisory service supported by a team of specialists in the field. Properties Pot life Specific gravity Cure time Initial hardness Full cure : 30 mins at 270C Oil, Mineral acid Petrol Sodium Hypochlorite 10% Sulpuric acid 20% Water Key :R : Resistant

constructive solutions

R R S R R

S : Indicates slight attack under continuous immersion. 'Attack' refers to any etching or swelling observed but ignores discolouration. Where chemicals at temperatures higher than ambient are involved, it may please be referred to Fosroc. Preparation Surface to be coated must be structurally sound, dry and free from loose material. All surface contamination must be removed. Grease and oil should be grit-blasted or water jetted. Deeper penetration must be removed by mechanical means. Any laitance must be removed from concrete surface by etching with Reebaklens (see separate data sheet) then washed off and dried. New concrete should be allowed to cure for at least 28 days prior to coating. Steel surfaces should be shot blasted to a profile of 125 microns. Priming Concrete : All concrete surfaces should be primed using Nitoprime 25, a two pack epoxy resin primer supplied in preweighed quantities ready for mixing. It is mixed in the proportions supplied and brushed in a thin continuous film over the concrete surface. Unlike Nitocote EP410 high build surface protective coating, the primer may be applied to a damp surface. The primer should be allowed to be cured for 4- 6 hours at 300C before applying Nitocote EP410 high build surface protective coating. The usage life after mixing is 30 minutes at 27 0C. Mixing The small can of hardener is completely emptied into the large can of resin and the components thoroughly mixed until a uniform colour is achieved. It is recommended that mechanical mixing is employed by using a stirrer in a heavy duty slow speed electric drill fitted with a mixing paddle. Coating Nitocote EP410 high build surface protective coating is applied to the primed substrate by nylon brush and finally smoothened out using a steel trowel. A continuous coating

: 1.4 to 1.5 g/cc : : : Tack free after 6 hours @270C 24 hours at 270C 5 days at 270C

Chemical resistance The results with some common chemicals using Nitocote EP410 high build surface protective coating film totally immersed for 1 year at 300C : Ammonium hydroxide 30% Causic soda 50% Citric acid 50% Detergents Fatty acids ( higher) Hydrochloric acid 20% Lactic acid 10% Nitric acid 10% S R R R S R R R

Nitocote EP410

page 1 of 2

Nitocote EP410

Precautions

of uniform thickness should be obtained. Normally 2 coats of Nitocote EP410 high build surface protective coating should be applied @ 250 mocrons/coat. Cleaning Tools and equipment should be cleaned immediately after use with Nitoflor Sol. Health & Safety instructions Some people are sensitive to epoxy resin systems and may develop dermatitis on skin contact. Gloves and barrier creams should be used when handling primers and Nitocote EP410. If contact with the skin occurs, wash with soap and plenty of water. Do not use solvent. Direct contact with the eyes will cause irritation and may cause serious damage if left untreated. Any eye contamination should be washed thoroughly with plenty of water and immediate medical treatment sought. The use of goggles when mixing is recommended. Smoking to be avoided. Fire Nitocote EP410 and Nitoflor Sol are flammable. Ensure adequate ventilation when using primers and solvents and do not use near a naked flame. Flash point Nitoflor Sol 33 0C

Estimating

Packaging and coverage Pack size Nitocote EP410 4 litres Coverage* 16m2 @ 250 microns thickness/coat 5.5 - 6.5 m2/litre

Nitoprime 25 Nitoflor Sol Reebaklens

1 & 4 litres 5 & 20 litres 5 & 20 litres

* The practical coverage may vary depending on the application thickness and surface porosity of the substrate.

Storage

Shelf life 12 months when stored under normal warehouse conditions in unopened containers.

Fosroc Chemicals (India) Pvt. Ltd.

Head Office Sapthagiri Palace, No.38, II & III Floor, 12th Cross, CBI Road, Ganganagar North, Bangalore 560 032

Important note : Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard terms and conditions of sale, copies of which may be obtained on request. Whilst Fosroc endeavours to ensure that any advice, recommendation specification or information it may give is accurate and correct, it cannot, because it has no direct or continuous control over where or how its products are applied, accept any liability either directly or indirectly arising from the use of its products whether or not in accordance with any advice, specification, recommendation or information given by it.

telephone ++91 80-23551500 fax ++91 80-23551510 e-mail enquiryindia@fosroc.com

Regional Offices

Bangalore

Sapthagiri Palace, No. 38 II & III Floor, 12th Cross, CBI Road, Ganganagar North, Bangalore 560 032. Ph:080-23551500 Fax : 080-23551510

Mumbai

1401/1402, 14 Floor, A-WingThe Great Eastern Summit Sector-15, CBD, Belapur Navi Mumbai 400 614 Ph: 022 -43406800-04

Noida

D-166 Sector 10 Noida, UP 201 301 Ph:0120-4270620

Kolkata

304, Jodhpur Park Kolkata 700 068 Ph:033-65343188 Fax: 033-2499-0280

www.fosroc.com

page 2 of 2

INDIA/2011/0739/B

You might also like

- Electrical Estimation & Costing PDFDocument36 pagesElectrical Estimation & Costing PDFecruz_yhwh75% (12)

- InSituTesting WebsiteDocument38 pagesInSituTesting Websiteag_007No ratings yet

- The Powder Coaters ManualDocument209 pagesThe Powder Coaters ManualOvation Audio Labs100% (4)

- Cal OSHA Handbook 2022Document92 pagesCal OSHA Handbook 2022Russell SadlerNo ratings yet

- Troubleshooting Precast Cracking in Double Tees - tcm77-1306891 PDFDocument5 pagesTroubleshooting Precast Cracking in Double Tees - tcm77-1306891 PDFsdagnihotriNo ratings yet

- Qualcast Trucks Catalog2015Document188 pagesQualcast Trucks Catalog2015Edwin Javier Garavito100% (2)

- Buckling of Spherical Shells Subjected To External PressureDocument7 pagesBuckling of Spherical Shells Subjected To External PressureSUBHASH100% (1)

- 7 The Mole ConceptDocument8 pages7 The Mole ConceptCris CorsinoNo ratings yet

- Twistlock TestingDocument44 pagesTwistlock Testingkandahar_specNo ratings yet

- Base Oil Production IIDocument15 pagesBase Oil Production IIrvsinghNo ratings yet

- CurtainDocument257 pagesCurtainvranceanu100% (13)

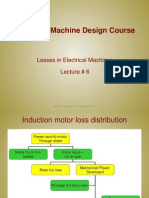

- Lecture6 - Losses in Electric MachinesDocument24 pagesLecture6 - Losses in Electric Machinesthulasi_krishnaNo ratings yet

- BS5400!10!1980-Code of Practice For FatigueDocument78 pagesBS5400!10!1980-Code of Practice For Fatiguezlq10081008No ratings yet

- Paints and Varnishes - General Tests Methods - Vol 1.1 - IndexDocument5 pagesPaints and Varnishes - General Tests Methods - Vol 1.1 - IndexGilberto ManhattanNo ratings yet

- Advances in Materials Technology For Fossil Power PlantsDocument1,121 pagesAdvances in Materials Technology For Fossil Power Plantsadadamovicines100% (5)

- Nitocote EP415 PDFDocument4 pagesNitocote EP415 PDFdejanmicic972No ratings yet

- Nitocote EPW100: Water Dispersed Epoxy Coating and SealerDocument2 pagesNitocote EPW100: Water Dispersed Epoxy Coating and SealerVenkata Raju KalidindiNo ratings yet

- Nitocote Ep405Document4 pagesNitocote Ep405Venkata RaoNo ratings yet

- Nitocote Ep410Document4 pagesNitocote Ep410pravi3434No ratings yet

- Conbextra EP10Document4 pagesConbextra EP10Venkata Raju KalidindiNo ratings yet

- 136Document4 pages136Mohamed ShehataNo ratings yet

- Nitocote EN901Document4 pagesNitocote EN901kalidindivenkatarajuNo ratings yet

- Nitocote Et402Document4 pagesNitocote Et402Venkata Rao100% (1)

- Nitocote Ep403Document4 pagesNitocote Ep403pravi3434No ratings yet

- Conbextra EP10Document4 pagesConbextra EP10Binoy Sankar SarkerNo ratings yet

- Nitobond EP : Constructive SolutionsDocument4 pagesNitobond EP : Constructive SolutionsmilanbrasinaNo ratings yet

- Nitobond Ep..Document4 pagesNitobond Ep..budhikurniawanNo ratings yet

- Conbextra EP10Document2 pagesConbextra EP10MuhammedHafis100% (1)

- Nitoseal 280Document2 pagesNitoseal 280shanon33No ratings yet

- Nitocote EN901Document4 pagesNitocote EN901ArieIndrawanNo ratings yet

- Nitofill EPLV: Low Viscous Epoxy Injection Resin GroutDocument2 pagesNitofill EPLV: Low Viscous Epoxy Injection Resin GroutkalidindivenkatarajuNo ratings yet

- Conbextra EP75Document4 pagesConbextra EP75Venkata Raju KalidindiNo ratings yet

- Nitoflor Eu50Document4 pagesNitoflor Eu50Venkata RaoNo ratings yet

- Conbextra EP300Document4 pagesConbextra EP300Venkata Raju KalidindiNo ratings yet

- Nitokit Surface SealantDocument2 pagesNitokit Surface SealantBalasubramanian AnanthNo ratings yet

- Nitoseal 280: Heavy Duty Epoxy Urethane Joint SealantDocument2 pagesNitoseal 280: Heavy Duty Epoxy Urethane Joint SealantVenkata Raju KalidindiNo ratings yet

- 2 Nitobond EPDocument3 pages2 Nitobond EPfatinaainaaNo ratings yet

- Nitoseal PU 280 PDFDocument2 pagesNitoseal PU 280 PDFhelloitskalaiNo ratings yet

- Nitocote Ep405Document4 pagesNitocote Ep405mohamedbossilyNo ratings yet

- Nitobond EPDocument3 pagesNitobond EPArun KumarNo ratings yet

- Nitomortar ElDocument4 pagesNitomortar ElBalasubramanian AnanthNo ratings yet

- Nitocote ET550Document4 pagesNitocote ET550waqas_11No ratings yet

- Nitocote HT120Document4 pagesNitocote HT120Venkata Raju KalidindiNo ratings yet

- Conbextra EP10TGDocument2 pagesConbextra EP10TGBambang SasikiranaNo ratings yet

- Nitozinc PrimerDocument4 pagesNitozinc Primervenkatasuri999No ratings yet

- Conbextra Ep75Document4 pagesConbextra Ep75Sathiya SeelanNo ratings yet

- Nitoprime 25 (M) : Epoxy Resin Based Primer For Concrete SurfacesDocument2 pagesNitoprime 25 (M) : Epoxy Resin Based Primer For Concrete SurfacesVenkata Raju KalidindiNo ratings yet

- Nitocote PE135Document2 pagesNitocote PE135Dejan MicicNo ratings yet

- Nitoflor EPU1000Document4 pagesNitoflor EPU1000Venkata Raju KalidindiNo ratings yet

- Nitoseal 220 PDFDocument4 pagesNitoseal 220 PDFmilanbrasinaNo ratings yet

- Nitokit Surface Sealant: Constructive SolutionsDocument2 pagesNitokit Surface Sealant: Constructive SolutionstalatzahoorNo ratings yet

- Nitocote NT550Document4 pagesNitocote NT550Venkata Raju KalidindiNo ratings yet

- Nitocote Et550Document4 pagesNitocote Et550Venkata RaoNo ratings yet

- Nitowrap EP (GF) : High Performance High Strength, Glass Fibre Sys-Tem For Structural StrengtheningDocument4 pagesNitowrap EP (GF) : High Performance High Strength, Glass Fibre Sys-Tem For Structural StrengtheningkalidindivenkatarajuNo ratings yet

- Nitobond PC: Thixotropic Epoxy AdhesiveDocument2 pagesNitobond PC: Thixotropic Epoxy AdhesiveVenkata Raju KalidindiNo ratings yet

- TDS Nitocote EP410Document3 pagesTDS Nitocote EP410Syed HassaanNo ratings yet

- Supercast EPT PDFDocument2 pagesSupercast EPT PDFmilanbrasinaNo ratings yet

- Nitocote EP405: Constructive SolutionsDocument4 pagesNitocote EP405: Constructive SolutionsrayNo ratings yet

- Nitotile Ep GroutDocument2 pagesNitotile Ep GroutBalasubramanian AnanthNo ratings yet

- Conbextra EP10 : High Strength, Epoxy Resin GroutDocument2 pagesConbextra EP10 : High Strength, Epoxy Resin GroutBudhi KurniawanNo ratings yet

- Nitotile 489 : Constructive SolutionsDocument2 pagesNitotile 489 : Constructive SolutionsmilanbrasinaNo ratings yet

- Nitoseal 220Document4 pagesNitoseal 220Venkata RaoNo ratings yet

- Novolac ScreedDocument4 pagesNovolac Screedmd_kureshiNo ratings yet

- Fosroc Nitocote EP410: Constructive SolutionsDocument4 pagesFosroc Nitocote EP410: Constructive SolutionsVJ QatarNo ratings yet

- Nitoflor FC150Document4 pagesNitoflor FC150Mohammad Abu Al-ToyourNo ratings yet

- Nitoflor FC150Document4 pagesNitoflor FC150Venkata Raju KalidindiNo ratings yet

- Nitotile Epoxy GroutDocument2 pagesNitotile Epoxy GroutmilanbrasinaNo ratings yet

- Conbextra EP Data SheetDocument4 pagesConbextra EP Data Sheetprabhu81No ratings yet

- Nitoflor EU5Document4 pagesNitoflor EU5Venkata Raju KalidindiNo ratings yet

- Resicoat R4-ES Fusion Bonded Epoxy: Product Data SheetDocument2 pagesResicoat R4-ES Fusion Bonded Epoxy: Product Data SheetmarciojunkNo ratings yet

- TDS Nitocote ET550 Saudi ArabiaDocument3 pagesTDS Nitocote ET550 Saudi Arabiaasdf325897No ratings yet

- (PDS) Conbextra EP300Document4 pages(PDS) Conbextra EP300Faizal HaziziNo ratings yet

- Understanding Dashboards in P6 PDFDocument52 pagesUnderstanding Dashboards in P6 PDFsh2awaaNo ratings yet

- San Jose Police CalcsDocument91 pagesSan Jose Police Calcscancery0707No ratings yet

- Bostik BoscolasticDocument2 pagesBostik BoscolasticVenkata Raju KalidindiNo ratings yet

- Building AnalysisDocument58 pagesBuilding AnalysisVenkata Raju KalidindiNo ratings yet

- Renderoc HSXtraDocument2 pagesRenderoc HSXtraVenkata Raju KalidindiNo ratings yet

- Conplast SD110Document2 pagesConplast SD110Venkata Raju KalidindiNo ratings yet

- Nitoseal® 200Document4 pagesNitoseal® 200Venkata Raju KalidindiNo ratings yet

- Renderoc LAXtra PlusDocument2 pagesRenderoc LAXtra PlusVenkata Raju Kalidindi100% (1)

- SP21Document506 pagesSP21Venkata Raju Kalidindi100% (1)

- SP40Document135 pagesSP40SourabhAdikeNo ratings yet

- Conplast SP430SRVDocument2 pagesConplast SP430SRVVenkata Raju KalidindiNo ratings yet

- Conplast SP500Document2 pagesConplast SP500Venkata Raju KalidindiNo ratings yet

- Cat Bombas de Vacío 2017 IngDocument2 pagesCat Bombas de Vacío 2017 IngGonzhalo Ramireç ChaveçNo ratings yet

- Ammonium ChlorideDocument5 pagesAmmonium ChloridekhushiNo ratings yet

- Electrochimica ActaDocument9 pagesElectrochimica ActareiroslesNo ratings yet

- Thermometry PDFDocument49 pagesThermometry PDFYe YeoNo ratings yet

- Cascade Data Sheet PDFDocument28 pagesCascade Data Sheet PDFvisutsiNo ratings yet

- Jis B 2291-1994Document9 pagesJis B 2291-1994Ilka RaffaelliNo ratings yet

- International Earth Science Olympiad (IESO) : RocksDocument14 pagesInternational Earth Science Olympiad (IESO) : RocksansariNo ratings yet

- BecherDocument7 pagesBechervalholNo ratings yet

- Coating Thickness GaugesDocument5 pagesCoating Thickness GaugesSheikh Muhammad AsifNo ratings yet

- Basalt Catalogue-CDocument4 pagesBasalt Catalogue-Cdanny buiNo ratings yet

- DSM-0329.1 WokaDur NiE ElectrodeDocument4 pagesDSM-0329.1 WokaDur NiE ElectrodeAlireza KhodabandehNo ratings yet

- Structural Design of A Water Intake Tower Located Inside A ReservoirDocument10 pagesStructural Design of A Water Intake Tower Located Inside A ReservoirArifullah WazirNo ratings yet

- Intro To Methyl Chloride Plant 1Document57 pagesIntro To Methyl Chloride Plant 1Kimberly ConleyNo ratings yet

- Failure Analysis Question BankDocument29 pagesFailure Analysis Question BankAbd-Elaleem Abdallah SosaNo ratings yet

- Lesson Plan 8Document9 pagesLesson Plan 8princesdianedelectorNo ratings yet

- Guia de Aditivos para Resolucao de ProblemasDocument20 pagesGuia de Aditivos para Resolucao de ProblemasFabiano DesangiacomoNo ratings yet

- 3003 Polyether Polyol TDSDocument1 page3003 Polyether Polyol TDSbkandemirpolexNo ratings yet