Professional Documents

Culture Documents

Networked Control System Based On Decoupler and PID Controller For TITO System

Uploaded by

Mixmikmic' KrittananOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Networked Control System Based On Decoupler and PID Controller For TITO System

Uploaded by

Mixmikmic' KrittananCopyright:

Available Formats

Networked Control System based on Decoupler and PID Controller for TITO System

Sasiprapa Dolpullop and Sakreya Chitwong

Department of Instrumentation and Control Engineering, Faculty of Engineering King Mongkuts Institute of Technology Ladkrabang Bangkok, 10520 THAILAND kcsakrey@kmitl.ac.th

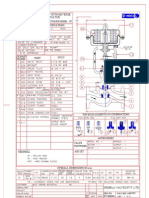

AbstractThis paper describes the two inputs - two outputs control theory. The theory is using the static decoupler filter that can reduce the disturbance arising from loop interaction. The system controls both the pressure and flow rate in the closed tank. The media of the process is water. The work includes four important aspects: Designing, Simulation, Implementation and Test. In this design consist of two parts such as models of the process and decoupler. In this simulation was used a MATLAB to finding a suitable decoupler. In this implementation was used a personal computer, Pressure Transmitter, Magnetic Flow Meter, DP/PA coupler, Convertered IF 303,FI303 and The controller of SIEMENS S7 400 Modules which all of implements was created to control systems by used the technology of PROFIBUS to create a networked control system(NCS). In this test was used to compare performance of the old TITO systems with the new TITO system. Index TermsTITO system, decoupler, interaction

decoupler. Fifth, Test of decoupling. Sixth, conclusion. Seventh, References.

II.

THEORY AND PRINCIPAL OF CONTROL

I.

INTRODUCTION

Most process control systems in industry are complex and multivariable. They consist of several measurement signals and control signal which are always interaction. Process control problems are always solved using singleloop PID controller that are connection as coupling such as cascade control, ratio control, split-range control, etc. It is very common that different process values interact, which mean that the different control loops disturb each other. Presently, the problem of interacting control loops is solved by tuning the most important loop to give good performance, while the other loop is detuned in such a way that the interaction with the first loop becomes acceptable. The result is one of the loops is forced to perform poorly in order to compensate for the interaction For this reason, a research project has been initiated where the goal is to develop a two input-two output control system which manage to reduce interaction of the process variable. This paper is presented as follows: First, Introduction. Second, Problem of TITO systems and the models of process and Static Decoupler Filter. Third, Configuration of TITO systems. Fourth, Simulation to find suitable

Footnotes: 8-point Times New Roman font; Manuscript received July 1, 2012; revised August 1, 2012; accepted September 1, 2012. Copyright credit, project number, corresponding author, etc.

A. Problem of TITO System [1] Two input two output systems, or TITO systems for short, are systems where there are two properties to control and both control signals may affect both process values. TITO systems are always assumed to be two separate single input single output systems, SISO systems for short, which are controlled by separated controllers. Fig.1 is described structure of TITO System. If we PV1 (Process variable in loop1) is changed then PV2 (Process variable in loop 2) is changed too. Because of relation of two process variables. So we have to design a new control structure of TITO Systems by adding advance compensated called Decoupler, which can reduce effect of interaction between loops, which is depicted in Fig. 2.

Figure 1. Block diagram of old control structure for TITO Systems.

Figure 2. Block diagram of new control structure for TITO Systems

B. The Process model [13] Normally, a process assumes First Order Plus Delay Time

G(s) =

K e Ls Ts +1

(1)

where L is diagonal. So we can find decoupler by

where K is process gain, T is time constant of the process, L is delay time of the process. A TITO system in Fig 3 can be modeled as a 2x2 matrix with transfer functions as elements, see equation (2)

D ( S ) = G ( S ) 1 L( S )

(4) There are many method of designing decoupler.So the static decoupler was used in this paper. The static decouple is a very simple decoupler without dynamics. The decouplers elements are simply static gains. Designing a static decoupler for a process only requires the static gains of the process transfer function at steady state (t and L(s) was assumed identity matrix. So the decoupler becomes to Number footnotes separately in superscripts 1, 2, . Place the actual footnote at the bottom of the column in which it was cited, as in this column. See first page footnote for an example. D. Abbreviations and Acronyms Define abbreviations and acronyms the first time they are used in the text, even after they have been defined in the abstract. Do not use abbreviations in the title unless they are unavoidable. E. Equations Equations should be centered in the column. The paragraph description of the line containing the equation should be set for 6 points before and 6 points after. Number equations consecutively with equation numbers in parentheses flush with the right margin, as in (1). Italicize Roman symbols for quantities and variables, but not Greek symbols. Punctuate equations with commas or periods when they are part of a sentence, as in

a +b=c.

K11 Ls e T11s + 1 G(S ) = K 21 Ls T s + 1e 21

(2)

K12 Ls e Ts + 1 K 22 Ls e T22 s + 1

Figure 3. Block Diagram of TITO systems.

C. The Static Decoupler Filer Model[2] The structure of the TITO System was added decoupler is depicted in Fig 4. Decoupler can reduce interaction between control loops because when set point in loop 1 (SP1) change not only manipulated in loop 1 (MV 1) changed but also manipulated in loop 2 changed after that process variable in loop 1 is changed (PV 1) and affect to process variable in loop 2(PV 2).The result is process variable in loop 2 is not changed because of advanced compensated by decouple.

(1)

Symbols in your equation should be defined before the equation appears or immediately following. Use (1), not Eq. (1) or equation (1), except at the beginning of a sentence: Equation (1) is ... F. Other Recommendations Use either SI (MKS) or CGS as primary units. (SI units are encouraged.) If your native language is not English, try to get a native English-speaking colleague to proofread your paper. Do not add page numbers. G. A Quick Checklist

Figure 4. Block diagram of new control structure for TITO Systems.

Designing the decoupler D added between the controller C and the process G is presented in Fig 4. If D compensated the system perfectly, GD is diagonal, See equation (3)

G ( S ) = D( S ) L( S )

(3)

Paper size=A4; Margins: top=3cm, bottom=left=right=2cm; Column spacing=0.6cm For the whole document (Ctrl-A to select the whole document), Font Type=Times New Roman, do NOT use any Asian font type like SimSun in formulas, section numbers (III, IV, V, ...), list numbers (1), 2), (1), (2), ...), or punctuation marks (,, ., :, ;, (, ), ...). Check Word Count (on the status bar at the

bottom of the window) to ensure the number of Asian Characters (including textboxes and footnotes) is 0 In Paragraph settings for the whole document ( Ctrl-A to select the whole document), Line spacing must be "Single", "Snap to grid" must NOT be checked. In Paragraph settings for main text except section titles, Indentation left=right=0, first line=0.37cm; Spacing before=after=0, not blank line between paragraphs Title and authors: font style=regular NOT bold NOT italic; font size for title is 24 with 6 spacing before & after, for authors names font size is 11, affiliations font size is 10 References: strictly follow the instructions in Section II.B. Biographies: it is strongly recommended adding for each author a short bio to the end of the paper. APPENDIX A APPENDIX TITLE

[7] SMAR Triple Channel Profibus PA to Current Convertor Series FI303 of Field Device, SMAR, USA, 2004. [8] SMAR Triple Channel Current to Profibus PA Convertor Series IF303 of Field Device , SMAR, USA, 2004. [9] SIMATIC Bus Link DP/PA Coupler DP/PA LinkManual, Siemens, German, 2006. [10] SIMATIC NET S7-CPs for Profibus Configuration and CommissioningManual, Siemens, German, 2009. [11] SIMATIC S7-400, M7-400 Programmable Controller Module Specifications, Siemens, German, 2002. [12] Electropneumatic Positioner type 4763 pneumatic positioned type 4765Manual, SAMSON, German, 2008. [13] K. Ogata, Modern Control Engineering, 3rd ed. NJ: Prentice-Hall, 1997.

Appendixes, if needed, is numbered by A, B, C... Use two spaces before APPENDIX TITLE. ACKNOWLEDGMENT The authors wish to thank A, B, C. This work was supported in part by a grant from XYZ. REFERENCES

[1] P. Nordfeidt and T. Hagglund, Decoupler and PID controller design of TITO system, Journal of Process Control, vol. 16, Iss. 9, pp. 923-936, October 2006. [2] A. Theorim, Implementation of an autotunable decoupling TITO control, M.S. thesis, Department of Automatic Control, Lund University, Lund, Sweden, 2007. [3] SIMATIC S7-SLC V5.3 for S7300/400Manual, Siemens, German, 2005. [4] Process Control System PSC7 Getting Started Part 1 Manual, Siemens, German, 2005. [5] Process Control System PSC7 Getting Started Part 2 Manual, Siemens, German, 2005. [6] SIMATIC Process Control System PSC7 Standard Library V7.1Function Manual, Siemens, German, 2009.

Firstname A. Lastname and the other authors may include biographies and photographs at the end of regular papers. Photographs, if provided, should be cropped into 26mm in width and 32mm in height. The first paragraph may contain a place and/or date of birth (list place, then date). Next, the authors educational background is listed. The degrees should be listed with type of degree in what field, which institution, city, state or country, and year degree was earned. The authors major field of study should be lower-cased. The second paragraph uses the pronoun of the person (he or she) and not the authors last name. It lists military and work experience, including summer and fellowship jobs. Job titles are capitalized. The current job must have a location; previous positions may be listed without one. Information concerning previous publications may be included. Try not to list more than three books or published articles. The format for listing publishers of a book within the biography is: title of book (city, state: publisher name, year) similar to a reference. Current and previous research interests ends the paragraph. The third paragraph begins with the authors title and last name (e.g., Dr. Smith, Prof. Jones, Mr. Kajor, Ms. Hunter). List any memberships in professional societies like the IEEE. Finally, list any awards and work for professional committees and publications. Personal hobbies should not be included in the biography.

Firstname B. Lastname includes the biography here.

Firstname C. Lastname includes the biography here.

You might also like

- (Ebook) Multivariable Control, An Introduction PDFDocument14 pages(Ebook) Multivariable Control, An Introduction PDFCaterine Feria RamirezNo ratings yet

- Smith PredictorDocument7 pagesSmith PredictorugurtasdelNo ratings yet

- PI Controller Design for DC MotorDocument4 pagesPI Controller Design for DC MotorsamielmadssiaNo ratings yet

- Modeling and Digital Simulation Case Studies: 3.1 Pre-Lab AssignmentDocument13 pagesModeling and Digital Simulation Case Studies: 3.1 Pre-Lab AssignmentLittle_skipNo ratings yet

- ENG331 Design ReportDocument3 pagesENG331 Design ReportDhruv PatelNo ratings yet

- Modem Control Systema Analysis and Design in MATLABDocument84 pagesModem Control Systema Analysis and Design in MATLABArmando CajahuaringaNo ratings yet

- Digital Control: Fundamentals: ENGI 7825: Control Systems II Andrew VardyDocument32 pagesDigital Control: Fundamentals: ENGI 7825: Control Systems II Andrew VardyZhraa NorNo ratings yet

- Simulating Control Systems With Simulink and MATLABDocument5 pagesSimulating Control Systems With Simulink and MATLABsaharNo ratings yet

- Structured H∞ Synthesis MATLABDocument6 pagesStructured H∞ Synthesis MATLABEstefany HuamanNo ratings yet

- Advanced Chemical AnalysisDocument32 pagesAdvanced Chemical AnalysisTomilola AinaNo ratings yet

- Diabatic CSTR Simulation ReportDocument5 pagesDiabatic CSTR Simulation ReportRenzo Jose Canro CalderonNo ratings yet

- 45 Icsia2011 H30024 PDFDocument5 pages45 Icsia2011 H30024 PDFEr Mayur PatilNo ratings yet

- Dead-time compensation digital controlDocument11 pagesDead-time compensation digital controlWagner MirandaNo ratings yet

- Process Dynamics and Control PREV PAPERDocument9 pagesProcess Dynamics and Control PREV PAPERNisha TNNo ratings yet

- Experiment 3Document7 pagesExperiment 3Usama NadeemNo ratings yet

- ECSE 548 - Electronic Design and Implementation of The Sine Function On 8-Bit MIPS Processor - ReportDocument4 pagesECSE 548 - Electronic Design and Implementation of The Sine Function On 8-Bit MIPS Processor - Reportpiohm100% (1)

- Detect Abrupt System Changes Using Identification TechniquesDocument6 pagesDetect Abrupt System Changes Using Identification TechniquesPierpaolo VergatiNo ratings yet

- Proportional and Derivative Control DesignDocument5 pagesProportional and Derivative Control Designahmed shahNo ratings yet

- Modeling and Simulation Lecture 1 IntroductionDocument14 pagesModeling and Simulation Lecture 1 IntroductionhassenbbNo ratings yet

- ps3 (1) From MAE 4780Document5 pagesps3 (1) From MAE 4780fooz10No ratings yet

- Yuqiang Jin, Yuliang Chen, Zijian Lin and Junwei LeiDocument5 pagesYuqiang Jin, Yuliang Chen, Zijian Lin and Junwei Leihaseebahmadbhatti0No ratings yet

- HLS AllocationDocument19 pagesHLS AllocationmohanraomamdikarNo ratings yet

- Unesco - Eolss Sample Chapters: Controller Design in Time-DomainDocument9 pagesUnesco - Eolss Sample Chapters: Controller Design in Time-DomainAnonymous EPSHB9tXZNo ratings yet

- Implementation of Resonant Controllers and Filters in Fixed-Point ArithmeticDocument9 pagesImplementation of Resonant Controllers and Filters in Fixed-Point Arithmeticmipanduro7224No ratings yet

- Architectural Specification of an Avionic Subsystem Data Entry SystemDocument13 pagesArchitectural Specification of an Avionic Subsystem Data Entry SystemSam SpNo ratings yet

- MCH3008 Lab ProjectDocument4 pagesMCH3008 Lab ProjectEJAZ AHMADNo ratings yet

- Logic Design Syllabus SummaryDocument193 pagesLogic Design Syllabus SummaryAnup Konnur100% (1)

- EEN 407 Sample QuestionsDocument41 pagesEEN 407 Sample QuestionsAbu SiddiqueNo ratings yet

- Bode V 2.31 SG: by Thomas ReitmayrDocument16 pagesBode V 2.31 SG: by Thomas ReitmayrFrank ParkerNo ratings yet

- Stability Analysis and Compensation of Time Delays in Analog Control SystemsDocument18 pagesStability Analysis and Compensation of Time Delays in Analog Control Systemsamir shaharanNo ratings yet

- Answer To Question No 1-Program CounterDocument8 pagesAnswer To Question No 1-Program CounterAbdul Mannan HanifNo ratings yet

- BlockDiagram and Signal Flow GraphsDocument29 pagesBlockDiagram and Signal Flow GraphsDienies TorresNo ratings yet

- Meen19111103 Lab 04Document9 pagesMeen19111103 Lab 04Engr. Usman WaheedNo ratings yet

- Wala Pa NahumanDocument3 pagesWala Pa NahumanJohnCarloTigueNo ratings yet

- Answer of Homework Chapter 1 20141009Document4 pagesAnswer of Homework Chapter 1 20141009NHÂN ĐẶNG HỮUNo ratings yet

- Ouput Signal y (T) Disturbance Z (T) Reference Signal R (T) Control Signal U (T) + Error Signal e (T) Noise N (T) +Document2 pagesOuput Signal y (T) Disturbance Z (T) Reference Signal R (T) Control Signal U (T) + Error Signal e (T) Noise N (T) +ioppoi poiNo ratings yet

- Department of Computer Science: Celestijnenlaan 200A (B-3001 Heverlee (Belgium)Document38 pagesDepartment of Computer Science: Celestijnenlaan 200A (B-3001 Heverlee (Belgium)maheshnagarkarNo ratings yet

- CSEXP2Document15 pagesCSEXP2Kavita DhamalNo ratings yet

- HINFSTRUCTDocument7 pagesHINFSTRUCTJohnNo ratings yet

- Transition Guide For Experienced Users: Out Out Out inDocument3 pagesTransition Guide For Experienced Users: Out Out Out inAli AHNo ratings yet

- 4150 Lab 3Document6 pages4150 Lab 3Tan Nguyen VanNo ratings yet

- Experiment No. 01 Introduction To System Representation and Observation Using MATLABDocument20 pagesExperiment No. 01 Introduction To System Representation and Observation Using MATLABRakayet RafiNo ratings yet

- Control Tutorials For MATLAB and Simulink - Introduction - PID Controller DesignDocument15 pagesControl Tutorials For MATLAB and Simulink - Introduction - PID Controller DesignSengottu VelusamyNo ratings yet

- Using Simulink To Perform Open-Loop SimulationsDocument4 pagesUsing Simulink To Perform Open-Loop SimulationsMansour AbdulazizNo ratings yet

- EEE350 Control Systems: Assignment 2Document15 pagesEEE350 Control Systems: Assignment 2Nur AfiqahNo ratings yet

- Model Definition, Development, and Analysis: Assignment 1 - Project Report 1Document5 pagesModel Definition, Development, and Analysis: Assignment 1 - Project Report 1SarahNo ratings yet

- Lab 3 - Introduction To MATLAB: G(S) S (S + 1) (S + 2)Document3 pagesLab 3 - Introduction To MATLAB: G(S) S (S + 1) (S + 2)saharNo ratings yet

- TR (Zak) : Xo+z,' Z + ZDocument5 pagesTR (Zak) : Xo+z,' Z + ZSara WigginsNo ratings yet

- Lab Experiment 1 (B)Document15 pagesLab Experiment 1 (B)Laiba MaryamNo ratings yet

- Tuning Equations For Cascaded Control Systems Based On The First Order Plus Dead Time ApproachDocument10 pagesTuning Equations For Cascaded Control Systems Based On The First Order Plus Dead Time ApproachMaria DelgadoNo ratings yet

- Design ControllerDocument34 pagesDesign ControllerMaezinha_MarinelaNo ratings yet

- Chapter 8Document22 pagesChapter 8Michael Zontche BernardNo ratings yet

- Mfa Merit Exercises 5 Simulink 5174 2Document8 pagesMfa Merit Exercises 5 Simulink 5174 2JamesNo ratings yet

- Study, Analysis and Evaluation of Block Diagram Reduction Name: University of Polytechnic/college ofDocument10 pagesStudy, Analysis and Evaluation of Block Diagram Reduction Name: University of Polytechnic/college ofTana AzeezNo ratings yet

- Introduction to the simulation of power plants for EBSILON®Professional Version 15From EverandIntroduction to the simulation of power plants for EBSILON®Professional Version 15No ratings yet

- Discrete Event Systems in Dioid Algebra and Conventional AlgebraFrom EverandDiscrete Event Systems in Dioid Algebra and Conventional AlgebraNo ratings yet

- Running Distance For WorkDocument1 pageRunning Distance For WorkMixmikmic' KrittananNo ratings yet

- รายงานความก้าวหน้าENG part 2Document2 pagesรายงานความก้าวหน้าENG part 2Mixmikmic' KrittananNo ratings yet

- ISA 5.4 Instrument Loop DiagramsDocument22 pagesISA 5.4 Instrument Loop DiagramsDiego Nieto100% (6)

- TemplateDocument3 pagesTemplateMixmikmic' KrittananNo ratings yet

- Ratio Control. Some of Its Applications and ImperfectionsDocument4 pagesRatio Control. Some of Its Applications and ImperfectionsHayden Lovett100% (1)

- Profibus Specification 1Document0 pagesProfibus Specification 1Mixmikmic' KrittananNo ratings yet

- Fisherr D4 Control Valve AssemblyDocument12 pagesFisherr D4 Control Valve AssemblyMixmikmic' KrittananNo ratings yet

- Dembla Control ValvesDocument30 pagesDembla Control ValvesMixmikmic' KrittananNo ratings yet