Professional Documents

Culture Documents

HF2100 en

Uploaded by

Bhakti PermanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HF2100 en

Uploaded by

Bhakti PermanaCopyright:

Available Formats

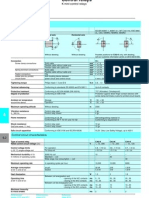

Features

File No.:E134517

File No.:CQC08002027546

HONGFA RELAY

File No.:R50153835

SO9001, SO/TS16949 , SO14001, OHSAS18001, ECQ QC 080000 CERTFED 2012 Rev. 1.01

Coil power Approx. 900mW

Contact

resistance

Contact rating

(Res. load)

Max. switching

power

Shock

resistance

Dielectric

strength

Ambient temperature

Between coil & contacts

1 x 10

7

OPS

1 x 10

5

OPS

1)

(See approval reports for more details)

HF2100

5

6

9

12

15

27 x (1 10%)

40 x (1 10%)

97 x (1 10%)

155 x (1 10%)

256 x (1 10%)

3.75

4.50

6.75

9.00

11.25

0.5

0.6

0.9

1.2

1.5

MINIATURE HIGH POWER RELAY

CONTACT DATA

CHARACTERISTICS

COIL

COIL DATA

Nominal

Voltage

VDC

Coil

Resistance

Pick-up

Voltage

VDC

max.

Drop-out

Voltage

VDC

min.

18

24

48

70

110

380 x (1 10%)

660 x (1 10%)

2560 x (1 10%)

5500 x (1 10%)

13450 x (1 10%)

13.50

18.00

36.00

52.50

82.50

1.8

2.4

4.8

7.0

11.0

& 30A switching capability

& PCB coil terminals, ideal for heavy duty load

& 2.5kV dielectric strength (between coil and contacts)

& Plastic sealed and flux proofed types available

& UL insulation system: Class F available

& Environmental friendly product (RoHS compliant)

& Outline Dimensions: (32 x 27.5 x 28.0) mm

Max.

Allowable

Voltage

VDC

at 23

6.5

7.8

11.7

15.6

19.5

23.4

31.2

62.4

91.0

143.0

1A 1B 1C (NO) 1C (NC)

50m max.(at 1A 24VDC)

AgCdO

30A 240VAC 15A 240VAC 20A 240VAC 10A240VAC

20A 30VDC 10A 30VDC 20A 30VDC 10A 30VDC

600W 300W 600W 300W

277VAC / 30VDC

40A 15A 20A 10A

Contact

arrangement

Max. switching

voltage

Max. switching

current

Contact material

Mechanical

endurance

Electrical

endurance

7200VA 3600VA 4800VA 2400VA

nsulation resistance

Between open contacts

Operate time (at nomi. volt.)

Release time (at nomi. volt.)

Functional

Destructive

Vibration resistance

Humidity

Termination

Unit weight

Construction

1000M (at 500VDC)

2500VAC 1min

1500VAC 1min

15ms max.

10ms max.

-55

o

C to 85

o

C

98m/s

2

980m/s

2

10Hz to 55Hz 1.5mm DA

5% to 85% RH

PCB & QC

Approx. 35g

Plastic sealed,

Dust protected

231

Notes: 1) For plastic sealed type, the venting-hole should be excised in

test. Typical electrical load & endurance: at 30A240VAC, Resistive,

at room temperature, 100,000 OPS, for NO contact.

2) The data shown above are initial values.

3) Please find coil temperature curve in the characteristic curves below.

4) UL insulation system: Class F, Class B.

Tungsten

Pilot duty

Motor load

Ballast

Notes: Only some typical ratings are listed above. f more details are required, please contact us.

SAFETY APPROVAL RATINGS

UL/CUL

Definite

purpose

(LRA-

loaded rotor)

(FLA-full load)

General

purpose

232

Load type VoIts 1 FormA 1 Form B 1 Form C (NO) 1 Form C (NC)

Resistive

125/240VAC 30A 15A 30A 15A

277VAC 30A 30A 30A 30A

125/240VAC 30A 15A

30VDC 20A 10A 20A 10A

277VAC 20A

240VAC 15A

250VAC 40A 40A

125/240/277VAC 6A 3A 6A 3A

125VAC 800VA 290VA 800VA 290VA

125VAC 690VA 690VA

125VAC 800VA 800VA

240VAC 1152VA 768VA 1152VA 768VA

277VAC 764VA 764VA

125VAC 1HP 1/4HP 1HP 1/4HP

240VAC 2HP 1HP 2HP 1HP

125VAC 1HP 1HP

125/277VAC 3/4HP 3/4HP

120VAC 82.8LRA, 13.8FLA 82.8LRA, 13.8FLA

125VAC 96LRA, 30FLA 33LRA, 10FLA 60LRA, 20FLA 33LRA, 10FLA

125VAC 60LRA, 20FLA 30LRA, 12FLA 60LRA, 20FLA 30LRA, 12FLA

125VAC 82.8LRA, 27FLA 82.8LRA, 27FLA

240VAC 80LRA, 30FLA 33LRA, 10FLA 60LRA, 20FLA 33LRA, 10FLA

240VAC 41.4LRA, 6.9FLA 41.4LRA, 6.9FLA

277VAC 60LRA, 20FLA 60LRA, 20FLA

125VAC 15A 15A

240VAC 5A 5A 3A

120VAC 3A

240VAC 3A

Customer speciaI code

1)

(Bottom view) (Top view)

1 FormA

233

(Bottom view)

InsuIation standard F: Class F NiI: Class B

OUTLINE DIMENSIONS, WIRING DIAGRAM AND PC BOARD LAYOUT

HF2100 -1A E -12D

ORDERING INFORMATION

CoiI voItage 5, 6, 9, 12, 15, 18, 24, 48, 70, 110VDC

Contact arrangement

Type

Construction E: Plastic sealed NiI: Dust protected

1A: 1FormA 1B: 1Form B

1C: 1Form C

(XXX)

Unit: mm

Outline Dimensions

PCB Layout Wiring Diagram

F

17.8

1

5

.

2

4

2

.

5

4

14

2- 1.1

3.8 2- 2.1

28 3.6

2

-

0

.

8

2

-

6

.

4

27.5

3

2

Notes: 1) We recommend dust protected types for a clean environment (free from contaminations like H

2

S, SO

2

, NO

2

, dust, etc.).

We suggest to choose plastic sealed types and validate it in real application for an unclean environment (with contaminations

like H

2

S, SO

2

, NO

2

, dust, etc.).

f water cleaning is required after the relay is assembled on PCB, please contact us for suggestion about suitable parts.

2) To avoid using relays under strong magnetic field which will change the parameters of relays such as pick-up voltage and drop-out voltage.

3) Relays may be damaged because of falling or when shocking conditions exceed the requirement.

4) Regarding the plastic sealed relay, we should leave it cooling naturally until below 40

o

C after welding, then clean it and deal with coating,

remarkably the temperature of solvents should also be controlled below 40

o

C.Please avoid cleaning the relay by ultrasonic, avoid using

the solvents like gasoline, Freon, and so on, which would affect the configuration of relay or influence the environment.

5) About preferable condition of operation, storage and transportation, please refer to "Explanation to terminology and guidetines of relay".

Disclaimer

This datasheet is for the customers' reference. All the specifications are subject to change without notice.

We could not evaluate all the performance and all the parameters for every possible application. Thus the user should be in a right position to

choose the suitable product for their own application. f there is any query, please contact Hongfa for the technical service. However, it is the user's

responsibility to determine which product should be used only.

Xiamen Hongfa Electroacoustic Co., Ltd. All rights of Hongfa are reserved.

Remark: 1) n case of no tolerance shown in outline dimension: outline dimension 1mm, tolerance should be 0.2mm; outline dimension `1mm

and 5mm, tolerance should be 0.3mm; outline dimension `5mm, tolerance should be 0.4mm.

2) The tolerance without indicating for PCB layout is always 0.1mm.

1 Form C

(Bottom view) (Top view)

1 Form B

234

(Bottom view) (Top view)

AC Load

DC Load

1A

1C (NO)

1B

1C (NC)

1A

1C (NO)

1B

1C (NC)

10 20 40 30

MAXMUM SWTCHNG POWER

C

o

n

t

a

c

t

C

u

r

r

e

n

t

(

A

)

Contact Voltage (V)

ENDURANCE CURVE

O

p

e

r

a

t

i

o

n

s

(

X

1

0

0

0

0

O

P

S

)

Contact Current (A)

CHARACTERISTIC CURVES

OUTLINE DIMENSIONS, WIRING DIAGRAM AND PC BOARD LAYOUT

Unit: mm

17.8

1

5

.

2

4

7

.

6

2

.

5

4

14

2- 1.1

3- 2.1

3.8

28 3.6

17.8

1

2

.

7

1

0

.

2

14

2- 1.1

2- 2.1

3.8

28 3.6

0

1

130 90 80 100 120 110 150 140 160

30A

0A

25A

20A

15A

COL TEMPERATURE RSE

T

e

m

p

e

r

a

t

u

r

e

r

i

s

e

(

K

)

Percentage Of Nominal Coil Voltage

0

40

110

90

80

70

50

60

100

40

30

20

15

100

10

10 100 200 1000

1

30

100

10

3

-

0

.

8

3

-

6

.

4

27.5

3

2

2

-

0

.

8

2

-

6

.

4

27.5

3

2

You might also like

- Power Transformer Complete Drawing Rev-00Document45 pagesPower Transformer Complete Drawing Rev-00aps100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- 012-SZST (Rele)Document5 pages012-SZST (Rele)el_george0079491No ratings yet

- LKP CatalogDocument3 pagesLKP Catalogvikas_ojha54706No ratings yet

- Datasheet Relay 12 V PDFDocument7 pagesDatasheet Relay 12 V PDFturkceNo ratings yet

- Datasheet Techman OMIT SS 124LMDocument2 pagesDatasheet Techman OMIT SS 124LMSteve MurphyNo ratings yet

- Relay 5vDocument2 pagesRelay 5vNgoc Loi Nguyen HoNo ratings yet

- MK 2 PiDocument7 pagesMK 2 PiA Whick Bumbum TralalaNo ratings yet

- G5Q PCB Relay: Ordering InformationDocument4 pagesG5Q PCB Relay: Ordering InformationLAU_CBrNo ratings yet

- Eng DS 1308242 T92 1112 PDFDocument4 pagesEng DS 1308242 T92 1112 PDFYashiro AlvaradoNo ratings yet

- Ds1e-S-dc5v Relay Ag231944 Data SheetDocument6 pagesDs1e-S-dc5v Relay Ag231944 Data SheetbananameepNo ratings yet

- G8P PCB Relay: Compact, Low-Cost 30-A Power Relay For PC Board or Panel-Mounted ApplicationsDocument6 pagesG8P PCB Relay: Compact, Low-Cost 30-A Power Relay For PC Board or Panel-Mounted Applicationsyocus_ooiNo ratings yet

- 793-P-1C Relay Data SheetDocument6 pages793-P-1C Relay Data SheetsendmebooksNo ratings yet

- DatasheetDocument4 pagesDatasheetNaresh KumarNo ratings yet

- G2RSDocument14 pagesG2RSMisaelRodriguezNo ratings yet

- Ordering Information: PCB RelayDocument6 pagesOrdering Information: PCB RelayΠΑΝΑΓΙΩΤΗΣΠΑΝΑΓΟΣNo ratings yet

- ReledakiaDocument5 pagesReledakiaapi-292778259No ratings yet

- Technical Data and Applications of RCCBsDocument16 pagesTechnical Data and Applications of RCCBsfndprojectNo ratings yet

- PCB Relay G5laDocument4 pagesPCB Relay G5laRamón ColónNo ratings yet

- Micro Relay A/VFMA: Automotive Relays Plug-In Micro ISO RelaysDocument4 pagesMicro Relay A/VFMA: Automotive Relays Plug-In Micro ISO Relaysnismo_gt4No ratings yet

- G9EB-1-B-AQ: Capable of Interrupting High-Voltage, High-Current LoadsDocument2 pagesG9EB-1-B-AQ: Capable of Interrupting High-Voltage, High-Current LoadsNandam SrinivasNo ratings yet

- HF43F DatasheetDocument3 pagesHF43F Datasheetdff1967dffNo ratings yet

- U4J - Diodo SMDDocument5 pagesU4J - Diodo SMDedgarlibanioNo ratings yet

- MCR100 Series Sensitive Gate Silicon Controlled Rectifiers: Reverse Blocking ThyristorsDocument7 pagesMCR100 Series Sensitive Gate Silicon Controlled Rectifiers: Reverse Blocking ThyristorsErnestoGarciaMontanoNo ratings yet

- 2-1415031-1 - 16 Amp PC Board Miniature RelayDocument2 pages2-1415031-1 - 16 Amp PC Board Miniature Relay06111981No ratings yet

- 32 Volt-100 AmpDocument4 pages32 Volt-100 AmpsagarscorpionNo ratings yet

- OnkyoC701A JP SMDocument21 pagesOnkyoC701A JP SMHelder MartinsNo ratings yet

- Relay Js PanasonicDocument4 pagesRelay Js Panasonicsalimos12No ratings yet

- 2-1393774-1 - P1 Relay V23026Document5 pages2-1393774-1 - P1 Relay V2302606111981No ratings yet

- Rele DatasheetDocument9 pagesRele Datasheetjluis57No ratings yet

- Silicon 5 Watt Zener Diodes: 1N5333B Thru 1N5388BDocument5 pagesSilicon 5 Watt Zener Diodes: 1N5333B Thru 1N5388Bwilburroberts20034852No ratings yet

- Song Chuan 841 P 2a C 12vdc - 085c2545daDocument7 pagesSong Chuan 841 P 2a C 12vdc - 085c2545daEver SucoNo ratings yet

- Heavy-Duty Miniature Power Relay for Switching MotorsDocument6 pagesHeavy-Duty Miniature Power Relay for Switching MotorsAndrei Ponce WongNo ratings yet

- Micro Relay FT B3Document11 pagesMicro Relay FT B3agus2kNo ratings yet

- Rf1v RelaysDocument8 pagesRf1v RelaysbansalrNo ratings yet

- Air Circuit BreakerDocument13 pagesAir Circuit BreakercjtagayloNo ratings yet

- Ordering Information: Miniature Power RelayDocument4 pagesOrdering Information: Miniature Power Relaynoob121No ratings yet

- Omron Auxiliary RelayDocument14 pagesOmron Auxiliary RelayNima MahmoudpourNo ratings yet

- 875B-1CH-F-S-24VDC Data SheetDocument4 pages875B-1CH-F-S-24VDC Data SheetdernivaljrNo ratings yet

- Panasonic SA-AK960 Mini ComboDocument121 pagesPanasonic SA-AK960 Mini Comboppstone100% (3)

- Ca3kn22bd Telemecanique - Unit5.relayDocument8 pagesCa3kn22bd Telemecanique - Unit5.relaykapenziNo ratings yet

- Special Purpose Basic SwitchDocument5 pagesSpecial Purpose Basic Switchng_viet_cuong_groupNo ratings yet

- Finder Serie 55Document14 pagesFinder Serie 55youri59490No ratings yet

- Ev200haana RelayDocument2 pagesEv200haana RelaySJS68No ratings yet

- ABB Interruptor Diferencial F804Document12 pagesABB Interruptor Diferencial F804Arthur E-n SpinosaNo ratings yet

- DC Components Co., LTD.: 1.5KE6.8 Thru 1.5KE440CADocument5 pagesDC Components Co., LTD.: 1.5KE6.8 Thru 1.5KE440CACarlos Sergio Costa CostaNo ratings yet

- 1.5KE100 To 1.5KE440ADocument5 pages1.5KE100 To 1.5KE440ARodolfo TurkevitzNo ratings yet

- Mini Industrial Relay Specs and ApplicationsDocument3 pagesMini Industrial Relay Specs and ApplicationsSami SaadNo ratings yet

- 833HDocument3 pages833HVivien RichterNo ratings yet

- Panasonic Sa-Ak270 (Eb, Eg)Document120 pagesPanasonic Sa-Ak270 (Eb, Eg)Rafael Hernandez100% (1)

- JQ1-24F Ds 61B03 en jq-469944Document7 pagesJQ1-24F Ds 61B03 en jq-469944NobodyNo ratings yet

- Trasfo CurentDocument11 pagesTrasfo CurentAlonso CoradoNo ratings yet

- G5LE 0813-267607 ReleDocument7 pagesG5LE 0813-267607 ReleSaulo Araujo QueirozNo ratings yet

- 842 1A C Relay DatasheetDocument3 pages842 1A C Relay DatasheetScott PomfretNo ratings yet

- Schrack RelayDocument4 pagesSchrack RelaydadddooooNo ratings yet

- Timers, Time, Switches, Hour Meters & Supply MonitorsDocument24 pagesTimers, Time, Switches, Hour Meters & Supply MonitorsnogeshwarNo ratings yet

- ReleDocument3 pagesRelevitor4santos_6No ratings yet

- PA1a slim power relay technical specificationsDocument0 pagesPA1a slim power relay technical specificationsPreeti KatiyarNo ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- CarSim BrochureDocument2 pagesCarSim BrochureBhakti PermanaNo ratings yet

- SOS System This Is Very Helpful For Anyone Who Need It......Document1 pageSOS System This Is Very Helpful For Anyone Who Need It......Bhakti PermanaNo ratings yet

- Effect ProcessorDocument1 pageEffect ProcessorBhakti PermanaNo ratings yet

- En125 Part List OldDocument0 pagesEn125 Part List OldBhakti PermanaNo ratings yet

- Password ComandosDocument1 pagePassword ComandosBhakti PermanaNo ratings yet

- Analisa Pengaruh Pembebanan Impact Terhadap Distribusi Tegangan Frame Model Toyota Kijang Innova Dengan Rasio Geometris 1:8Document2 pagesAnalisa Pengaruh Pembebanan Impact Terhadap Distribusi Tegangan Frame Model Toyota Kijang Innova Dengan Rasio Geometris 1:8Bhakti PermanaNo ratings yet

- STS Prelim ExamDocument2 pagesSTS Prelim ExamMychie Lynne MayugaNo ratings yet

- Developing the cycle of maslahah based performance management system implementationDocument27 pagesDeveloping the cycle of maslahah based performance management system implementationM Audito AlfansyahNo ratings yet

- DOE Tank Safety Workshop Presentation on Hydrogen Tank TestingDocument36 pagesDOE Tank Safety Workshop Presentation on Hydrogen Tank TestingAlex AbakumovNo ratings yet

- Journals OREF Vs ORIF D3rd RadiusDocument9 pagesJournals OREF Vs ORIF D3rd RadiusironNo ratings yet

- OS LabDocument130 pagesOS LabSourav BadhanNo ratings yet

- Endangered EcosystemDocument11 pagesEndangered EcosystemNur SyahirahNo ratings yet

- Mrs. Universe PH - Empowering Women, Inspiring ChildrenDocument2 pagesMrs. Universe PH - Empowering Women, Inspiring ChildrenKate PestanasNo ratings yet

- Eye Bags ReliefDocument27 pagesEye Bags ReliefNatsu DragneelNo ratings yet

- A Database of Chromatographic Properties and Mass Spectra of Fatty Acid Methyl Esters From Omega-3 ProductsDocument9 pagesA Database of Chromatographic Properties and Mass Spectra of Fatty Acid Methyl Esters From Omega-3 ProductsmisaelNo ratings yet

- Bio310 Summary 1-5Document22 pagesBio310 Summary 1-5Syafiqah ArdillaNo ratings yet

- PNBONE_mPassbook_134611_6-4-2024_13-4-2024_0053XXXXXXXX00 (1) (1)Document3 pagesPNBONE_mPassbook_134611_6-4-2024_13-4-2024_0053XXXXXXXX00 (1) (1)imtiyaz726492No ratings yet

- A Guide To in The: First AidDocument20 pagesA Guide To in The: First AidsanjeevchsNo ratings yet

- CENG 5503 Intro to Steel & Timber StructuresDocument37 pagesCENG 5503 Intro to Steel & Timber StructuresBern Moses DuachNo ratings yet

- White Box Testing Techniques: Ratna SanyalDocument23 pagesWhite Box Testing Techniques: Ratna SanyalYogesh MundhraNo ratings yet

- Chapter 4 DeterminantsDocument3 pagesChapter 4 Determinantssraj68No ratings yet

- Mosfet 101Document15 pagesMosfet 101Victor TolentinoNo ratings yet

- 2010 HD Part Cat. LBBDocument466 pages2010 HD Part Cat. LBBBuddy ButlerNo ratings yet

- Methods to estimate stakeholder views of sustainabilityDocument7 pagesMethods to estimate stakeholder views of sustainabilityAlireza FatemiNo ratings yet

- Bengali (Code No - 005) COURSE Structure Class - Ix (2020 - 21Document11 pagesBengali (Code No - 005) COURSE Structure Class - Ix (2020 - 21Břîšťỹ ÃhmęđNo ratings yet

- Meet Joe Black (1998) : A Metaphor of LifeDocument10 pagesMeet Joe Black (1998) : A Metaphor of LifeSara OrsenoNo ratings yet

- Job Order Costing: Patrick Louie E. Reyes, CTT, Micb, Rca, CpaDocument45 pagesJob Order Costing: Patrick Louie E. Reyes, CTT, Micb, Rca, CpaClaudette Clemente100% (1)

- Condition Based Monitoring System Using IoTDocument5 pagesCondition Based Monitoring System Using IoTKaranMuvvalaRaoNo ratings yet

- Galaxy Owners Manual Dx98vhpDocument10 pagesGalaxy Owners Manual Dx98vhpbellscbNo ratings yet

- Kaydon Dry Gas SealDocument12 pagesKaydon Dry Gas Sealxsi666No ratings yet

- ITP Exam SuggetionDocument252 pagesITP Exam SuggetionNurul AminNo ratings yet

- How To Text A Girl - A Girls Chase Guide (Girls Chase Guides) (PDFDrive) - 31-61Document31 pagesHow To Text A Girl - A Girls Chase Guide (Girls Chase Guides) (PDFDrive) - 31-61Myster HighNo ratings yet

- Hydraulics Engineering Course OverviewDocument35 pagesHydraulics Engineering Course Overviewahmad akramNo ratings yet

- Mutual Fund PDFDocument22 pagesMutual Fund PDFRajNo ratings yet

- Induction ClassesDocument20 pagesInduction ClassesMichelle MarconiNo ratings yet

- Tutorial 1 Discussion Document - Batch 03Document4 pagesTutorial 1 Discussion Document - Batch 03Anindya CostaNo ratings yet