Professional Documents

Culture Documents

478 - Maxi Rotor Uk

Uploaded by

LTE002Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

478 - Maxi Rotor Uk

Uploaded by

LTE002Copyright:

Available Formats

Maxi-Rotor

Krger's Maxi-Rotor is simple and sturdy in design, highly reliable and requires only a minimum of maintenance. The rotor is fitted with a baffle plate offering maximum oxygen transfer efficiency relative

to power consumption. The rotor can also be equipped with aerosol and noise reduction equipment satisfying stringent working environment standards.

Design

The maxi-rotor consists of a horisontal shaft with mounted-on blades, end bearing, gear and electric motor. The rotor is suspended from a concrete bridge which offers effective protection against splashes and noise. The rotor is fitted with a baffle plate increasing the oxygen transfer efficiency and is available with aerosol reduction equipment in various designs. All parts of the rotor are protected effectively against corrosion by hot-dip galvanisation, twocomponent epoxy tar paint and neoprene rubber as base for the mounted-on blades. The rotor is driven by an electric motor of high quality

and with reinforced bearings. The gear unit is specially designed to ensure a high degree of reliability. The motor is protected by a silencing casing.

Operation

The operation of the maxi-rotor is controlled automatically by an oxygen meter in the tank. The oxygen transfer efficiency depends on the submersion of the rotor (min. 10 cm - max. 30 cm). The motor is also an effective stirring device and is available with a two-speed motor.When operating at slow speed of rotation, the rotor serves as a stirring device only.

Oxygen transfer efficiency and power consumption

The oxygen transfer efficiency is based on operation in clean water at 10oC under standard conditions. The oxygen transfer efficiency and the power consumption are shown in the figure below. The conversion into activated sludge is based on factor a. The test data refer to a rotor with a baffle plate and a water depth of 3.5 m. The power consumption refers to the input to the electric motor.

Range of equipment

The maxi-rotor is available in three standard lengths: 6.0 m, 7.5 m and 9 m.

a= 1.0 Oxygen transfer efficiency kg O2/m rotor/hour 10 9 8 7 6 5 4 3 2 1 0 kg O2/kWh Power consumption Oxygen transfer efficiency Power consumption in kW/m rotor 10 9 8 7 6 5 4 3 2 1 0

Maxi-Rotor with concrete bridge, baffle plate and aerosol reduction equipment

2.2 2.2 2.0 2.0 1.8 1.8 1.6 1.6 1.4 1.4 10 12 14 16 18 20 22 24 26 28 30 cm submersion

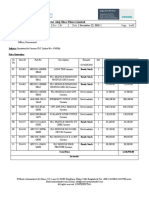

Technical specifications for Maxi-Rotor

DA 60-63

DA 75-78

DA 90-93

SM5gb December 1998

Rotor diameter A (rotor length) B (installation length) Electric motor (standard) Rotor speed (standard) Net weight, excl. shipping equipment

m m mm kW rpm. kg

1000 6140/7590 30 73-73/49 2650

1000 7640/9090 37 73-73/49 3080

1000 9140/10590 45 73-73/49 3245

Krger A/S reserves the right to change technical specifications without prior notice

Gladsaxevej 363 DK-2860 Sborg Tel.: +45 39 69 02 22 Fax: +45 39 69 08 06 E-mail: kruger@kruger.dk Homepage: www.kruger.dk

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- ZH - 09 Steel ConnectionDocument65 pagesZH - 09 Steel ConnectionLTE002No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- ZH - 09 Steel ConnectionDocument65 pagesZH - 09 Steel ConnectionLTE002No ratings yet

- YZ - 11 Intumescent Coating ModellingDocument39 pagesYZ - 11 Intumescent Coating ModellingLTE002No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- YZ - 10 Intumescent CoatingDocument26 pagesYZ - 10 Intumescent CoatingLTE002No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- ZH - 2005 RCDocument99 pagesZH - 2005 RCLTE002No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- YYJ - Stiff - 2003 Caternary Action - Steel BeamDocument29 pagesYYJ - Stiff - 2003 Caternary Action - Steel BeamLTE002No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Gas ChromatographDocument21 pagesGas ChromatographLTE002No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Building Digest 20Document4 pagesBuilding Digest 20LTE002No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Bridges - Asia-22-25 02 10Document84 pagesBridges - Asia-22-25 02 10LTE002100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Oxygen RequirementsDocument22 pagesOxygen RequirementsLTE002No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Whitepaper - Affinity LawsDocument3 pagesWhitepaper - Affinity Lawssubramanyanvenkat6185No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Heat Exchanger VibrationDocument3 pagesHeat Exchanger VibrationTim KuNo ratings yet

- Bio Gas Burner 1Document21 pagesBio Gas Burner 1saadullah_siddiqui6076No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Soil WashingDocument19 pagesSoil WashingLTE002No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 32438Document154 pages32438vasakaNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- MethaneDocument24 pagesMethaneLTE002No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- PH MeasurementsDocument12 pagesPH MeasurementsLTE002No ratings yet

- High PerformanceDocument3 pagesHigh PerformanceLTE002No ratings yet

- Otis About ElevatorsDocument14 pagesOtis About ElevatorsRajeshkragarwalNo ratings yet

- Fire Sprinklers PDFDocument28 pagesFire Sprinklers PDFChristopher BrownNo ratings yet

- Biomass To Ethanol ProcessDocument132 pagesBiomass To Ethanol ProcessLTE002No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Simulation of High-Speed FillingDocument13 pagesSimulation of High-Speed FillingLTE002No ratings yet

- Trigger Sprayer Dynamic Systems ModelDocument5 pagesTrigger Sprayer Dynamic Systems ModelLTE002No ratings yet

- Centrifugal PumpDocument42 pagesCentrifugal Pumprumabiswas853100% (2)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Cal Methodology - Energy Saving - Electrical - HouseholdDocument15 pagesCal Methodology - Energy Saving - Electrical - HouseholdLTE002No ratings yet

- I. Introduction, Purpose, and Study LayoutDocument17 pagesI. Introduction, Purpose, and Study LayoutLTE002No ratings yet

- Toxicity of BiodieselDocument53 pagesToxicity of BiodieselLTE002No ratings yet

- 833 Anaerobic Digestion ParametersDocument4 pages833 Anaerobic Digestion ParametersLTE002No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- EarthingDocument40 pagesEarthingmamoun_hammad7917No ratings yet

- Ettv - BcaDocument56 pagesEttv - BcaHo Chee YongNo ratings yet

- Technical Sheet Racloflex NTDocument2 pagesTechnical Sheet Racloflex NTAnthony AngNo ratings yet

- Fundasurv 215 Plate 1mDocument3 pagesFundasurv 215 Plate 1mKeith AtencioNo ratings yet

- E7d61 139.new Directions in Race Ethnicity and CrimeDocument208 pagesE7d61 139.new Directions in Race Ethnicity and CrimeFlia Rincon Garcia SoyGabyNo ratings yet

- Installing Surge Protective Devices With NEC Article 240 and Feeder Tap RuleDocument2 pagesInstalling Surge Protective Devices With NEC Article 240 and Feeder Tap RuleJonathan Valverde RojasNo ratings yet

- English Test For Grade 7 (Term 2)Document6 pagesEnglish Test For Grade 7 (Term 2)UyenPhuonggNo ratings yet

- Aristotle - OCR - AS Revision NotesDocument3 pagesAristotle - OCR - AS Revision NotesAmelia Dovelle0% (1)

- Multiple Choice Practice Questions For Online/Omr AITT-2020 Instrument MechanicDocument58 pagesMultiple Choice Practice Questions For Online/Omr AITT-2020 Instrument Mechanicمصطفى شاكر محمودNo ratings yet

- Community Profile and Baseline DataDocument7 pagesCommunity Profile and Baseline DataEJ RaveloNo ratings yet

- 1188 2665 1 SMDocument12 pages1188 2665 1 SMRita BangunNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- G.Devendiran: Career ObjectiveDocument2 pagesG.Devendiran: Career ObjectiveSadha SivamNo ratings yet

- FIR FliterDocument10 pagesFIR FliterasfsfsafsafasNo ratings yet

- Etag 002 PT 2 PDFDocument13 pagesEtag 002 PT 2 PDFRui RibeiroNo ratings yet

- CL Honours Report NamanDocument11 pagesCL Honours Report NamanNaman VermaNo ratings yet

- Quality Standards For ECCE INDIA PDFDocument41 pagesQuality Standards For ECCE INDIA PDFMaryam Ben100% (4)

- Cameron International Corporation: FORM 10-KDocument31 pagesCameron International Corporation: FORM 10-KMehdi SoltaniNo ratings yet

- Civil Rights Vocabulary Lesson PlanDocument4 pagesCivil Rights Vocabulary Lesson PlanKati ArmstrongNo ratings yet

- KRAS QC12K-4X2500 Hydraulic Shearing Machine With E21S ControllerDocument3 pagesKRAS QC12K-4X2500 Hydraulic Shearing Machine With E21S ControllerJohan Sneider100% (1)

- بتول ماجد سعيد (تقرير السيطرة على تلوث الهواء)Document5 pagesبتول ماجد سعيد (تقرير السيطرة على تلوث الهواء)Batool MagedNo ratings yet

- Chapter 01 What Is Statistics?Document18 pagesChapter 01 What Is Statistics?windyuriNo ratings yet

- Governance Operating Model: Structure Oversight Responsibilities Talent and Culture Infrastructu REDocument6 pagesGovernance Operating Model: Structure Oversight Responsibilities Talent and Culture Infrastructu REBob SolísNo ratings yet

- HRM Practices in NepalDocument22 pagesHRM Practices in NepalBodhiNo ratings yet

- Diverging Lenses - Object-Image Relations: Previously in Lesson 5 Double Concave LensesDocument2 pagesDiverging Lenses - Object-Image Relations: Previously in Lesson 5 Double Concave LensesleonNo ratings yet

- Engineering Management: Class RequirementsDocument30 pagesEngineering Management: Class RequirementsMigaeaNo ratings yet

- Manhole Head LossesDocument11 pagesManhole Head Lossesjoseph_mscNo ratings yet

- Arudha PDFDocument17 pagesArudha PDFRakesh Singh100% (1)

- CHAPTER 2 Part2 csc159Document26 pagesCHAPTER 2 Part2 csc159Wan Syazwan ImanNo ratings yet

- Ultra Electronics Gunfire LocatorDocument10 pagesUltra Electronics Gunfire LocatorPredatorBDU.comNo ratings yet

- Work Energy Power SlidesDocument36 pagesWork Energy Power Slidessweehian844100% (1)

- Blackberry: Terms of Use Find Out MoreDocument21 pagesBlackberry: Terms of Use Find Out MoreSonu SarswatNo ratings yet

- LC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Document2 pagesLC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Mahadi Hassan ShemulNo ratings yet

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Advanced Production Decline Analysis and ApplicationFrom EverandAdvanced Production Decline Analysis and ApplicationRating: 3.5 out of 5 stars3.5/5 (4)

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet