Professional Documents

Culture Documents

Hazardous Area Classification - Assignment 1

Uploaded by

Selvakumar JOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hazardous Area Classification - Assignment 1

Uploaded by

Selvakumar JCopyright:

Available Formats

J.

Selvakumar

Hazardous Area Classification: Assignment-1

Review Chapter 6 of IP-15 and identify how the ventilation aspects have been considered in your project

INTRODUCTION: Ventilation is one of the important factors to be considered in determining the hazardous zone classification in addition to operating condition (temperature/ pressure), material handled, flammability of fluid handled, ignition source, occupancy, release source & likelihood of release. Inadequate ventilation in a shelter or enclosed area or obstructed open area may lead to gradual accumulation of gas or vapour over time leading to higher risk of fire & explosion. Adequate ventilation eventually dilutes or removes the contaminated air until its safe limit concentration is reached. EXCERPTS OF CHAPTER-6 OF IP-15: Effect of ventilation on hazardous area classification is detailed in this section. Degree of Ventilation: For assessing the degree of ventilation the following procedure needs to be considered. Determine the openness of the region whether open area or enclosed area. If area is open and sheltered/ obstructed it is restricted natural ventilation otherwise is it adequate natural ventilation. If area is enclosed and contain internal source of release with ventilation greater than 12 air changes per hour gives dilute ventilation else it is adequate ventilation. If area is enclosed and contain internal source of release with ventilation less than 12 air changes per hour it is inadequate ventilation. If area is enclosed pressurized to greater than 50 N/m2 and without internal source of release but having external source of release it is classified as non-hazardous. If area is enclosed and not pressurized to greater than 50 N/m2 without internal source of release but having external source of release it is classified as dilution ventilation provided ventilation is greater than 12 air changes per hour.

Open Area: Natural ventilation and obstacles to free air movement: Facilities classified as open area (i.e. with natural ventilation) the hazardous area classification applies without further ventilation consideration. Some obstacles may impede natural ventilation and this may enlarge the extent of the hazardous area and possibly increase the severity of the zone classification. However, obstacles like dyke, walls and ceilings may limit the movement of gaseous release, reducing the extent of the hazardous area. Effect of fire or deflection wall on hazardous area: Due to limitation of space if a source of ignition is located inside a hazardous area, imperforated firewall with suitable fire rating may be provided on the side of the facility containing the source of release allowing free ventilation in all other directions.

Hazardous Area Classification: Assignment-1

Buildings adjacent to open hazardous areas

J. Selvakumar

The buildings should be assigned a zone classification of a higher severity than the adjacent area if it is possible for any leakage to persist in the building. Sheltered or Obstructed Areas: Area with restricted natural ventilation should be assigned a zone classification of a severity of one step higher than if it were a fully open area. Releases from low pressure or evaporation sources are dependent upon the ventilation flow to induce mixing as well as transport. In these conditions, if the density of the vapour is greater than air, there is possibility of vapour entrapment at floor/ roof level. Enclosed areas: An enclosed area is any building or enclosed space within which, in the absence of artificial ventilation, the air movement will be limited and any flammable atmosphere will not be dispersed naturally. Based on its degree of ventilation it is classified as adequate or inadequate ventilation. Adequate ventilation ensured that a building containing secondary grade of release source can be properly classified as Zone 2. In large buildings it may be possible to classify some parts as nonhazardous, while other parts as Zone 2. Continuous or primary grade release should not be discharged internally, but should be piped directly to an external safe location through ducting. Localized exhaust ventilation, gas detection or other means of prompt identification of release of flammable materials should be considered. Continuous and primary grade source of release should be avoided in areas having inadequate ventilation. These areas should be classified as Zone 1 since a secondary grade source may form a localized flammable atmosphere and persist for a long period. Flammable gas detectors may be installed in the area if adequate ventilation cannot be provided. Effect of loss of ventilation on HAC of an enclosed area: An enclosed area classified as Zone 2 by virtue of adequate ventilation contains normally secondary grade source of release. On loss of adequate ventilation there will not necessarily be an immediate development of a flammable atmosphere and it be acceptable, subject to monitoring of the atmosphere and plant conditions, to continue for a short period to operate equipment only suitable for Zone 2. There should be an audio-visual alarm to indicate ventilation loss. Equipment not suitable for Zone 1 should be electrically isolated. Location of an enclosed area without over pressure protection on a Zone 0 or 1 is not acceptable practice and should be avoided if the enclosed area with no internals source of release but adjacent to an external hazardous area.

2|Page

Hazardous Area Classification: Assignment-1 J. Selvakumar

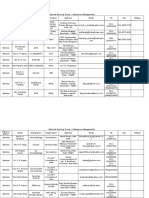

Effect of Ventilation on Hazardous area Classification in Bab Compression Project: Shelters are provided for the gas compressor area, chemical injection area handling flammable fluids. The natural ventilation in these area were restricted. Hence the zone classification assigned is Zone 1 (i.e. severity of one step higher than if it were a fully open area) for the sheeted area ( from 3.5 m above grade till roof height) and Zone 2 form grade level till 3.5m height which is open at all sides. Since primary grade source of release should be avoided in areas having inadequate ventilation, the from compressor seal gas vent, diesel day tank vent are released outside the shelter to a safe location. Closed drain drum and drain pumps are inside pit i.e. situated below grade level. These areas have restricted natural ventilation. Hence the pit area is classified as Zone 1, which is one step higher than the if it were an open area. In addition, the open drain pit, burn pit, diesel tank in well head area are classified as Zone 1 due to restricted natural ventilation.

3|Page

You might also like

- Harley DavidsonDocument40 pagesHarley Davidsonristosk100% (1)

- Firearms in America 1600 - 1899Document310 pagesFirearms in America 1600 - 1899Mike100% (3)

- Ventilation in Confined SpaceDocument6 pagesVentilation in Confined SpaceTS Wong100% (1)

- Confined Space EntryDocument6 pagesConfined Space EntryrigelNo ratings yet

- Electrical Equipment in Hazardous Areas - Wikipedia, The Free EncyclopediaDocument12 pagesElectrical Equipment in Hazardous Areas - Wikipedia, The Free EncyclopediaMrNo ratings yet

- Hazardous Area Classification - JacobsDocument53 pagesHazardous Area Classification - JacobsPedro Luis Choque Mamani100% (1)

- Confined Space SafetyDocument30 pagesConfined Space SafetyJerome GarganeraNo ratings yet

- Electrical Equipment in Hazardous AreasDocument10 pagesElectrical Equipment in Hazardous Areasperumal1312No ratings yet

- Confined Space TrainingDocument21 pagesConfined Space TrainingIvan RocoNo ratings yet

- Abs Rules Hazardous Area Mobile Offshore Drilling Units - 2008Document5 pagesAbs Rules Hazardous Area Mobile Offshore Drilling Units - 2008avk99100% (1)

- ch46Document15 pagesch46jose perezNo ratings yet

- 7 Habits of Control EngineersDocument9 pages7 Habits of Control EngineersAshok KrpNo ratings yet

- Hazardous Area PresentationDocument98 pagesHazardous Area PresentationcamspsNo ratings yet

- Dissolved Gas Analysis of Transformer Oil: Mrs. Harsha Shah Insulation DivisionDocument38 pagesDissolved Gas Analysis of Transformer Oil: Mrs. Harsha Shah Insulation Divisionsjavre9390100% (1)

- Hazardous Area Classification & Intrinsic SafetyDocument35 pagesHazardous Area Classification & Intrinsic SafetyMukesh C ChavanNo ratings yet

- Hazardous Area Classification - JacobsDocument53 pagesHazardous Area Classification - Jacobskarthikraja21No ratings yet

- Sis & SilDocument65 pagesSis & SilGecNo ratings yet

- Despiece Completo ThwaittesDocument60 pagesDespiece Completo ThwaittesJuan Antonio Cano Diaz100% (1)

- Electrical Safety Week - HAC & EEQ 2022Document62 pagesElectrical Safety Week - HAC & EEQ 2022SanjayNo ratings yet

- Hazardous Area Classification QuestionsDocument9 pagesHazardous Area Classification QuestionsVraja KisoriNo ratings yet

- NFPA 33 PresentationDocument53 pagesNFPA 33 Presentationmarciojunk100% (1)

- Confined Space Entry ProcedureDocument4 pagesConfined Space Entry ProcedureShahlaNo ratings yet

- Section 10, Conducting The Well TestDocument24 pagesSection 10, Conducting The Well TesthammamiNo ratings yet

- Hazardous Area ClassificationDocument48 pagesHazardous Area ClassificationRakesh suvarnaNo ratings yet

- Definitions: Hazardous Area Clasiffication & Protection Compiled By: B.VenugopalDocument7 pagesDefinitions: Hazardous Area Clasiffication & Protection Compiled By: B.VenugopalkhalafNo ratings yet

- Ventilation For Confined SpaceDocument6 pagesVentilation For Confined SpaceWONG TSNo ratings yet

- Series 94 Ball Valve FMEDADocument26 pagesSeries 94 Ball Valve FMEDASelvakumar J100% (2)

- Enclosed Space Entry Precautions Onboard ShipsDocument5 pagesEnclosed Space Entry Precautions Onboard ShipsSumit Sama100% (2)

- Hazardous Area ClassificationDocument2 pagesHazardous Area ClassificationRatnakar Pai100% (1)

- BBRAUNDocument9 pagesBBRAUNLuis RosasNo ratings yet

- Exida Webinar Benchmarking Practices For The Use of Alarms As Safeguards and IPLs PDFDocument41 pagesExida Webinar Benchmarking Practices For The Use of Alarms As Safeguards and IPLs PDFSelvakumar JNo ratings yet

- Manual Hardware Lenovo Yoga BookDocument68 pagesManual Hardware Lenovo Yoga BookRADU OCTAVIAN100% (2)

- Introduction To HacDocument51 pagesIntroduction To HacYuliyaNo ratings yet

- Introduction To HacDocument51 pagesIntroduction To HacYuliyaNo ratings yet

- Economics Case StudyDocument28 pagesEconomics Case StudyZehra KHanNo ratings yet

- Hazardous Area Classification of Large Scale PlantsDocument13 pagesHazardous Area Classification of Large Scale PlantsAl Faruq Shinaga100% (2)

- Safety Zone ClassificationDocument1 pageSafety Zone Classificationrajeshdubey7No ratings yet

- Ventilation System in Confined SpaceDocument6 pagesVentilation System in Confined Spacecaleb_yangNo ratings yet

- 5-1 Chemical, Biological, and Radiological MeasuresDocument36 pages5-1 Chemical, Biological, and Radiological Measuresa123456978No ratings yet

- Appendix 20 Electrical Installation Requirements: Hazardous Area ClassificationsDocument12 pagesAppendix 20 Electrical Installation Requirements: Hazardous Area ClassificationsNaveedNo ratings yet

- Confined SpaceDocument6 pagesConfined SpaceAnonymous LpCD3hNo ratings yet

- Purged-Pressurized EnclosuresDocument1 pagePurged-Pressurized EnclosuresKennedy K'OdoyoNo ratings yet

- Ventilation For Wastewater NfpaDocument36 pagesVentilation For Wastewater NfpaKarim El ShamashergyNo ratings yet

- Electrical Safety in Hazardous Area Area: Ref: Api Rp14F Api RP 500 Oisd Stds & IE RulesDocument25 pagesElectrical Safety in Hazardous Area Area: Ref: Api Rp14F Api RP 500 Oisd Stds & IE RulesAyushi GuptaNo ratings yet

- Confinedspace OMSDocument21 pagesConfinedspace OMSMurthy LaxmanNo ratings yet

- Chap 03Document11 pagesChap 03megahedmNo ratings yet

- Confined Safety Entry: NtroductionDocument10 pagesConfined Safety Entry: NtroductionSteve manicsicNo ratings yet

- Hazardous Area ClassificationDocument4 pagesHazardous Area ClassificationmkkamarajNo ratings yet

- Hazardous Location LightingDocument4 pagesHazardous Location LightingwahyuNo ratings yet

- ManualDocument13 pagesManualkenoly123No ratings yet

- Sfa CspaceDocument137 pagesSfa CspaceAbdul RehmanNo ratings yet

- Cdi6 Module 4Document14 pagesCdi6 Module 4SamuelNo ratings yet

- Unit 4Document6 pagesUnit 4Sai KumarNo ratings yet

- Fire Safety Report EdittedDocument5 pagesFire Safety Report EdittedVictor OladeleNo ratings yet

- Intro & Theory VentilationDocument7 pagesIntro & Theory VentilationSyahir HadziqNo ratings yet

- Hazardous Area Classification: Emergency Response QuizDocument1 pageHazardous Area Classification: Emergency Response QuizBaladeenaNo ratings yet

- Checklist For High Risk Work - Confined Space EntryDocument8 pagesChecklist For High Risk Work - Confined Space EntrySalsabilla Putri anggrainiNo ratings yet

- Definitions of Classes and ZonesDocument8 pagesDefinitions of Classes and ZonesAdindra Vickar EgaNo ratings yet

- Sources and Grades of ReleaseDocument10 pagesSources and Grades of Releasebaaziz2015No ratings yet

- Ventilation SOPDocument5 pagesVentilation SOPAdeel AnsariNo ratings yet

- Toolbox Talks What Is A Confined Space?Document16 pagesToolbox Talks What Is A Confined Space?adeeb zahidNo ratings yet

- I-8594 de enDocument34 pagesI-8594 de enCretu DanNo ratings yet

- Hazardous Area CllassificationDocument8 pagesHazardous Area CllassificationUlhas VajreNo ratings yet

- Gas Temp&Smoke HeightDocument83 pagesGas Temp&Smoke HeightJohn ANo ratings yet

- Interview Questions O&G-1Document10 pagesInterview Questions O&G-1Ahmed IsahNo ratings yet

- Ventilation in Confined SpaceDocument2 pagesVentilation in Confined Spacereda mesbahNo ratings yet

- Explosive Atmospheres - Classification of Hazardous Areas (Zoning) and Selection of EquipmentDocument8 pagesExplosive Atmospheres - Classification of Hazardous Areas (Zoning) and Selection of EquipmentRMRE UETNo ratings yet

- Area ZoningDocument8 pagesArea ZoningafnakshNo ratings yet

- Mir ValveDocument14 pagesMir ValveSelvakumar JNo ratings yet

- R10 On XPDocument182 pagesR10 On XPadenihun Adegbite100% (1)

- Guideline G6 Certification Process v2 0Document18 pagesGuideline G6 Certification Process v2 0Wong Wong WLNo ratings yet

- Man Ssa Ug en 0698Document43 pagesMan Ssa Ug en 0698Andy LNo ratings yet

- Is Iec 60534 2 1 1998Document48 pagesIs Iec 60534 2 1 1998Sreeram PanigrahiNo ratings yet

- Using Gelatin For Moulds and ProstheticsDocument16 pagesUsing Gelatin For Moulds and Prostheticsrwong1231100% (1)

- 1213-23-Si-Og RR GecDocument8 pages1213-23-Si-Og RR Gecvkj5824No ratings yet

- Files - Pumps - Turbo Pumps - Pfeiffer TMH 071 Turbo Pump ManualDocument25 pagesFiles - Pumps - Turbo Pumps - Pfeiffer TMH 071 Turbo Pump ManualOséias Maciel SilvaNo ratings yet

- Key Responsibility AreaDocument8 pagesKey Responsibility AreaNitin SharmaNo ratings yet

- CV Product C-EtdDocument6 pagesCV Product C-EtdmrmskymanNo ratings yet

- 1z0 062Document274 pages1z0 062Dang Huu AnhNo ratings yet

- Timetable Victoria Chichester PDFDocument2 pagesTimetable Victoria Chichester PDFLizzie CosterNo ratings yet

- CL21C650MLMXZD PDFDocument45 pagesCL21C650MLMXZD PDFJone Ferreira Dos SantosNo ratings yet

- TEJASWINIDocument4 pagesTEJASWINIShìVâ KùMàrNo ratings yet

- R Values For Z PurlinsDocument71 pagesR Values For Z PurlinsJohn TreffNo ratings yet

- University of Colombo Faculty of Graduate Studies: PGDBM 504 - Strategic ManagementDocument15 pagesUniversity of Colombo Faculty of Graduate Studies: PGDBM 504 - Strategic ManagementPrasanga WdzNo ratings yet

- Fuses & Circuit Breakers PDFDocument13 pagesFuses & Circuit Breakers PDFCarlos Luis Santos SomcarNo ratings yet

- Contact List For All NWGDocument22 pagesContact List For All NWGKarthickNo ratings yet

- An 4160Document8 pagesAn 4160aurumstar2000No ratings yet

- Reduced Chemical Kinetic Mechanisms For Methane Combustion Ino /N and O /co AtmosphereDocument51 pagesReduced Chemical Kinetic Mechanisms For Methane Combustion Ino /N and O /co Atmosphereariel zamoraNo ratings yet

- BMC ProactiveNetDocument202 pagesBMC ProactiveNetfranc_estorsNo ratings yet

- Professional Project ManagementDocument2 pagesProfessional Project ManagementVirginia Virgie100% (3)

- Hydraulic TechnicalDocument102 pagesHydraulic TechnicalSunil SinghNo ratings yet