Professional Documents

Culture Documents

LS-TSZD - QJ005 Turbine Bypass System Commissioning Procedure

Uploaded by

Bharath NadimpalliOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LS-TSZD - QJ005 Turbine Bypass System Commissioning Procedure

Uploaded by

Bharath NadimpalliCopyright:

Available Formats

RPSCL

ROSA POWER SUPPLY COMPANY LIMITED LUCKNOW, UTTAR PRADESH

2 x 300 MW - Stage - I Rosa Thermal Power Project Rosa, Shahjahanpur (U.P.)

DOCUMENT TITLE

Turbine Bypass System Commissioning Procedure

DOCUMENT NO:

LS-TSZD-- QJ 005

UEEPL

Utility Energytech and Engineers Pvt. Ltd. Ground Floor, H-146/147 Sector-63 Noida 201 307 Uttar Pradesh DEVELOPMENT CONSULTANTS PRIVATE LIMITED CONSULTING ENGINEERS 24B, PARK STREET, KOLKATA - 700 016, INDIA TPSC (INDIA) PRIVATE LIMITED A-1 Module, D-Quadrant, 2nd Floor Cyber Towers, Hi-Tec City, Hyderabad-81 Shanghai Electric Group Co. Ltd. No. 8 , Xingyi Road. Shanghai China - 200336 Tianjin Electric Power Construction Company The 26th floor, Harbor Centre ,No. 240 Zhangzizhong Road, Heping district, Tianjin P.R.China p.c:300041

Turbine Bypass System Commissioning Procedure

2300 MW Rosa Thermal Power Project

DOCUMENT CONTROL SHEET

PROJECT

2300 MW ROSA THERMAL POWER PROJECT

CLIENT

ROSA POWER SUPPLY COMPANY LIMITED

DOCUMENT TITLE

TURBINE BYPASS SYSTEM COMMISSIONING PROCEDURE

DOCUMENT

NO.

LS-TSZD-- QJ005

REV. NO.

ENDORSEMENTS

Rev No

Date

Description

Initials Sgn. Prepared by

Initials

Sgn.

Initials

Sgn.

Reviewed by

Approved by

Initials Sgn. Issue Authorization

DOCUMENT NO.

LS-TSZD-- QJ005

Page 1 of 23

Turbine Bypass System Commissioning Procedure

2300 MW Rosa Thermal Power Project

Technical training list for commissioning measure

Project name Number: Technical training list Specialty Training contents: System Date Unit name

Complementarily and modification

Trained person

Training person Remarks

Project in charge person

DOCUMENT NO.

LS-TSZD-- QJ005

Page 2 of 23

Turbine Bypass System Commissioning Procedure

2300 MW Rosa Thermal Power Project

Contents

1. Project overview and work quantity ...........................................................................................4 1.1 Project overview ............................................................................................................................4 1.2 Commissioning schedule ...............................................................................................................7 2 .System function introduction...........................................................................................................7 3. Compiling basis ...............................................................................................................................7 4. Required conditions before turbine bypass system commissioning ................................................8 4.1 Organization and division of work ................................................................................................8 4.2 Required conditions before system commissioning ......................................................................8 4.3 Commissioning person deployment and qualification.................................................................10 4.4 Equipment and instruments for commissioning.......................................................................10 5. Commissioning procedure and method......................................................................................10 5. Flow chart...................................................................................................................................10 5.2 Commissioning procedure and methods ..................................................................................12 6. Commissioning quality checking standard ................................................................................17 6.1 key control point setting...........................................................................................................17 6.2 Quality standard .......................................................................................................................18 6.3 Recording content ....................................................................................................................18 7. Safety requirement and environment condition during commissioning ....................................18 7.1 Danger factors identification and control.................................................................................18 7.2 Commissioning environment condition ...................................................................................19 8. Appendix ....................................................................................................................................19

DOCUMENT NO.

LS-TSZD-- QJ005

Page 3 of 23

Turbine Bypass System Commissioning Procedure

2300 MW Rosa Thermal Power Project

This document is only for technical direction, is not the site construction and commissioning execution document.

1. Project overview and work quantity 1.1 Project overview

The boiler for India ROSA project 2300MW is of SG1025/17.5-M type designed and made by Shanghai Boiler Works. It is of subcritical pressure parameter, natural circulation drum, single furnace, once through reheating. Boiler continuous steam output is 1025t/h, rated superheating steam temperature is 541, and pressure is 17.57Mpa. Turbine is of N300-16.67/538/538 type made by Shanghai Turbine Company, Ltd. It is reversed operation, single shaft, once reheat, two casings and two steam exhausts, pure condensate type. Its rated power is 300MW. Generator is of QFSN-300-2 type made by Shanghai Turbine Generator Co., Ltd, its rated power is 300MW, and cooling method is water-hydrogen-hydrogen. Boiler makeup water is DM water. The bypass system is supplied by Shanghai XIXIAI energy control equipment company which is the hydraulic control system, and the type is the HLP secondary class series hydraulic bypass. The design capability of HP bypass is 60% BMCR, and the LP is 60% BMCR plus desuperheating water quantity of HP bypass. HP bypass system includes bypass valve and desuperheating water spray governing valve and isolation valve. And the LP bypass system includes LP bypass valve and dusuperheating water spray governing valve. The bypass control system adopts the hydraulic actuator, and the main equipments are as following: 1) HP bypass valve (1 set) 2) HP bypass desuperheating spray valve (1 set) 3) HP bypass desuperheating isolation valve (1 set) 4) LP bypass valve (2 sets ) 5) LP bypass desuperheating spray valve (2 sets)

DOCUMENT NO.

LS-TSZD-- QJ005

Page 4 of 23

Turbine Bypass System Commissioning Procedure

2300 MW Rosa Thermal Power Project

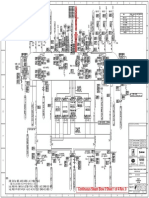

M a in s te a m

H P b y p a ss

C o ld s e c tio n o f re h e a te r

R e h e a te r

C o n d e n se r

L P b y p a ss

H e a t s e c tio n o f re h e a te r

Bypass system hydraulic oil station is made up by 2 nos oil pump and the corresponding system that supply the high pressure oil to the system as the power resource for hydraulic parts. Meanwhile, there has a accumulator installed on the oil supply pipe to stabilize the system work pressure. This bypass hydraulic control system includes the oil supply device, HP bypass actuator, LP bypass actuator, HP accumulator parts, LP accumulator parts and pipe fittings. The working medium for the bypass hydraulic system is adopted the phosphate burning resistance oil which has the good burning resistance and stability. And the oil is supplied by the single oil supply device. The system work pressure range is 15-13.5 MPa. And the oil temperature range is 40-55 deg C. While operation, the cleanness of the work medium shall reach NAS 6 Class or higher Class. Oil supply device has been set the regeneration device, circulation cooling device; main pump, standby pump is designed as redundancy. This is supplying the power resource for the actuator of the valve. The valve actuator has two types, one is regulation type, and the other is switch type, the HP & LP desuperheating valve actuator, HP & LP bypass spray governing valve actuator is regulation type, and the HP bypass spray valve actuator is switch type. There are two control methods for the regulation type valve, viz. normal regulating control and fast control, this two methods are parallel, while the operation, this two control methods are interlocked, and controlled by DCS. In order to open or close the valve quickly, there is set the 40L HP accumulator and 40L LP accumulator for the HP bypass valve and LP bypass valve actuator respectively to guarantee the valve can active quickly and guarantee the oil device supply oil or discharge oil in time.

DOCUMENT NO. : LS-TSZD-- QJ005 Page 5 of 23

Turbine Bypass System Commissioning Procedure

2300 MW Rosa Thermal Power Project

Technical parameter of bypass system rating work condition Valve name Model Inlet Rating flux (t/h) Inlet working parameter 16.67 MPa/538 Discharge working parameter 3.663 MPa/318.5

HP bypass valve HP bypass desuperheating spray valve HP bypass desuperheating isolation valve LP bypass valve LP bypass desuperheating spray valve

C7z61Y-P5519.2V

615

Tp7z63Y-32.01

Tp764Y-32.01 3.296 MPa/538

C7z61Y-P554.6V

716.3

0.598MPa/160

Tp7z64Y-4.01

bypass valve regulating factor Valve name HP Bypass valve HP bypass desuperheating spray valve HP bypass desuperheating isolating valve LP bypass 1 1 2 Qty. Driving method Hydraulic driven Hydraulic driven Hydraulic driven Hydraulic Actuator Switch on/off time Switch off 3s BP-300 quickly, 3s quick Switch off 3s LBP-300 quickly, 3s quick Switch off 3s BPE-300 BD-300 quickly, 3s quick Switch off 3s 70%BMCR 60%BMCR Design capability

DOCUMENT NO.

LS-TSZD-- QJ005

Page 6 of 23

Turbine Bypass System Commissioning Procedure

2300 MW Rosa Thermal Power Project

valve LP bypass desuperheating spray valve 2

driven

quickly, 3s quick Switch off 3s LBPE-300 quickly, 3s quick

Hydraulic driven

1.2 Commissioning schedule

The absolute commissioning schedule is 8 days.

2 .System function introduction

Bypass control system (BPS) is the important part to realize the unit auto control, it plays a very important role while unit start up, normal stop and emergency stop. The function of this system is to make the operation parameter in a controlled range, to guarantee the unit safety and economic operation. Desuperheating water of HP bypass is from the feeder water system, and the desuperheating water of LP bypass is from the condensate water system. HP & LP bypass valve is the angle type bypass valve with the throttle spray valve. This bypass valve can lead the main steam going through the bypass to the cold section of reheater and also lead the reheater heat section steam going through LP bypass to the condenser while the unit start-up, stop or at other conditions. Through TG setting, this system can make the unit on load operation with the auxiliary power. While the turbine tipping or generator breaker switch on, it can make the HP & LP bypass open automatically. The valve leakage glass is the minimum V glass, and the spray valve outlet flow speed shall not exceed 30M/S.

3. Compiling basis

3.1 3.2 3.3 3.4 3.5 Indian ROSA 2 x 300MW unit commissioning outline Indian ROSA project equipment erection instruction Indian ROSA project China-Indian general contract The relevant drawings from GEDI Equipment instruction, drawings, and data documents for Indian ROSA project

DOCUMENT NO.

LS-TSZD-- QJ005

Page 7 of 23

Turbine Bypass System Commissioning Procedure

2300 MW Rosa Thermal Power Project

generator bypass system

4. Required conditions before turbine bypass system commissioning 4.1 Organization and division of work

NO. Organization and division of work Under organized and directed by sub-system commissioning 4.1.1 group, the person in charge of commissioning should carry out commissioning of system and make out commissioning measures of such system. Commissioning person should be responsible for transmission 4.1.2 of related valve, C&I signal and interlock in the system. Before the trial, shall give the technical and safety training, Meanwhile, measure and record necessary data. Operation person is in charge of the operating and operation 4.1.3 monitoring, making the safety isolation for the trial run equipments. Construction 4.1.4 unit should be responsible for finishing commissioning of related individual units in the system and maintaining, overhauling and eliminating the defects in commissioning of system. Organize and coordinate safety, fire fighting and safeguard works on commissioning site The commissioning direction unit shall be in charge of 4.1.5 compiling the commission measure and directing the site commissioning. And shall make the technical training before trial run. Supervision unit shall be in charge of coordinating and attending the system acceptance, coordinating the equipment 4.1.6 and system storage problem, and coordinating the problems disposal which happened in the commissioning. Quality supervising and checking before/ after trial run. Confirmation

4.2 Required conditions before system commissioning

DOCUMENT NO.

LS-TSZD-- QJ005

Page 8 of 23

Turbine Bypass System Commissioning Procedure

2300 MW Rosa Thermal Power Project

NO.

Required conditions before commissioning Site is flat without debris, the scaffolding shall be removed, the handrail of stairways shall be installed completely, and adequate light is prepared. Fire fighting device is ready. There shall have the clear dividing line around the trial run site. The warning board or enclosure shall be set around the danger area Covers of ditch and holes are complete; ladders, paths, handrails are available for platform. Enough firefighting facilities are available at site; Adequate light is ready for using at the trail run site. And the emergency light can operate automatically. Good ventilation establishment Good communication system. Equipments, pipes, valves shall be hanged the nameplate Equipment and system are installed as per the requirement and accepted. The installation recording is complete. And the relevant equipment individual trial run is finished. The instrument calibration is accepted, and the warning and showing is correct. The person deployment is clear, and the commissioning work training is finished. Equipment and system are installed as per the requirement and accepted. The installation recording is complete. And the relevant equipment individual trial run is finished. And the unit is ready for starting. The entire pipes and equipment in the bypass system shall be installed complete. The oil circu8lation is finished, oil quality is accepted, the oil pressure test for hydraulic pipe is accepted, the bypass oil station commissioning is accepted. The pressure filling to accumulator is finished.

: LS-TSZD-- QJ005

Confirmation

4.2.1

4.2.2 4.2.3 4.2.4 4.2.5 4.2.6 4.2.7 4.2.8

4.2.9 4.2.10

4.2.11

4.2.12

4.2.13

DOCUMENT NO.

Page 9 of 23

Turbine Bypass System Commissioning Procedure

2300 MW Rosa Thermal Power Project

Calibration, erection and wire connection for C & I and 4.2.14 electrical equipment is finished, and the bypass system C & I commissioning is finished and accepted. The steam blowing for HP bypass system is accepted, and the 4.2.15 cleaning for LP bypass system is accepted, flushing for HP, LP bypass desuperheating piping is accepted. Commissioning instrument is ready, the calibration for the 4.2.16 instrument is accepted, and the precision of the test instrument meets the requirement.

4.3 Commissioning person deployment and qualification

Sn. 1 Person Commissioning person Erection person Operation person Qty 2 Quality Commissioning Technical person in 4 So many charge and person on duty Operator Each operation during test Maintenance and overhaul Responsibility In charge of executing the measure and operation direction

4.4 Equipment and instruments for commissioning

S.N. 1 Items Infrared thermal meter Model Precision Qty 1 Remarks

5. Commissioning procedure and method 5. Flow chart

DOCUMENT NO.

LS-TSZD-- QJ005

Page 10 of 23

Turbine Bypass System Commissioning Procedure

2300 MW Rosa Thermal Power Project

DOCUMENT NO.

LS-TSZD-- QJ005

Page 11 of 23

Turbine Bypass System Commissioning Procedure

2300 MW Rosa Thermal Power Project

5.2 Commissioning procedure and methods

5.2.1 S.N. 1 System commission plan Items System inspection Content Inspect the main steam ,reheating steam/ bypass system piping as per the scheme Main steam and reheating steam bypass pipe system blowing HP & LP bypass desuperheating water pipe flushing Control oil system circulation Cleanness checking Main steam pipe hydraulic test Main steam reheating steam pipe steam tightness test Governing valve, spray valve leakage test Electrical motor operation commissioning Measurement and C & I signal Interlock protection loop Function group commissioning Auto regulation loop Control oil system HP & LP bypass governing valve HP & LP desuperheating spray valve Close LP bypass governing valve Discharge valve Signal, interlock and protection test

LS-TSZD-- QJ005 Page 12 of 23

Result

Time

Remarks

System blowing

System tightness

C&I commissio ning

Component commissio ning

C & I system test

:

DOCUMENT NO.

Turbine Bypass System Commissioning Procedure

2300 MW Rosa Thermal Power Project

Function group test 7 Static state regulation test System operation Control system factor test Regulation function simulation test Operation at any condition Bypass system operation Operation characteristic checking Parameter optimizing setting Dynamic characteristic inspection on the load rejection condition and other working condition

Test regulation after operation

5.2.2 5.2.2.1 5.2.2.2 5.2.2.3 5.2.2.4 5.2.2.5 5.2.3 5.2.3.1 A 1 2 3 B 1

System commissioning items Inspect the complete bypass system. Transmission test, switch on/off test shall be done for the valve to check whether it is flexible and reliable. DAS measurement point and local instrument checking Interlock protection and C & I signal test Bypass system, static state function test Main commissioning procedure bypass system static state commissioning Bypass valve static state characteristic test HP & LP bypass governing valve switch feedback calibration, fast switch on/ off time measurement HP bypass spray governing valve switch feedback calibration, fast switch on/off time measurement LP bypass spray governing valve switch feedback calibration, fast switch on/off time measurement Bypass system control function and interlock protection test HP bypass protection test

HP bypass protection function, the HP bypass is forced to close in the following status

DOCUMENT NO.

LS-TSZD-- QJ005

Page 13 of 23

Turbine Bypass System Commissioning Procedure

2300 MW Rosa Thermal Power Project

a) manual HP valve close quickly b) HP spray valve pressure is lower c) reheater pressure is higher The HP bypass desuperheating water control: HP bypass desuperheating water control subsystem to control HP bypass outlet temperature in the suitable temperature around the setting value. HP decompression control: the HP bypass decompression control subsystem to control the main steam pressure as per the pressure setting value. Before the HP cylinder starting to stably the main steam pressure till the unit parameter reaches to the turbine rolling parameter, and then the HP bypass valve is switch to the heating standby status. While the HP cylinder starting, in order to avoid affecting the reheater pressure and HP cylinder steam discharge stop valve action caused by HP bypass switch on/off quickly, the auto control of the bypass shall be changed into manual control. In addition, while the unit operated as load rejection model, the HP bypass can be operation in time. 2 LP bypass control function

LP bypass protection function, the LP bypass is forced to close as the following status: a) condenser vacuum pressure is low b) condenser temperature is high c) LP desuperheating spray water pressure is low d) three-class desuperheating water pressure is low e) condenser water level is high The LP bypass is open as the following status: a) reheating steam pressure is high b) open the LP bypass by manual method LP bypass desuperheating water control: LP bypass desuperheating water control subsystem to control the LP bypass outlet temperature in the suitable value around the setting value. . LP bypass keeps closed while the HP cylinder starting. Before the turbine rolling, the LP bypass valve switch to heat standby status, in addition, while the unit is operated as the load rejection model, the LP bypass can operate immediately.

DOCUMENT NO.

LS-TSZD-- QJ005

Page 14 of 23

Turbine Bypass System Commissioning Procedure

2300 MW Rosa Thermal Power Project

3 Reheating steam over-pressure protection While the unit operation, if the deviation between reheating steam pressure and the setting value is more than___ MPa (refer to the setting value from GEDI) or the reheating steam pressure exceeds ___ MPa (refer to the setting value from GEDI), the LP bypass open immediately, and the LP desuperheating valve is also open. 4 condenser protection test While the condenser vacuum is lower, and the condenser water level or the high temperature protection at the downstream of the LP are active, LP decompression valve shall be close, meanwhile, the LP desuperheating valve is also close, 5.2.3.2 A bypass control system dynamic commissioning Regulate the dynamic control parameter of each control subsystem at the different load, and setting the corresponding PID parameter. After the bypass control system operation and the control parameter regulated, B the setting valve dynamic perturbation test for this control system shall be done to precisely regulate the control parameter and improve the regulation quality of control system while the controlled heating power system is operated stably. 5.2.3.3 A 1 2 3 B 1 bypass system operation operation condition Bypass system static state commissioning work is finished. water discharge system commissioning for main steam, reheating steam is finished, and this system is ready for operation The staring preparation work of the main unit is finished. system operation Open the water discharge valve of the bypass system, HP & LP bypass are operated automatically. After the boiler lighting and the pressure generation, HP bypass is switch to the minimum opening, and the LP bypass is opening gradually, go along with the 2 main steam parameter rising, warm the HP & LP bypass piping. Control the temperature rising speed to 2 deg C per min. While the main steam pressure rising to the setting value, control the HP bypass valve to maintenance the main

DOCUMENT NO.

LS-TSZD-- QJ005

Page 15 of 23

Turbine Bypass System Commissioning Procedure

2300 MW Rosa Thermal Power Project

steam valve at the setting value. 3 4 5.2.3.4 Control the LP bypass opening as per the main steam pressure changing to maintenance the main steam setting valve. During operation, monitor the desuperheating water governing valve following status, checking the pipe expansion, and discharge is normal. test after bypass system operation

The test after bypass system operation shall be finished before the turbine rolling. Because the HP cylinder is operating, before the turbine rolling, first, secondary class bypass system shall be removed. 1 A 1 2 B 1 2 3 4 5 C 1 bypass system characteristic test test goal Measure the relationship between HP & LP bypass governing valve pressure and flux characteristic Check the spray desuperheating system working characteristic Test condition Unit bypass is operation, and the main body is in the barring gear status Bypass operation is normal Boiler operation is normal Condenser vacuum is normal Circulation water system is operation test procedure HP bypass characteristic test

a) Under the different opening of the governing valve, change the boiler working rate, doing the test till the bypass system valve is full open and the main steam parameter reaches to the rating valve b) During test, the LP bypass is in the following model, the HP bypass desuperheating water is operated automatically. c) Record the relative data d) Calculate the characteristic relationship 2 LP bypass characteristic test

: LS-TSZD-- QJ005 Page 16 of 23

DOCUMENT NO.

Turbine Bypass System Commissioning Procedure

2300 MW Rosa Thermal Power Project

a) Under the different opening of the governing valve, change the boiler working rate and the HP bypass opening, doing the test till the LP bypass governing valve is full open and the main steam parameter reaches to the rating valve b) During test, the LP desuperheating water can operate automatically, and the HP bypass can be operated by manual method. c) Record the relative data d) Calculate the characteristic relationship 2 dynamic characteristic test Before the load rejection operation model, the warming and water discharge shall be done for the bypass system, while the unit load rejection operation starting, the HP & LP bypass valve open immediately, in order to estimate the HP & LP spray desuperheating water refection characteristic, record the valve open time, steam pressure, temperature stability valve, peak value and its time.

6. Commissioning quality checking standard 6.1 key control point setting

Inspection unit Sn. Work control point Bypass oil station control oil pressure and temperature Bypass oil station oil flushing and oil cleanness Bypass system interlock protection test Fast open time for bypass system Constru ction Commi ssionin g * Develo pment unit Produc e unit Supervi sion unit * Witness method

DOCUMENT NO.

LS-TSZD-- QJ005

Page 17 of 23

Turbine Bypass System Commissioning Procedure

2300 MW Rosa Thermal Power Project

R- record confirmed point W- witness point continually

Hhold for inspection point

Ssupervise

6.2 Quality standard

Sn. 1 2 Items Interlock and signal Fast open time of Bypass system Inspection standard Item completely, and the action is correct 3S

6.3 Recording content

1 2 3

HP & LP bypass system valve transmission recording list HP & LP bypass system subsection trial run recording list HP & LP bypass system logical transmission recording list

7. Safety requirement and environment condition during commissioning 7.1 Danger factors identification and control

Danger factors identification and control list Executive Sn. Description Control and strategy Operation person and erection person to check the equipment operation status periodically Operation person and 2 Injured by the system leakage erection person to check the equipment operation status periodically Operation person and 3 Leakage in the steam valve erection person monitor the pressure and temperature on the downstream of bypass

DOCUMENT NO. : LS-TSZD-- QJ005

person in charge Operation person, erection person Operation person, erection person Operation person, erection person

Signature person Commissioning person in charge Commissioning person in charge Commissioning person in charge

lose control of 1 temperature and pressure

Page 18 of 23

Turbine Bypass System Commissioning Procedure

2300 MW Rosa Thermal Power Project

valve periodically, and dispose the leakage once the leakage appeared. LP bypass desuperheating water pressure is 4 lower, the LP bypass will be open by interlocked Maintenance the CEP normal operation to avoid the low pressure at the CEP outlet Operation person, erection person Commissioning person in charge

7.2 Commissioning environment condition

Executive Sn. Description Control strategy Operation person and 1 Steam leakage erection person to check the equipment operation status periodically person in charge Operation person, erection person Signature person Commissioning person in charge

8. Appendix

NO. 1 2 3 4 Content HP & LP bypass system subsection trial run recording list HP & LP bypass system logical transmission recording list HP & LP bypass system valve transmission recording list HP & LP bypass system subsection trial run acceptance and signature card

DOCUMENT NO.

LS-TSZD-- QJ005

Page 19 of 23

Turbine Bypass System Commissioning Procedure

2300 MW Rosa Thermal Power Project

Number Specialty Turbine

Motor bearing vibration Time Level direction Axial direction Verti cal direc tion

Unit subsystem commissioning recording list HP & LP bypass system

Oil pump bearing vibration Level direction Axial directio n Vertical direction Motor bearing temperat ure Oil pump bearing temperat ure Outlet pressur e of pump

Commissioning in charge person : Date:

Commissioning recording person:

DOCUMENT NO.

LS-TSZD-- QJ005

Page 20 of 23

Turbine Bypass System Commissioning Procedure

2300 MW Rosa Thermal Power Project

Number Specialty

Sn.

Unit subsystem commissioning recording list Turbine HP & LP bypass system logical transmission recording

Items Result Signature

Commissioning in charge person : Date:

Commissioning recording person:

DOCUMENT NO.

LS-TSZD-- QJ005

Page 21 of 23

Turbine Bypass System Commissioning Procedure

2300 MW Rosa Thermal Power Project

Number Specialty

Valve name

Unit subsystem commissioning recording list Turbine

Fast open times

HP & LP bypass system valve transmission recording

Fast close times Open time s Close time s Remarks

Commissioning in charge person : Date:

Commissioning recording person:

DOCUMENT NO.

LS-TSZD-- QJ005

Page 22 of 23

Turbine Bypass System Commissioning Procedure

2300 MW Rosa Thermal Power Project

Subsection trial run acceptance and signature card

Specialty: turbine Item name: turbine bypass system

Turbine specialty Sn. 1 2 3 4 5

HP & LP bypass system

Date Evaluation Remarks

Inspection Content System interlock protection and signal item complete, and action is correct System C & I instrument is complete, and the show is correct System pressure, temperature parameter is conformed to the design regulation System trial run, each valve is flexible, and can be operated normally Piping is tightness without leakage

Acceptance Non-acceptance

Evaluation: The subsection trial run of this equipment/system has been completed between _____ (Day) _____ (Month), _____ (Year) and _____ (Day) _____ (Month), _____ (Year). Through acceptance inspection according to the Criteria for Acceptance Inspection and Assessment of Adjustment Commissioning Quality of Thermal Power Projects by former Ministry of Electric Power, this equipment/system is rated as qualified ( ) / good ( )

and has achieved conditions required for operation. We hereby agree to enter the whole-set startup stage. Construction unit signature : Commissioning unit signature Commissioning direction unit signature Production unit signature Development unit signature Supervision unit signature Date: Date: Date: Date: Date: Date:

DOCUMENT NO.

LS-TSZD-- QJ005

Page 23 of 23

You might also like

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- Vung Ang 1 Thermal Power Plant 2 X 600Mw: Chapter 5 Boiler Piping System InstructionDocument8 pagesVung Ang 1 Thermal Power Plant 2 X 600Mw: Chapter 5 Boiler Piping System InstructionHai NguyenNo ratings yet

- 60-F8451S-H0101-01 RevD DBR of CPPDocument19 pages60-F8451S-H0101-01 RevD DBR of CPPK R Kumar RanjanNo ratings yet

- Ioties Document No:-Mccpl-Pctl-Acc-Doc-M-0001 - Rev. P3Document23 pagesIoties Document No:-Mccpl-Pctl-Acc-Doc-M-0001 - Rev. P3pramodtryNo ratings yet

- Commissioning Procedure For Main Steam, Reheat Ste...Document77 pagesCommissioning Procedure For Main Steam, Reheat Ste...Lan RungNo ratings yet

- 000-Performance Test Procedure (General)Document10 pages000-Performance Test Procedure (General)K R Kumar RanjanNo ratings yet

- T07073-LBH-SY-M001 Rev.A PDFDocument43 pagesT07073-LBH-SY-M001 Rev.A PDFRanjanaWajeNo ratings yet

- Md1 0 V 111-09-00008 A Extraction System RequirementsDocument29 pagesMd1 0 V 111-09-00008 A Extraction System RequirementsNguyễn ĐứcNo ratings yet

- Lara Super Thermal Power Project (2X800 MW) Comment Reply SheetDocument25 pagesLara Super Thermal Power Project (2X800 MW) Comment Reply SheetA N MadhavanNo ratings yet

- SH1-DHI-P1MAN-M-M01-PHL-5355 - Operating Description For Hydraulic Power Unit For HPLP Bypass SystemDocument17 pagesSH1-DHI-P1MAN-M-M01-PHL-5355 - Operating Description For Hydraulic Power Unit For HPLP Bypass Systemminhhoang091No ratings yet

- Uong Bi 300 MW Extension Power Plant: OwnerDocument32 pagesUong Bi 300 MW Extension Power Plant: OwnerAmEnPro100% (1)

- Recommended Schemes & Writeup of Auto ControlsDocument25 pagesRecommended Schemes & Writeup of Auto ControlsShirshendu RoyNo ratings yet

- 003-Auxiliary Power Consumption PGT ProcedureDocument9 pages003-Auxiliary Power Consumption PGT ProcedureK R Kumar RanjanNo ratings yet

- LPBFP - Sizing Calculation LP HRSG Feed Pump - Doc PG DC 292 100 d603 - R 1Document8 pagesLPBFP - Sizing Calculation LP HRSG Feed Pump - Doc PG DC 292 100 d603 - R 1anbesivam87_49857255No ratings yet

- Final Revision: Nghi Son 2 Bot Thermal Power Plant ProjectDocument10 pagesFinal Revision: Nghi Son 2 Bot Thermal Power Plant ProjectĐể Mai100% (1)

- Dcs Feb 20Document271 pagesDcs Feb 20skypeNo ratings yet

- Gne Presentation 201009Document20 pagesGne Presentation 201009Hardik HardNo ratings yet

- Lara Super Thermal Power Project (2X800 MW) Comment Reply SheetDocument34 pagesLara Super Thermal Power Project (2X800 MW) Comment Reply SheetA N MadhavanNo ratings yet

- Cold Start Up Check ListDocument6 pagesCold Start Up Check ListSreekanthMylavarapuNo ratings yet

- GTGT STGT Specification Vemagiri II R0Document53 pagesGTGT STGT Specification Vemagiri II R0Jason Williams100% (1)

- PP10CC 00 6LBB Yr Abc 001 PDFDocument26 pagesPP10CC 00 6LBB Yr Abc 001 PDFanbesivam87No ratings yet

- HPBP Writeup Dadri-IIDocument17 pagesHPBP Writeup Dadri-IIrajan_me083No ratings yet

- 19 Boiler ESP System Commissioning Procedure-Töàtéëtö TÖñs Ÿt +T+ƑF Âf Ò Ä Û+Document31 pages19 Boiler ESP System Commissioning Procedure-Töàtéëtö TÖñs Ÿt +T+ƑF Âf Ò Ä Û+kvsagarNo ratings yet

- Commissioning of Combined Cycle Power Plants Nov 2021 R 1Document11 pagesCommissioning of Combined Cycle Power Plants Nov 2021 R 1thirupathi mookaiahNo ratings yet

- Turbine Control GraphicDocument54 pagesTurbine Control Graphicminhhoang091No ratings yet

- KMPCL 6í-600MW DCS FSSS Writeup R1.1Document74 pagesKMPCL 6í-600MW DCS FSSS Writeup R1.1MAGUNAMNo ratings yet

- Turbo Generator & Its AuxiliariesDocument89 pagesTurbo Generator & Its AuxiliariesPapun ScribdNo ratings yet

- 11V02 Acc SPC M 0001 V2 Part ADocument182 pages11V02 Acc SPC M 0001 V2 Part Asuparnabhose100% (1)

- PLC Tender - R2 - 17.11.22Document34 pagesPLC Tender - R2 - 17.11.22SUSOVAN BISWASNo ratings yet

- Commissioning Programme For Mahan TPPDocument49 pagesCommissioning Programme For Mahan TPPsambhuNo ratings yet

- 2 - 1!01!02 - Basic Operation Concept For Turbine and Auxiliary Plant - r00Document59 pages2 - 1!01!02 - Basic Operation Concept For Turbine and Auxiliary Plant - r00Tiara Noir100% (2)

- Technical Diary-KMPCLDocument221 pagesTechnical Diary-KMPCLChandrahas SahuNo ratings yet

- CCPP Plant Operating Procedures PDFDocument123 pagesCCPP Plant Operating Procedures PDFReda Nari100% (1)

- Steam Turbine Start UpDocument84 pagesSteam Turbine Start UpEdward Effendy SitompulNo ratings yet

- تشغيل محطة بخارية مهم ورائع PDFDocument157 pagesتشغيل محطة بخارية مهم ورائع PDFelsayed100% (1)

- 500MW Starting ProceduresDocument38 pages500MW Starting Proceduresthangarajm1984No ratings yet

- Continuous Steam Blow 3 Sheet 1 of 4 Rev. 0Document4 pagesContinuous Steam Blow 3 Sheet 1 of 4 Rev. 0Anonymous JtYvKt5XENo ratings yet

- T10206-DN02-P1ZEN - 860012 FGD Capability Test Procedure - Rev 0Document13 pagesT10206-DN02-P1ZEN - 860012 FGD Capability Test Procedure - Rev 0Thắng NguyễnNo ratings yet

- CCGT Process Control Dec 2010.359152853Document81 pagesCCGT Process Control Dec 2010.359152853tvskraoNo ratings yet

- Shop Test InspectionDocument1 pageShop Test InspectionMathivanan AnbazhaganNo ratings yet

- Dehydration and Combined Cycle Power Plant of 50 MMSCFD Low BTU Natural GasDocument42 pagesDehydration and Combined Cycle Power Plant of 50 MMSCFD Low BTU Natural GasShaikh BilalNo ratings yet

- TurboDocument8 pagesTurboKorichiKarimNo ratings yet

- Captive Power Plant - Encon Measures: A Sunrise Project For A Sunshine FutureDocument20 pagesCaptive Power Plant - Encon Measures: A Sunrise Project For A Sunshine Futuremujeebtalib100% (1)

- 660mw Sop LancoDocument17 pages660mw Sop Lancokalyanm203515No ratings yet

- CC Pump Commissioning ProcedureDocument15 pagesCC Pump Commissioning Procedurerohit_me083No ratings yet

- Guide To General Purpose Steam TurbinesDocument7 pagesGuide To General Purpose Steam TurbinessppramNo ratings yet

- Generator Turbine Shutdown ProcedureDocument3 pagesGenerator Turbine Shutdown ProcedureAfifexNo ratings yet

- Thermodynamic Correction Curves For Model n600-16 7538538 Steam TurbineDocument27 pagesThermodynamic Correction Curves For Model n600-16 7538538 Steam Turbinearunrajmech09No ratings yet

- Boiler ControlsDocument27 pagesBoiler ControlsMY NAME IS NEERAJ..:):)No ratings yet

- Bi-Drum Vs Single Drum - Research Paper 2Document6 pagesBi-Drum Vs Single Drum - Research Paper 2Parth Merchant100% (1)

- Control Room Engineer - CCPPDocument4 pagesControl Room Engineer - CCPPsambhuNo ratings yet

- Ash Handling System Operetaion and Maintenance InstructionDocument162 pagesAsh Handling System Operetaion and Maintenance InstructionHari PrasadNo ratings yet

- performance test procedure 最终提交业主版 - 都利项目性能试验大纲(英文)2014-9-30 PDFDocument36 pagesperformance test procedure 最终提交业主版 - 都利项目性能试验大纲(英文)2014-9-30 PDFarunrajmech09100% (1)

- GWR As RLI For Boiler Drum LevelDocument14 pagesGWR As RLI For Boiler Drum LevelRoger SeaverNo ratings yet

- 600MW TurbineDocument45 pages600MW TurbineDharmaray Doddi100% (2)

- 2B - Heat Exchanger Equipments - Additional Sec 2.1 - ENGDocument43 pages2B - Heat Exchanger Equipments - Additional Sec 2.1 - ENGVõ Hoài Nam100% (1)

- 6.1.2 Detail DesignDocument11 pages6.1.2 Detail DesignfaisalnadimNo ratings yet

- Technical Diary TurbineDocument29 pagesTechnical Diary TurbineDurjoy Chakraborty100% (1)

- Pctran AbwrDocument118 pagesPctran AbwrjakkkkeNo ratings yet

- Fluid Power & Tribology Section Refuelling Technology Division Bhabha Atomic Research Centre Trombay, Mumbai - 85Document28 pagesFluid Power & Tribology Section Refuelling Technology Division Bhabha Atomic Research Centre Trombay, Mumbai - 85rkp17No ratings yet

- Boarding Pass (Web Check-In) Goindigo - inDocument1 pageBoarding Pass (Web Check-In) Goindigo - inBharath Nadimpalli0% (1)

- Government of Andhra Pradesh Boilers Department: Application ID: BEC1900108Document2 pagesGovernment of Andhra Pradesh Boilers Department: Application ID: BEC1900108Bharath NadimpalliNo ratings yet

- Man Power Matrix For O & M of 1 X 130 TPH CFBC Boiler & Auxiliaries, AHS & FHS For DeccanDocument1 pageMan Power Matrix For O & M of 1 X 130 TPH CFBC Boiler & Auxiliaries, AHS & FHS For DeccanBharath NadimpalliNo ratings yet

- Government of Andhra Pradesh Boilers Department: Application ID: BEC1800264Document2 pagesGovernment of Andhra Pradesh Boilers Department: Application ID: BEC1800264Bharath NadimpalliNo ratings yet

- Government of Andhra Pradesh Boilers Department: Application ID: BEC2000186Document2 pagesGovernment of Andhra Pradesh Boilers Department: Application ID: BEC2000186Bharath Nadimpalli0% (1)

- CPF India.Document1 pageCPF India.Bharath NadimpalliNo ratings yet

- Government of Andhra Pradesh Boilers Department: Application ID: BEC1900513Document2 pagesGovernment of Andhra Pradesh Boilers Department: Application ID: BEC1900513Bharath NadimpalliNo ratings yet

- Case Study Hydrogen Compressor PDFDocument2 pagesCase Study Hydrogen Compressor PDFBharath NadimpalliNo ratings yet

- Intel g41 Uatx Memory QVLDocument1 pageIntel g41 Uatx Memory QVLBharath NadimpalliNo ratings yet

- XTV Trip ValvesDocument4 pagesXTV Trip ValvesBharath Nadimpalli50% (4)

- RTDocument10 pagesRTBharath NadimpalliNo ratings yet

- 1st Class Examination and Certification Guide July 2011 Rev4Document18 pages1st Class Examination and Certification Guide July 2011 Rev4Bharath NadimpalliNo ratings yet

- Strength of Materials Basics and Equations - Mechanics of Materials - Engineers EdgeDocument6 pagesStrength of Materials Basics and Equations - Mechanics of Materials - Engineers EdgeansarNo ratings yet

- 02-Dr Ooi-Design of Jacked-In Piles & Case Studies in SingaporeDocument39 pages02-Dr Ooi-Design of Jacked-In Piles & Case Studies in SingaporefreezefreezeNo ratings yet

- 4 MPM Scope - OutputDocument45 pages4 MPM Scope - OutputSajid Ali MaariNo ratings yet

- Ceilcote 383 Corocrete: Hybrid Polymer Broadcast FlooringDocument3 pagesCeilcote 383 Corocrete: Hybrid Polymer Broadcast FlooringNadia AgdikaNo ratings yet

- APP157 CoP For Site Supervision 2009 202109Document92 pagesAPP157 CoP For Site Supervision 2009 202109Alex LeungNo ratings yet

- Deepwater Horizon Accident Investigation Report Appendices ABFGHDocument37 pagesDeepwater Horizon Accident Investigation Report Appendices ABFGHBren-RNo ratings yet

- 2 Strokes 4 Strokes: 1 CylinderDocument2 pages2 Strokes 4 Strokes: 1 CylinderariffNo ratings yet

- LN3 Geng2340Document61 pagesLN3 Geng2340Seth VineetNo ratings yet

- En 12604 (2000) (E)Document7 pagesEn 12604 (2000) (E)Carlos LanzillottoNo ratings yet

- Mastering Microcontrollers Helped by ArduinoDocument23 pagesMastering Microcontrollers Helped by ArduinoMeri Terihaj100% (2)

- Experiment SCDocument5 pagesExperiment SCnitinmgNo ratings yet

- Owners Manuel SupplementDocument6 pagesOwners Manuel SupplementJohn HansenNo ratings yet

- 1504805126-HPI - CR-Series Copper Crusher - 04-2021ENDocument1 page1504805126-HPI - CR-Series Copper Crusher - 04-2021ENCaio BittencourtNo ratings yet

- METCALDocument28 pagesMETCALa1006aNo ratings yet

- GIT CloudDocument20 pagesGIT CloudGyanbitt KarNo ratings yet

- CFJV00198BDocument360 pagesCFJV00198BCheongNo ratings yet

- Excel 2016: Large Data 1 : Sorting and FilteringDocument19 pagesExcel 2016: Large Data 1 : Sorting and FilteringSapna JoshiNo ratings yet

- MMD 74 XX DR PS 0020 - C03Document1 pageMMD 74 XX DR PS 0020 - C03bramexNo ratings yet

- Floor Plans & ElevationsDocument6 pagesFloor Plans & Elevationsbryan cardonaNo ratings yet

- CambuzaDocument45 pagesCambuzaMia Marin Pâslaru100% (2)

- Chapter 2 Magnetic Effects of Current XDocument25 pagesChapter 2 Magnetic Effects of Current XPawan Kumar GoyalNo ratings yet

- MB m.2 Support Am4Document2 pagesMB m.2 Support Am4HhhhCaliNo ratings yet

- Department of Education: Republic of The PhilippinesDocument14 pagesDepartment of Education: Republic of The PhilippinesRich TactaconNo ratings yet

- JAVA Stack Installation in ERPDocument2 pagesJAVA Stack Installation in ERPsai_balaji_8No ratings yet

- Health Safety StatementDocument22 pagesHealth Safety StatementShafiqul IslamNo ratings yet

- Drying AgentDocument36 pagesDrying AgentSo MayeNo ratings yet

- 3 3 1 Material Sorter Design ChallengeDocument3 pages3 3 1 Material Sorter Design Challengeapi-343534512No ratings yet

- Logcat 1693362990178Document33 pagesLogcat 1693362990178MarsNo ratings yet

- VX-1700 Owners ManualDocument32 pagesVX-1700 Owners ManualVan ThaoNo ratings yet

- Knowledge Area Quiz-Project Integration ManagementDocument4 pagesKnowledge Area Quiz-Project Integration Managementcrown212No ratings yet