Professional Documents

Culture Documents

Workbook For Chemical Reactor Relief System Sizing

Uploaded by

Ricardo BecOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Workbook For Chemical Reactor Relief System Sizing

Uploaded by

Ricardo BecCopyright:

Available Formats

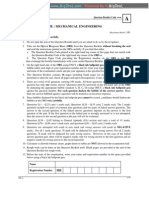

WORKBOOK FOR CHEMICAL REACTOR RELIEF SYSTEM SIZING

ANNEX 10

NOMENCLATURE

A Aactual Aapprox Ae An Ap AR a asw b bsw C Cf Cf Cfe CfR CD C0 Cp Cv Cs Csv csw D De dP/dt (dP/dt)max (dP/dt)R dPG/dt dPv/dt dPv/dT dT/dt (dT/dt)e (dT/dt)external (dT/dt)R (dT/dt)reaction cross-sectional flow area of relief system (m2) actual cross-sectional area of safety valve nozzle (m2) approximate cross-sectional flow area of relief system obtained from screening technique (m2) cross-sectional area of relief system in calorimeter used for direct scaling test (m2) cross-sectional area of nozzle in safety valve (m2) cross-sectional flow area of relief pipe (m2) cross-sectional area of reactor (m2) constant in Antoine equation (ln N/m2) parameter defined by equation (A5.9) constant in Antoine equation (K ln N/m2) parameter defined by equation (A5.10) specific heat capacity (J/kgK) liquid specific heat capacity (J/kgK) average "liquid" specific heat capacity, taking account of the presence of solids (J/kgK) liquid specific heat capacity in small-scale calorimetric test (J/kgK) liquid specific heat capacity at relief pressure conditions (J/kgK) discharge coefficient correlating parameter in level swell correlations specific heat capacity at constant pressure (J/kg K) specific heat capacity at constant volume (J/kg K) specific heat capacity of solid (J/kgK) parameter defined by Table A6.1 parameter defined by equation (A5.11) relief system diameter (m) relief system diameter in small-scale experimental test (m) rate of pressure rise (N/m2 s) maximum rate of pressure rise (N/m2 s) rate of pressure rise at relief pressure or at start of two-phase relief, whichever is higher (N/m2 s) rate of rise of gas partial pressure (N/m2 s) rate of rise of vapour pressure (N/m2 s) slope of vapour pressure curve (N/m2K) adiabatic rate of temperature rise due to the runaway reaction (K/s) adiabatic rate of temperature rise due to the runaway reaction as measured in calorimeter (K/s) rate of temperature rise due to external heating (K/s) adiabatic rate of temperature rise due to the runaway reaction at relief pressure (K/s) adiabatic rate of temperature rise due to the runaway reaction alone (K/s) 231

WORKBOOK FOR CHEMICAL REACTOR RELIEF SYSTEM SIZING

adiabatic rate of temperature rise due to the runaway reaction at maximum accumulated pressure (K/s) (dT/dt)max maximum adiabatic rate of temperature rise (K/s) (dT/dt)measured total measured rate of temperature rise (K/s) (dT/dt)max adiabatic rate of temperature rise due to the runaway reaction at point of maximum reaction rate (K/s) EA activation energy (J/kmol) FB back pressure correction factor FD dynamic load factor F frictional correction factor in Fauske's method (see A5.3) Fi flow inclination number F0 safety factor for uncertainty in relief sizing f Fanning friction factor G two-phase mass flow rate per unit flow area (kg/m2 s) Gc choked two-phase mass flow rate per unit flow area (kg/m2 s) Gc* dimensionless choked two-phase mass flow rate per unit flow area Gg gas or vapour-only mass flow rate per unit flow area (kg/m2s) GG two-phase mass flow rate per unit flow area for gassy two-phase flow (neglecting vapour pressure in a hybrid system) (kg/m2 s) GL laminar two-phase mass flow rate per unit flow area (kg/m2 s) GLe laminar two-phase mass flow rate per unit flow area obtained in experimental test (kg/m2 s) Gnozzle two-phase mass flow rate per unit flow area for a frictionless nozzle (kg/m2 s) GR two-phase mass flow rate per unit flow area at relief pressure (kg/m2 s) Gv two-phase mass flow rate per unit flow area for flashing two-phase flow (neglecting permanent gas in a hybrid system) (kg/m2 s) GT turbulent two-phase mass flow rate per unit flow area (kg/m2 s) G* dimensionless G (G/Gc)friction correction factor in Omega method for friction (G/Gc)backpressure correction factor in Omega method for non-choked flow g acceleration due to gravity (m/s2) hfg latent heat of vaporisation (J/kg) H static head change (m) jg superficial gas/ vapour velocity in reactor (m/s) k isentropic coefficient K number of velocity heads lost Kfittings number of velocity heads lost in pipe fittings KG constant in equation (A5.30) KS parameter in equation (A5.22) L equivalent length of vent line (m) LE equivalent length (m) m mass in reactor (kg) me mass in calorimetric test (kg) mf mass of liquid in reactor (kg) mm mass remaining in reactor at maximum accumulated pressure (kg) mR mass in reactor at relief pressure (kg) ms mass of solid in reactor (kg) MW molecular weight (relative molecular mass) P pressure (N/m2 abs.) 232

(dT/dt)m

WORKBOOK FOR CHEMICAL REACTOR RELIEF SYSTEM SIZING

Pa PB Pe PE PG Pi Pm Ppg Ppgi PR PRe Pt PTc Pv Pvi P0 P P/T q qmodified q QG QGmax QHEAT Qv Qvmax R Re ref RF T Tc Te Ti TR T0 TF TTc T TH t tempty tm

atmospheric pressure (N/m2 abs.) back pressure (N/m2 abs.) measurement pressure in calorimeter (N/m2 abs.) pressure at the exit of the relief pipe (N/m2 abs.) partial pressure of gas (N/m2 abs.) initial total pressure (at start of calorimetric test) (N/m2 abs.) maximum accumulated pressure (N/m2 abs.) partial pressure of pad gas (N/m2 abs.) initial partial pressure of pad gas (N/m2 abs.) relief pressure (N/m2 abs.) pressure in calorimeter corresponding to full-scale relief pressure (N/m2 abs.) estimated downstream pressure for calculation of Omega (see equation (A8.4) (N/m2 abs.) thermodynamic critical pressure (N/m2 abs.) vapour pressure (N/m2 abs.) initial vapour pressure (N/m2 abs.) stagnation pressure (in upstream equipment) (N/m2 abs.) difference between maximum pressure and relief pressure (N/m2) approximate slope of pressure versus temperature curve (N/m2K) heat release rate per unit mass of reacting mixture (W/kg) heat release rate per unit mass of reacting mixture modified for presence of external heating (W/kg) average heat release rate per unit mass of reacting mixture (W/kg) volumetric rate of permanent gas evolution in the reactor (m3/s) peak volumetric rate of permanent gas evolution in the reactor (m3/s) external heating rate (W) volumetric rate of vapour generation in reactor (m3/s) peak volumetric rate of vapour generation in reactor (m3/s) universal gas constant (J/kmol K) Reynolds number reference number reaction force at a bend (N) temperature (K) temperature in containment vessel of bench-scale calorimeter (K) temperature in calorimetric test cell (K) initial temperature (at start of calorimetric test (K) temperature at relief pressure (K) temperature at stagnation condition at inlet to relief system (K) thrust (N) thermodynamic critical temperature (K) temperature difference between the temperatures at the relief pressure and maximum accumulated pressure (K) temperature change in a closed vessel as the pressure of a hybrid system rises from the relief pressure to the maximum accumulated pressure (K) time (s) time from start of venting until reactor is empty (s) time from start of venting corresponding to maximum accumulated pressure (s) 233

WORKBOOK FOR CHEMICAL REACTOR RELIEF SYSTEM SIZING

tB tempty u v v0 vf vfg vt

V Ve Vf VfR Vg VgR VG VGe VGi W W approx Wg x yg yg0 yv yv0 Z Z0 D R 0 c

Boyle time: time for pressure to rise from relief pressure to maximum pressure in an adiabatic closed vessel test (s) time to empty reactor by homogeneous two-phase relief (s) characteristic bubble rise velocity (m/s) velocity (m/s) specific volume (m3/kg) specific volume at stagnation conditions at inlet to relief system (m3/kg) liquid specific volume (m3/kg) difference between vapour and liquid specific volumes (m3/kg) specific volume at estimated downstream pressure for calculation of Omega (see equation (A8.4)) (m3/kg) volume of reactor (m3) volume of gas-space within calorimeter, including the containment vessel volume for an open test (m3) volume of liquid space in reactor (m3) volume of liquid space in reactor at relief pressure (just before operation of relief system) (m3) volume of gas space in reactor (m3) volume of gas space in reactor at relief pressure (just before operation of relief system) (m3) volume of gas space (m3) volume of gas space in test cell (m3) initial volume of gas space in test cell (m3) mass flow rate (kg/s) approximate required relief rate estimated using screening method (kg/s) mass flow rate of single-phase gas or vapour (kg/s) mass fraction of gas/vapour in a two-phase mixture mole fraction of gas in the gas/vapour phase mole fraction of gas in the gas/vapour phase at stagnation condition at inlet to the relief line mole fraction of vapour in the gas/vapour phase mole fraction of vapour in the gas/vapour phase at stagnation condition at inlet to the relief line compressibility factor compressibility factor at stagnation condition at inlet to relief system

void fraction void fraction at disengagement void fraction in reactor when relief system first operates (at relief pressure) void fraction in reactor at inlet to relief line parameter in Huff's relief sizing method (see A5.2) thermal inertia pressure ratio critical pressure ratio dynamic viscosity (Ns/m2) liquid dynamic viscosity (Ns/m2) 234

WORKBOOK FOR CHEMICAL REACTOR RELIEF SYSTEM SIZING

f v g sat

liquid dynamic viscosity in small-scale experimental test (Ns/m2) density (kg/m3) liquid density (kg/m3) vapour density (kg/m3) gas density (kg/m3) surface tension (N/m) dimensionless gas/vapour superficial velocity in reactor angle of a bend (o) the Omega dimensionless number the Omega dimensionless number, calculated for the vapour pressure component of a hybrid system, as if the permanent gas was not present

Subscripts a B c calculated closed D e E f F g G H i L m max pg p R s sat T Tc t v 0 at atmospheric pressure refers to environment downstream of pressure relief system in containment vessel within calorimeter obtained by calculation rather than experiment in a closed (unvented) reactor or calorimeter at point of vapour/liquid disengagement in experimental test equipment at exit of relief system piping liquid force gas or vapour gas hybrid initial , or at the beginning of a step for method A5.5 laminar flow at the maximum pressure during a vented runaway (or at the end of a step for method A5.5) at the maximum rate pad gas refers to relief pipe at the relieving pressure solid saturated (i.e. the value for saturated liquid with no permanent gas present) total evaluated at the thermodynamic critical point at an intermediate pressure between the upstream reactor and the choking condition vapour refers to stagnation conditions in upstream reactor

Superscripts

235

WORKBOOK FOR CHEMICAL REACTOR RELIEF SYSTEM SIZING

TM *

trade mark dimensionless (as in G*)

236

You might also like

- Workbook For Chemical Reactor Relief System Sizing PDFDocument256 pagesWorkbook For Chemical Reactor Relief System Sizing PDFTran Van HaiNo ratings yet

- Simulation Compresseur PDFDocument85 pagesSimulation Compresseur PDFyamakunNo ratings yet

- Phast: Tutorial ManualDocument42 pagesPhast: Tutorial ManualNitesh KirnakeNo ratings yet

- Heat Transfer Assignment QuestionsDocument2 pagesHeat Transfer Assignment QuestionsMurali KrishnaNo ratings yet

- Depressuring Systems PDFDocument32 pagesDepressuring Systems PDFkumar_chemicalNo ratings yet

- Choice of Runaway Reaction Scenarios For Vent Sizing Based Onpseudo Adiabatic Calorimetric TechniquesDocument48 pagesChoice of Runaway Reaction Scenarios For Vent Sizing Based Onpseudo Adiabatic Calorimetric TechniquesgiovanniNo ratings yet

- Phast Micro: Tutorial ManualDocument34 pagesPhast Micro: Tutorial ManualmelancholicNo ratings yet

- Vessel Depressurization ModelingDocument14 pagesVessel Depressurization ModelingemaengNo ratings yet

- P & I Design LTDDocument34 pagesP & I Design LTDYunping Huang100% (1)

- Infytq With SolutionsDocument37 pagesInfytq With SolutionsÃbhilâśh Rêddÿ100% (1)

- Vapor Liquid Equilibrium of Water + Ethanol + GlycerolDocument8 pagesVapor Liquid Equilibrium of Water + Ethanol + GlycerolcsandrasNo ratings yet

- Smokelesss Flare - Air AssistsedDocument19 pagesSmokelesss Flare - Air Assistsedvasu100% (1)

- GPA Kuwait Final Paper 2016aDocument10 pagesGPA Kuwait Final Paper 2016aSdadNo ratings yet

- Coefficient of Thermal Expansion of LiquidDocument3 pagesCoefficient of Thermal Expansion of LiquidDavid RodriguezNo ratings yet

- Depressurisation: A Practical Guide Updated For Version 3.2 / 2004Document20 pagesDepressurisation: A Practical Guide Updated For Version 3.2 / 2004Samuel ValbuenaNo ratings yet

- Flare System DesignDocument2 pagesFlare System Designomar alnasserNo ratings yet

- Gun Barrel Sizing For Crude Oil DehydrationDocument3 pagesGun Barrel Sizing For Crude Oil DehydrationRicardo BecNo ratings yet

- Safeti NL: Tutorial ManualDocument55 pagesSafeti NL: Tutorial ManualmelancholicNo ratings yet

- Basco IBC Catalog 2013Document16 pagesBasco IBC Catalog 2013Mario BarbarićNo ratings yet

- Flow Through Packed BedDocument7 pagesFlow Through Packed BedHomo SapienNo ratings yet

- PSSCV ZixxingDocument2 pagesPSSCV ZixxingShashi Kant KumarNo ratings yet

- Control Valve SizingDocument42 pagesControl Valve SizingSalim AhamedNo ratings yet

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7From EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7No ratings yet

- 9.1 Overview: 9 Wiped Film EvaporatorDocument12 pages9.1 Overview: 9 Wiped Film EvaporatorNoman AslamNo ratings yet

- Toxic Release and Dispersion ModelsDocument42 pagesToxic Release and Dispersion ModelsAdeel RazaNo ratings yet

- Fire Relief Dynamic StudyDocument2 pagesFire Relief Dynamic StudylguardiaNo ratings yet

- P & I Design LTD: Emergency Relief System (Ers) Sizing Software Methods & PracticeDocument29 pagesP & I Design LTD: Emergency Relief System (Ers) Sizing Software Methods & PracticeATUL SONAWANENo ratings yet

- Two Phase Flow BibliographyDocument41 pagesTwo Phase Flow BibliographyShiv Pratap SinghNo ratings yet

- Relief Load CalculationDocument8 pagesRelief Load CalculationMuthuKumar ArunachalamNo ratings yet

- BDVDocument3 pagesBDVJason ThomasNo ratings yet

- HMB Latest Stream ReporterDocument20 pagesHMB Latest Stream ReporterConnor SailorNo ratings yet

- Volume and Wetted Area of Partially Filled Horizontal VesselsDocument11 pagesVolume and Wetted Area of Partially Filled Horizontal VesselsMelvin MagbanuaNo ratings yet

- Manual Flare Sim ExproDocument69 pagesManual Flare Sim ExproJuan Pablo AlonsoNo ratings yet

- Cepde - Valve Sizing (U16ch036, U16ch037, U16ch083)Document15 pagesCepde - Valve Sizing (U16ch036, U16ch037, U16ch083)VRUSHABHNo ratings yet

- Training CaseDocument15 pagesTraining CaseThái Xuân QuangNo ratings yet

- Improved Control Valve Sizing For Multiphase FlowDocument10 pagesImproved Control Valve Sizing For Multiphase FlowThitikorn WassanarpheernphongNo ratings yet

- Pressure Relief ValveDocument1 pagePressure Relief ValveCham Kok SoonNo ratings yet

- Study On Ethanol-Water Batch Distillation Tsf-1022Document11 pagesStudy On Ethanol-Water Batch Distillation Tsf-1022Robiel GashuNo ratings yet

- Estimation of Relief Load and Realistic Relieving Temperature For Heavy-End Fractionating ColumnsDocument10 pagesEstimation of Relief Load and Realistic Relieving Temperature For Heavy-End Fractionating ColumnssdddNo ratings yet

- 08b PDFDocument38 pages08b PDFProcess EngineerNo ratings yet

- Simulation of Distillation For ACETONE-BENZENE-CHLOROFORMDocument8 pagesSimulation of Distillation For ACETONE-BENZENE-CHLOROFORMfjcgNo ratings yet

- Distillation ColumnDocument18 pagesDistillation ColumnChristy John NinanNo ratings yet

- Flare Radiation 1.3: User ManualDocument10 pagesFlare Radiation 1.3: User ManualLazaro Hernandez GallegosNo ratings yet

- Consider Bottom Venting For Reactive LiquidDocument10 pagesConsider Bottom Venting For Reactive LiquidAndri SaputraNo ratings yet

- Relief SystemDocument24 pagesRelief SystemFarhanSaatNo ratings yet

- Volume 3-The Origins of ProtreatDocument2 pagesVolume 3-The Origins of ProtreatIbhar Santos MumentheyNo ratings yet

- Installation in Process Systems: 6.1. Design Considerations With Respect To Other System ComponentsDocument8 pagesInstallation in Process Systems: 6.1. Design Considerations With Respect To Other System ComponentsJosé LuísNo ratings yet

- Boiling Liquid Expanding Vapour Explosions (Bleve) Jes VenartDocument17 pagesBoiling Liquid Expanding Vapour Explosions (Bleve) Jes Venartgambito2000No ratings yet

- Design Part 3 - Sizing Orifices and PipingDocument11 pagesDesign Part 3 - Sizing Orifices and PipingtrebsantiaNo ratings yet

- Lc370wud Sab1 LG PDFDocument34 pagesLc370wud Sab1 LG PDFARTMehr Eng. GroupNo ratings yet

- Introduction To Inherently Safer Design: Prepared For Safety and Chemical Engineering Education (SACHE) byDocument71 pagesIntroduction To Inherently Safer Design: Prepared For Safety and Chemical Engineering Education (SACHE) bySebastian iacopiNo ratings yet

- Tutorial Alkylation Group 3Document9 pagesTutorial Alkylation Group 3Jiana NasirNo ratings yet

- Furnace Heater DesignDocument7 pagesFurnace Heater DesignAaAaA_88No ratings yet

- Select Best Model Two-Phase Relief Sizing: The ForDocument9 pagesSelect Best Model Two-Phase Relief Sizing: The ForjowarNo ratings yet

- GoyalDocument3 pagesGoyalVan LeNo ratings yet

- Refrigerated Gas Plant Hysys SimulationDocument6 pagesRefrigerated Gas Plant Hysys SimulationOsas UwoghirenNo ratings yet

- Gun Barrel Sizing For Crude Oil DehydrationDocument3 pagesGun Barrel Sizing For Crude Oil DehydrationRicardo BecNo ratings yet

- Design - and - Development Tank DehydrationDocument16 pagesDesign - and - Development Tank DehydrationRicardo BecNo ratings yet

- Cases and Tools in Biotechnology Management 1555630271. PrintDocument790 pagesCases and Tools in Biotechnology Management 1555630271. PrintRicardo BecNo ratings yet

- How To Know If Cogeneration Is The Right Choice For YouDocument4 pagesHow To Know If Cogeneration Is The Right Choice For YouRicardo BecNo ratings yet

- Gas Flare Design Debottlenecking Using Pinch AnalysisDocument25 pagesGas Flare Design Debottlenecking Using Pinch AnalysisRicardo BecNo ratings yet

- Five Things You Didn't Know About Rotary PD PumpsDocument2 pagesFive Things You Didn't Know About Rotary PD PumpsRicardo BecNo ratings yet

- Rotary PD Pump Inlet Pressure RequirementsDocument4 pagesRotary PD Pump Inlet Pressure RequirementsRicardo BecNo ratings yet

- CHE - Facts - 0321 - THERMAL OXIDIZER SELECTIONDocument1 pageCHE - Facts - 0321 - THERMAL OXIDIZER SELECTIONRicardo BecNo ratings yet

- Compressor Myth - Bearing Temperature Must Be Below 200FDocument2 pagesCompressor Myth - Bearing Temperature Must Be Below 200FRicardo BecNo ratings yet

- Pump and System Magazine PapersDocument76 pagesPump and System Magazine PapersRicardo BecNo ratings yet

- Inspecting Distillation Towers Part 2Document11 pagesInspecting Distillation Towers Part 2Ricardo Bec50% (2)

- The Need For Capital BudgetingDocument5 pagesThe Need For Capital BudgetingRicardo BecNo ratings yet

- Steam VS Electric Heating (The Basics)Document5 pagesSteam VS Electric Heating (The Basics)Ricardo BecNo ratings yet

- Vapor Recovery Unit (VRU) Principles: Oil Storage Vapor PressureDocument5 pagesVapor Recovery Unit (VRU) Principles: Oil Storage Vapor PressureRicardo BecNo ratings yet

- Water Hammer Understand and MitigateDocument5 pagesWater Hammer Understand and MitigateRicardo BecNo ratings yet

- Load Sharing Parallel Compressor Operation PDFDocument3 pagesLoad Sharing Parallel Compressor Operation PDFVamsi MahantiNo ratings yet

- Vapor Pressure in The Transport, Storage, and Bending of Crude OilDocument10 pagesVapor Pressure in The Transport, Storage, and Bending of Crude OilRicardo BecNo ratings yet

- Emulsions Electrostatic SeparatorsDocument20 pagesEmulsions Electrostatic SeparatorsRicardo BecNo ratings yet

- Psychometrics Nonequilibrium Properties of AirDocument5 pagesPsychometrics Nonequilibrium Properties of AirRicardo BecNo ratings yet

- Chap 10 SolnDocument20 pagesChap 10 Solngarbage94No ratings yet

- Egr Coolant FillDocument3 pagesEgr Coolant FillPHÁT NGUYỄN THẾ100% (2)

- Daily Lesson Plan 1Document5 pagesDaily Lesson Plan 1Saima BaraNo ratings yet

- Lecture 5Document11 pagesLecture 5عبدالله عمرNo ratings yet

- Split Type AcuDocument40 pagesSplit Type AcuKristine Ann ReclosadoNo ratings yet

- Gate 2013 Question Paper With AnswerDocument16 pagesGate 2013 Question Paper With AnswerGurmail Singh GillNo ratings yet

- Homework 1Document3 pagesHomework 1blexizNo ratings yet

- ASTM C 195 Standard Specification For Mineral Fiber Thermal Insulating CementDocument3 pagesASTM C 195 Standard Specification For Mineral Fiber Thermal Insulating CementRyan LasacaNo ratings yet

- Hay Bale - Heat TransferDocument5 pagesHay Bale - Heat TransferAbhishek ParikhNo ratings yet

- Fire Case and Hydraulic Thermal Expansion Acc To API 521 and ISO 23251 PDFDocument8 pagesFire Case and Hydraulic Thermal Expansion Acc To API 521 and ISO 23251 PDFAnggya AnggyNo ratings yet

- Air-Conditioning & RefrigirationDocument36 pagesAir-Conditioning & RefrigirationMohamed Rizwan100% (1)

- Phys 31 - University Physics Ii Course Syllabus: University Vision University MissionDocument12 pagesPhys 31 - University Physics Ii Course Syllabus: University Vision University MissionJun YoutubeNo ratings yet

- 2014 - Influence of Y Substitution in Gd2-xYx Fe17 CompoundsDocument5 pages2014 - Influence of Y Substitution in Gd2-xYx Fe17 CompoundsLuis Ángel Polanco GarcíaNo ratings yet

- Bitumen Grading System - From Penetration GradingDocument12 pagesBitumen Grading System - From Penetration GradingrajibchattarajNo ratings yet

- Chemistry Unit 4 PDFDocument60 pagesChemistry Unit 4 PDFsammam mahdi samiNo ratings yet

- DLL HeatDocument2 pagesDLL HeatIAN BERNARDONo ratings yet

- An Investigation of The Effects On Agglomeration of Changing The Speed of A Mechanical MixerDocument6 pagesAn Investigation of The Effects On Agglomeration of Changing The Speed of A Mechanical MixerSalman AshfaqNo ratings yet

- HVAC Absorption Chillers Vs Electric ChillersDocument8 pagesHVAC Absorption Chillers Vs Electric ChillersOcchitya MudgalNo ratings yet

- Thermodynamics Manual 9Document7 pagesThermodynamics Manual 9uzair akramNo ratings yet

- M3003 Expression of Uncertainty and Confidence in Measurement Edition 4 October 2019Document81 pagesM3003 Expression of Uncertainty and Confidence in Measurement Edition 4 October 2019Sonja KostićNo ratings yet

- Thermolib UserManualDocument334 pagesThermolib UserManualFreeway SmileNo ratings yet

- Pressure Switch (Refrigerant) : Systems OperationDocument3 pagesPressure Switch (Refrigerant) : Systems OperationEshop ManualNo ratings yet

- Cooling TowerDocument34 pagesCooling Towerkapenzia0% (1)

- MiyabiDocument18 pagesMiyabiLê Bảo TrúcNo ratings yet

- Macroscopic Conductors: θR. The corresponding θ/R. This noise is referred to asDocument21 pagesMacroscopic Conductors: θR. The corresponding θ/R. This noise is referred to asJU PMIT SabujNo ratings yet

- Ashrae Standards 62.2-VentilationDocument44 pagesAshrae Standards 62.2-Ventilationmepengineer4uNo ratings yet

- Tapered Resonance TubesDocument2 pagesTapered Resonance TubesAri Garcia OscosNo ratings yet

- Data Sheet Chiller Air CooledDocument1 pageData Sheet Chiller Air CooledM MiftakhNo ratings yet

- The Risk Assessment of Fire Damper InstallationsDocument43 pagesThe Risk Assessment of Fire Damper Installationsalan.edwards7282100% (1)

- Drying Tea in A Kilburn Vibro Uid Bed Dryer: June 2013Document7 pagesDrying Tea in A Kilburn Vibro Uid Bed Dryer: June 2013Abdul BasitNo ratings yet