Professional Documents

Culture Documents

Review On Optimization of Machining Operation

Uploaded by

Sadasiva Rao TOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Review On Optimization of Machining Operation

Uploaded by

Sadasiva Rao TCopyright:

Available Formats

INTERNATIONAL JOURNAL Of ACADEMIC RESEARCH

Vol. 3. No. 3. May, 2011, II Part

REVIEW ON OPTIMIZATION OF MACHINING OPERATION

C. Dhavamani , T. Alwarsamy

1 1 2

Asst.Prof , Department of Mechanical Engg, Mahendra Engineering College, Namakkal-637503 2 Professor of Mech Engg Liaison Officer, DOTE, Chennai-25, (INDIA)

ABSTRACT In this paper an attempt is made to review the literature on optimizing the machining parameters in drilling processes. Various conventional techniques employed for machining optimization include geometric programming geometric plus linear programming, Non-Linear Programming, goal programming, sequential unconstrained minimization technique and dynamic programming etc. The latest techniques for optimization include fuzzy logic, scatter search technique, ant colony technique, genetic algorithm, Taguchi technique and response surface methodology are being applied successfully in industrial applications for optimal selection of process variables in the area of machining. Taguchi methods is latest design techniques widely used in industries for making the product/process insensitive to any uncontrollable factors such as environmental variables Key words: machining operation, drilling process, programming, fuzzy logic, Taguchi methods 1. INTRODUCTION It has long been recognized that conditions during cutting, such as feed rate, cutting speed and diameter of cut, should be selected to optimize the economics of machining operations. Drilling of composite material substantially different from metallic materials due to its mechanical properties. The drilling of this material may generate delamination of drilled holes on work piece. The objective of this research is to study the effect of cutting speed, feed, diameter of cut, machining time on metal removal rate, specific energy, surface roughness, volume fraction and flank wear. Taylor showed that an optimum or economic cutting speed exists which could maximize material removal rate. Considerable efforts are still in progress on the use of hand book based conservative cutting conditions and cutting tool selection at the process planning level. The need for selecting and implementing optimal machining conditions and most suitable cutting tool has been felt over the last few decades. Despite Taylors early work on establishing optimum cutting speeds in machining, progress has been slow since all the process parameters need to be optimized. Furthermore, for realistic solutions, the many constraints met in practice, such as low machine tool power, torque, force limits and component surface roughness must be overcome. 2. REVIEW OF CONVENTIONAL OPTIMIZATION TECHNIQUES Traditionally, the selection of cutting conditions for metal cutting is left to the machine operator. In such cases, the experience of the operator plays a major role, but even for a skilled operator it is very difficult to attain the optimum values each time. Machining parameters in metal drilling are cutting speed, feed rate and dia of cut. The setting of these parameters determines the quality characteristics of turned parts. Following the pioneering work of Taylor (1907) and his famous tool life equation, different analytical and experimental approaches for the optimization of machining parameters have been investigated. Gilbert (1950) studied the optimization of machining parameters in turning with respect to maximum production rate and minimum production cost as criteria. Armarego & Brown (1969) investigated unconstrained machine-parameter optimization using differential calculus.Brewer & Rueda (1963) carried out simplified optimum analysis for non-ferrous materials. For cast iron (CI) and steels, they employed the criterion of reducing the machining cost to a minimum. A number of nomograms were worked out to facilitate the practical determination of the most economic machining conditions. They pointed out that the more difficult- to-machine materials have a restricted range of parameters over which machining can be carried out and thus any attempt at optimizing their costs is artificial. Brewer (1966) suggested the use of Lagrangian multipliers for optimization of the constrained problem of unit cost, with cutting power as the main constraint. Walvekar & Lambert (1970) discussed the use of geometric programming to selection of machining variables. They optimized cutting speed and feed rate to yield minimum production cost. Petropoulos (1973) investigated optimal selection of machining rate variables, viz. cutting speed and feed rate, by geometric programming. Sundaram (1978) applied a goal-programming technique in metal cutting for selecting levels of machining parameters in a fine operation on AISI 4140 steel using cemented tungsten carbide tools. Ermer & Kromodiharajo (1981) developed a multi-step mathematical Optimization of machining techniques 701 model to solve a constrained multi-pass machining problem. They concluded that in some cases with certain constant total depths of cut, multi-pass machining was more economical than single-pass machining, if depth of cut for each pass was properly allocated. They used high speed steel (HSS) cutting tools to machine carbon steel. Hinduja et al (1985) described a procedure to calculate the optimum cutting conditions for machining operations with minimum cost or maximum production rate as the objective function. For a given combination of tool and work material, the search for the optimum was confined to a feed rate versus depth-of-cut plane defined by the chip-breaking constraint. Some of the other constraints considered include power available, work holding, surface finish and dimensional accuracy. Tsai (1986) studied the relationship between the multi-pass machining and single-pass machining. He presented the concept of a breakeven point, i.e. there is always a point, a certain value of depth of cut, at which single-pass and double-pass

476 | www.ijar.lit.az

INTERNATIONAL JOURNAL Of ACADEMIC RESEARCH

Vol. 3. No. 3. May, 2011, II Part

machining are equally effective. When the depth of cut drops below the break-even point, the single-pass is more economical than the double-pass, and when the depth of cut rises above this break-even point, double-pass is better. Carbide tools are used to machine the carbon steel work material. Gopalakrishnan & Khayyal (1991) described the design and development of an analytical tool for the selection of machine parameters in drilling. Geometric programming was used as the basic methodology to determine values for feed rate and cutting speed that minimize the total cost of machining SAE 1045 steel with cemented carbide tools of ISO P-10 grade. Surface finish and machine power were taken as the constraints while optimizing cutting speed and feed rate for a given depth of cut. Agapiou (1992) formulated single-pass and multi-pass machining operations. Production cost and total time were taken as objectives and a weighting factor was assigned to prioritize the two objectives in the objective function. He optimized the number of passes, depth of cut, cutting speed and feed rate in his model, through a multi-stage solution process called dynamic programming. Several physical constraints were considered and applied in his model. In his solution methodology, every cutting pass is independent of the previous pass; hence the optimality for each pass is not reached simultaneously. Prasad et al (1997) reported the development of an optimization module for determining process parameters for operations as part of a PC-based generative CAPP system. The work piece materials considered in their study include steels, cast iron, aluminium, copper and brass. HSS and carbide tool materials are considered in this study. The minimization of production time is taken as the basis for formulating the objective function. The constraints considered in this work include power, surface finish, tolerance, and work piece rigidity, range of cutting speed, maximum and minimum depths of cut and total depth of cut. Improved mathematical models are formulated by modifying the tolerance and work piece rigidity constraints for multi-pass turning operations. 3. REVIEW ON LATEST TECHNIQUES The latest techniques for optimization include fuzzy logic, scatter search technique, ant colony technique, genetic algorithm, Taguchi technique and response surface methodology. 3.1 Fuzzy logic Fuzzy logic has great capability to capture human commonsense reasoning, decision-making and other aspects of human cognition. Kosko (1997) shows that it overcomes the limitations of classic logical systems, which impose inherent restrictions on representation of imprecise concepts. Vagueness in the coefficients and constraints may be naturally modelled by fuzzy logic. Modelling by fuzzy logic opens up a new way to optimize cutting conditions and also tool selection. 3.1a Methodology: Klir & Yuan (1998) fuzzy logic involves a fuzzy interference engine and a fuzzificationdefuzzification module. Fuzzification expresses the input variables in the form of fuzzy membership values based on various membership functions. Governing rules in linguistic form, such as if cutting force is high and machining time is high, then tool wear is high, are formulated on the basis of experimental observations. Based on each rule, inference can be drawn on output grade and membership value. Inferences obtained from various rules are combined to arrive at a final decision. The membership values thus obtained are defuzzified using various techniques to obtain true value. 3.2 Genetic algorithm (GA) These are the algorithms based on mechanics of natural selection and natural genetics, which are more robust and more likely to locate global optimum. It is because of this feature that GA goes through solution space starting from a group of points and not from a single point. The cutting conditions are encoded as genes by binary encoding to apply GA in optimization of machining parameters. A set of genes is combined together to form chromosomes, used to perform the basic mechanisms in GA, such as crossover and mutation. Crossover is the operation to exchange some part of two chromosomes to generate new offspring, which is important when exploring the whole search space rapidly. Mutation is applied after crossover to provide a small randomness to the new chromosomes. To evaluate each individual or chromosome, the encoded cutting conditions are decoded from the chromosomes and are used to predict machining performance measures. Fitness or objective function is a function needed in the optimization process and selection of next generation in genetic algorithm. Optimum results of cutting conditions are obtained by comparison of values of objective functions among all individuals after a number of iterations. Besides weighting factors and constraints, suitable parameters of GA are required to operate efficiently. GA optimization methodology is based on machining performance predictions models developed from a comprehensive system of theoretical analysis, experimental database and numerical methods. The GA parameters along with relevant objective functions and set of machining performance constraints are imposed on GA optimization methodology to provide optimum cutting conditions. 3.2a Implementation of GA: First of all, the variables are encoded as n-bit binary numbers assigned in a row as chromosome strings. To implement constraints in GA, penalties are given to individuals out of constraint. If an individual is out of constraint, its fitness will be assigned as zero. Because individuals are selected to mate according to fitness value, zero fitness individuals will not become parents. Thus most individuals in the next generation are ensured in feasible regions bounded by constraints. The GA is initialized by randomly selecting individuals in the full range of variables. Individuals are selected to be parents of the next generation according to their fitness value. The larger the fitness value, the greater their possibility of being selected as parents.Wang &

B a k u , A z e r b a i j a n | 477

INTERNATIONAL JOURNAL Of ACADEMIC RESEARCH

Vol. 3. No. 3. May, 2011, II Part

Jawahir (2004) have used this technique for optimization of milling machine parameters. Kuo & Yen (2002) have used a genetic algorithm based parameter tuning algorithm for multidimensional motion control of a computer numerical control machine tool. 3.3 Scatter search technique (SS) This technique originates from strategies for combining decision rules and surrogate constraints. SS is completely generalized and problem-independent since it has no restrictive assumptions about objective function, parameter set and constraint set. It can be easily modified to optimize machining operation under various economic criteria and numerous practical constraints. It can obtain near-optimal solutions within reasonable execution time on PC. Potentially, it can be extended as an on-line quality control strategy for optimizing machining parameters based on signals from sensors. Chen & Chen (2003) have done extensive work on this technique. 3.3a Methodology: First of all, machining models are required to determine the optimum machining parameters including cutting speed, feed rate and depth of cut, in order to minimizeunit production cost. Unit production cost can be divided into four basic cost elements: Cutting cost by actual cut in time Machine idle cost due to loading and unloading operation and idling tool motion cost Tool replacement cost Tool cost For the optimization of unit production cost, practical constraints which present the state of machining processes need to be considered. The constraints imposed during machining operations are: Parameter constraint Ranges of cutting speed, feed rate and depth of cut Tool life constraint Allowable values of flank wear width and crater wear depth Operating constraint Maximum allowable cutting force, power available on machine tool and surface finish requirement. An optimization model for multi-pass turning operation can be formulated. The multipass turning model is a constrained nonlinear programming problem with multiple variables (machining variables). The initial solution for SS is picked in a randomway. The user- pecified parameters have to be given. The experimentation can be run on a PC with Pentium800Mhz processor. The computational results validate the advantage of SS in terms of solution quality and computational requirement. 3.4 Taguchi technique Genichi Taguchi is a Japanese engineer who has been active in the improvement of Japans industrial products and processes since the late 1940s. He has developed both the philosophy and methodology for process or product quality improvement that depends heavily on statistical concepts and tools, especially statistically designed experiments. Many Japanese firms have achieved great success by applying his methods.Wu (1982) has reported that thousands of engineers have performed tens of thousands of experiments based on his teachings. Sullivan (1987) reports that Taguchi has received some of Japans most prestigious awards for quality achievement, including the Deming prize. In 1986, Taguchi received the most prestigious prize from the International Technology Institute TheWillard F. Rockwell Medal for Excellence in Technology. Taguchis major contribution has involved combining engineering and statistical methods to achieve rapid improvements in cost and quality by optimizing product design and manufacturing processes. Barker (1990) reported that since 1983, after Taguchis association with the top companies and institutes in USA (AT & T Bell Laboratories, Xerox, Lawrence Institute of Technology (LIT), Ford Motor Company etc.), his methods have been called a radical approach to quality, experimental design and engineering. Sullivan (1987) reported that the term Taguchi methods (TM) refers to the parameter design, tolerance design, quality loss function, on-line quality control, design of experiments using orthogonal arrays, and methodology applied to evaluate measuring systems. Pignatiello (1988) identifies two separate aspects of the Taguchi methods: the strategy of Taguchi and the tactics of Taguchi. Taguchi tactics refer to the collection of specific methods and techniques used by Genichi Taguchi, and Taguchi strategy is the conceptual framework or structure for planning a product or process design experiment. Ryan (1988) and Benton (1991) reported that Taguchi addresses design and engineering (off-line) as well as manufacturing (on-line) quality. This fundamentally differentiates TM from statistical process control (SPC), which is purely an on-line quality control method. Taguchis ideas can be distilled into two fundamental concepts: (a) Quality losses must be defined as deviations from targets, not conformance to arbitrary specifications (Benton 1991). (b) Achieving high system-quality levels economically requires quality to be designed into the product. Quality is designed, not manufactured, into the product (Daetz 1987; Taguchi 1989). Lin et al (1990) stated that Taguchi methods represent a new philosophy. Quality is measured by the deviation of a functional characteristic from its target value. Noises (uncontrolled variables) can cause such deviations resulting in loss of quality. Taguchi methods seek to remove the effect of noises. Taguchi (1989) described that quality engineering encompasses all stages of product/process development: system design, parameter design, and tolerance design. Byrne & Taguchi (1987), however, pointed out that the key element for achieving high quality and low cost is parameter design. Through parameter design, levels of product and process factors are determined, such that the products functional characteristics are optimized and the effect of noise factors is minimized. Kackar & Shoemaker (1986) observed that parameter design reduces performance variation

478 | www.ijar.lit.az

INTERNATIONAL JOURNAL Of ACADEMIC RESEARCH

Vol. 3. No. 3. May, 2011, II Part

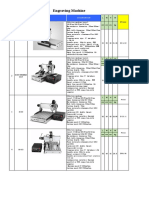

by reducing the influence of the sources of variation rather than by controlling them, it is thus a very cost-effective technique for improving engineering design. 3.5 Response surface methodology (RSM) Experimentation and making inferences are the twin features of general scientific methodology. Statistics as a scientific discipline is mainly designed to achieve these objectives. Planning of experiments is particularly very useful in deriving clear and accurate conclusions from the experimental observations, on the basis of which inferences can be made in the best possible manner. The methodology for making inferences has three main aspects. First, it establishes methods for drawing inferences from observations when these are not exact but subject to variation, because inferences are not exact but probabilistic in nature. Second, it specifies methods for collection of data appropriately, so that assumptions for the application of appropriate statistical methods to them are satisfied. Lastly, techniques for proper interpretation of results are devised. The advantages of design of experiments as reported by Adler et al (1975) and Johnston (1964) are as follows. (1) Numbers of trials are reduced. (2) Optimum values of parameters can be determined. (3) Assessment of experimental error can be made. (4) Qualitative estimation of parameters can be made. (5) Inference regarding the effect of parameters on the characteristics of the process can be made. Cochran & Cox (1962) quoted Box andWilson as having proposed response surface methodology for the optimization of experiments. Box & Hunter (1957) have proposed that the scheme based on central composite rotatable design fits the second-order response surfaces very accurately. Table 3.1 Summary of recent machining optimization technique:

Techniques Taguchi Authors Gu Tosum & Mehtap Muatoglu (2003) Tools used Optimum surface roughness was determined when the solid carbide drill tools were used on the specimens with peakaged condition Fracture surfaces were examined optically and in a scanning electron The obtained outcomes were arranged in graphical form and analyzed to make the proper decision for different process preferences. The measured results were collected and analyzed with the help of commercial software package MINITAB14 and Taly profile.s Remarks Surface integrity of drilled Al/17% SiC particulate MMCs. Dry drilling spindle speed , feed rates, drills, Point angles of drill and heat treatment were conducted . Improvement of the Mechanical Properties of 2124 Al/SiCp MMC plate by optimization of the solution treatment Multi-Objective Optimization of cutting parameters for drilling Laminate Composite materials by using G.A Optimization of process parameters during drilling of Glass-fiber Polyester reinforced composites using DOE and ANOVA. Main objective is to optimize the process parameters to achieve low cutting thrust, torque and good surface roughness. The roundness and flank wear of the ultrasonically and conventionally machined work pieces were measured and compared. Optimization of cutting conditions during machining by using Neural. The approach is suitable for fast determination of optimum cutting parameters during machining . Optimization elements for Deep-hole drilling. Method for entering angle, eccentricity and chip breaking , shoulder dimensions optimization Optimal drilling of particular metal matrix composites based on experimental and numerical procedures. An evoluation strategy is adopted to obtain the optimal solution for cutting speed, feed rate, and tool life. Some Studies on drilling of hybrid metal matrix composites based on Taguchi Techniques. Influence of process Parameters on cutting force and torque during drilling of GlassFiber Polyester reinforced composites. The main objective is to find the important factors and combination of factors influence the machining process to achieve low cutting thrust and torque.

Taguchi Technique Micro Genetic Algorithm. Posteriori approach. Design of Experiments, ANOVA

Thomas & king (1996)

Ramon Quiza Sadinas, Pedro Ries, J.Paul Davim (2006) Mohan,.Kulkarni, Ramachandra (2009)

Taguchi

Neural Network

Guey-Jiuh Tzou, Ding-yeng chen, Chun-Yao Hsu. Uros Zperl and Franc cus (2000)

Design of Experiments

Genetic Algorithm.

Criston Constantinescu, Mirca cozminca, and irina croitoru(2001) J.PauloDavim C.A.Conceicao Antonia (2000)

The signal to Noise ratio and Analysis of variance (ANOVA) are employed to study the performance To reach higher precision of the predicted results a neural optimization algorithm is developed and presented to ensure simple, fast and efficient optimization of all parameters. Reliable chip removal, cutting with low forces and high tool life.

The concept of the Pareto optimum solution is considered in the optimization procedure.

Taguchi Technique , ANOVA Taguchi optimization technology

Basavarajapa Chandramohan Paulo Davim (2008) Mohan Ramachandra M.Kulkarni (2005)

Analysis of variance are employed to analyse the drilling characteristics of these composites. Analysis of variance (ANOVA) is used to study the effect of process parameters on machining process. MINITAB14 package is used , Orthoganal array , Signal to noise ratio are employed.

B a k u , A z e r b a i j a n | 479

INTERNATIONAL JOURNAL Of ACADEMIC RESEARCH

Multiple objective linear program Taguchi D.kim M.Ramulu (2003) Paulo Davim.Pedro Reis, Vitro Lapa, C.Conceicao Antonia (2003) L.yu, L.Cheng, Yam, Yan, Jiang (2006) Analysis of variance (ANOVA) The Analysis of Variance (ANOVA) was performed to investigate the cutting characteristics of PEEK An artificial neural network (ANN) is trained using numerically simulated structural damage index to establish the mapping relationship between the structural damage index and damage status. Analysis of Variance (ANOVA)

Vol. 3. No. 3. May, 2011, II Part Drilling Process optimization for graphite / bismaleimide -Titanium ally stacks Machinability study on Polyether ether Keton (PEEK) reinforced (GF30) for applications in structural component Experimental validation of vibration based damage detection for static laminated composite shells partially filled with fluid

Artificial Neural Network.

Taguchi analysis

Tsao, Hocheng (2004)

Orthogonal array - Grey relational analysis ANOVA

Noorul Haq Marimuthu and Jeyapaul (2007)

Taguchi

Palanikumar, Karunamoorthy, Karthikeyan, and Latha. E. Kilickap (2010)

Taguchi

multiple responses based on orthogonal array with grey relational analysis. Based on the grey relational grade, optimum levels of parameters have been identified and significant contribution of parameters is determined by ANOVA Fuzzy logic to optimize the machining parameters for machining of GFRP composites. A multi response performance index (MRP) was used for optimization ANOVA, analysis of signal-to-noise ratio

Taguchi analysis of delamination associated with various drill bits in drilling of composite materials Multi response optimization of machining parameters of drilling Al/SiC metal matrix composite using grey relational analysis in the taguchi method

Optimization of the Machinability of the AlSiC Metal Matrix Composite Using the Dynamic Material Model

Optimization of cutting parameters on delamination based on Taguchi method during drilling of GFRP composite Application of Taguchi methods in the optimization of cutting parameters for surface finish and hole diameter accuracy in dry drilling processes Tauguchi approach with multiple performance characteristics for burr size minimization in drilling

Taguchis experimental design method

Mustafa Kurt 2 Eyup Bagci and Yusuf Kaynak (2008) Gaintonde, Karnik, Achuytha, & Siddeswarappa (2006)

Orthogonal arrays of Taguchi, the signal-to-noise (S/N) ratio, the analysis of variance (ANOVA), and regression analyses The fitness function is derived through mapping the objective function of the drill optimization problem.

Taguchis optimization technique

Minimum machining costs criterian. Fuzzy Logic

Design of Experiments

Milon brozek, Rostislav choteborsky, Miroslav muller , petr HRABE ( 2007) Vimal sam singh , Latha and Senthilkumar (2009) Dong-Woo Kim Myeong-Woo Cho 1, Tae-Il Seo and EungSug Lee (2008)

Cutting condition optimizations were calculated for the minimum machining costs criterion using the basic economic indexes of the workshop L27 orthoganal array, fuzzy based model is developed to predict thrust force and torque. ANOVA (Analysis of Variance) is carried out

Optimization of cutting conditions at drilling.

Modeling and Analysis of thrust force and torque in drilling GFRP composites by multi-facet drill using fuzzy logic. to minimize the thrust forces in the step-feed micro drilling process by application of the DOE (Design of Experiment) method.

Response Surface Methodology

Palanikumar , Shanmugam , Paulo Davim (2010)

Analysis of variance is used for checking the validity of the model

Analysis and optimisation of cutting parameters for surface roughness in machining Al/SiC particulate composites by PCD tool Investigation of drilling in ((0/90)/10)s glass fiber reinforced plastics using taguchi method

Taguchi Method

Kishore,Tiwari.& Singh (2009)

Design of Experiments

Duroa, Magalhesa, Marquesb, Joo Manuel Tavaresb (2007)

An attempt to investigate experimentally the significance of the drill point geometry and operating variables on the drilling forces and the drilling induced damage Non Destructive inspection technique.

Effect Of Drilling parameters on composite plates damage. A proper selection of tool and drilling parameters can reduce the risk of delamination.

A review of literature shows that various traditional machining optimization techniques like Lagranges method, geometric programming, goal programming, dynamic programming etc. have been successfully applied in the past for optimizing the various machining process variables. Fuzzy logic, genetic algorithm, scatter search,

480 | www.ijar.lit.az

INTERNATIONAL JOURNAL Of ACADEMIC RESEARCH

Vol. 3. No. 3. May, 2011, II Part

Taguchi technique and response surface methodology are the latest optimization techniques that are being applied successfully in industrial applications for optimal selection of process variables in the area of machining. In the recent optimization technique Taguchi methods is latest design techniques widely used in industries for making the product/process insensitive to any uncontrollable factors such as environmental variables. Taguchi approach has potential for savings in experimental time and cost on product or process development and quality improvement. REFERENCES 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. A.M.Abrao, P.E.Faria, J.C.Campos Rubio, and J.Paulo Davim, Drilling of fiber reinforced plastics: a review, Journal of Materials Processing Technology, Vol. 186, pp.1-7, (2007). Abbass HA, Sarker R, Newton C. PDE: A Pareto-frontier differential evolution approach for multiobjective optimization problems. In: Congress on evolutionary computation. Piscataway, NJ;(2001). Abeesh C. Basheer, Uday A. Dabade, , Modeling of surface roughness in precision machining of metal matrix composites using ANN Journal of Materials Processing Technology, 197, 1-3, 439444 (2009). Adler Y P, Markova E V, Granovsky Y V (1975) The design of experiments to find optimal conditions(Moscow: Mir Publishers) Agapiou J S (1992) The optimization of machining operations based on a combined criterion,Part 1 The use of combined objectives in single-pass operations, Part 2: Multi-pass operations. J. Eng. Ind., Trans. ASME 114: 500513 Ai X, Xiao S (1985) Metal cutting condition handbook (China: Mechanics Industry Press) Ai X, Tao Q, Xiao S (1966) Metal cutting condition handbook (China: Mechanics Industry Press) Alakesh Manna, Bijay Bhattacharyya Taguchi method based optimization of cutting tool flank wear during turning of PR-Al/20vol.% SiC-MMC. Int. Journal of Machining and Machinability of Materials 1 4 488 - 499 (2006) Aman Aggarwal and Hari Singh Optimization of machining techniques A retrospective and literature review Sadhana Vol. 30, Part 6, December 2005, pp. 699711. printed in India (2005) Armarego E J A, Ostafiev D A study of a proprietary computerized technological machining performance database. 8th Int. Manufacturing Conference, pp 2633 (1998) Armarego E J A, Brown R H (1969) The machining of metals (Englewood Cliffs, NJ: Prentice Hall) ASME 1952 Research committee on metal cutting data and bibliography. Manual on cutting of metals with single point tools 2nd edn. B. Berginc, Z. Kampus, B. Sustarsic, The use of the Taguchi approach to determine the influence of injection-moulding parameters on the properties of green parts, Journal of Achievements in Materials and Manufacturing Engineering 15 63-70; (2006) B.Latha, and V.S.Senthilkumar, Fuzzy rule based modeling of drilling parameters for delamination in drilling GFRP composites, Journal of Reinforced Plastics and Composites, DOI:10.1177/0731684407087570, (2009) Balamurugan Gopalsamy, Biswanth Mondal, Sukamal Ghosh, Taguchi Method and ANOVA, An approach for process parameters optimization of hard machining while machining hardened steel, Journal of scientific and Industrial research Vo.68, pp 686-695 (2009) Barker T B Engineering quality by design (New York: Marcel Dekker) (1990) Benton W C Statistical process control and the Taguchi method: A comparative evaluation. Int. J. Prod. Res. 29: 17611770 (1991) Bhattacharya A, Faria-Gonzalez R, Inyong H; Regression analysis for predicting surface finish and its application in the determination of optimum machining conditions. Trans. Am. Soc. Mech. Eng. (1970) 92: 711 Box G E P, Hunter J S Multifactor experimental Design. J. Ann. Math. Stat. 28: (1957) Brewer R C ;Parameter Selection Problem in Machining. Ann. CIRP (1966 ) 14: 11 Brewer R C, Rueda R ; A simplified approach to the optimum selection of machining parameters. Eng. Dig. 24(9): (1963) 133150 Byrne D M, Taguchi S ; The Taguchi approach to parameter design. Quality Progress (1987) 20: 1926 C. C. Wang and B. H. Yan, Blind-hole drilling of Al2O3/6061 Al composite using rotary electrodischargemachining, Journal of MaterialsProcessing Technology, Vol.102, pp.90-102 Technology, Vol.22,pp.344-356 (2003). C.C.Tsao, and H.Hocheng, Taguchi analysis of delamination associated with various drill bits in drilling of composite material, International journal of Machine tools & manufacture, Vol.44, pp.1085-1090, (2004). C.Dandekar, E.Orady, and P.M.Mallick, Drilling characteristics of an e-glass fabric reinforced polypropylene composite and an aluminum alloy: a comparative study, American Society of Mechanical Engineering, Vol.129, pp.14-18, (2007). C.P. Fung , Manufacturing process optimization for wear property of fiber-reinforced polybutylene terephthalate composite with grey relational analysis, Wear 254 298-306. (2003).

B a k u , A z e r b a i j a n | 481

INTERNATIONAL JOURNAL Of ACADEMIC RESEARCH

Vol. 3. No. 3. May, 2011, II Part

27. Camposrubio, A.M. Abrao, P.E. Faria, A. Esteves Coreeia, and J. Paulo davim, Effects of high speed in drilling of glass fibre reinforced plastic: evaluation of delamination factor, International Journal of Machine Tools & Manufacture, Vol.48, pp.715-721, (2008). 28. Chanin M N, Kuei Chu-Hua, Lin C, Using Taguchi design, regression analysis and simulation to study maintenance float systems. Int. J. Prod. Res.( 1990 ); 28: 19391953 29. Chen M, Chen K Y Determination of optimum machining conditions using scatter search. New optimization techniques in engineering, pp 681697 ;(2003) 30. Cihan Ozel and Erol Kilickap, Optimisation of surface roughness with GA approach in turning 15% SiCp reinforced AlSi7Mg2 MMC material, International Journal of Machining and Machinability of Materials, 4 ,476 487 , (2006), 31. Cochran G, Cox G M , Experimental design (New Delhi: Asia Publishing House) (1962). 32. Daetz D 1987 The effect of product design on product quality and product cost. Quality Progress 20(6): 5461 33. Daniel Kirby E. et al , Optimizing surface finish in a turning operation using the Taguchi parameter design method Int J Adv Manuf Technol (2006) 30: 10211029 34. Davim, J.P., A Note on the Determination of Optimal Cutting Conditions For Surface Finish Obtained in Turning Using Design of Experiments. Journal of Materials Processing Technology 116(2-3), pp. 305-308. (2001) 35. El Baradie M A, Surface roughness model for turning grey cast iron (154 BHN). Proc. Inst. Mech. Eng. (1993 )207: 4350 36. Ermer D S, Kromordihardjo S, Optimization of multi-pass turning with constraints. J. Eng. Ind. (1981) 103: 462468 37. Franci Cus, Joze Balic , Optimization of cutting process by GA approach, Robotics and Computer Integrated manufacturing 19 pp113-121, (2003), 38. Ghosh S, Statistical design and analysis of industrial experiments (New York: Marcel Dekker), (1990) 39. Gilbert W W, Economics of machining. In Machining Theory and practice. Am. Soc. Met. (1950 ) 476480 40. Gopala Krishna, Alluru Mallikarjuna Rao, K. Optimisation of machining parameters for milling operations using a scatter search approach International Journal of Advanced Manufacturing Technology, 3-4, 219-224(6) 41. H. Oktem, T. Erzurumlu, H. Kurtaran, Application of response surface methodology in the optimization of cutting conditions for surface roughness. Journal of Materials Processing Technology 170, pp.1116, (2005). 42. H.-S. Lu, J.-Y. Chen, Ch.-T. Chung, The optimal cutting parameter design of rough cutting process in side milling. Int. Achievements in Materials and Manufacturing Engineering 29, 2 , (2008). 43. H.S. Lu, B.Y. Lee, C.T. Chung, Optimization of the micro-drilling process based on the grey relational analysis, Journal of the Chinese Society of Mechanical Engineerings 27 273-278, (2006). 44. HassanGA, Suliman SMA, Experimental modeling and optimization of turning medium carbon steel. Int. J. Prod. Res. 28: 10571065, (1990) 45. Hinduja S, Petty D J, Tester M, Barrow G, Calculation of optimum cutting conditions for turning operations. Proc. Inst. Mech. Eng. 199(B2): 8192, (1985). 46. J.L.Lin, K.S.Wang, B.H.Yan, and Tarng, Optimization of the electrical discharge machining process based on the Taguchi method with fuzzy logic, Journal of materials Processing Technology, vol.102, pp.48-55, (2000). 47. J. Kopac, Optimal machining for achieving the desired surface roughness in fine turning of cold pre-formed steel workpiece, International Journal of Machine Tools Manufacture 42,) 707-716, (2002).. 48. Jha, N. K., A discrete data base multiple objective optimization of milling operation through geometric programming. Journal of Engineering for Industry, Transactions of the ASME, 112, 368 374, (1990). 49. Iuliano.L , L. Settineri, A. Gatto , High-speed turning experiments on metal matrix composites, Composites Part A: Applied Science and Manufacturing 29, 12, 1501-1509 ohnston R E 1964 Statistical methods in foundry expts. AFS Trans. 72: 1324, (1998 ). 50. Kackar R N, Shoemaker A C , Robust design: A cost effective method for improving manufacturing processes. AT & T Tech. J. 65(MarApr): 3950, (1986) 51. Kamat Y V, Rao M V , A Taguchi optimization of the manufacturing process for die cast components.Proc. 6th AIMTDR Conference, Bangalore, 174179, (1994). 52. Karin Kandananond, Characterization of FDB Sleeve Surface Roughness Using the Taguchi Approach, EuroJournals Publishing . ISSN 1450-216X Vol.33 No.2 pp.330-337, (2009) . 53. Kasilova A G, Mescheryakov R K, Technological machining handbook (Englewood Cliffs, NJ: Prentice Hall), (1985 ) Vol. 2 54. Klir G J, Yuan B , Fuzzy system and fuzzy logic theory and practice (Englewood Cliffs, NJ:Prentice Hall), (1998) 55. Kopac, J., Bahor, M. and Sokovic, M., Optimal Machining Parameters for Achieving the Desired Surface Roughness in Fine Turning of Cold Pre-formed Steel Workpieces. International Journal of Machine Tools Manufacture 42, pp. 707-716, (2002)

482 | www.ijar.lit.az

INTERNATIONAL JOURNAL Of ACADEMIC RESEARCH

Vol. 3. No. 3. May, 2011, II Part

56. Kosko B, Neural network and fuzzy systems A dynamic approach to machine intelligence (New Delhi: Prentice Hall of India), (1997) 57. KronebergM, Theory and practice for operation and development of machining process (Oxford: Pergamon), (1966) 58. Kuo L Y, Yen J Y, A genetic algorithm based parameter-tuning algorithm for multi dimensional motion control of a computer numerical control machine tool. Proc. Inst. Mech. Eng. B216: (2002). 59. L.Zadeh, Fuzzy sets, information and control, vol.8, pp.338-353, (1965). 60. Lambert B K, Taraman K , Development and utilization of a mathematical model of a turning operation. Int. J. Prod. Res. 11: 6981, (1973). 61. LinKM, KackarRN, Wave soldering optimization by orthogonal array design method. Electrical packaging and production (1985), 108115 62. Lin, Paul K H, Sullivan L P, Taguchi G, Using Taguchi methods in quality engineering. Quality Progress, (1990), 5559 63. M. C. Shaw, Metal cutting principles, Oxford Science Publications, (1996). 64. M.D. Jean, Y.F. Tzeng, Optimization of election-beam surface hardening of cast iron for high wear resistance using the 65. Taguchi method, International Journal of Advanced Manufacturing Technology 24 (2004) 190-198. 66. Mahapatra Amar Patnaik Prabina. Patnaik, Parametric Analysis and Optimization of Cutting Parameters for Turning Operations based on Taguchi Method Proceedings of the International Conference on Global Manufacturing and Innovation, (2006) 67. Mariam S. El-Gallab, Mateusz P. Sklad , Machining of aluminum/silicon carbide particulate metal matrix composites: Part IV. Residual stresses in the machined workpiece, Journal of Materials Processing Technology, 152, 1, 23-34, (2004). 68. Milan Broek, Rostislav Chotborsk, Miroslav Mller, Petr Hrab, Optimization of cutting conditions at drilling International Conference on Economic Engineering and Manufacturing Systems. (2007). 69. Michalewicz, Z. and Janikow, C. Z., Genetic algorithms for numerical optimization. Statistics Computing, 1, (1991), 75 91. 70. Mohan S. Venugopal A. Rajadurai and S.L Mannan, Optimization of the Machinability of the Al-SiC Metal Matrix Composite Using the Dynamic Material Model .Int. Metallurgical and Materials Transaction, 39, 2931-2940, (2008). 71. Moneymaker D R, Hubbard A R , Loss function techniques as applied to steel foundry processes.AFS Trans. 95: 755756, (1987). 72. Mustafa Kurt Eyup Bagci Yusuf Kaynak, Application of Taguchi methods in the optimization of cutting parameters for surface finish and hole diameter accuracy in dry drilling processes International Journal of Advanced Manufacturing Technology 40 pp 458-469,( 2009) 73. Mukherjee.A, S. Schmauder, M. Ruhle, Artificial neural networks for the prediction of mechanical behavior of metal matrix composites, Acta Metallurgica et Materialia, 43, 11, 4083-4091,( 1995) 74. Muthukrishnan.N Paulo Davim.J, Optimization of machining parameters of Al/SiC-MMC with ANOVA and ANN analysis, Int. Journal of Material Processing Technology 209,1, 225-232, (2008) 75. Nalbant, M., Gokkaya H. and Sur, G., Application of Taguchi Method in the Optimization of Cutting Parameters for Surface Roughness in Turning, Materials & Design 28, pp. 13791385, (2007) 76. Noordin M Y et al , Application of response surface methodology in describing the performance of coated carbide tools when turning AISI 1045 steel. J. Mater. Process Technol. 145: 4658 , (2004). 77. Noorul Haq.A Marimuthu.P Jeyapaul.R , Multi response optimization of machining parameters of drilling Al/Sic metal matrix composite using grey relational analysis in the Taguchi method. Int.J Adv Manuf Technol, 250-255, (2007). 78. Orlando Durn1, Roberto Barrientos1, and Luiz Airton, Multi Objective Optimization in Machining Operations .): Anal. and Des. of Intel. Sys. using SC Tech., ASC 41, pp. 455462, (2007 ). 79. Ostafiev D, Multiple constraint optimization analysis and software for selecting machining condition on rough turning operation. Ph D thesis, University of Melbourne, Melbourne, Australia, (1999). 80. P.J. Ross, Taguchi techniques for quality engineering, Mc Graw-Hill, New York, (1998). 81. Palanikumar.K , Cutting Parameters Optimization for Surface Roughness in Machining of GFRP Composites using 79. 79. Taguchis Method Journal of Reinforced Plastics and Composites, 25, 1739-1751, (2006). 82. P.V.S. Suresh, P. Venkateswara Rao, S.G. Deshmukh, A genetic algorithmic approach for optimization of surface roughness prediction model, International Journal of Machine Tools & Manufacture 42 , pp 675680, (2002). 83. Palanikumar.K Shanmugam K Paulo Davim. J , Analysis and optimisation of cutting parameters for surface roughness in machining Al/SiC particulate composites by PCD tool International Journal of Materials and Product Technology Volume 37, Number 1-2 117 128, (2010). 84. Palanikumar Karunamoorthy Karthikeyan Latha, Optimization of Machining parameters in in turning GFRP composites using a carbide (K10) Tool based on the Taguchi method with fuzzy logics, Int.J. Metals and Materials, 12 : 483-491, (2006). 85. Palanikumar K Karthikeyan R, Optimal machining conditions for turning of particulate metal matrix composites using taguchi and response surface methodologies Machining science and technology 10, . 417-433, ( 2006)

B a k u , A z e r b a i j a n | 483

INTERNATIONAL JOURNAL Of ACADEMIC RESEARCH

Vol. 3. No. 3. May, 2011, II Part

86. Paulo Davim J, Pedro Reis, and C.Conceicao Antonio, Experimental study of drilling glass fiber reinforced plastics manufactured by hand lay up, Composite Science and Technology, Vol.64, pp.289-297, (2004). 87. Paulo Davim.J Pedro Reis, and C.Conceicao Antonio, Drilling fiber reinforced plastics manufactured by hand lay-up: influence of matrix, (VIAPAL VUP 9731 and ATLAC 382-05), Journal of Materials Processing Technology, Vol. 155-156, pp.1828-1833, (2004). 88. Paulo Davim, Design of optimisation of cutting parameters for turning metal matrix composites based on the orthogonal arrays Journal of Material processing Technology 132 : 340-344, (2003). 89. P. Davim and P. Reis, Study of delamination in drilling carbon fiber reinforced plastic (CFRP) using design experiment, Compos Struct 59 (4), pp. 481487, (2003). 90. Pedersen.W, M. Ramulu, Facing SiCp/Mg metal matrix composites with carbide tools Journal of Materials Processing Technology, 172, 3 417-423, (2006). 91. Petropoulos P G , Optimal selection of machining rate variable by geometric programming. Int. J. Prod. Res. 11: 305314, (1973). 92. Phadke M S, Design optimization case studies. AT&T Tech. J. 65(MarApr): (1986), 5184 93. Pignatiello J J , An overview of the strategy and tactics of Taguchi. Inst. Ind. Eng. Trans. 20: (1988),247254 94. Pignatiello J J , Strategies for robust multi-response quality engineering. Inst. Ind. Eng. Trans. 25:525, (1993). 95. Prasad A.V.S.R.K, Rao P.N., Rao U.R.K. , Optimal selection of process parameters for turning operations in a CAPP system. Int. J. Prod. Res. 35: 14951522, (1997). 96. Quiza.R, Rivas.M and. Alfonso.E, Genetic algorithm-based multi-objective optimization of cutting parameters in turning process, Eng Appl Artif Intel 19 (2), pp. 127133, (2006) 97. Sandvik A B , Coroplan process planning software and coroplan user manual, Sandvik Automation, GmbH Singh H,Kumar P 2003 Quality optimization of turned parts (En24 steel) by Taguchi method. Product. J. 44: (1981), 4349 98. R.K. Roy, Design of experiments using the Taguchi approach, John Willey & Sons, Inc., New York, (2001). 99. Roy Ranjit K., Design of Experiments Using the Taguchi Approach, John Wiley and Sons, Inc., (2001). 100. Sahin, Y. and Motorcu, A.R. Surface Roughness Model for Machining Mild Steel with Coated Carbide Tool, Materials & Design 26, pp. 321-326, (2005). 101. Said Abdi, Yacine Ouroua, Development and characterization of Metal Matrix composite steel /cuzn Asian Journal of Material Science1-7, (2009). 102. Shaw, M.C., Metal cutting principles, Oxford University, Oxford, (1984) 103. Singh H, Kumar P, A Tool wear optimization in turning operation by Taguchi method. Indian J. Eng. Mater.Sci. 11: (2004),1924 104. Singh H, Kumar P, b Effect on power consumption for turned parts using Taguchi technique, Product. J. 45 (2004), 231238 105. Singh H, Kumar P Optimizing cutting force for turned parts using Taguchis parameter design approach. Indian J. Eng. Mater. Sci. 12:(2005), 97103 106. Subas,, Ramaraja Bhat. Ramachandra, Balakrishna, simultaneous Optimization of Machining Parameters for Dimensional Instability Control in Aero Gas Turbine Components Made of Inconel 718 Alloy, Journal of Manufacturing Science and Engineering 122, 3, 586-590, (2000). 107. Sundaram R M , An application of goal programming technique in metal cutting. Int. J. Prod. Res. 16: 375382, (1978) 108. T. R. Lin, Experimental design and performance analysis of TiN-coated carbide tool in face milling stainless steel, Journal of Materials Processing Technology, ol.127, pp. 1-7 , (2002). 109. Taguchi G , Quality engineering in production systems (New York: McGraw-Hill), (1989) 110. Taraman K, Multi-machining output-multi independent variable turning research by response surface methodology. Int. J. Prod. Res. 12: 232245, (1974) 111. Taylor F W, On the art of cutting metals. Trans. ASME 28: 3135, (1907) 112. Tsai P, An optimization algorithm and economic analysis for a constrained machining model. PhD thesis, West Virginia University, (1986). 113. Tsui K L , Robust design optimization for multiple characteristics problems. Int. J. Prod. Res. 37: (1999 ), 433445 114. Vimal Sam Singh.R, Latha B. and. Senthilkumar V.S, Modeling and Analysis of Thrust Force and Torque in Drilling GFRP Composites by Multi-Facet Drill Using Fuzzy Logic International Journal of Recent Trends in Engineering, Vol.1, No. 5, (2009) 115. Uros Zuperl, Franci Cus, Optimization of cutting conditions during cutting by using neural networks, Robotics and Computer Integrated Manufacturing 19 ,pp189199. (2003). 116. W.F. Lin, H.S. Lu, Optimal cutting-parameter design on heavy cutting process for side milling using Taguchi method with fuzzy logics, Journal of Technology 21 (2006) 111 117. W. H. Yang, Y. S. Tarng, Design optimization of cutting parameters for turning operations based on the Taguchi method, Journal of Materials Processing Technology, Vol.84, pp.122-129, (1998). 118. Walvekar A G, Lambert B K, An application of geometric programming to machining variable selection. Int. J. Prod. Res. 8: 3, (1970)

484 | www.ijar.lit.az

INTERNATIONAL JOURNAL Of ACADEMIC RESEARCH

Vol. 3. No. 3. May, 2011, II Part

119. Wang X, Jawahir I S, Web based optimization of milling operations for the selection of cutting conditions using genetic algorithms. Proc. Inst. Mech. Eng. 218: 212223, (2004) 120. Wang, J., (1993b), Multiple-objective optimization of machining operations based on neural networks. International Journal of Advanced Manufacturing Technology, 8, 235 243, (1993b). 121. Wu V, Off-line quality control: Japanese quality engineering (Dearborn, MI: American Supplier Institute), (1982) 122. Y.J. Xing, Z.Q. Wang, J. Sun, J.J. Meng, A multi-objective fuzzy genetic algorithm for job-shop scheduling problems, Journal of Achievements in Materials and Manufacturing Engineering 17,297300, (2006). 123. Yue Jiao, Shuting Lei, Z.J.Pei, and E.S.Lee, Fuzzy adaptive networks in machining process modeling: surface roughness prediction for turning, International Journal of Machine Tools & Manufacture, vol.44, pp.1643-1651, (2004). 124. Z. C. Lin and D. Y. Chang, Tool wear investigation on the precision progressive die for the IC dambar cutting process Int. Journal of Advanced Manufacturing technology, Vol.22, pp.344-356, (2003).

B a k u , A z e r b a i j a n | 485

You might also like

- 2011 (C. Dhavamani, T. Alwarsamy) Review On Optimization of Machining Operation PDFDocument10 pages2011 (C. Dhavamani, T. Alwarsamy) Review On Optimization of Machining Operation PDFFikri SiplhoNo ratings yet

- Optimization of Machining Parameters in CNC Turning Using Firefly AlgorithmDocument6 pagesOptimization of Machining Parameters in CNC Turning Using Firefly AlgorithmElakkiya KarthicNo ratings yet

- International Journal of Industrial Engineering ComputationsDocument12 pagesInternational Journal of Industrial Engineering ComputationsKabil RajNo ratings yet

- Optimization of Machining Parameters For Surface Roughness in Milling OperationDocument5 pagesOptimization of Machining Parameters For Surface Roughness in Milling OperationArmando Rosas GonzalitosNo ratings yet

- Optimization techniques for metal cutting processesDocument21 pagesOptimization techniques for metal cutting processesnavabnavab786No ratings yet

- Optimization of Cutting Parameters in High Speed TurningDocument8 pagesOptimization of Cutting Parameters in High Speed TurningcevherimNo ratings yet

- Optimization of Broaching Tool Design: Intelligent Computation in Manufacturing Engineering - 4Document6 pagesOptimization of Broaching Tool Design: Intelligent Computation in Manufacturing Engineering - 4Rishikesh GunjalNo ratings yet

- IJMSEDocument13 pagesIJMSEShafayat HossainNo ratings yet

- Tool WearDocument13 pagesTool Wearsakthistory1922No ratings yet

- An Overview of Optimization Techniques For CNC Milling MachineDocument4 pagesAn Overview of Optimization Techniques For CNC Milling MachineAllaboyinamahidharNo ratings yet

- Effect of Drilling Parameters On Surface Roughness, Tool Wear, Material Removal Rate and Hole Diameter Error in Drilling of OhnsDocument6 pagesEffect of Drilling Parameters On Surface Roughness, Tool Wear, Material Removal Rate and Hole Diameter Error in Drilling of Ohnsistyawan priyahapsaraNo ratings yet

- 152 S 851 PDFDocument7 pages152 S 851 PDFDarling RajNo ratings yet

- Literature ReviewDocument15 pagesLiterature Reviewnwaokorie_thaddeusNo ratings yet

- 2ExperimentalAnalysisofCNCTurning PDFDocument5 pages2ExperimentalAnalysisofCNCTurning PDFVũ Mạnh CườngNo ratings yet

- 2 Experimental Analysisof CNCTurningDocument5 pages2 Experimental Analysisof CNCTurningVũ Mạnh CườngNo ratings yet

- Effect of Machining Parameters and Optimization of Machining Time in Facing Operation Using Response Surface Methodology and Genetic AlgorithmDocument9 pagesEffect of Machining Parameters and Optimization of Machining Time in Facing Operation Using Response Surface Methodology and Genetic AlgorithmDr. Mahesh GopalNo ratings yet

- Jurnal Prospro 2Document6 pagesJurnal Prospro 2I Gede Nengah Wika GunawanNo ratings yet

- Wear Analysis of Multi Point Milling Cutter using FEADocument8 pagesWear Analysis of Multi Point Milling Cutter using FEAAravindkumarNo ratings yet

- Optimization of Process Parameters of CNC Milling: International Journal of Advance Research and InnovationDocument5 pagesOptimization of Process Parameters of CNC Milling: International Journal of Advance Research and InnovationAbdullah Raghib SiddiquiNo ratings yet

- Optimization of Cutting Parameters in CNC Turning: Harish Kumar, Mohd. Abbas, Dr. Aas Mohammad, Hasan Zakir JafriDocument4 pagesOptimization of Cutting Parameters in CNC Turning: Harish Kumar, Mohd. Abbas, Dr. Aas Mohammad, Hasan Zakir JafriShakeel RanaNo ratings yet

- Materials Today: Proceedings: J. Yadu Krishnan, S. Poorna Sundar, L. Karthikeyan, C. Veera Ajay, K. ManisekarDocument6 pagesMaterials Today: Proceedings: J. Yadu Krishnan, S. Poorna Sundar, L. Karthikeyan, C. Veera Ajay, K. ManisekarMat EnriqueNo ratings yet

- Ijaiem 2014 03 15 042Document12 pagesIjaiem 2014 03 15 042International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Optimization of Micro Milling of Hardened SteelDocument12 pagesOptimization of Micro Milling of Hardened SteelLincoln BrandãoNo ratings yet

- Original ResearchDocument6 pagesOriginal ResearchbalajimetturNo ratings yet

- Silva Et Al - Ijcim 2012Document14 pagesSilva Et Al - Ijcim 2012RACHEL BOSSNo ratings yet

- Optimizing Surface Roughness in Turning Using Taguchi TechniqueDocument7 pagesOptimizing Surface Roughness in Turning Using Taguchi Techniquekarpaga raj aNo ratings yet

- Multi-Objective Optimization of Milling Parameters e The Trade-Offs Between Energy, Production Rate and Cutting QualityDocument10 pagesMulti-Objective Optimization of Milling Parameters e The Trade-Offs Between Energy, Production Rate and Cutting QualityJesvin AbrahamNo ratings yet

- Simultaneous Determination of The Optimal Process Mean and Cutting Speed For A Manufacturing ProcessDocument6 pagesSimultaneous Determination of The Optimal Process Mean and Cutting Speed For A Manufacturing ProcessKamel MohammedNo ratings yet

- An Overview of Optimization Techniques For CNC Milling MachineDocument4 pagesAn Overview of Optimization Techniques For CNC Milling MachineArif NurrohmanNo ratings yet

- Insert Selection For Turning Operation On CNC Turning Centre Using MADM MethodsDocument11 pagesInsert Selection For Turning Operation On CNC Turning Centre Using MADM Methodsprince duhanNo ratings yet

- Immune Hill ClimbingDocument8 pagesImmune Hill ClimbingHarun ÇetinNo ratings yet

- Surface Roughness Analysis in Milling Machining Using Design of ExperimentDocument9 pagesSurface Roughness Analysis in Milling Machining Using Design of Experiment21P410 - VARUN MNo ratings yet

- Review of Material TestedDocument14 pagesReview of Material Testedmanasha majhiNo ratings yet

- Correlation Among The Cutting Parameters, Surface Roughness and Cutting Forces in Turning Process by Experimental StudiesDocument6 pagesCorrelation Among The Cutting Parameters, Surface Roughness and Cutting Forces in Turning Process by Experimental StudiesSurendra ShekhawatNo ratings yet

- Ijmer 46064551 PDFDocument7 pagesIjmer 46064551 PDFIJMERNo ratings yet

- NCD IcaestDocument6 pagesNCD IcaestNaresh DeshpandeNo ratings yet

- Optimization of Machining Parameters For Turning Different Alloy Steel Using CNC - ReviewDocument8 pagesOptimization of Machining Parameters For Turning Different Alloy Steel Using CNC - Reviewsreejith2786No ratings yet

- A Review On Machining Parameters Influencing The Responses On CNC: An Optimization TechniqueDocument8 pagesA Review On Machining Parameters Influencing The Responses On CNC: An Optimization TechniquebalajimetturNo ratings yet

- Genetic Algorithm-Based Multi-Objective Optimization of Cutting Parameters in Turning ProcessesDocument7 pagesGenetic Algorithm-Based Multi-Objective Optimization of Cutting Parameters in Turning ProcessesAshwani VermaNo ratings yet

- Design of Experiment Based Analysis For Sheet Metal Blanking Processes OptimisationDocument9 pagesDesign of Experiment Based Analysis For Sheet Metal Blanking Processes OptimisationMD Al-AminNo ratings yet

- Optimization of Cutting Parameters in Turning Operation of Mild SteelDocument6 pagesOptimization of Cutting Parameters in Turning Operation of Mild SteelIzzah HzmhNo ratings yet

- Prediction of Delamination in End Milling of GFRP Using ANSYSDocument8 pagesPrediction of Delamination in End Milling of GFRP Using ANSYSVinicius PetrucciNo ratings yet

- Optimization of Machining Parameters For Face Milling Operation in A Vertical CNC Milling Machine Using Genetic AlgorithmDocument6 pagesOptimization of Machining Parameters For Face Milling Operation in A Vertical CNC Milling Machine Using Genetic AlgorithmdindaNo ratings yet

- Multi-objective Optimization of End Milling Parameters for Minimum VibrationDocument17 pagesMulti-objective Optimization of End Milling Parameters for Minimum VibrationSivasakthivelPsNo ratings yet

- Paper Rajshahi 3Document9 pagesPaper Rajshahi 3Shantonu Mitra ShantoNo ratings yet

- Cutting Force 1Document20 pagesCutting Force 118P202 - AJAY SIVARAMAN ANo ratings yet

- In TodayDocument8 pagesIn Todayshaim mahamudNo ratings yet

- Litrature ReviewDocument9 pagesLitrature ReviewJyothendra Pavan DamarlaNo ratings yet

- Lean Thi Nki NGDocument17 pagesLean Thi Nki NGcevherimNo ratings yet

- A Study of The Effects of Machining Parameters On The Surface Roughness in The End-Milling ProcessDocument7 pagesA Study of The Effects of Machining Parameters On The Surface Roughness in The End-Milling ProcessDesalegn DgaNo ratings yet

- Experimental Investigation of Process Parameters in Drilling Operation Using Different Software TechniqueDocument20 pagesExperimental Investigation of Process Parameters in Drilling Operation Using Different Software TechniqueResearch Cell: An International Journal of Engineering SciencesNo ratings yet

- An Experimental Analysis of Process Parameters For EN-36C Alloy Steel Using CNC Lathe  " A ReviewDocument5 pagesAn Experimental Analysis of Process Parameters For EN-36C Alloy Steel Using CNC Lathe  " A ReviewfaizanNo ratings yet

- Optimization of Process Prarmeters in Grinding Process To Reduce The Rework in Case of Piston Using Taguchi TechniqueDocument6 pagesOptimization of Process Prarmeters in Grinding Process To Reduce The Rework in Case of Piston Using Taguchi TechniqueInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Investigation of Tool Life in Al / Sic Composite Material With Ultrasonic Waves MachiningDocument8 pagesInvestigation of Tool Life in Al / Sic Composite Material With Ultrasonic Waves MachiningTJPRC PublicationsNo ratings yet

- Minimizing Energy Consumption and Surface Roughness in Wet TurningDocument10 pagesMinimizing Energy Consumption and Surface Roughness in Wet TurningAtul ChauhanNo ratings yet

- 2009 (Bala Murugan Gopalsamy & Biswanath Mondal & Sukamal Ghosh) PDFDocument19 pages2009 (Bala Murugan Gopalsamy & Biswanath Mondal & Sukamal Ghosh) PDFFikri SiplhoNo ratings yet

- Modeling and Optimization of End Milling Machining ProcessDocument18 pagesModeling and Optimization of End Milling Machining ProcessInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Optimization of Wood Machining Parameters in CNC Routers: Taguchi Orthogonal Array Based Simulated Angling AlgorithmDocument18 pagesOptimization of Wood Machining Parameters in CNC Routers: Taguchi Orthogonal Array Based Simulated Angling AlgorithmDavid duranNo ratings yet

- CastingDocument26 pagesCastingInayat KhanNo ratings yet

- 01 - Fundamentals of Metalworking PDFDocument50 pages01 - Fundamentals of Metalworking PDFSadasiva Rao TNo ratings yet

- Lathe accessories session guideDocument63 pagesLathe accessories session guideMohammed Rehan0% (1)

- CarpentryDocument35 pagesCarpentrySadasiva Rao TNo ratings yet

- Elements of Mechanical EngineeringDocument33 pagesElements of Mechanical EngineeringSadasiva Rao TNo ratings yet

- L5 Metal CastingDocument27 pagesL5 Metal Castingpradeep_i19No ratings yet

- Workshop ManualDocument60 pagesWorkshop ManualSadasiva Rao T83% (6)

- Basic Mechanical EngineeringDocument64 pagesBasic Mechanical EngineeringSadasiva Rao TNo ratings yet

- Basic Mechanical EngineeringDocument64 pagesBasic Mechanical EngineeringSadasiva Rao TNo ratings yet

- FE EEE ManualDocument31 pagesFE EEE ManualSadasiva Rao TNo ratings yet

- Analitical Modelling of Residual StressDocument11 pagesAnalitical Modelling of Residual StressSadasiva Rao TNo ratings yet

- 04 ExtrusionDocument57 pages04 Extrusion9811923100% (1)

- 5 Shaper and PlanerDocument33 pages5 Shaper and PlanerSadasiva Rao TNo ratings yet

- 4 DrillingDocument26 pages4 DrillingSadasiva Rao TNo ratings yet

- Thermal Power Plant Layout: Steam TurbineDocument1 pageThermal Power Plant Layout: Steam TurbineSadasiva Rao TNo ratings yet

- ICE1Document8 pagesICE1Sadasiva Rao TNo ratings yet

- 6 MillingDocument34 pages6 MillingSadasiva Rao TNo ratings yet

- ISOMETRICDocument39 pagesISOMETRICKaustubh MallikNo ratings yet

- Orthographic ProjectionDocument29 pagesOrthographic ProjectionSadasiva Rao TNo ratings yet

- Machining TurningDocument10 pagesMachining Turningasa_aha789No ratings yet

- FEM For StressDocument9 pagesFEM For Stresstasha_oksariaNo ratings yet

- Behaviors of End Milling Inconel 718 Superalloy by Cemented Carbide ToolsDocument6 pagesBehaviors of End Milling Inconel 718 Superalloy by Cemented Carbide ToolsMathieu_94No ratings yet

- Milling and GrindingDocument9 pagesMilling and GrindingPassmore DubeNo ratings yet

- Manual Sierra BandaDocument62 pagesManual Sierra BandaElvis Luis Rivera Dueñas100% (1)

- Weighing Feeding BrochureDocument4 pagesWeighing Feeding BrochureDjura ElmerNo ratings yet

- User Manual Eco100-4Document26 pagesUser Manual Eco100-4hireallbuyerNo ratings yet

- VMC ProgrammingDocument22 pagesVMC ProgrammingDynamic bhagwanNo ratings yet

- CNC-engraving Machine - Unit PriceDocument2 pagesCNC-engraving Machine - Unit PriceШеф ОтрисовкаNo ratings yet

- FullManual Manual BridgeportDocument134 pagesFullManual Manual BridgeportlaerciofilhoNo ratings yet

- C006a JDocument44 pagesC006a JVignesh WaranNo ratings yet

- Grey Relational Analysis PDFDocument38 pagesGrey Relational Analysis PDFCody LeeNo ratings yet

- CVRU FinalDocument20 pagesCVRU FinalSOBHARANI KOTHAKOTANo ratings yet

- Manual Guide I CNC Milling Made Easy ManualDocument126 pagesManual Guide I CNC Milling Made Easy ManualJasminNo ratings yet

- Parts of Lathe Machine:: Take Protecting It SeriouslyDocument1 pageParts of Lathe Machine:: Take Protecting It SeriouslyKlucifer XinNo ratings yet

- Winding Math For Preparation of The Exam - CompressDocument10 pagesWinding Math For Preparation of The Exam - CompressHưng HoàngNo ratings yet

- A Review On Tool Wear Monitoring SystemDocument7 pagesA Review On Tool Wear Monitoring Systemiaetsdiaetsd100% (1)

- Tribology in EngineeringDocument252 pagesTribology in EngineeringNedret Bajramovic100% (2)

- D24x40II 0109Document6 pagesD24x40II 0109Marian OpreaNo ratings yet

- Chapter 7drilling MachineDocument27 pagesChapter 7drilling MachineYosephNo ratings yet

- Chapter 1 Supplemental Text Material on Planning ExperimentsDocument179 pagesChapter 1 Supplemental Text Material on Planning ExperimentsHanapi AliNo ratings yet

- Force Calculation Using Analytical and CAE Methods PDFDocument14 pagesForce Calculation Using Analytical and CAE Methods PDFDanielle MascarenhasNo ratings yet

- Southbend Lathe NewDocument132 pagesSouthbend Lathe NewbackyardcncNo ratings yet

- REMS Katalog 2013 GBRoP - Stand 2013-03-07Document224 pagesREMS Katalog 2013 GBRoP - Stand 2013-03-07Stelian Olaru100% (1)

- G33 ThreadingDocument8 pagesG33 ThreadingAvinash KumarNo ratings yet

- Cincom L12Document8 pagesCincom L12asilka68No ratings yet

- Using Tutorials Tutorial 1in MM Tutorial 1in Inch Tutorial 2Document55 pagesUsing Tutorials Tutorial 1in MM Tutorial 1in Inch Tutorial 2patel_vicky87100% (1)

- PDF WEIHONG Ncstudio Users Manual - CNC Manual PDFDocument118 pagesPDF WEIHONG Ncstudio Users Manual - CNC Manual PDFSơn Nguyễn Thanh100% (1)

- Drills and Drilling Machines-1Document27 pagesDrills and Drilling Machines-1Tafadzwa E ChigwazaNo ratings yet

- 82 2010 Irwin Metal DrillingDocument20 pages82 2010 Irwin Metal DrillingDonizetti ManutençãoNo ratings yet

- The Roland CNC Mill ManualDocument7 pagesThe Roland CNC Mill ManualsuatomuzNo ratings yet

- Manufacturing Processes Tooling GuideDocument25 pagesManufacturing Processes Tooling GuideFakhru Rozi ZNo ratings yet

- Description For M Codes3Document19 pagesDescription For M Codes3balabooksNo ratings yet