Professional Documents

Culture Documents

Starch Capsules

Uploaded by

kunalprabhu148Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Starch Capsules

Uploaded by

kunalprabhu148Copyright:

Available Formats

reviews

research focus

PSTT Vol. 3, No. 2 February 2000

Starch capsules: an alternative system for oral drug delivery

Vinod D. Vilivalam, Lisbeth Illum and Khurshid Iqbal

Manufactured by the process of injection moulding, starch capsules have been shown to be a very useful alternative delivery system for orally administered compounds. This review describes the starch capsule manufacturing and filling processes and provides an overview of the capsules physical characteristics. In addition, investigations supporting the development of novel delivery technologies based on the starch capsules are described. Particular emphasis is given to a technology that facilitates drug delivery to specific sites in the human gastrointestinal tract. Manufacturing process Recent advances in injection moulding technology have permitted the manufacture of starch capsules. Various authors have described the process in detail1,3,4, and Fig. 2 illustrates the essential parts of a conventional injection-moulding machine used. During the production process, starch in the form of powder, granules or pellets is fed through the hopper onto a rotating reciprocating screw.The feed material moves along the screw towards the tip. During this process the temperature is increased by means of external heaters around the outside of the barrel and by the shearing action of the screw. From the feed zone to the compression zone, the feed material is gradually melted down; it is then conveyed through the metering zone, where homogenization of the melt occurs, to the end of the reciprocating screw. When sufficient melt is collected for injection, it is injected into the mould. The rotation of the screw stops while the polymer in the mould cools sufficiently for the mould to be opened and the moulded parts ejected. Pressures of between 7002000 bar and temperatures of between 120180C are normally seen in the transport, injection and moulding operations. Throughout the process the mould is maintained below the glass transition temperature of starch, and the time for a complete cycle is usually a few seconds. Capsule filling As starch capsule caps and bodies are manufactured separately, existing capsule filling machines Hard shell capsules made of potato starch consist of two pieces, a cap and body, which are sealed together at the time of filling to prevent separation (Fig. 1). Sealing is achieved by applying a hydroalcoholic solution to the inner section of the cap, immediately prior to its being placed onto the body.

Vinod D. Vilivalam* Lisbeth Illum and Khurshid Iqbal Drug Delivery Systems West Pharmaceutical Services 101 Gordon Drive Lionville PA 1934 USA *tel: 1 610 594 3157 fax: 1 610 594 3016 e-mail: vinod_vilivalam@ westpharma.com

w In the early 19th century, Mathes developed

the first capsule dosage form from gelatin: an alternative to the traditional tablet dosage form. Since then, this technology has been continually improved and refined, yielding the range of capsule forms available today. There have been attempts to find other substances to replace gelatin, although the successful manufacture of starch capsules has only recently been achieved. The starch capsule, a unique solid oral dosage form, is made of potato starch and represents a direct alternative to hard gelatin capsules. In the search for an alternative process to the dip moulding of gelatin capsules, Capsugel, a division of Warner Lambert, investigated and developed an injection moulding technique for the manufacture of starch capsules (Capill), the starch capsules currently manufactured by West Pharmaceutical Services. In some respects, the starch capsule can be considered to be equivalent to the hard gelatin capsule. However, starch capsules feature several advantages: dissolution is independent of pH, they are suitable for enteric coating1, moisture in the shell is tightly bound to starch, and the capsules are tamper-evident2 and preservative-free and produced from non-animal-derived ingredients2.

64

1461-5347/00/$ see front matter 2000 Elsevier Science Ltd. All rights reserved. PII: S1461-5347(99)00238-2

PSTT Vol. 3, No. 2 February 2000

research focus

reviews

400C, the normal output is approximately 270 capsules per minute when filling powder or pellets, and approximately 150180 capsules per minute for the filling of semi-solids. Physical characteristics Starch capsules can be manufactured in different sizes size numbers 0, 1, 2, 3 and 4 by changing the moulds (Fig. 3). An essential advantage of the capsule design is that the samesized cap is used to fit different body lengths. The diameter of the junction of the cap and body is always the same on all sizes of starch capsules. Unlike the lipped seal on a gelatin capsule, the starch capsule cap fits evenly in place over the body, leading to a good surface finish. This is a further advantage as the capsules are easily tamper-evident.The starch capsule is odourless and rigid, and exhibits similar dissolution behaviour to the gelatin capsules. In vitro release studies of acetaminophen, as a model drug, using the United States Pharmacopeia (USP) Apparatus 2, demonstrated that the release properties of starch capsules were independent of pH (West Pharmaceutical Services, unpublished). The storage conditions, especially the humidity, have significant influence on the integrity of all types of capsules.Typically, the moisture content of the starch capsules ranges between 1214% w/w, with more than 50% being tightly bound to the starch. The presence of bound moisture suggests that starch capsules may provide better stability properties and reduced susceptibility to changes on storage. Starch capsules, containing

Figure 1. Starch capsules (cap and body). The cap is designed to fit the body with a smooth seal.

require some modification for the filling and sealing of the starch capsules.Two types of machines are available for the filling of starch capsules; a semi-automatic bench-top filling machine for laboratory development, and a production-scale Bosch (GKF) 400C filling machine (Bosch, Minneapolis, MN, USA). Using a bench-top filling machine, 20 capsules can be filled or sealed at a time. In a fully automated Bosch GKF

Hopper

Nozzle

Check ring

Screw

Barrel Compression zone (25%) Metering zone (25%)

Pharmaceutical Science & Technology Today

Feed zone (50%)

Figure 2. Schematic representation of the starch processing parts of injection moulding equipment.

65

reviews

research focus

PSTT Vol. 3, No. 2 February 2000

0.333 [8.47 mm]

0.227 [5.77 mm]

0.538 [13.67 mm]

0.700 [17.79 mm]

Size 0

Size 1

0.419 [10.63 mm]

Size 2

0.357 [9.06 mm]

Size 3

0.275 [6.99 mm]

Size 4

Pharmaceutical Science & Technology Today

Figure 3. Engineering drawing of the available sizes of starch capsules.

acetaminophen, were studied for stability in PVC-PVdC-Alu blisters and high-density polyethylene (HDPE) bottles. PVCPVdC-Alu blister is a type of pharmaceutical packaging that uses aluminum blisters to package each starch capsule.The PVC (polyvinyl chloride) is coated with PVdC (polyvinylidene chloride) to improve water vapour and oxygen protection. The results of this study suggest an acceptable stability profile after 18 months in both packages (West Pharmaceutical Services, unpublished). Enteric-coated starch capsules There is considerable interest in the enteric coating of pharmaceutical preparations for drug delivery to the intestinal region5,6. Such coatings have been traditionally reserved for drug substances that cause gastric irritation, produce nausea or which are destroyed by acid or gastric enzymes. Recently, functional coatings have been applied to dosage forms intended for targeted delivery, especially to the colon7.The delivery of drugs to the colon has applications in several therapeutic areas. These include the topical treatment of colonic diseases and the oral delivery of drugs destroyed in the upper gastrointestinal (GI) tract. Many diseases of the colon, such as ulcerative colitis, Crohns disease and irritable bowel syndrome, could be better treated when site-specific delivery of the therapeutic agent is effective. There have been considerable technical problems in the manufacture of coated hard gelatin capsules, especially since the advent of aqueous coating systems8. For example, during

66

coating with aqueous spray formulations, the gelatin shell can often soften and become sticky because of solubilization, or brittle as a result of water evaporation and drying, especially at the onset of coating. In addition, there are difficulties associated with the coating of the lipped hard gelatin capsules, which could compromise the protective characteristics of the coating (West Pharmaceutical Services, unpublished). The coating of starch capsules appears to be less problematic because of the smooth seal of the filled unit, coupled with the higher bulk density of the capsules, which provide for a more uniform coating bed. Studies have been performed to evaluate the stability of the coated starch capsules. Brogmann et al. compared the stability of enteric-coated gelatin and starch capsules using aqueous dispersions of methacrylic acid copolymers9. The results obtained indicated the presence of a smooth and glossy coating layer on starch capsules. The hardness of the coated starch capsules was found to be 280 Newtons (N), and no cracks or separation of the coating from the capsule shell were observed during hardness testing. In contrast, only a modified formulation, with a highly controlled procedure, resulted in an acceptable smooth coating on gelatin capsules, with a relatively lower hardness level of 65 N. The coated starch capsules also demonstrated an excellent stability profile for 12 months at room temperature and at 37C, as well as gastroresistance and disintegration in the intestinal fluid. The stability of enteric-coated starch capsules was studied by Vilivalam et al. using 5-ASA (amino salicylic acid) as a model

PSTT Vol. 3, No. 2 February 2000

research focus

reviews

drug10.The capsules were evaluated in terms of coat integrity at various time points by testing for drug release and disintegration, using the USP dissolution and disintegration apparatus. The study design included the development of processing conditions to enable coating using a solvent-based coating system containing Eudragits in a perforated pan coater (Hi-Coater, Vector Corporation, Marion, IA, USA), and to evaluate in vitro dissolution and disintegration changes on storage at 25C and 55% RH and 40C and 75% RH.The capsules were successfully coated using this system, and visual observation indicated a uniform and smooth seal, especially at the junction of cap and body. The 5-ASA release remained unchanged for 24 weeks (40C and 75% RH), as seen in Fig. 410.The coated capsules remained intact in gastric medium, and reproducibly disintegrated at between one and two hours after insertion in intestinal medium. In another study, Vilivalam et al. used an extrusionspheronization process to develop 5-ASA beads designed to deliver the drug to the colonic region using the coated starch capsules11. The in vitro release showed that the uncoated starch capsules had a slower rate of 5-ASA release compared with unencapsulated beads; this was because of the required capsule disintegration. The enteric-coated capsules showed an increased lag time in 5ASA release because of slower disintegration. The 5-ASA release from the beads modelled a Higuchis square-root time model, indicating diffusion as the primary mechanism of release. Burns et al. compared in vitro release profiles of non-enteric and enteric-coated liquid-filled starch capsules with that of gelatin capsules using a lipophilic model drug, propanalol12. Initial studies indicated that some of the liquid-filled starch

capsules leaked. The leakage was overcome by modifying the formulation to incorporate a thermosoftening agent, such as Gelucire 33/01 (polyglycolysed glyceride) (Gattefosse, Saintpriest, France). The dissolution profiles of the non-entericcoated capsule formulations indicated similar biphasic release characteristics to both hard gelatin and starch capsules. However, the dissolution profile for enteric-coated starch capsules was considerably slower than that of coated hard gelatin capsules. An increased concentration of bile acid (14 mM as opposed to 7 mM) was incorporated into the dissolution medium to test for its effect on the rate of propanalol release from coated starch capsules. The subsequent change in the dissolution method produced a similar release profile to that seen for enteric-coated gelatin capsules containing the same formulation. The authors concluded that starch capsules represent an alternative dosage form for complex formulations such as the HALO delivery system12, a drugoleic acid solution with a biphasic release characteristic, particularly where reliable enteric coating is of prime importance. Scintigraphy studies Gamma scintigraphy has been routinely used to follow the transit and release characteristics of dosage forms in the human GI tract13. Scintigraphy techniques were used to confirm the in vivo behaviour of starch capsules compared with traditional hard gelatin capsules14. Doll et al. studied capsule opening and GI transit times for hard gelatin and starch capsules in human volunteers14. The GI transit data were correlated with drug (amoxicillin) plasma concentrations. In each study, a starch capsule and a gelatin capsule, each containing 250 mg of

20.0 Amount of 5-ASA released (mg)

15.0

Figure 4. Release profiles of 5-ASA from enteric-coated starch capsules (stored for up to 24 weeks at 40C and 75% RH). Initial time point (open circle); Four-week time point (closed square); 12-week time point (closed triangle); 24-week time point (closed circle). Adapted from Ref. 11.

10.0

5.0

0.0 0.0

1.0

2.0

3.0

4.0 Time (h)

5.0

6.0

7.0

8.0

Pharmaceutical Science & Technology Today

67

reviews

research focus

PSTT Vol. 3, No. 2 February 2000

amoxicillin and a radiolabel, were administered under fasted conditions. Analysis of the GI transit and plasma amoxicillin data showed no statistical difference between the starch and gelatin capsules in normal human volunteers. Wilding et al. used gamma scintigraphy in a study designed to evaluate the GI transit and in vivo disintegration characteristics of Aquateric-coated starch capsules in eight healthy subjects under fasted and fed condition15. Aquateric is a completely water-based reconstituted dispersion of cellulose acetate phthalate (CAP) latex. The product is sold as a dry, white, waterinsoluble powder, which may be dispersed in water to create an enteric film-coating liquid. No loss of capsule integrity was observed in the stomach following administration, after either an overnight fast or a medium breakfast, thereby confirming the gastroresistant properties of the coated capsules. Initial signs of capsule disintegration were observed in the small intestine. Once disintegration had commenced, complete break-up occurred, on average, within 20 minutes.The study also included a test on the effect of food on the in vivo behaviour of an aqueous enteric-coated starch capsule formulation16. In vitro disintegration testing showed that the coated capsules remained intact in 0.1 N hydrochloric acid for more than two hours, but disintegrated within 20 min after the acid medium was exchanged for pH 6.8 phosphate buffer. Gamma scintigraphy confirmed the gastroresistant properties of the coated starch capsules and that they remained intact in the stomach until disintegration occurred in the small intestines at 66 28 and 95 3.3 minutes (average standard deviation) respectively, after leaving the stomach, following fasted and fed administrations. The use of starch capsules in conjunction with a variety of coatings, such as a pH-sensitive material, a redox-sensitive material, or a material broken down by specific enzymes or bacteria present in the colon, for site-specific delivery to the colon is the subject of a patent filed in Europe, USA, Japan and other territories17. Watts et al. designed an enteric-coated starch capsule system (TARGIT technology) for targeting specific sites within the colonic region17. The coating employed is based on a mixture of Eudragit L and S, chosen to provide a coating that starts dissolving when the capsule enters the small intestine after leaving the stomach. The thickness of the coating can be designed so that the capsule disintegrates within a predetermined region in the intestine, such as the terminal ileum, the ascending-, the transverse-, or even the descending colon. The TARGIT delivery system therefore works by both a pH and time-dependent mechanism, which is considered to be more fail-safe than systems depending only on a pH change in the environment (Fig. 5). The TARGIT system has been tested with a range of drugs in several Phase I clinical trials involving both gamma scintigraphy and pharmacokinetic studies, and has achieved targeting to the colonic region7.

68

Figure 5. Scintigraphic images of a radiolabelled TARGIT capsule in a human following oral administration. At zero hours the capsule is in the stomach (a); one hour (small intestine) (b); 3.5 hours (ascending colon) (c); and 8.5 hours (dispersed in transverse and descending colon) (d). Adapted from Ref. 7.

Regulatory status Capsules prepared from starch are officially recognized in United States Pharmacopoeia 23 and National Formulary 18 (Ref. 18). The USP also permits the use of colouring agents, opacifying agents such as titanium dioxide, dispersing and hardening agents, as well as preservatives. European pharmacopoeias do not specifically include starch as an ingredient in capsules. Instead, the wording is capsule shells are composed of gelatin or other materials. Conclusion Recent advances in injection moulding technology have facilitated the manufacture of starch capsules.Various physical characteristics have indicated that starch capsules are, in some ways, comparable with those of gelatin capsules; however, starch capsules have some noted advantages. This type of capsule may prove to be a useful alternative to its gelatin counterpart. The enteric coating of starch capsules is a successful approach to targeted intestinal drug delivery, especially with drugs that cannot be compressed into tablets. In addition, starch capsules in the form of TARGIT will deliver formulations to the terminal ileum or colon, and provide the means for local drug delivery for the treatment of diseases such as ulcerative colitis, Crohns disease or irritable bowel syndrome. It is also envisaged that the TARGIT system will facilitate vaccine delivery to the large

PSTT Vol. 3, No. 2 February 2000

research focus

reviews

bowel for mucosal vaccination. It is known that the colon is rich in lymphoid tissue and that the creation of a high local antibody response is feasible. Additionally, the outbreak of bovine spongiform encephalopathy (BSE), or mad cows disease, there is concern about the quality of certain animal products involved in the production of gelatin capsules19. As an alternative, starch is a viable option because of the absence of products of animal origin. Acknowledgements The authors wish to thank the following individuals for their assistance: S.S. Davis and Lisa Nolan for their comments and critical review of the manuscript; Nick Klutcka for his insights on the manufacture of the injection-moulded capsule; Ryan Waddell and David Howe for their assistance in the research and development. References

1 2 3 4 5 Eith, L. and Tomka, I. (1987) Injection molded drug delivery systems. Manuf. Chem. 58, 2125 Idrissi, S. et al. (1991) Capill (R) de charbon activ; formulation faisabilit industrielle stabilit. Pharm.Acta. Helv. 66, 246252 Eith, L. et al. (1986) The injection-moulded capsule. Drug Dev. Ind. Pharm. 12, 21132126 Stepto, R.F.T. and Tomka, I. (1987) Injection moulding of natural hydrophilic polymers in the presence of water. Chimia 41, 7681 Hardy, J.G. et al. (1987) Evaluation of an enteric-coated delayed-release 5aminosalicylic acid tablet in patients with inflammatory bowel disease. Aliment. Pharmacol.Ther. 1, 273280 6 7 Wilding, I.R. et al. (1992) In Vivo evaluation of enteric-coated naproxen tablets using gamma scintigraphy. Pharm. Res. 9, 14361441 Watts, P.J. and Illum, L. (1997) Colonic drug delivery. Drug Dev. Ind. Pharm. 23, 893913

Plaizier-Vercammen, J. et al. (1992) Enteric coating properties of Eudragit, Aquateric and Cellulose Acetate Trimellitate applied to capsules. Eur.J.Pharm. Biopharm. 38, 145149

Brogmann, B. and Lehmann, K. (1994) Stability of enteric gelatin and starch capsules coated with aqueous dispersions of methacrylic acid copolymers. Pharm.Res. 11, S-167

10

Vilivalam,V .D. et al. (1997) Enteric coating and drug release evaluation of starch capsules in the development of colon specific drug delivery systems. Pharm.Res. 14, S-659

11

Vilivalam,V .D. et al. (1998) Development and evaluation of 5-ASA beads by an extrusion-spheronization process for colonic drug delivery using starch capsules. Pharm.Res. 1, S-645

12 13 14

Burns, S.J. et al. (1996) An in vitro assessment of liquid-filled Capill potato starch capsules with biphasic release characteristics. Int.J.Pharm. 134, 223230 Davis, S.S. et al. (1992) Gamma scintigraphy in the evaluation of pharmaceutical dosage forms. Eur.J.Nucl.Med. 19, 971986 Doll,W .J. et al. (1993) A scintigraphic and pharmokinetic evaluation of a novel capsule manufactured from potato starch compared with a conventional hard gelatin capsule in normal and in normal subjects administered omperazole. Pharm.Res. 10, S-213

15 16 17 18 19

Wilding, I.R. et al. (1993) Enteric coated starch capsules:A new approach for targeted intestinal delivery. Pharm.Res. 10, S-183 Kenyon, C.J. et al. (1994) The effect of food on the in vivo behaviour of enteric coated starch capsules. Int.J.Pharm. 112, 207213 Watts, P.J. et al. (1995) Colonic drug delivery composition. Patent pending WO35100 USP23/NF18 (1995) Capsules, 1151 Pharmaceutical dosage forms, pp. 1942 Guidance for Industry (1997) The sourcing and processing of gelatin to reduce the potential risk posed by bovine spongiform encephalopathy (BSE) in FDA-regulated products for human use. U.S. Department of Health and Human Services, US Food and Drug Administration, USA

Reviews appearing in the March issue of Pharmaceutical Science & Technology Today

The importance of drug delivery systems in tissue engineering Yasuhiko Tabata Recombinant in vitro tools to predict drug metabolism and safety Thomas Friedberg Advances in the use of monoclonal antibodies in cancer radiotherapy Serengulam V. Govindan, David M. Goldenberg, Hans J. Hansen, and Gary L. Griffiths

69

You might also like

- Toxicological ScreeningDocument11 pagesToxicological Screeningkunalprabhu148No ratings yet

- Tech TransferDocument51 pagesTech Transferkunalprabhu148No ratings yet

- Modulated drug release from spray dried mupirocin calcium microparticlesDocument14 pagesModulated drug release from spray dried mupirocin calcium microparticleskunalprabhu148No ratings yet

- Multi ComponentDocument53 pagesMulti Componentkunalprabhu148No ratings yet

- CPSCEA GuidelinesDocument18 pagesCPSCEA Guidelineskunalprabhu148No ratings yet

- AFM More InfoDocument6 pagesAFM More Infokunalprabhu148No ratings yet

- SPMModule BasicTheoryAFMDocument8 pagesSPMModule BasicTheoryAFMprinceamitNo ratings yet

- Tech. Transfer KunalDocument26 pagesTech. Transfer Kunalkunalprabhu148No ratings yet

- Analytical Profiles of Drug Substances Volume 18 1989Document643 pagesAnalytical Profiles of Drug Substances Volume 18 1989kunalprabhu148100% (3)

- AFM More InfoDocument6 pagesAFM More Infokunalprabhu148No ratings yet

- Aasr 2010 2 1 225 229Document5 pagesAasr 2010 2 1 225 229Rajesh KumarNo ratings yet

- Molecular Markers in Herbal Medicine TechnologyDocument7 pagesMolecular Markers in Herbal Medicine TechnologyRommelKarloDelaCruzNo ratings yet

- K. ShakesheffDocument206 pagesK. Shakesheffkunalprabhu148No ratings yet

- Electron MicrosDocument21 pagesElectron Microskunalprabhu148No ratings yet

- Neuropathic PainDocument15 pagesNeuropathic Painkunalprabhu148No ratings yet

- Traditional Medicine Plants Provide Valuable Drug Discovery CluesDocument7 pagesTraditional Medicine Plants Provide Valuable Drug Discovery CluesMuhammad Usman RashidNo ratings yet

- Biocat Lecture10Document23 pagesBiocat Lecture10k_2_kNo ratings yet

- An Introduction To Patchouli (Pogostemon Cablin Benth.)Document9 pagesAn Introduction To Patchouli (Pogostemon Cablin Benth.)Nasrull BinHzNo ratings yet

- Microparticles - An Approach For Betterment of Drug Delivery SystemDocument17 pagesMicroparticles - An Approach For Betterment of Drug Delivery Systemkunalprabhu148No ratings yet

- CapsulesDocument61 pagesCapsuleskunalprabhu148No ratings yet

- Safety Performance TestDocument42 pagesSafety Performance Testkunalprabhu148No ratings yet

- Pharmacoieal StandardsDocument28 pagesPharmacoieal StandardsnikhildedhiaNo ratings yet

- Starch CapsulesDocument6 pagesStarch Capsuleskunalprabhu148100% (1)

- Hydro TropyDocument8 pagesHydro Tropykunalprabhu148No ratings yet

- HPMC CapsulesDocument15 pagesHPMC Capsuleskunalprabhu148No ratings yet

- Feton FillingDocument8 pagesFeton Fillingkunalprabhu148No ratings yet

- Tablets TextDocument18 pagesTablets TextarunbaskaranjNo ratings yet

- Pharmacogenetics and The Concept of Individualized Medicine: BS ShastryDocument6 pagesPharmacogenetics and The Concept of Individualized Medicine: BS Shastrykunalprabhu148No ratings yet

- Shampoos 1Document10 pagesShampoos 1kunalprabhu148No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Presentation Operational ProcedureDocument27 pagesPresentation Operational ProcedureZee Khan100% (1)

- Advances in engineering technologiesDocument11 pagesAdvances in engineering technologiesSudarshan AhireNo ratings yet

- Art07 EngDocument8 pagesArt07 Engcerbu_bass_cdcNo ratings yet

- Sample Teaching PlanDocument5 pagesSample Teaching PlanteuuuuNo ratings yet

- AES Encryption Algorithm Hardware Implementation Architecture: Resource and Execution Time OptimizationDocument9 pagesAES Encryption Algorithm Hardware Implementation Architecture: Resource and Execution Time OptimizationInternational Journal of Information and Network Security (IJINS)No ratings yet

- CPUDocument7 pagesCPUWerry sudiwijayaNo ratings yet

- BAED STAT2112 Statistics and Probability Second Quarter ExamDocument51 pagesBAED STAT2112 Statistics and Probability Second Quarter ExamHarriel RebollosNo ratings yet

- FS19 Hof Bergmann ChangelogDocument6 pagesFS19 Hof Bergmann ChangelogErik0% (1)

- Neijing TuDocument3 pagesNeijing TuCupidayNo ratings yet

- 550kVA CaterpillarDocument16 pages550kVA CaterpillarfazalmusaferNo ratings yet

- Script Short FilmDocument9 pagesScript Short FilmKino Go AninangNo ratings yet

- Lab 1 - Diode Characteristics and ApplicationsDocument8 pagesLab 1 - Diode Characteristics and ApplicationsMD NAZMUN HASAN NAFEESNo ratings yet

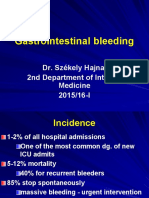

- Gastrointestinal Bleeding: Dr. Székely Hajnal 2nd Department of Internal Medicine 2015/16-IDocument74 pagesGastrointestinal Bleeding: Dr. Székely Hajnal 2nd Department of Internal Medicine 2015/16-ISutisna NisaNo ratings yet

- Tanker cargo discharge and inert gas system safety checklistDocument9 pagesTanker cargo discharge and inert gas system safety checklistAjay SinghNo ratings yet

- (Validity-2020.09.30) - Rev - 180709Document3 pages(Validity-2020.09.30) - Rev - 180709Waleed AliNo ratings yet

- District Heating NorwayDocument8 pagesDistrict Heating Norwaymahmoud4871No ratings yet

- Introduction To The Basics of UQDocument25 pagesIntroduction To The Basics of UQhfmath miaoNo ratings yet

- Evolution of Intel ProcessorsDocument4 pagesEvolution of Intel Processors이고양No ratings yet

- Epidemiology of Human African TrypanosomiasisDocument19 pagesEpidemiology of Human African Trypanosomiasisrifa iNo ratings yet

- Bio Poli MerosDocument8 pagesBio Poli MerosYanella Smith Arevalo GonzalesNo ratings yet

- Me Air Conditioning and Ventilation Range enDocument284 pagesMe Air Conditioning and Ventilation Range enCaserta Technical GamerNo ratings yet

- Basic Concepts of ChemistryDocument82 pagesBasic Concepts of ChemistryGowri ShankarNo ratings yet

- Hadamard Regularization: ReferencesDocument2 pagesHadamard Regularization: ReferencesAtikshaNo ratings yet

- Activity in 21st Century LiteratureDocument3 pagesActivity in 21st Century Literatureheart AquinoNo ratings yet

- PSYC2512 - Evolution and Human BehaviourDocument44 pagesPSYC2512 - Evolution and Human BehaviourLauren NewmanNo ratings yet

- Health Status of Rural Women in OdishaDocument10 pagesHealth Status of Rural Women in OdishaEditor IJTSRDNo ratings yet

- SOAL SULIT UN 2017/2018 IDENTIFIKASI DAN PEMBAHASANDocument12 pagesSOAL SULIT UN 2017/2018 IDENTIFIKASI DAN PEMBAHASANJuzt JoNo ratings yet

- VeltassaDocument3 pagesVeltassaMikaela Gabrielle GeraliNo ratings yet

- Rock Properties Guide: Porosity, Permeability, Compressibility & MoreDocument42 pagesRock Properties Guide: Porosity, Permeability, Compressibility & MorecudumbasseriNo ratings yet

- A.2 PHPP Introduction: Author: FF / PHI / PHDDocument36 pagesA.2 PHPP Introduction: Author: FF / PHI / PHDDoru FecheteNo ratings yet