Professional Documents

Culture Documents

Alternador Con Regulador

Uploaded by

Ilarion CiobanuOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Alternador Con Regulador

Uploaded by

Ilarion CiobanuCopyright:

Available Formats

Maintenance

ALTERNATOR WITH REGULATOR

COVERS DELCO, MOTOROLA, AND LEECE-NEVILLE ALTERNATORS USED ON YALE LIFT TRUCKS

PART NO. 524150791

2200 YRM 2

SAFETY PRECAUTIONS MAINTENANCE AND REPAIR

When lifting parts or assemblies, make sure all slings, chains, or cables are correctly fastened, and that the load being lifted is balanced. Make sure the crane, cables, and chains have the capacity to support the weight of the load. Do not lift heavy parts by hand, use a lifting mechanism. Wear safety glasses. DISCONNECT THE BATTERY CONNECTOR before doing any maintenance or repair on electric lift trucks. Disconnect the battery ground cable on internal combustion lift trucks. Always use correct blocks to prevent the unit from rolling or falling. See HOW TO PUT THE LIFT TRUCK ON BLOCKS in the Operating Manual or the Periodic Maintenance section. Keep the unit clean and the working area clean and orderly. Use the correct tools for the job. Keep the tools clean and in good condition. Always use YALE APPROVED parts when making repairs. Replacement parts must meet or exceed the specifications of the original equipment manufacturer. Make sure all nuts, bolts, snap rings, and other fastening devices are removed before using force to remove parts. Always fasten a DO NOT OPERATE tag to the controls of the unit when making repairs, or if the unit needs repairs. Be sure to follow the WARNING and CAUTION notes in the instructions. Gasoline, Liquid Petroleum Gas (LPG), Compressed Natural Gas (CNG), and Diesel fuel are flammable. Be sure to follow the necessary safety precautions when handling these fuels and when working on these fuel systems. Batteries generate flammable gas when they are being charged. Keep fire and sparks away from the area. Make sure the area is well ventilated. NOTE: The following symbols and words indicate safety information in this manual:

WARNING

Indicates a condition that can cause immediate death or injury!

CAUTION

Indicates a condition that can cause property damage!

Alternator with Regulator

Table of Contents

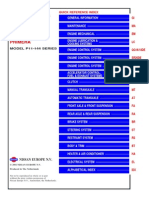

TABLE OF CONTENTS

General................................................................................................................................................................ Description .......................................................................................................................................................... Alternator Repair ................................................................................................................................................. Alternator Type A............................................................................................................................................. Remove and Disassemble .......................................................................................................................... Clean .......................................................................................................................................................... Assemble .................................................................................................................................................... Install .......................................................................................................................................................... Alternator Type B............................................................................................................................................. Remove and Disassemble .......................................................................................................................... Clean .......................................................................................................................................................... Assemble .................................................................................................................................................... Install .......................................................................................................................................................... General Check and Adjustment........................................................................................................................... Low Output Check (Type A or Type B)................................................................................................................. High Output Check (Type A or Type B)................................................................................................................ Brushes Circuit Check ......................................................................................................................................... Delco Alternators............................................................................................................................................. Motorola Alternators........................................................................................................................................ Diodes Check ...................................................................................................................................................... Diode Bridge Check............................................................................................................................................. Delco and Leece-Neville Alternators............................................................................................................... Motorola Alternators........................................................................................................................................ Rotor Field Winding Check.................................................................................................................................. Stator Windings Check ........................................................................................................................................ Voltage Regulator Check ..................................................................................................................................... Troubleshooting ................................................................................................................................................... This section is for the following models: Covers Delco, Motorola, and Leece-Neville alternators used on Yale lift trucks 1 1 3 3 3 4 4 5 8 8 8 9 10 11 11 13 14 14 15 16 16 16 16 17 18 18 18

2004 Yale Materials Handling Corp.

2200 YRM 2

Description

General

CAUTION

When using an arc welder, always disconnect the ground lead from the lift truck battery to prevent alternator or battery damage. Attach the welding ground clamp as close to the weld area as possible to prevent welding current from damaging the bearings. The diodes and resistors in the electrical system can be damaged if the following cautions are not followed: Do not disconnect the battery when the engine is running. The voltage surge can damage the diodes and resistors in the electrical system. Do not disconnect an electric wire before the engine is stopped and the switches are OFF. Do not cause a short circuit by connecting the electric wires to the wrong terminals. Make sure a correct identification is made of the wire before it is connected. Make sure a battery is the correct voltage and polarity before it is connected. Do not check for current flow by making a spark because the electronic components can be damaged. NOTE: Information on alternators manufactured outside the United States is in the YRM sections for lift trucks that use those alternators. This section has a description and the repair procedures for the alternator with a voltage regulator as part of the alternator.

Description

NOTE: For this YRM section, the alternators are in two groups: Type A and Type B. The two types are very similar, but the Type A alternators have a set of three diodes (diode set) as well as the diode bridge. The Type B alternator has zener diodes as part of the diodes in the diode bridge. This alternator does not have a diode set, but does have an additional fan inside the rear housing. The basic operation of both types is very similar. The alternator generates an alternating current when the engine is running. The alternator is either ON or OFF. The alternator generates maximum current when it is ON and no current when it is OFF. The regulator switches the alternator between ON and OFF to get the average current needed to charge the battery. Alternator output is directly changed by engine speed and rotor field current. The alternating current is changed to a direct current by the diode bridge inside the alternator. The alternator has these parts (see Figure 1 and Figure 2): A stator A rotor A diode bridge A diode set (Type A only) Two end housings or frame halves A solid-state voltage regulator NOTE: DELCO TYPE A SHOWN. 1. BRUSH ASSEMBLY 2. ROLLER BEARING 3. GREASE RESERVOIR 4. LIP SEAL 5. 6. 7. 8. DIODE BRIDGE BALL BEARINGS FELT SEAL REGULATOR

Figure 1. Alternator Cross Section

Description

2200 YRM 2

Figure 2. Alternator Schematics

2200 YRM 2 Legend for Figure 2 NOTE: LEECE-NEVILLE NOT AVAILABLE, SIMILAR TO THOSE SHOWN. A. DELCO TYPE A (SMALL CAPACITY LIFT TRUCKS) B. DELCO TYPE B 1. 2. 3. 4. 5. 6. 7. BATTERY KEY SWITCH FUSE RESISTOR INDICATOR LIGHT OR AMMETER VOLTAGE REGULATOR ROTOR FIELD

Alternator Repair

C. MOTOROLA TYPE A D. DELCO TYPE A (LARGE CAPACITY LIFT TRUCKS) 8. 9. 10. 11. 12. 13. 14. STATOR DIODE BRIDGE DIODE SET FIELD TERMINAL REGULATOR TERMINAL OUTPUT (BAT) TERMINAL VOLTAGE ADJUSTMENT

The direct current from the diodes of the diode bridge flows to the output or BAT terminal. A capacitor between the BAT terminal and the electrical ground removes any remaining alternating current from the direct current. The capacitor also protects the diodes from high voltages. The voltage is controlled by the amount of current flowing through the field winding in the alternator and the rpm of the rotor. The voltage regulator, inside the housing, contains a transistor, diodes, resistors, and capacitor. The voltage regulator cannot be repaired. NOTE: On some large capacity lift trucks, the alternator has an external voltage adjustment.

The voltage regulator controls the alternator to charge the battery. The voltage is set by the manufacturer and is not usually adjustable. Battery voltage decreases as the starting circuit and other circuits take energy from the battery. When the key switch is put in the IGN position, the voltage regulator is energized. A positive current flows to the field terminal (F or 1) on Type A alternators and (L) on Type B alternators. The battery sends a positive current to the regulator terminal (Type A R or 2) and the BAT terminal. The regulator senses a decrease in battery voltage and increases the alternator output to charge the battery.

Alternator Repair

ALTERNATOR TYPE A Remove and Disassemble WARNING

Always disconnect the battery ground cable before making repairs to prevent possible damage and injury. Install a tag on the battery terminal so that no one connects the cable on the terminal. NOTE: Use Troubleshooting and General Check and Adjustment, Low Output Check (Type A or Type B), High Output Check (Type A or Type B), Brushes Circuit Check, Diodes Check, Diode Bridge Check, Rotor Field Winding Check, Stator Windings Check, and Voltage Regulator Check procedures of this YRM before starting any repair procedures. Make sure that repair or replacement of that part is necessary before removal, disassembly, or replacement of the part. NOTE: There are some checks of the alternator that are done with the alternator on the engine. See General Check and Adjustment, Low Output Check (Type A or Type B), High Output Check (Type A or Type B), Brushes Circuit Check, Diodes Check, Diode Bridge Check, Rotor Field Winding Check, Stator Windings Check, and Voltage Regulator Check procedures of this YRM before starting any removal or repair procedures. NOTE: Many parts of the Leece-Neville alternator can be replaced without disassembling the alternator. See Figure 5. The alternator must be disassembled to replace only the diode bridge, filter capacitor, rotor, stator, or bearings. 1. Disconnect the battery ground cable. See Figure 3, Figure 4, and Figure 5. Install labels and disconnect the wires at the alternator. Loosen the alternator mount capscrews and remove the drive belt. Remove the capscrews that hold the alternator to the engine.

Alternator Repair

2200 YRM 2

A. DELCO 1. GROUND TERMINAL 2. BATTERY TERMINAL (BAT OR +)

B. MOTOROLA 3. FIELD TERMINAL 4. REGULATOR TERMINAL

Figure 3. Type A Alternators, Rear Views 2. On Leece-Neville alternators, remove the brushes, voltage regulator, or diode set. Install labels on all wires for correct connection during installation. 3. Put a mark on each housing and on the stator for correct alignment during assembly. Remove the bolts that hold the housings together. Separate the housings and stator. 4. Put the rotor in a vise that has soft jaws. Do not tighten the vise to cause rotor distortion. Use a socket wrench to remove the pulley nut. Remove the pulley, fan, collar, spacer, shield, or other parts between the fan and housing. Remove the front housing from the rotor. 5. Remove any nuts or screws that fasten parts inside to the rear housing. Then, remove the stator assembly from the rear housing so that the other parts can be removed. Remove the screws for the capacitor, diode bridge, diode set, brushes, and other parts as necessary. If the stator will be removed from the diode bridge, make sure the wires have tags for correct connection during assembly. 6. Mark the stator to show the position of the brushes and connector or diode bridge assembly. Use pliers as a heat sink to keep heat from the diodes. Use a soldering iron to remove the stator leads from the diode assembly. 7. Remove the bearings from the housings only if they will be replaced.

Clean CAUTION

Never use solvent on the parts of the alternator.

CAUTION

Compressed air can move particles so that they cause injury to the user or to other personnel. Make sure that the path of the compressed air is away from all personnel. Wear protective goggles or a face shield to prevent injury to the eyes. NOTE: If necessary, use fine abrasive cloth to polish the slip rings. The abrasive cloth must be number 500 to 600. Remove all dust. Turn the rotor while polishing the slip rings. Use compressed air to remove dirt from the alternator. Clean the brushes and slip rings with a clean, dry cloth.

Assemble

1. For Delco (Type A) alternators, install a new bearing(s) in the housing as follows (see Figure 3, Figure 4, and Figure 5):

2200 YRM 2 a. Install a new plug and seal in the rear housing. Push the bearing from the outside of the housing until the top of the bearing is even with the outside of the housing. Hold the housing with the collar on the inside of the housing. Keep the lip of the seal away from the bearing. Lubricate the bearing area with non-conductive grease. b. Install a new bearing in the front housing. Fill one quarter of the grease reservoir with nonconductive grease. Move the grease so that it touches the bearing when the retainer plate is installed. c. Add the same type of grease to fill the area between the retainer plate and the bearing. Install the spacer, gasket, and retainer plate on the bearing. Fasten the retainer plate in position with the three screws and lockwashers. 2. For Motorola and Leece-Neville alternators, use a press to install the rear bearing on the rotor. Install the bearing and bearing retainer in the front housing. If used, install the spacer on the bearing.

Alternator Repair bridge and fasten at the studs. Connect the wires from the diodes to the studs on the diode bridge. Install and tighten the three lockwashers and nuts. c. Install the brushes in the brush holders. To hold the brushes in position, put a pin through the hole in the brush holders. Apply a thin layer of oil to the lip of the seal for the bearing. 6. On Motorola alternators, install parts as follows: a. Install the diode bridge on the stator. Use pliers to keep the heat from the soldering iron away from the diodes. b. Install the capacitor, diode set, and terminal on the diode bridge. Align the marks made during removal and install the stator and bridge assembly in the rear housing. 7. Align the marks made during disassembly. Carefully install the stator and the rear housing over the rotor. Do not damage the seal while sliding the housing over the rotor shaft. Install the front housing. 8. Install the four screws to hold the alternator together. On Delco alternators, remove pin to release the brushes. 9. On Motorola alternators, install the brush holder and brushes. Make sure the washer is on the righthand screw. Install the voltage regulator and tighten the screws. 10. On Leece-Neville alternators, install the brushes, voltage regulator, or diode set in the reverse order of removal.

CAUTION

Hold the rotor in a vise that has soft jaws. Do not tighten the vise more than necessary. 3. Install the front housing on the rotor. If used, install the spacer or shield, shaft key, and washer. Install the fan, pulley, lockwasher, and nut. Tighten the nut to 54 to 81 Nm (40 to 60 lbf ft).

CAUTION

Be sure to install the insulators. Make sure the heat sink does not touch the housing. 4. Install the diode bridge and heat sink in the reverse order of disassembly. Make sure the insulators and washers are in the correct positions. Install the capacitor. 5. On Delco alternators, install parts as follows: a. Install the brush and holder, voltage regulator, and diodes from the inside of the alternator. Make sure the insulator sleeves are on the screws for the brush holder. Install the capacitor. b. Install the stator in the rear housing. Connect the three wires from the stator to the diode

Install

1. Install the alternator in the bracket on the engine, and adjust the tension of the belt. 2. Connect all wires and the connector according to the labels made during removal. Also see the schematic diagram for your alternator in Figure 2. Make sure all wires are connected correctly and all fasteners are tight. See Figure 3. 3. Check the indicator light or the ammeter to check the operation of the alternator. The indicator light for Type A alternators will only be ON if the battery is discharged.

Alternator Repair

2200 YRM 2

Figure 4. Type A Alternators, Exploded Views

2200 YRM 2 Legend for Figure 4 A. DELCO 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. INSULATOR PLUG AND BEARING BEARING SEAL BOLT HOUSING VOLTAGE REGULATOR LOCKWASHER BRUSH AND HOLDER BRUSH SPRING WASHER ROTOR STATOR DIODES B. MOTOROLA 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 26. NUT SCREW DIODE BRIDGE CAPACITOR BEARING SLIP RINGS TERMINAL PULLEY FAN RETAINER SPACER SHIELD GASKET

Alternator Repair

A. LEECE-NEVILLE 1. 2. 3. 4. 5. 6. 7. 8. TERMINAL DIODE SET BRUSH AND SPRING BRUSH HOLDER VOLTAGE REGULATOR BEARING RETAINER BEARING FRONT HOUSING 9. 10. 11. 12. 13. 14. 15. 16. BOLT FAN ROTOR STATOR NEGATIVE DIODE BRIDGE POSITIVE DIODE BRIDGE FILTER CAPACITOR REAR HOUSING

Figure 5. Type A Alternator, Exploded View

Alternator Repair

2200 YRM 2 4. Use a punch to remove the rivets or pins that fasten the cover. Remove the cover for access to the stator leads. Discard the cover. See Figure 7. 5. Cut the stator leads as close to the connectors as possible. Install labels on the leads for correct connection during assembly and remove the stator from the rear housing. 6. Use a punch to remove the three baffle pins and remove the baffle. See Figure 7. NOTE: Carefully make a note of the sequence of removal of parts in Step 7 and Step 8 for correct installation. Also make a note of all types of connections (crimp, soldered, or welded) as well as all mechanical fasteners. 7. Remove the three mount screws and BAT terminal nut. See Figure 8. Lift the brush holder, voltage regulator, and diode bridge from the housing. 8. Open the crimps or use a soldering iron and disconnect the connectors to separate the brush holder, voltage regulator, and diode bridge. 9. If the bearing will be replaced in the rear housing, remove the bearing and retainer ring.

ALTERNATOR TYPE B Remove and Disassemble WARNING

Always disconnect the battery ground cable before making repairs to prevent possible damage and injury. Install a tag on the battery terminal so that no one connects the cable on the terminal. NOTE: Use the Troubleshooting and General Check and Adjustment, Low Output Check (Type A or Type B), High Output Check (Type A or Type B), Brushes Circuit Check, Diodes Check, Diode Bridge Check, Rotor Field Winding Check, Stator Windings Check, and Voltage Regulator Check procedures of this YRM before starting any repair procedures. Make sure that repair or replacement of that part is necessary before removal, disassembly, or replacement of the part. NOTE: There are some checks of the alternator that are done with the alternator on the engine. See General Check and Adjustment, Low Output Check (Type A or Type B), High Output Check (Type A or Type B), Brushes Circuit Check, Diodes Check, Diode Bridge Check, Rotor Field Winding Check, Stator Windings Check, and Voltage Regulator Check procedures of this YRM before starting any removal or repair procedures. 1. Disconnect the battery ground cable. See Figure 6, Figure 7, and Figure 8. Install labels and disconnect the wires at the alternator. Disconnect the wire connector. Loosen the alternator mount capscrews and remove the drive belt. Remove the capscrews that hold the alternator to the engine. 2. Put a mark on each housing and on the stator for correct alignment during assembly. Remove the bolts that hold the housings together. Separate the housings and stator. 3. Put the rotor in a vise that has soft jaws. Do not tighten the vise to cause rotor distortion. Use a socket wrench to remove the pulley nut. Remove the pulley, collar, fan, outside collar, front housing, and inside collar from the rotor. NOTE: The cover must be replaced if the parts will be removed from the stator. If necessary, remove the stator as described in Step 4 and Step 5.

Clean CAUTION

Never use solvent on the parts of the alternator.

CAUTION

Compressed air can move particles so that they cause injury to the user or to other personnel. Make sure that the path of the compressed air is away from all personnel. Wear protective goggles or a face shield to prevent injury to the eyes. NOTE: If necessary, use fine abrasive cloth to polish the slip rings. The abrasive cloth must be number 500 to 600. Remove all dust. Turn the rotor while polishing the slip rings. Use compressed air to remove dirt from the alternator. Clean the brushes and slip rings with a clean, dry cloth.

2200 YRM 2

Alternator Repair

A. DELCO 1. 2. 3. 4. 5. 6. 7. NUT PULLEY COLLAR OUTSIDE FAN OUTSIDE COLLAR FRONT HOUSING INSIDE COLLAR 8. 9. 10. 11. 12. 13. 14. STATOR ROTOR AND FAN BAFFLE SCREW DIODE BRIDGE BRUSHES AND HOLDER VOLTAGE REGULATOR 15. 16. 17. 18. 19. 20. COVER REAR HOUSING BALL BEARING RETAINER RING TERMINAL SET BOLT

Figure 6. Type B Alternator, Exploded View

Assemble

1. If the bearing was removed from the rear housing, install a new retainer ring. See Figure 6.

connect the parts as originally assembled. Use a pin to hold the brushes in the brush holder. 4. Put a thin coating of silicon grease on the inside of the rear housing under the diode bridge. 5. Install the bridge, regulator, and brush holder assembly in the rear housing and install the screws as removed during disassembly. 6. Install the baffle and use a punch to fasten the pins. 7. Align the marks made during disassembly and install the stator in the rear housing. Use pliers on the connectors of the diode bridge to keep heat from the diodes. Use a soldering iron to connect the stator leads to the connectors.

CAUTION

The bearing is not completely installed until Step 11 is complete. 2. Install a new bearing by pushing on the new bearing outer race until the bearing hits the bottom in the rear housing. 3. Assemble the voltage regulator, diode bridge, and brush holder on a flat surface. Put crimps in the connectors or solder the connectors to fasten and

Alternator Repair

2200 YRM 2

NOTE: TYPE B ONLY. 1. REAR HOUSING 2. VOLTAGE REGULATOR 3. BRUSH HOLDER 4. DIODE BRIDGE 5. TERMINALS FOR STATOR LEADS 6. NUT ON "BAT" TERMINAL 7. MOUNT SCREWS 8. SOLDERED OR WELDED CONNECTOR 9. BRUSH PIN

NOTE: TYPE B ONLY. 1. REAR HOUSING 2. COVER 3. COVER RIVETS OR PINS 4. BAFFLE PINS 5. BOLTS TO FASTEN HOUSINGS TOGETHER

Figure 8. Inside Rear Housing

Figure 7. Outside Rear Housing 8. Install a new cover using rivets or pins to fasten the cover to the rear housing. 9. If necessary, install the bearing in the front housing. Put the rotor in a vise with soft jaws and install the inner collar, front housing, outer collar, fan, collar pulley, and nut on the rotor. Tighten the nut to 54 to 108 Nm (40 to 80 lbf ft). 10. Align the front and rear housings using the marks made during disassembly. Push on both the inner and outer races of the rear bearing to push the two housings and stator together. Install the three bolts that fasten the alternator together. 11. Push on both the inner and outer race of the rear bearing so that the outer race is 1.9 to 2.2 mm (0.075 to 0.087 in.) below the surface of the rear housing.

Install

1. Install the alternator in the bracket on the engine and adjust the tension of the belt. 2. Connect all wires and the connector according to the labels made during removal. Also see the schematic diagram for your alternator in Figure 2. Make sure all wires are connected correctly and all fasteners are tight. See Figure 7. 3. Check the indicator light or the ammeter to check the operation of the alternator. The indicator light can also be ON if the alternator output is too high on Type B alternators.

10

2200 YRM 2

Low Output Check (Type A or Type B)

General Check and Adjustment

There are no adjustments for the alternator or most regulators. One Delco alternator and the Leece-Neville alternator has a voltage adjustment. Always check the general condition of the complete system before doing a complete check on each part. Check the general condition of the following parts: (1) battery, (2) battery cables and connections, and (3) alternator and regulator wires and connectors. Also check the condition and tension of the fan belt for the alternator.

CAUTION

Do not change the polarity of the circuits. Do not connect any wires in the circuits, except as described in these instructions. Never connect the wire from the terminal marked BAT to an open circuit. When connecting a charger or another battery, connect the positive terminals to the positive terminal of the battery. Then connect the negative terminal to a clean metal part of the engine. Disconnect the charger or other battery in the reverse order. Problems in the charging circuit are indicated by one or more of the following: The starter motor turns slowly. The battery voltage is low because of low alternator output or a bad battery. The specific gravity readings are low. Battery is not fully charged or is damaged. The battery uses more than 30 ml (1 oz) of water per cell per month. The alternator output is too high. The two problems of the charging circuit are low output and high output. Low output causes a low battery and difficult starting. A high output causes heating of the battery and evaporation of water from the electrolyte. The following two checks will find out if the alternator, regulator, or wiring has a charging fault. The two checks will also find out if the charging system has a correct output. Do the following two checks before removal, disassembly, or replacement of alternator or regulator. NOTE: Information on alternators manufactured outside the United States is in the YRM sections for lift trucks that use those alternators.

CAUTION

NEVER operate the engine if the alternator output BAT terminal is not connected to the battery. Do not short-circuit or connect jumper wires to any of the alternator terminals unless told to by the procedures. Make sure polarity is correct before connecting a battery charger or another battery. Remove the battery cables and clean the terminals and cable connectors. Inspect the insulation on the wires. Make sure all the fasteners and connections are clean and tight. If necessary, use a water and soda solution to clean the top of the battery. Do NOT remove the cell caps or permit the water and soda solution to get in the battery.

WARNING

Put the transmission in NEUTRAL. Apply the parking brake.

Low Output Check (Type A or Type B)

CAUTION

Do not connect the wire from the BAT terminal to the electrical ground. NOTE: Make sure the wire from the voltmeter makes contact with each terminal on the alternator. 1. Connect a voltmeter between the BAT terminal and the electrical ground. Turn the key switch to the ON position and check the reading. 2. Connect a voltmeter to the field terminal and the regulator terminal. Follow the procedure in Step 1 and check the readings. 3. If there are no readings on the voltmeter during Step 1 and Step 2, check for an open circuit between each terminal and the battery. 4. If there are readings on the voltmeter during Step 1 and Step 2, disconnect the cable for the electrical ground on the battery. 5. Make connections to the Type A alternator as shown in Figure 9. Make connections to the Type B alternator as shown in Figure 10. 6. Connect the cable for the electrical ground on the battery.

11

Low Output Check (Type A or Type B) 7. Connect a carbon pile across the terminals of the battery. 8. Run the engine at 2000 to 2500 rpm. Adjust the carbon pile until the maximum charging rate is reached. 9. Read the value of the maximum charging rate shown on the alternator housing or in the section Capacities and Specifications for your lift truck. Read the ammeter. The reading on the ammeter must be within 10% of the maximum value.

2200 YRM 2

NOTE: TYPE B ONLY. 1. 2. 3. 4. BATTERY CARBON PILE VOLTMETER RESISTOR (35-OHM, 5-WATT TO 500-OHM, 1/2-WATT) 5. 6. 7. 8. AMMETER ALTERNATOR BAT TERMINAL CONNECT TO L TERMINAL

NOTE: TYPE A ONLY. 1. 2. 3. 4. CARBON PILE BATTERY AMMETER STARTER 5. ALTERNATOR 6. BAT TERMINAL 7. FIELD TERMINAL

Figure 10. Alternator Output Check 11. On Type A Delco alternators, do the following checks:

CAUTION

Do not push the screwdriver into the hole for more than 25 mm (1 in.). a. If the output shown is not within 10%, put a screwdriver into the hole shown in Figure 11. b. Run the engine at 2000 to 2500 rpm. Adjust the carbon pile until the maximum charging rate is reached. c. If the output is within 10%, check the field winding. If the field winding is in good condition, replace the voltage regulator.

Figure 9. Alternator Output Check 10. If the ammeter reading is within 10%, the alternator is in good condition. Check the starter or wires for problems. Some alternators on larger lift trucks have a voltage adjustment. See Figure 12. For alternators with the voltage adjustment, do Step a to set the voltage: a. The voltage setting can be increased by changing the position of the adjustment plug. LO is the lowest voltage setting. 2 is medium low and 3 is the medium setting. The voltage setting is highest when HI is aligned with the arrow on the alternator. Change the setting as necessary.

12

2200 YRM 2 d. If the output is not within 10%, check the wires to the brushes, diodes, diode bridge, field winding, and stator. e. Remove the screwdriver, ammeter, and variable resistor.

High Output Check (Type A or Type B)

NOTE: DELCO TYPE A SHOWN. 1. HOLE 2. MAKE SURE SCREWDRIVER TOUCHES HOUSING AND METAL TAG. Figure 11. Electrical Ground on Field Winding

High Output Check (Type A or Type B)

1. Connect a voltmeter from the regulator terminal to the electrical ground. Check the reading on the voltmeter. See Figure 9 or Figure 10. 2. If there are no readings, check for an open circuit between the regulator terminal and the battery. 3. If there is a reading, connect a voltmeter between the BAT terminal and the electrical ground. 4. Increase the engine speed until the maximum voltage reading is reached. 5. If the voltage shown is more than 15.5 volts on a 12-volt system or 31 volts on a 24-volt system, disassemble the alternator and do the remainder of the checks. For alternators with the voltage adjustment, do the following: a. Delco alternator. The voltage setting can be increased or decreased by changing the position of the adjustment plug. See Figure 12. LO is the lowest voltage setting. 2 is medium low and 3 is the medium setting. The voltage setting is highest when HI is aligned with the arrow on the alternator. Do not change the setting when engine is operating. Change the setting as necessary. b. Leece-Neville alternator. Remove the screw in the cover. See Figure 12. Start the engine. Connect a voltmeter across the battery terminals and use a screwdriver to adjust the voltage.

13

Brushes Circuit Check

2200 YRM 2

1. VOLTAGE ADJUSTMENT CAP SHOWN IN MEDIUM HIGH (3) POSITION.

2. DELCO TYPE A 3. LEECE-NEVILLE

Figure 12. Voltage Adjustment

Brushes Circuit Check

DELCO ALTERNATORS

1. Use an ohmmeter that has a 1.5 volt cell. (Use the lowest range scale.) Connect the ohmmeter from the clip for the brushes to the metal housing. Make the test, then connect the ohmmeter leads in the reverse direction and test again. 2. If both readings are zero, either the wire or the clip for the brushes has a short circuit to ground, or the voltage regulator has damage. 3. The cause of the problem can also be a missing washer, a missing sleeve on a screw, or a damaged insulator. See Figure 13. Remove the screw and inspect the insulator. If the insulator is in good condition, do Step 4, Step 5, and Step 6. 4. Connect the ohmmeter from the wire of the diodes to the housing. 5. If the reading is zero on the ohmmeter, either the wire to the diodes has a short circuit to ground, or the voltage regulator has damage. 6. The cause of the problem can be a missing washer, a missing sleeve on a screw, or a damaged insulator. Remove the screw and inspect the insulator. If the insulator is in good condition, replace the voltage regulator.

14

2200 YRM 2

Brushes Circuit Check

MOTOROLA ALTERNATORS

1. Use an ohmmeter or a 12-volt test lamp to check the brushes as shown in Figure 13. 2. For correct operation, there must be continuity between A to B and C to D. There must be no continuity from A to D or from C to B. See Figure 13. If there is continuity, the brushes are connected to the wrong terminal.

A. DELCO 1. 2. 3. 4. BRUSH HOLDER CAPACITOR DIODE BRIDGE NUTS

B. MOTOROLA 5. DIODES 6. INSULATOR WASHERS 7. OHMMETER

Figure 13. Brushes Circuit Check

15

Diode Bridge Check

2200 YRM 2

Diodes Check

Use an ohmmeter with a 1.5 volt cell. Use the lowest range scale. Connect one lead of tester to the common connector and one lead to one of the three diode connections. Make the test; then reverse the tester leads and make the same test. If both readings are the same reading, replace the diodes. A good diode will show one high reading and one low reading. See Figure 14.

A. DELCO TYPE A 1. OHMMETER 2. COMMON FOR DIODE SET 3. DIODE SET CONNECTIONS

B. MOTOROLA

Figure 14. Diodes Check

Diode Bridge Check

DELCO AND LEECE-NEVILLE ALTERNATORS CAUTION

Do not use a 120-volt test lamp to check the diode bridge. Use a 12-volt tester to prevent diode damage. To check the diode bridge, connect the ohmmeter to one heat sink and each of the three diodes in turn. Check the readings; then connect the leads in the reverse direction. If both readings are the same, replace the diode. Repeat the test for the other heat sink checking in both directions. See Figure 15.

MOTOROLA ALTERNATORS

Remove the wires for the diode set from the terminals A, B, and C. Use an ohmmeter, diode tester, or 12-volt test lamp to check between points A, B, and C, and points D and E. Good diodes indicate continuity in only one direction. If any parts are bad, replace the diode bridge assembly. See Figure 14.

16

2200 YRM 2

Rotor Field Winding Check

A. DELCO TYPE A 1. BRUSH HOLDER 2. HEAT SINK

B. DELCO TYPE B 3. VOLTAGE REGULATOR 4. DIODE Figure 15. Diode Bridge Check

C. LEECE-NEVILLE 5. OHMMETER

Rotor Field Winding Check

Connect an ohmmeter to each slip ring and check for open circuits. If the reading is high (infinity), the winding has an open circuit. To check the resistance of the field, connect the ohmmeter to the two slip rings. The correct reading is 4.0 to 4.5 ohms. If the reading is less than specified, there is a short circuit in the windings. If the reading is more than specified, there is excessive resistance in the windings. NOTE: Make sure the needle in the ohmmeter always returns to zero correctly. The readings will change when the temperature of the winding changes. To check the electrical ground, connect the ohmmeter between either slip ring and the electrical ground as shown in Figure 16. Replace the rotor if the reading is less than infinity. Figure 16. Rotor Coil Checks

17

Troubleshooting

2200 YRM 2

Stator Windings Check

To check the stator windings for electrical ground, connect an ohmmeter as shown in Figure 17. There must be no continuity between any of the stator terminals and the metal housing. To check the stator for open circuits, connect the ohmmeter or test lamp between each pair of wires to the stator as shown in Figure 17. If the test lamp does not illuminate or the meter reading is high, the windings have an open circuit.

Figure 17. Stator Checks

Voltage Regulator Check

Use a voltage regulator test device. Do not use an ohmmeter. If the voltage regulator has damage, replace the voltage regulator.

Troubleshooting

PROBLEM Battery is charged above normal. POSSIBLE CAUSE Alternator is not charging correctly. Electrical ground in wire to brush or clip. High resistance in the circuit. PROCEDURE OR ACTION Repair or install new parts. Repair or install new parts. Repair or install new parts.

Battery uses more water than normal.

Battery is charging more than normal. Alternator has damage in the field windings, diodes, diode bridge, or stator. Battery has damage or is too old.

Replace voltage regulator. Install new parts.

Replace battery.

18

2200 YRM 2

Troubleshooting

PROBLEM There is no charge from the alternator.

POSSIBLE CAUSE The brushes are worn or damaged. Weak springs for brushes. Brushes or brush holders do not move freely. Dirt on the slip rings.

PROCEDURE OR ACTION Install new brushes. Install new parts. Clean or install new parts.

There is no charge from the alternator. The indicator light or ammeter indicates a discharged condition when the rpm is high and the load is high.

There is an electrical ground in the field winding.

Replace rotor or alternator.

Drive belt is not tight or is broken.

Adjust or replace drive belt.

Ammeter or the indicator light indicates a discharged condition at all speeds.

There is a short circuit in the diodes.

Install new parts.

There is an electrical ground at the end of the windings. The voltage regulator has damage.

Replace rotor or alternator. Replace voltage regulator.

19

NOTES ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________ ____________________________________________________________

20

Yale Materials Handling Corp. 1400 Sullivan Dr., Greenville, NC 27834-2011

2200 YRM 2

12/04 (3/03)(9/02)(8/01) Printed in U.S.A.

You might also like

- Control Electronico Del Motor GM 2Document18 pagesControl Electronico Del Motor GM 2adelmomouraNo ratings yet

- Troubleshooting Guide for Control Circuit FaultsDocument125 pagesTroubleshooting Guide for Control Circuit FaultsMahmoud AshmawyNo ratings yet

- VOLTAGE DROP Testing Overview and Lab SheetDocument6 pagesVOLTAGE DROP Testing Overview and Lab SheetSabastian Edwards100% (1)

- Charging System: PrecautionDocument17 pagesCharging System: PrecautionlogammicNo ratings yet

- DC Alternator TestDocument5 pagesDC Alternator TestAbdul KhaliqNo ratings yet

- Accelerator Control System OverviewDocument5 pagesAccelerator Control System OverviewING. RUBENSNo ratings yet

- The Charging System Has Three Main Components: The Alternator, The Voltage Regulator, and The BatteriesDocument20 pagesThe Charging System Has Three Main Components: The Alternator, The Voltage Regulator, and The BatteriesMae CherryNo ratings yet

- Bucket Hydraulic SystemDocument4 pagesBucket Hydraulic SystemNay SoeNo ratings yet

- Alternator Regulator TroubleshootingDocument2 pagesAlternator Regulator Troubleshootingsheba1023No ratings yet

- ENGINE CONTROL SYSTEM TROUBLESHOOTING GUIDEDocument486 pagesENGINE CONTROL SYSTEM TROUBLESHOOTING GUIDEkendediNo ratings yet

- PMS 601c三维图使用说明 - mono - cinese - 060629Document43 pagesPMS 601c三维图使用说明 - mono - cinese - 060629Handy Lee100% (1)

- Troubleshooting Guidelines: AlternatorsDocument5 pagesTroubleshooting Guidelines: AlternatorsanilNo ratings yet

- Charging System - Test: Previous ScreenDocument15 pagesCharging System - Test: Previous ScreenWalterNo ratings yet

- Eccentric Weight Housing Oil - Change: Operation and Maintenance ManualDocument3 pagesEccentric Weight Housing Oil - Change: Operation and Maintenance ManualLuis AugustoNo ratings yet

- Alternator Warning Light PDFDocument4 pagesAlternator Warning Light PDFEriflonaNo ratings yet

- Group 13 Monitoring System: 1. OutlineDocument13 pagesGroup 13 Monitoring System: 1. OutlineRafał DworakNo ratings yet

- Main Hydraulic Pump Air - PurgeDocument3 pagesMain Hydraulic Pump Air - Purgemekanicobucaro100% (1)

- Air Conditioning Compressor/Clutch Service ManualDocument2 pagesAir Conditioning Compressor/Clutch Service ManualromulofcarreraNo ratings yet

- Hydraulic Master CylinderDocument35 pagesHydraulic Master CylinderBernard Jnr NkhomaNo ratings yet

- A Shop ManualDocument93 pagesA Shop Manualhectorhernandez311No ratings yet

- So, You Think You Know Shuttle Valves?Document6 pagesSo, You Think You Know Shuttle Valves?AkileshNo ratings yet

- 1920s Drum Brakes to Modern Disc Brakes EvolutionDocument2 pages1920s Drum Brakes to Modern Disc Brakes EvolutionAfit KenshyNo ratings yet

- Directional Control Valves ExplainedDocument48 pagesDirectional Control Valves ExplainedMohamed ZahranNo ratings yet

- Alternator Description and TestingDocument11 pagesAlternator Description and TestingadillukNo ratings yet

- 621 State Street Case Construction Racine, Wisconsin 53404 866-542-2736 x1Document3 pages621 State Street Case Construction Racine, Wisconsin 53404 866-542-2736 x1Jhonny RodriguezNo ratings yet

- SEHS7633 BattTestProc PDFDocument29 pagesSEHS7633 BattTestProc PDFSergio Velarde Romay100% (1)

- Electronic Control System ComponentsDocument4 pagesElectronic Control System ComponentsThein Htoon lwinNo ratings yet

- Crankshaft - InstallDocument7 pagesCrankshaft - InstallLeonardo PerezNo ratings yet

- Hydraulics Part 2Document28 pagesHydraulics Part 2MACHINERY101GEAR100% (1)

- Coach Bat. Diconnect Solenoid How It Works 5322019100Document9 pagesCoach Bat. Diconnect Solenoid How It Works 5322019100Clifton Jamison100% (1)

- d9n Track-Type TractorDocument78 pagesd9n Track-Type Tractorandresfido123No ratings yet

- HWH Joystick-Controlled 200/210 Series Leveling SystemDocument40 pagesHWH Joystick-Controlled 200/210 Series Leveling SystemEdward Tillman100% (3)

- Troubleshooting PDFDocument95 pagesTroubleshooting PDFwillianNo ratings yet

- Hydrostatic System - Test and AdjustDocument26 pagesHydrostatic System - Test and AdjustRajan Mullappilly100% (1)

- Charging SystemDocument24 pagesCharging SystemAnup M Upadhyaya100% (1)

- 001-008 Camshaft: InstallDocument6 pages001-008 Camshaft: InstallNaing Min HtunNo ratings yet

- Ottawa Air Brakes Service ManualDocument32 pagesOttawa Air Brakes Service ManualcbudkuleyNo ratings yet

- ChassisElectrical PDFDocument111 pagesChassisElectrical PDFDhany SiregarNo ratings yet

- Hydro-Boost: GM Full Size Vans 1987-1997 Repair GuideDocument7 pagesHydro-Boost: GM Full Size Vans 1987-1997 Repair GuideEndry Enrique Rincón VargasNo ratings yet

- The Basics of Crank and Cam Sensors PDFDocument12 pagesThe Basics of Crank and Cam Sensors PDFmasakpNo ratings yet

- C9 Valve SpecDocument7 pagesC9 Valve SpecWa TokeNo ratings yet

- Water Temperature Regulator - Remove and InstallDocument3 pagesWater Temperature Regulator - Remove and InstallMbahdiro KolenxNo ratings yet

- Understanding and Troubleshooting Hydrostatic SystemsDocument7 pagesUnderstanding and Troubleshooting Hydrostatic Systemsvinod ybNo ratings yet

- Device Test ModeDocument14 pagesDevice Test ModeDANIEL VARGAS RODRIGUEZNo ratings yet

- ECM Engine Control System SectionDocument1,061 pagesECM Engine Control System SectionTeguh SantosoNo ratings yet

- Testeoajuste320l PDFDocument222 pagesTesteoajuste320l PDFJimmyJavierTorresSalas100% (1)

- Install Cylinder Block Diesel EngineDocument11 pagesInstall Cylinder Block Diesel EngineCutiiVitezaNo ratings yet

- D6D Tractor Power TrainDocument17 pagesD6D Tractor Power Trainariel rubioNo ratings yet

- 320, 320 L and 320 N Operation Hydraulic SystemDocument162 pages320, 320 L and 320 N Operation Hydraulic SystemF Labio AlexNo ratings yet

- 2.6 CLSS Electronics.Document7 pages2.6 CLSS Electronics.agus haryono100% (1)

- Solenoid Valve (Proportional Reducing) - Calibrate - 084514Document11 pagesSolenoid Valve (Proportional Reducing) - Calibrate - 084514Juan Lopez100% (1)

- 08 TR Shoot-Hyd SysDocument92 pages08 TR Shoot-Hyd SysAnonymous ByaV1f100% (2)

- Global Service Learning: 300D Series Hydraulic Excavators - Tier Iii EnginesDocument61 pagesGlobal Service Learning: 300D Series Hydraulic Excavators - Tier Iii EnginesDe JavuNo ratings yet

- Murray Model 405000x8c Lawn Tractor (2004) Parts ListDocument16 pagesMurray Model 405000x8c Lawn Tractor (2004) Parts ListKarloz MedinaNo ratings yet

- Knowing Your Cooling SystemDocument124 pagesKnowing Your Cooling SystemAbdul AzisNo ratings yet

- Hydraulic Diagrams WA380-6 PDFDocument2 pagesHydraulic Diagrams WA380-6 PDFHenry SalasNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Electrical System/Lights: H36.00-48.00E (H800-1050E) (D117)Document20 pagesElectrical System/Lights: H36.00-48.00E (H800-1050E) (D117)Nguyễn Văn Hùng0% (1)

- Alternator WithDocument26 pagesAlternator Withjaneth.10037No ratings yet

- Ebook - How To - The Morrow Guide To Knots (647 Knots in Color) - Quill (English, Illustrated, Crafts, Macrame, Bondage)Document253 pagesEbook - How To - The Morrow Guide To Knots (647 Knots in Color) - Quill (English, Illustrated, Crafts, Macrame, Bondage)Isacio San Gon100% (2)

- Esr 5000Document84 pagesEsr 5000Ilarion CiobanuNo ratings yet

- 445028019 Renault Logan после 2009 Sandero Sandero Stepway 1 4 1 6 8V 1 6 16VDocument1 page445028019 Renault Logan после 2009 Sandero Sandero Stepway 1 4 1 6 8V 1 6 16VIlarion CiobanuNo ratings yet

- 2954 4960 01 - Branded EU Lighting Tower - ENDocument50 pages2954 4960 01 - Branded EU Lighting Tower - ENIlarion Ciobanu100% (1)

- Bomba HidraulicaDocument16 pagesBomba HidraulicaIlarion Ciobanu100% (1)

- Cabina Del OperadorDocument20 pagesCabina Del OperadorIlarion Ciobanu100% (1)

- Capacidades y EspecificacionesDocument16 pagesCapacidades y EspecificacionesIlarion CiobanuNo ratings yet

- 2954 4650 00 - Qas 600 - enDocument58 pages2954 4650 00 - Qas 600 - enIlarion CiobanuNo ratings yet

- 151Document70 pages151Ilarion CiobanuNo ratings yet

- 2954 2960 03 - Qas 125-150 - enDocument108 pages2954 2960 03 - Qas 125-150 - enIlarion CiobanuNo ratings yet

- 2954 2990 00 - QAS 330 John Deere - ENDocument52 pages2954 2990 00 - QAS 330 John Deere - ENIlarion Ciobanu100% (1)

- 2954 2460 02 - Oah 2-Oav 4 - enDocument34 pages2954 2460 02 - Oah 2-Oav 4 - enIlarion CiobanuNo ratings yet

- SampleDocument2 pagesSampleIlarion CiobanuNo ratings yet

- Atlas Copco Seri Xa 60-70-80-120-160 DD y Nueva Serie Deutz Xas DDDocument36 pagesAtlas Copco Seri Xa 60-70-80-120-160 DD y Nueva Serie Deutz Xas DDRay Cepeda Mena100% (5)

- 2954 2980 00 - QAS 250 John Deere - ENDocument52 pages2954 2980 00 - QAS 250 John Deere - ENIlarion CiobanuNo ratings yet

- Data SourcesDocument1 pageData SourcesIlarion CiobanuNo ratings yet

- ST - Steering SystemDocument34 pagesST - Steering SystemIlarion CiobanuNo ratings yet

- Primera: GI MA EM LC QG16/18DE SR20DE CD20T FE CL MT AT FA RA BR ST RS BT HA EL IDXDocument2 pagesPrimera: GI MA EM LC QG16/18DE SR20DE CD20T FE CL MT AT FA RA BR ST RS BT HA EL IDXIlarion CiobanuNo ratings yet

- SMJ - Super Multiple JunctionDocument7 pagesSMJ - Super Multiple JunctionIlarion CiobanuNo ratings yet

- FE - Accelerator Control, Fuel & Exhaust SystemsDocument10 pagesFE - Accelerator Control, Fuel & Exhaust SystemsIlarion CiobanuNo ratings yet

- SU - Front & Rear SuspensionDocument26 pagesSU - Front & Rear SuspensionIlarion CiobanuNo ratings yet

- MT - Manual TransaxelDocument64 pagesMT - Manual TransaxelIlarion CiobanuNo ratings yet

- MA - MaintenanceDocument28 pagesMA - MaintenanceIlarion CiobanuNo ratings yet

- Gear CalcDocument2 pagesGear CalcIlarion CiobanuNo ratings yet

- MT - Manual TransaxelDocument64 pagesMT - Manual TransaxelIlarion CiobanuNo ratings yet

- Primera: GI MA EM LC QG16/18DE SR20DE CD20T FE CL MT AT FA RA BR ST RS BT HA EL IDXDocument2 pagesPrimera: GI MA EM LC QG16/18DE SR20DE CD20T FE CL MT AT FA RA BR ST RS BT HA EL IDXIlarion CiobanuNo ratings yet

- BT - Body & TrimDocument62 pagesBT - Body & TrimIlarion CiobanuNo ratings yet

- SMJ - Super Multiple JunctionDocument7 pagesSMJ - Super Multiple JunctionIlarion CiobanuNo ratings yet

- FE - Accelerator Control, Fuel & Exhaust SystemsDocument10 pagesFE - Accelerator Control, Fuel & Exhaust SystemsIlarion CiobanuNo ratings yet

- G66-99 (2013) Standard Test Method For Visual Assessment of Exfoliation Corrosion Susceptibility of 5XXX Series Aluminum Alloys (ASSET Test)Document5 pagesG66-99 (2013) Standard Test Method For Visual Assessment of Exfoliation Corrosion Susceptibility of 5XXX Series Aluminum Alloys (ASSET Test)islamakthamNo ratings yet

- Source Code Programs to Print Triangles, Pyramids and Pascal's TriangleDocument28 pagesSource Code Programs to Print Triangles, Pyramids and Pascal's TriangleaaushNo ratings yet

- Lilypond Essay On Automated Music Engraving: The Lilypond Development TeamDocument39 pagesLilypond Essay On Automated Music Engraving: The Lilypond Development TeamSookwan LeeNo ratings yet

- What Are Microservices - An Introduction To Microservice Architecture - DZone MicroservicesDocument5 pagesWhat Are Microservices - An Introduction To Microservice Architecture - DZone MicroservicesAbhishek BharadwajNo ratings yet

- OOAD Review: Tcs InternalDocument36 pagesOOAD Review: Tcs InternalSourav DasNo ratings yet

- Disk SectorDocument5 pagesDisk Sectorkarakedi123No ratings yet

- How To InstallDocument2 pagesHow To Installbenzen353No ratings yet

- Lecture9 SIQ3003 PDFDocument18 pagesLecture9 SIQ3003 PDFFion Tay0% (1)

- E 350 12 PDFDocument28 pagesE 350 12 PDFHamdi NaufelNo ratings yet

- ID Pengaruh Persistensi Laba Alokasi Pajak Antar Periode Ukuran Perusahaan PertumbuDocument21 pagesID Pengaruh Persistensi Laba Alokasi Pajak Antar Periode Ukuran Perusahaan PertumbuGheaMarisyaPuteriNo ratings yet

- RCT Appraisal Sheets 2005 EnglishDocument4 pagesRCT Appraisal Sheets 2005 EnglishAmanda SoebadiNo ratings yet

- Instruction Manual Fisher 249 Caged Displacer Sensors en 134918Document20 pagesInstruction Manual Fisher 249 Caged Displacer Sensors en 134918Senthil KumarNo ratings yet

- EEE Digital Assignment (Software) : Logic GatesDocument12 pagesEEE Digital Assignment (Software) : Logic Gatesbolbo naNo ratings yet

- 10.1007@978 3 030 47717 2Document413 pages10.1007@978 3 030 47717 2riadhNo ratings yet

- Orbitrap Espectrometro de MassasDocument11 pagesOrbitrap Espectrometro de MassasDiegoNo ratings yet

- Jitter, Noise, and Signal Integrity at High-Speed A Tutorial-Part I PDFDocument2 pagesJitter, Noise, and Signal Integrity at High-Speed A Tutorial-Part I PDFkunduru_reddy_3No ratings yet

- ISD4003 Rev 1 1 (Voice Recorder)Document37 pagesISD4003 Rev 1 1 (Voice Recorder)Guillermo Hernandez100% (1)

- Experiment 6: Coefficient of Restitution: Nicole Irvin H. Balbastro, Phy10L/BC2Document4 pagesExperiment 6: Coefficient of Restitution: Nicole Irvin H. Balbastro, Phy10L/BC2GedNo ratings yet

- Sanog 13 Mpls Lab2v5Document8 pagesSanog 13 Mpls Lab2v5innovativekaluNo ratings yet

- RockwellarmymillDocument82 pagesRockwellarmymillCurt WiseNo ratings yet

- Data Management - Exer1Document2 pagesData Management - Exer1ron barceloNo ratings yet

- Smartotdr Testing Solution Brochures enDocument2 pagesSmartotdr Testing Solution Brochures enzafraniarifinNo ratings yet

- Examples of Z Soil Application To Dam Engineering PDFDocument16 pagesExamples of Z Soil Application To Dam Engineering PDFMirza FadlulahNo ratings yet

- Cswip 3.1 New BookDocument342 pagesCswip 3.1 New BookMohsin Rasul90% (52)

- Kaun Banega Crorepati C++ ProjectDocument47 pagesKaun Banega Crorepati C++ ProjectSam SamNo ratings yet

- Intelligent Stepper Motor Driver With DRV8824Document22 pagesIntelligent Stepper Motor Driver With DRV8824RintheGreatNo ratings yet

- ETHANOL VAPOR PRESSURE AntoineCalculatio PDFDocument2 pagesETHANOL VAPOR PRESSURE AntoineCalculatio PDFTasic NenadNo ratings yet

- Chapter 3 Tutorial QuestionsDocument5 pagesChapter 3 Tutorial QuestionsMolike HononoNo ratings yet

- White Paper Application of Orifice Meter For Accurate Gas Flow Measurement Daniel en 43716Document5 pagesWhite Paper Application of Orifice Meter For Accurate Gas Flow Measurement Daniel en 43716Najem A. SakorNo ratings yet

- Introduction To BiostatisticsDocument19 pagesIntroduction To BiostatisticsMuhammad ShahidNo ratings yet