Professional Documents

Culture Documents

NMDC Limited 3.0 Mtpa Integrated Steel Plant: at Nagarnar, Chhattisgarh

Uploaded by

Danish AhmadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NMDC Limited 3.0 Mtpa Integrated Steel Plant: at Nagarnar, Chhattisgarh

Uploaded by

Danish AhmadCopyright:

Available Formats

NMDC LIMITED 3.

0 MTPA INTEGRATED STEEL PLANT

AT NAGARNAR, CHHATTISGARH

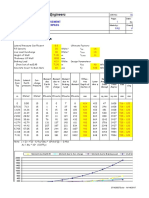

Agency : M/s Siemens VAI Metals Technologies Gmb., Linz LABORATORY BUILDING: DESIGN OF ISOLATED FOOTING "F1" fck Characteristic compressive strength of concrete, = fy Characteristic compressive strength of steel, = Unit weight of concrete Unit weight of soil (dry condition) Unit weight of soil (fully submerged condition) Unit weight of ground water

Depth of column footing below the F.F.L

25 415 25 18 8.19 9.81 1.5 1.5 1.20 200 0.2 0.25 1300 25 200 5 1 6 8 8 1.4 1.2 1.2 1.5 30

N/mm N/mm kN/m kN/m

2 2

p1

Foundation Plan p2 Z

Critical Section for Moment 1

lx

Critical Section for 2 One-way shear

Critical Section for Two-way shear 3

gc gsoil g' gwater h h1 h2 t1 D 0.25 L1 Cmin

w1

= = = = = = = = = mm (a) x = = = = = = = = = = = = =

kN/m3

3

B X

Fx 1

lz

d/2

1

d d/2

kN/m3 m m m mm m mm (b) mm mm kN/m2 kN/m2 kN/m mm mm D A

Section along X-X direction

2

2 p3 Fz A P1 Fx F.G.L. F.F.L. h2 p4 1 Fig. 1 2 Fig. 2

SIGN CONVENTION:

* Vertical load P1: downwards positive

2 Fig. 3

KEY NOTES:

Height of overburden soil, prior to excavation Height between top of concrete and F.G.L.

Thickness of grade slab

P1 Fx Fz P2

= Unfactored axial load acting on column = Lateral force acting in X-X direction = Lateral force acting in Z-Z direction = Dead load due to column supporting pedestals = a * b * L1 * g c = Self-weight of backfill, stored above footing slab = ((A * B) - (a * b)) * (L1 - t1) * gsoil = Force due to surcharge acting on foundation slab = ((A * B) - (a * b)) * w = Self-weight of the footing slab = A * B * D * gc = Total vertical force acting on foundation = P1 + P2 + P3 + P4 + P5 = Total design moment acting about x-x axis = Total design moment acting about z-z axis = Max. and Min. of gross soil pressures (upward) among p1, p2, p3 & p4

= Downward press. due to selfweight of (footing +

Foundation slab thickness @ the face of column R.C.C Pedestal size (a x b) = Unsupported length of pedestal, above the footing, Concrete cover for footing main reinforcement Permissible Net SBC considered for design

Surcharge pressure due to self-weight of grade slab,

* Fx : left to right: +ve x-direction * Fz : top to bottom: +ve z-direction * Mx: anti-clock wise positive * Mz: clock wise positive P p1 = 6Mx AB L1 h1 h p2 = P AB p3 = P AB p4 = P AB

FOOTING DETAILS

AB2 6Mx AB2 6Mx AB2 6Mx AB2 +

6Mz A2B 6Mz A2B 6Mz A2B 6Mz A2B

P3 P4 P5

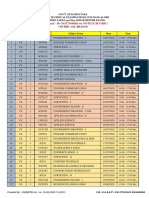

Surcharge pressure considered due to floor live load, Diameter of footing bottom reinforcement Diameter of footing top reinforcement Factor of Safety against overturning Factor of Safety against sliding Factor of Safety against buoyancy Partial load factor considered for design Angle of internal friction Permissible Gross SBC considered (for loads without WL/EQ) Permissible Gross SBC considered (for loads with WL/EQ) Node: Critical #REF! Load Support Reactions P1 Fx Fz (in kN) 234.99 234.99 234.99 234.99 234.99 234.99 (in kN) 9.03 9.03 9.03 9.03 9.03 9.03 (in kN) 11.89 11.89 11.89 11.89 11.89 11.89

w2 b t

Total surcharge load acting on foundation slab,w = w1 + w2

kN/m2

F.O.Soverturning F.O.Ssliding F.O.Suplift gf = = = =

P

Mx

Mz pupward pdown

CALCULATION OF GROSS SAFE BEARING CAPACITY OF SOIL: SBC + Overburden soil

227

kN/m2

Foundation Size Foundation Identity

1.10 (A) = =

m x F1 4

1.10 (B) Nos.

backfill + surcharge) = w + D * gc + (L1 - t1) * gsoil pnet

= Net soil pressure for foundation design

= = pupward - pdown

2 30.8 kN/m

SBC * 1.25 + Overburden soil

277

kN/m2

No. of found. belongs to the group Foundation Force/Moment P Mx Mz

FOR THE DESIGN OF BOTTOM STEEL

FOR THE DESIGN OF TOP STEEL

P2 (in kN) 0.00 0.00 0.00 0.00 0.00 0.00

Other dead-weights P3 P4 (in kN) 23.96 23.96 23.96 23.96 23.96 23.96 (in kN) 7.26 7.26 7.26 7.26 7.26 7.26

P5 (in kN) 6.05 6.05 6.05 6.05 6.05 6.05

Bearing Pressures @ corners p1 p2 p3

2 2 2

X-X Direction pgross,up pgross,up p4

2

Z-Z Direction pgross,up pgross,up @ edge

2

X-X Direction pgross,up pgross,up @ edge

2

Z-Z Direction pgross,up pgross,up @ edge

2

Allowable

2

Check SAFE SAFE SAFE SAFE SAFE SAFE

@ edge

2

@ face

2

@ face

2

@ face

2

@ face

Condition Comb Pmax 1 DL+LL Pmin 1 DL+LL Fxmax Fxmin Fzmax Fzmin Node: Critical Condition Pmax 1 DL+LL 1 DL+LL 1 DL+LL 1 DL+LL 0 Load Comb #N/A

(in kN) (in kN-m) (in kN-m) (in kN/m ) (in kN/m ) (in kN/m ) (in kN/m ) (in kN/m ) 272.26 4.49 -4.50 225.06 184.46 265.55 224.95 277.00 272.26 272.26 272.26 272.26 272.26 4.49 4.49 4.49 4.49 4.49 -4.50 -4.50 -4.50 -4.50 -4.50 225.06 225.06 225.06 225.06 225.06 184.46 184.46 184.46 184.46 184.46 265.55 265.55 265.55 265.55 265.55 224.95 224.95 224.95 224.95 224.95 277.00 277.00 277.00 277.00 277.00

(in kN/m ) (in kN/m ) (in kN/m ) (in kN/m ) (in kN/m ) (in kN/m ) (in kN/m ) (in kN/m2) 265.55 245.25 265.55 245.31 184.46 204.76 184.46 204.70 265.55 265.55 265.55 265.55 265.55 245.25 245.25 245.25 245.25 245.25 265.55 265.55 265.55 265.55 265.55 245.31 245.31 245.31 245.31 245.31 184.46 184.46 184.46 184.46 184.46 204.76 204.76 204.76 204.76 204.76 184.46 184.46 184.46 184.46 184.46 204.70 204.70 204.70 204.70 204.70

Support Reactions P1 Fx Fz (in kN) #N/A (in kN) #N/A (in kN) #N/A

P2 (in kN) 0.00

Other dead-weights P3 P4 (in kN) 23.96 (in kN) 7.26

P5 (in kN) 6.05

Foundation Force/Moment P Mx Mz (in kN) #N/A

Bearing Pressures @ corners p1 p2 p3

2 2 2

X-X Direction pgross,up pgross,up p4

2

Z-Z Direction pgross,up pgross,up @ edge

2

X-X Direction pgross,up pgross,up @ edge

2

Z-Z Direction pgross,up pgross,up @ edge

2

Allowable

2

Check #N/A

@ edge

2

@ face

2

@ face

2

@ face

2

@ face

(in kN-m) (in kN-m) (in kN/m ) (in kN/m ) (in kN/m ) (in kN/m ) (in kN/m ) #N/A #N/A #N/A #N/A #N/A #N/A #N/A

(in kN/m ) (in kN/m ) (in kN/m ) (in kN/m ) (in kN/m ) (in kN/m ) (in kN/m ) (in kN/m2) #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A

NMDC LIMITED 3.0 MTPA INTEGRATED STEEL PLANT

AT NAGARNAR, CHHATTISGARH

Agency : M/s Siemens VAI Metals Technologies Gmb., Linz Pmin Fxmax Fxmin Fzmax Fzmin Node: Critical Condition Pmax Pmin Fxmax Fxmin Fzmax Fzmin Node: Critical Condition Pmax Pmin Fxmax Fxmin Fzmax Fzmin #N/A #N/A #N/A #N/A #N/A 0 Load Comb #N/A #N/A #N/A #N/A #N/A #N/A 0 Load Comb #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A 0.00 0.00 0.00 0.00 0.00 23.96 23.96 23.96 23.96 23.96 7.26 7.26 7.26 7.26 7.26 6.05 6.05 6.05 6.05 6.05 #N/A #N/A Plan #N/A Foundation #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A

Support Reactions P1 Fx Fz (in kN) #N/A #N/A #N/A #N/A #N/A #N/A (in kN) #N/A #N/A #N/A #N/A #N/A #N/A (in kN) #N/A #N/A #N/A #N/A #N/A #N/A

P2 (in kN) 0.00 0.00 0.00 0.00 0.00 0.00

Other dead-weights P3 P4 (in kN) 23.96 23.96 23.96 23.96 23.96 23.96 (in kN) 7.26 7.26 7.26 7.26 7.26 7.26

P5 (in kN) 6.05 6.05 6.05 6.05 6.05 6.05

Foundation Force/Moment P Mx Mz (in kN) #N/A #N/A #N/A #N/A #N/A #N/A

Bearing Pressures @ corners p1 p2 p3

2 2 2

X-X Direction pgross,up pgross,up p4 Allowable Check #N/A #N/A #N/A #N/A #N/A #N/A @ edge

2

Z-Z Direction pgross,up pgross,up @ edge

2

X-X Direction pgross,up pgross,up @ edge

2

Z-Z Direction pgross,up pgross,up @ edge

2

@ face

@ face

@ face

@ face

(in kN-m) (in kN-m) (in kN/m ) (in kN/m ) (in kN/m ) (in kN/m2) (in kN/m2) #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A

(in kN/m ) (in kN/m2) (in kN/m ) (in kN/m2) (in kN/m ) (in kN/m2) (in kN/m ) (in kN/m2) #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A

Support Reactions P1 Fx Fz (in kN) #N/A #N/A #N/A #N/A #N/A #N/A (in kN) #N/A #N/A #N/A #N/A #N/A #N/A (in kN) #N/A #N/A #N/A #N/A #N/A #N/A

P2 (in kN) 0.00 0.00 0.00 0.00 0.00 0.00

Other dead-weights P3 P4 (in kN) 23.96 23.96 23.96 23.96 23.96 23.96 (in kN) 7.26 7.26 7.26 7.26 7.26 7.26

P5 (in kN) 6.05 6.05 6.05 6.05 6.05 6.05

Foundation Force/Moment P Mx Mz (in kN) #N/A #N/A #N/A #N/A #N/A #N/A

Bearing Pressures @ corners p1 p2 p3

2 2 2

X-X Direction pgross,up pgross,up p4

2

Z-Z Direction pgross,up pgross,up @ edge

2

X-X Direction pgross,up pgross,up @ edge

2

Z-Z Direction pgross,up pgross,up @ edge

2

Allowable

2

Check #N/A #N/A #N/A #N/A #N/A #N/A

@ edge

2

@ face

2

@ face

2

@ face

2

@ face

(in kN-m) (in kN-m) (in kN/m ) (in kN/m ) (in kN/m ) (in kN/m ) (in kN/m ) #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A

(in kN/m ) (in kN/m ) (in kN/m ) (in kN/m ) (in kN/m ) (in kN/m ) (in kN/m ) (in kN/m2) #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A #N/A

NMDC LIMITED 3.0 MTPA INTEGRATED STEEL PLANT

AT NAGARNAR, CHHATTISGARH

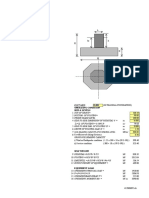

Agency : M/s Siemens VAI Metals Technologies Gmb., Linz Foundation Slab Design: Design Notes/Assumptions: 1. From the soil base pressure analysis, cases yielding maximum and minimum corner pressures is only considered for design. 2. Soil base pressure calculated in the prior procedure, is assumed acting uniformly; Also, maximum footing projection length is consider as the span for moment calculation. 3. Conservatively, reinforcement calculated against the maximum factored design moment is assigned both ways. 4. While designing foundation slab, cases where calculated net downward pressure is more than net upward pressure, top face reinforcement is provided to resist the corresponding net downward pressure. Otherwise nominal reinforcement only provided as per Clause 26.5.2.1 of IS 456: 2000. Step-by-step design procedure for foundation slab Step 1 Calculate bending moments and shears in foundation slab Critical sections for bending moments and shears are illustrated in the earlier sheet * Section 1 - design bending moment * Section 2 - One-way shear * Section 3 - Two-way shear Step 2 Calculate area of tension reinforcement and distribution Critical sections for bending moments and shears are illustrated in the earlier sheet M = pnet * (lx or ly)2 / 2 Mu = Factored bending moment = gf * M tc 1 1 4.6 * Mu fck * b * d2 = Find effective depth 'd' b = Width of section (Consider 1 m wide strip) Calculate Mu b * d2 ; and

FOOTING:

Step 3 Check for One-way shear @ distance 'd' from the face of column Shear at Section 2 Check shear stress: Actual shear stress, tv V Vu b d tc =

Step 6 Check for stability against over-turning F.O.S against overturning =

0.9 * Mr

>= 1.4 About Z-Z axis: = #N/A kN-m #N/A #N/A kN-m #N/A

Vu bd

< =

tc pnet * (lx or ly) = gf * V Mx =

M About X-X axis: #N/A kN-m (maximum) #N/A #N/A #N/A kN-m Mz

Total shear at Section 2 = Total factored shear at Section 2 = Total width of Section 2 = =

Load Combination: Mxr = P * B = F.O.Soverturning 2 =

Load Combination: Mzr = P * A = 2 =

Effective depth of Section 2 Permissible shear stress; The value of tc is obtained from Table 19 of IS 456: 2000, depending on 100As/bd where As is the total area of tensile reinforcement in the section 2

>= 1.4 F.O.Soverturning >= 1.4 P F = Fz #N/A >= 1.2 tan

#N/A Step 7 Check for stability against sliding F.O.S against sliding =

#N/A

Step 4 Check for Two-way shear @ distance 'd/2' from the face of column

Shear at Section 3 Check shear stress: Fx Actual shear stress, tv V = Vu bo d ks bc = = = = = = Vu bod Total shear over area enclosed by critical section perimeter (A * B) - ((a + d) * (b + d)) * pnet Periphery of the critical section 3 = Effective depth of Section 3 0.5 + bc (but not greater than 1) Short side of the column/pedestal Long side of the column/pedestal 0.25fck 2 * ((a + d) + (b + d)) < kstc

= Sliding co-efficient Along x-x direction: #N/A kN (maximum) #N/A P Fx >= 1.2 #N/A =

0.58

Along z-z direction: = #N/A kN #N/A P Fz >= 1.2

Load Combination: F.O.Ssliding =

Load Combination: F.O.Ssliding = = #N/A #N/A

= gf * V

Step 8 Check for buoyancy due to ground water table

F.O.S against uplift =

0.9 * Downward pressure Uplift pressure

>= 1.2 1.50 m 2 kN/m 14.715 =

Height of ground water level from the founding level, h1 = Total uplift pressure acting at the base = Total downward pressure of sub structure kN/m2 = 24.80 F.O.Suplift = 1.52 >= 1.2 HENCE SAFE ONE-WAY SHEAR CHECK tv = tc Vu Vu/bd

2

gwater * h1 =

pt Ast

= =

50 * fck fy bd * pt 100

Step 5 Check minimum reinforcement for tension Minimum tensile reinforcement = 0.0012bD in both directions (fy = 415 N/mm2) Provide this minimum reinforcement also at the top of the foundation where top reinforcement is required for tension and Mu b*d

2

P2 + P3 + P5 (A * B) =

Bottom Reinforcement: 10 @ 200 mm C/C (parallel to X-X direction) Max. gross Max. gross Max. net Max. net Cantilever B.Moment Factored Rebar Effective @ edge

2

F1

@ face

2

@ edge

2

@ face

2

length,

Mu

diameter depth 'd'

pt,reqd (in %)

10 @ 200 mm C/C (parallel to Z-Z direction) and Spacing Spacing Ast,reqd Ast,min Max. Ast required provided pt,prov (in mm ) (in mm ) (in mm ) (in mm)

2 2 2

TWO-WAY SHEAR CHECK

kstc

(for M25)

2

Vu Check (in kN)

bo

Vu / bod

2

(for M25) Check

(in kN/m ) (in kN/m ) (in kN/m ) (in kN/m )

(in m)

(in kN-m) (in kN-m) (in mm)

(in mm)

(in mm)

(in %)

(in kN) (in N/mm ) (in N/mm )

(in mm) (in N/mm ) (in N/mm2)

Design for Bottom Steel along X-X Direction #N/A #N/A #N/A #N/A 0.54988 #N/A #N/A 10 171 #N/A #N/A #N/A 120 #N/A #N/A 200 0.230 #N/A #N/A 0.35 #N/A #N/A 685 #N/A 1.25 #N/A

Design for Bottom Steel along Z-Z Direction #N/A #N/A #N/A #N/A 0.54988 #N/A #N/A 10 163 #N/A #N/A #N/A 120 #N/A #N/A 200 0.241 #N/A #N/A 0.35 #N/A #N/A 685 #N/A 1.25 #N/A

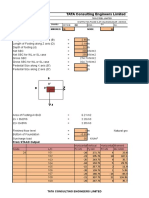

NMDC LIMITED 3.0 MTPA INTEGRATED STEEL PLANT

AT NAGARNAR, CHHATTISGARH

Agency : M/s Siemens VAI Metals Technologies Gmb., Linz Top Reinforcement: 8 @ 250 mm C/C (parallel to X-X direction)

Min. gross Min. gross Min. net Min. net

and

8 @ 250 mm C/C (parallel to Z-Z direction)

Cantilever B.Moment Factored Mu length, M

@ edge

2

@ face

2

@ edge

2

@ face

2

Rebar Effective diameter depth 'd'

Mu b*d

2

pt,reqd (in %)

Ast,reqd (in mm )

2

Ast,min (in mm )

2

Max. Ast

2

Spacing Spacing required provided (in mm)

pt,prov (in %)

(in kN/m ) (in kN/m ) (in kN/m ) (in kN/m )

Check for the requirement of design steel

(in m)

(in kN-m) (in kN-m) (in mm)

(in mm)

(in mm ) (in mm)

Design for Top Steel along X-X Direction #N/A #N/A #N/A #N/A #N/A 0.54988 #N/A #N/A 8 171 #N/A #N/A #N/A 120 #N/A 418.88 250 0.118

Design for Top Steel along Z-Z Direction #N/A #N/A #N/A #N/A #N/A 0.54988 #N/A #N/A 8 163 #N/A #N/A #N/A 120 #N/A 418.88 250 0.123

Reinforcement detail parallel to the longer dimension

8 @ 250 mm C/C

8 @ 250 mm C/C

10 @ 200 mm C/C B

10 @ 200 mm C/C

NMDC LIMITED 3.0 MTPA INTEGRATED STEEL PLANT

AT NAGARNAR, CHHATTISGARH

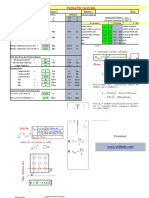

Agency : M/s Siemens VAI Metals Technologies Gmb., Linz Reference Detailed Calculation CHECK FOR CRACK WIDTH OF FOUNDATION SLAB "F1": Basic Design Data: Characteristic compressive strength of concrete, Characteristic compressive strength of steel, Typical foundation slab strip size (1 m wide strip) Concrete cover for footing main reinforcement

Clause 35.3.2 of IS 456: 2000 Table 21 of IS 456: 2000

Out put

fck fy

= = =

25 415 1000 (b) 50 0.2 2 8.5

N/mm2 N/mm2 mm x mm mm x 105 N/mm2 N/mm2 350 mm (D)

Cmin Est scbc

= = = =

Limited crack width Modulus of elasticity of steel Permissible stress in concrete due to bending CRACK WIDTH CALCULATION FOR R.C.C SLAB: Typical foundation slab strip size (1 m wide strip) Maximum bending moment (service condition) Diameter of tension reinforcement used Provided tensile rebar spacing Diameter of compression reinforcement used Provided tensile rebar spacing Provided effective thickness of slab Depth of compression reinforcement from the compressive face

= = = = = = d =

1000 11.70 10 250 10 250 295

mm x kN-m mm mm mm mm mm

350 mm

d' m

= = =

55 280 3scbc 10.98 314 314.2

mm

Clause B-2.1.2 of Modular ratio IS 456: 2000

Provided area of tensile reinforcement, Provided area of compression reinforcement,

Ast Asc

= =

mm2 mm2

DETERMINATION OF DEPTH OF NEUTRAL AXIS (N.A.): (1.5m - 1)Asc Asc d x N.A. Ast a) Slab Section mAst fst/Est b) Transformed Section c) Strain Diagram fc/Ec

printed: 9/26/2013

NMDC LIMITED 3.0 MTPA INTEGRATED STEEL PLANT

AT NAGARNAR, CHHATTISGARH

Agency : M/s Siemens VAI Metals Technologies Gmb., Linz Reference Detailed Calculation Position of N.A. can be found out by taking moment of transformed areas about N.A. bx2 2

2 500 x

Out put

+ (1.5m - 1) Asc (x - d') 8309.53 x -

mAst (d - x) = x = 517422 52.3 mm

1284898.692

From the above equation, depth of neutral axis, Calculation of modular inertia of section: Ixx = bx3 3

+ (1.5m - 1) Asc (x - d')2 Ixx = =

mAst (d - x)2

10 4 0.02509 x 10 mm

Stress in tension steel,

fst

m * M (d - x) Ixx

Stress in tension steel, Strain in tension steel,

fst est

= =

2 124.26 N/mm

fst Est

est

Clause 34.3.2 of SP 24: 1983

= =

0.000621 est * (D - x) (d - x)

The strain on the tension face of the slab,

e1

=

Clause 34.3.2 of SP 24: 1983

0.000762 e1 0.7* btD (a' - x) * 10-3 As (D - x) fs

The average strain at the level of cracks,

em

Clause 34.3.2 of SP 24: 1983

The stiffening effect of the concrete in tension zone, where, bt =

0.7* btD (a' - x) * 10-3 As (D - x) fs

The width of the section at the centroid of the tension steel = 1000 mm

a'

The distance from the compression face to the point of crack = = = 350 mm

fs

= Service stress in tension reinforcement

0.58fy * Ast,required Ast,provided

2 240.7 N/mm

printed: 9/26/2013

NMDC LIMITED 3.0 MTPA INTEGRATED STEEL PLANT

AT NAGARNAR, CHHATTISGARH

Agency : M/s Siemens VAI Metals Technologies Gmb., Linz Reference

Clause 34.3.2 of SP 24: 1983

Detailed Calculation The stiffening effect of the concrete in tension zone, = = The average strain at the level of cracks, em = = Hence em W cr = = 1+2 where, acr = Distance from the point considered to the surface of the nearest longitudinal bar Critical dimensions for crack width: From the diagram, Face of concrete Clear spacing between bars in tension s1 s3 Spacing acr1 acr2 Spacing Then s3 acr1 = = = Then acr2 = = Maximum (acr1 , acr2) Design surface crack width W cr acr = = 1+2 55 mm s2 = 250 mm s2 Spacing s1 = 55 mm = 240 mm 0.7* btD (a' - x) * 10-3 As (D - x) fs 0.00324 e1 -0.002478 0 3acrem acr - Cmin D-x

Out put

0.7* btD (a' - x) * 10-3 As (D - x) fs

Clause 34.3.2 of SP 24: 1983

Design surface crack width

(s

2 1

+ s32) mm

2

72.8

((s /2)

2

+ s32) mm mm

- 2

131.6 131.6

3acrem acr - Cmin D-x

= < Hence Safe

0.000

mm

0.2 mm

printed: 9/26/2013

Node

L/C 12 1 DL+LL

Force-X kN Force-Y kN Force-Z kN Moment-X kNm Moment-Y kNm -9.031 234.988 -11.889 -4.491 -0.698

Moment-Z kNm 4.503

You might also like

- ACI Beam DesignDocument1 pageACI Beam DesigndantevariasNo ratings yet

- Thermodynamics P K Nag Exercise Unsolved Problems SolvedDocument265 pagesThermodynamics P K Nag Exercise Unsolved Problems SolvedRavinder Antil90% (40)

- Column design and analysis in STAADDocument45 pagesColumn design and analysis in STAADMohmmedhusain FruitwalaNo ratings yet

- Design of Combined-Footing: Input DataDocument7 pagesDesign of Combined-Footing: Input DataUzziel Abib GabiolaNo ratings yet

- RCC51 Column Load Take-Down & DesignDocument8 pagesRCC51 Column Load Take-Down & DesignirrezaNo ratings yet

- Fuel Tank Ring Beam Design CalculationDocument11 pagesFuel Tank Ring Beam Design CalculationDawson Preethi EA94% (16)

- Rafter & Rafter connection designDocument3 pagesRafter & Rafter connection designnikmmmecNo ratings yet

- 50 1 323-1-Base Isolation and Dampers 2022Document121 pages50 1 323-1-Base Isolation and Dampers 2022elidstone@hotmail.comNo ratings yet

- Design of Pinned Base ConnectionDocument21 pagesDesign of Pinned Base ConnectionShawkat Ali KhanNo ratings yet

- Prestress Sls CheckDocument18 pagesPrestress Sls CheckWL TamNo ratings yet

- Combined Footing Design CF4-2Document10 pagesCombined Footing Design CF4-2Saugat ThapaNo ratings yet

- Calculations: Project: of Section: File/ref No: Designed: Date: Checked: DateDocument6 pagesCalculations: Project: of Section: File/ref No: Designed: Date: Checked: DateWintun73No ratings yet

- Main Truss Design DetailsDocument19 pagesMain Truss Design Detailsformwork companyNo ratings yet

- Strip Beam Design 24 07 19Document37 pagesStrip Beam Design 24 07 19Ahammad KabeerNo ratings yet

- L&T Construction Water Treatment Filter Complex DesignDocument3 pagesL&T Construction Water Treatment Filter Complex DesignPowerhouse ShaftNo ratings yet

- Water Tank Wall FootingDocument4 pagesWater Tank Wall FootingAbhishekKumarNo ratings yet

- ICT Structured Cabling GuidelinesDocument37 pagesICT Structured Cabling GuidelinesSylvester Muzendah100% (1)

- 1.FB - Balkhu - Star Design With Break - 36m Edit Opt 2 - Copy (2) OldDocument32 pages1.FB - Balkhu - Star Design With Break - 36m Edit Opt 2 - Copy (2) OldTriChandra MaharjanNo ratings yet

- Introduction to Transportation Engineering ProposalDocument2 pagesIntroduction to Transportation Engineering ProposalRaheel ADNANNo ratings yet

- Base Plate BiaxilDocument19 pagesBase Plate BiaxilGunjan KolarkarNo ratings yet

- COUNTERFORTDocument2 pagesCOUNTERFORTMALAY MRIDHANo ratings yet

- Bridge BearingDocument11 pagesBridge BearingAmadu Farrow100% (1)

- Column DesignDocument22 pagesColumn DesignMuhammad Atif IqbalNo ratings yet

- Foundation Design f1Document2 pagesFoundation Design f1Sampath Kumar KandasamyNo ratings yet

- Moment ConnectionDocument30 pagesMoment ConnectionpandyatusharNo ratings yet

- Input Datas: N/mm2 N/mm2 DEG KN/m3 KN/m2 DEGDocument117 pagesInput Datas: N/mm2 N/mm2 DEG KN/m3 KN/m2 DEGradhi_rads89No ratings yet

- Spring Coefficient CalculationDocument8 pagesSpring Coefficient CalculationamirNo ratings yet

- Pile CapDocument7 pagesPile CapKTMONo ratings yet

- Water TankDocument26 pagesWater Tankabhi aroteNo ratings yet

- Analysis of 2 - Pile Group - Pc2 MX Design Data: Load Case 100 DL+LL Joint No MZ Grid Mark Column LoadDocument9 pagesAnalysis of 2 - Pile Group - Pc2 MX Design Data: Load Case 100 DL+LL Joint No MZ Grid Mark Column LoadMythili BysaniNo ratings yet

- Chequred PlateDocument2 pagesChequred PlateKumar Prasanna HNNo ratings yet

- Factors Influencing Procurement SystemsDocument10 pagesFactors Influencing Procurement SystemsYudish Deerpaul100% (8)

- Abutment Wall and Footing DesignDocument10 pagesAbutment Wall and Footing DesigngertjaniNo ratings yet

- Retaining Wall Design CalculationsDocument14 pagesRetaining Wall Design CalculationsMonjit GogoiNo ratings yet

- D 001 Octa FDNDocument18 pagesD 001 Octa FDNMayuresh Kudve0% (1)

- Design of Combined Footing (CFDocument12 pagesDesign of Combined Footing (CFp_ignatiusNo ratings yet

- Dome Design Dimensions and Stress AnalysisDocument2 pagesDome Design Dimensions and Stress Analysisnavneet3bawaNo ratings yet

- Load Cal 1 Corner RBDocument41 pagesLoad Cal 1 Corner RBDanish AhmadNo ratings yet

- F87T PDFDocument6 pagesF87T PDFHung Cuong Pham100% (1)

- Client: KOC Job No: JI-180 Page: of Prepared By: Nehal Akhter Subject: Design of Foundation, PW7a Checked By: RPM/FSDocument28 pagesClient: KOC Job No: JI-180 Page: of Prepared By: Nehal Akhter Subject: Design of Foundation, PW7a Checked By: RPM/FSOMARB26No ratings yet

- Kentledge Design SpreadsheetDocument4 pagesKentledge Design SpreadsheetUtaya Kumar Veelmurugan100% (1)

- Fin Plate To Column Flange - LRFDDocument23 pagesFin Plate To Column Flange - LRFDkalpanaadhiNo ratings yet

- JSW Severfield Structure Ltd. composite column design EC4Document3 pagesJSW Severfield Structure Ltd. composite column design EC4RonakShahNo ratings yet

- Design of RCC Column (C1)Document5 pagesDesign of RCC Column (C1)Ramachandra SahuNo ratings yet

- Design of Propped Cantilever Retaining WallDocument3 pagesDesign of Propped Cantilever Retaining WallkkgcNo ratings yet

- Composite Column DesignDocument95 pagesComposite Column DesignYanfei JinNo ratings yet

- Doubly Reinforced BeamDocument10 pagesDoubly Reinforced Beamkalpanaadhi50% (2)

- Water Tank - Is 3370-Sludge TankDocument4 pagesWater Tank - Is 3370-Sludge TankDhayalan PalanisamyNo ratings yet

- Depth of Fixity & Pile DesignDocument2 pagesDepth of Fixity & Pile DesignSoumya BandyopadhyayNo ratings yet

- Beam Design With Deflection CheckDocument2 pagesBeam Design With Deflection Checkbhavin_civilNo ratings yet

- Chequred Plate CheckDocument2 pagesChequred Plate Check_jessecaNo ratings yet

- Design of Biaxial ColumnDocument5 pagesDesign of Biaxial ColumndineshNo ratings yet

- Well SBCDocument5 pagesWell SBCVenkat PalliNo ratings yet

- APPENDIX-A (Cohesive Soil: Clay) - FIXED: Pile - Lateral Load - Capacity: Is 2911 - Part 1 - Section 2-2010Document4 pagesAPPENDIX-A (Cohesive Soil: Clay) - FIXED: Pile - Lateral Load - Capacity: Is 2911 - Part 1 - Section 2-2010Kanaiyalal N. ShethNo ratings yet

- Pile Cap Design Calculations With CSI SAFEDocument6 pagesPile Cap Design Calculations With CSI SAFEroshanNo ratings yet

- Project Spreadsheets to BS 8110 Client Advisory GroupDocument1 pageProject Spreadsheets to BS 8110 Client Advisory GroupnurNo ratings yet

- Ep HSSDocument191 pagesEp HSSJane NishaNo ratings yet

- Beam Design TorsionDocument20 pagesBeam Design Torsionmailmaverick8167100% (1)

- DBR 1515 PDFDocument4 pagesDBR 1515 PDFSELVA GANESH P 14MST1009No ratings yet

- 09) UB356x171x51TOUB610X305X149-B2CW - MC-1Document126 pages09) UB356x171x51TOUB610X305X149-B2CW - MC-1Asaru DeenNo ratings yet

- Y Y Z ZD Y Y Z ZD Y Y Z ZD: Axis About Which Minimum Eccentricity Moment Is To Be ConsideredDocument2 pagesY Y Z ZD Y Y Z ZD Y Y Z ZD: Axis About Which Minimum Eccentricity Moment Is To Be ConsideredWanda Beasley100% (1)

- Coupling Beam Steel PlateDocument2 pagesCoupling Beam Steel PlateShashankSinghNo ratings yet

- Design of foundation for 400kV transmission towerDocument4 pagesDesign of foundation for 400kV transmission towerOuseppachan AmbookenNo ratings yet

- BA 001 R0A (Without Mezzanine)Document1 pageBA 001 R0A (Without Mezzanine)Muhammad Hassan TariqNo ratings yet

- Two Way Slab - IS Code - LSMDocument12 pagesTwo Way Slab - IS Code - LSMNitesh SinghNo ratings yet

- Tank 100cm Pad Base DesignDocument53 pagesTank 100cm Pad Base DesignMuhammad Auwal TahirNo ratings yet

- Pad Footing Analysis and Desig1Document8 pagesPad Footing Analysis and Desig1Louiskiwa NilehouseNo ratings yet

- Footing Pressure CheckDocument1 pageFooting Pressure CheckVaishak KrishnanNo ratings yet

- Provided: XT XB YT YBDocument2 pagesProvided: XT XB YT YBDanish AhmadNo ratings yet

- Normal Case: ProvidedDocument3 pagesNormal Case: ProvidedDanish AhmadNo ratings yet

- Irc Gov in SP 050 2013Document124 pagesIrc Gov in SP 050 2013prashant singh50% (2)

- 6077 Pressuremeter and Foundation Design - Deep Foundations ARCHIVEDocument49 pages6077 Pressuremeter and Foundation Design - Deep Foundations ARCHIVEDanish AhmadNo ratings yet

- Kennedy & Dominion Report on Santo Rita 1000 MW SubstationDocument1 pageKennedy & Dominion Report on Santo Rita 1000 MW SubstationDanish AhmadNo ratings yet

- Litl 020 Cve 111 B 87625 - r2 Civil Ga ClariflocculatorDocument1 pageLitl 020 Cve 111 B 87625 - r2 Civil Ga ClariflocculatorDanish AhmadNo ratings yet

- BPI-Base PLDocument162 pagesBPI-Base PLDanish AhmadNo ratings yet

- GAUSDocument1 pageGAUSDanish AhmadNo ratings yet

- Litl 020 Cve 111 B 87628 Sh.1 - r1 Reinf. Detail of Parshall FlumeDocument1 pageLitl 020 Cve 111 B 87628 Sh.1 - r1 Reinf. Detail of Parshall FlumeDanish AhmadNo ratings yet

- Irc 78 2014 - CL706Document1 pageIrc 78 2014 - CL706Danish AhmadNo ratings yet

- Load Cal-1-RBDocument54 pagesLoad Cal-1-RBDanish AhmadNo ratings yet

- Eng Eco 3&4Document55 pagesEng Eco 3&4Danish AhmadNo ratings yet

- 1893 Dynamic StaadDocument3 pages1893 Dynamic StaadDanish AhmadNo ratings yet

- Introduction To Computer Science and Programming - Introduction To 6.00 SlidesDocument7 pagesIntroduction To Computer Science and Programming - Introduction To 6.00 SlidesCoursePinNo ratings yet

- Application Form Employment (Oct29th) PDFDocument9 pagesApplication Form Employment (Oct29th) PDFDanish AhmadNo ratings yet

- Tabel Pemajemukan Diskrit MantapDocument24 pagesTabel Pemajemukan Diskrit MantapYasir ArafatNo ratings yet

- GATE Syllabus For Civil Engineering PDFDocument3 pagesGATE Syllabus For Civil Engineering PDFDanish AhmadNo ratings yet

- BarkanDocument476 pagesBarkanDanish AhmadNo ratings yet

- Pile Reinf CalcDocument14 pagesPile Reinf CalcDanish Ahmad100% (1)

- UGC NET PSYCHOLOGY Model Paper 2 Answer Key PDFDocument0 pagesUGC NET PSYCHOLOGY Model Paper 2 Answer Key PDFDanish AhmadNo ratings yet

- Lecture6 (Seepage)Document9 pagesLecture6 (Seepage)Muhammed Sarwar Hussin RosunNo ratings yet

- General Manager (P), East Central Railway, Hajipur Recruitment under Sports QuotaDocument16 pagesGeneral Manager (P), East Central Railway, Hajipur Recruitment under Sports QuotaDanish AhmadNo ratings yet

- Reference Books For IES Civil Engineering PDFDocument1 pageReference Books For IES Civil Engineering PDFDanish Ahmad100% (1)

- UGC NET PSYCHOLOGY Model Paper 2 Answer Key PDFDocument0 pagesUGC NET PSYCHOLOGY Model Paper 2 Answer Key PDFDanish AhmadNo ratings yet

- CSIR Life Science Question Paper-June 2013Document58 pagesCSIR Life Science Question Paper-June 2013Santhosh Kalash100% (2)

- Part V 2 PDFDocument11 pagesPart V 2 PDFprieten20006936No ratings yet

- enggcodeCS 42Document1 pageenggcodeCS 42Danish AhmadNo ratings yet

- Leeds Guidelines ConnecticutDocument48 pagesLeeds Guidelines ConnecticutDuong Thai BinhNo ratings yet

- 2015 PGCET SeatDocument253 pages2015 PGCET Seatvivek2mbNo ratings yet

- Hydraulics - Part3 - HydraulicsDocument23 pagesHydraulics - Part3 - Hydraulicsahm531No ratings yet

- How Does The Ratio of Sand To Cement Affect The Strength of ConcreteDocument4 pagesHow Does The Ratio of Sand To Cement Affect The Strength of ConcreteMani Kandan ArunachalamNo ratings yet

- Controllogix Power Supplies: Installation InstructionsDocument14 pagesControllogix Power Supplies: Installation InstructionsneoflashNo ratings yet

- Communication SecurityDocument15 pagesCommunication SecurityShahid AzeemNo ratings yet

- Universal Beam and Column Properties SheetDocument11 pagesUniversal Beam and Column Properties SheetkalpanaadhiNo ratings yet

- Aeronautical Engineers Board Exam Room Assignments - November 2013Document11 pagesAeronautical Engineers Board Exam Room Assignments - November 2013ScoopBoyNo ratings yet

- Electronics Thesis PDFDocument4 pagesElectronics Thesis PDFCarrie Tran100% (2)

- Mech Brochure PDFDocument16 pagesMech Brochure PDFarvi_vinNo ratings yet

- Allocation of Lab Instructors 201910Document1 pageAllocation of Lab Instructors 201910Hassan AnwerNo ratings yet

- Eight DimensionsDocument1 pageEight DimensionsAnonymous FfaqvAx45GNo ratings yet

- Bachelor of Civil Engineering - An Official Site of Pokhara UniversityDocument1 pageBachelor of Civil Engineering - An Official Site of Pokhara UniversityaayushNo ratings yet

- 2 B.Tech CSE R20Document235 pages2 B.Tech CSE R20Vijayakumar KNo ratings yet

- PHD Ferrario PDFDocument263 pagesPHD Ferrario PDF8790922772No ratings yet

- Selecting Lightweight Steel Beams for Varying Unbraced LengthsDocument8 pagesSelecting Lightweight Steel Beams for Varying Unbraced LengthsShahram HawramiNo ratings yet

- BCM Report (16c01c4003)Document31 pagesBCM Report (16c01c4003)Lakshman Sai100% (1)

- Communication Systems Engineering by John G Proakis PDFDocument2 pagesCommunication Systems Engineering by John G Proakis PDFBill0% (2)

- All Branch Time TableDocument10 pagesAll Branch Time TableUday hpNo ratings yet

- Instruction ENG NCVTDocument10 pagesInstruction ENG NCVTDba ApsuNo ratings yet

- Reinforcing SteelDocument5 pagesReinforcing SteelStraus WaseemNo ratings yet

- Sure-Stop PVC Waterstop BrochureDocument4 pagesSure-Stop PVC Waterstop Brochuremyke_0101No ratings yet

- Vaari Textile Company ProfileDocument7 pagesVaari Textile Company ProfileMukesh kannan MahiNo ratings yet

- Class 1Document91 pagesClass 1meenasundarNo ratings yet