Professional Documents

Culture Documents

M2U3

Uploaded by

agama1188Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M2U3

Uploaded by

agama1188Copyright:

Available Formats

TRADE OF PAINTING & DECORATING

PHASE 2

Module 2

Surface Preparation

UNIT: 3

Gloss Paint Systems

Module 2 Unit 3

Gloss Paint Systems

Table of Contents

Introduction .................................................................................................................. 1 Learning Outcomes .................................................................................................. 1 1.0 1.1 1.2 1.3 1.4 1.5 1.6 2.0 2.1 3.0 3.1 4.0 High Gloss Finish using Solvent Based Paints .......................................... 2 Hazards Associated with use and disposal of Solvents ......................... 2 Satisfying Absorbency of Fillers ............................................................... 2 Characteristics & function of undercoat and gloss Paint ...................... 2 Effects of White Spirit in Paints ............................................................... 5 Function of 50/50s in oil based paints .................................................... 5 Sequence, Application & Brushes for Oil Based Paints ........................ 5 High Gloss Finish Using Water Based Paints ............................................ 7 Water based paints ...................................................................................... 7 High Gloss Finish on Previously Painted wood surfaces......................... 8 Advantages of wet abrasion ...................................................................... 8 Sequence for Painting A Panelled Door ..................................................... 9

4.1 Correct sequence when painting flush and panelled door .................... 9 4.2 Cleaning and Storing Brushes. ................................................................11 4.3 Safe and Clean Working Practice............................................................11 4.4 Importance of Team Working ................................................................12 Summary ..................................................................................................................13 Suggested Exercises................................................................................................13 Questions .................................................................................................................13 Suggested reading ...................................................................................................14 Training Resources .................................................................................................14

Painting and Decorating Phase 2

Revision 1.0 September 2007

Module 2 Unit 3

Gloss Paint Systems

Introduction

The production of a high class piece of work is a process that involves good quality preparation, filling undercoating etc, and the final step in this is the skilled application of gloss paint in order to bring the work to an attractive lustre which is not alone aesthetically attractive but is functional and durable thereby offering maximum protection to the substrate.

Module 2

Surface Preparation

Unit 1

Paint Removal

Unit 2

Knotting, Priming and Flush Filling Woodwork

Unit 3

Gloss Paint Systems

Learning Outcomes

By the end of this unit each apprentice will be able to: Bring a primed and filled panel to a high gloss finish using solvent based paints Bring a primed and filled panel to a high gloss finish using water based paints Bring previously painted door, skirting and architrave to a high gloss finish State the correct sequence for painting a paneled door

Painting and Decorating Phase 2

Revision 1.0 September 2007

Module 2 Unit 3

Gloss Paint Systems

1.0

High Gloss Finish using Solvent Based Paints

Key Learning Points Hazards associated with use and disposal of solvents Satisfying absorbency of fillers Characteristics and functions of undercoats and gloss paints Effects of white spirit in paints Function of 50/50s in oil based paints Sequence, application and brushes required for water based paints

1.1

Hazards Associated with use and disposal of Solvents

Reference Module 1 Unit 3.1

1.2

Satisfying Absorbency of Fillers

Undercoatings are heavy bodied paints with little or no flow. They should not be applied thickly as brushing will be difficult and brush marks which will show through spoiling the finish. Brush marks will be highlighted after the application of the gloss finish. Adjusted by the addition of white spirit and linseed oil to increase its flow and slow its setting up time to accommodate even application and laying off. This will help to keep wet edges alive so that proper brushing can be carried out. Additives are available for this purpose and are very successful addition to the painters material list.

1.3

Characteristics & function of undercoat and gloss Paint

Reference Module 1 Unit 3.1.6 & Module 2 Unit 2 1.4 Undercoating: (oil based) The coating applied to a surface after priming & filling or, in the case of previously painted work, after the preparation. Oil based undercoating is a highly pigmented (titanium white plus extenders) with low film former content. Its film former is alkyd resin and drying oils. It has very good opacity because of its high pigment low film former content. Function: 1. To provide build to the paint film. 2. To provide the most suitable ground for the reception of finishing coats. 3. Introduces colour to the paint system. 4. High opacity

Painting and Decorating Phase 2

Revision 1.0 September 2007

Module 2 Unit 3

Gloss Paint Systems

Has excellent adhesion. A non reversible coating. Touch dry 2-4 hrs. Recoat able 6-16 hours (depending on temp. & drying conditions). Suitable for internal & external use. Application by brush roller or spray. Acrylic primer/undercoat: A quick drying paint for interior or exterior use on raw timber plaster, concrete, building boards. Film former Acrylic latex. Colour white. Thinner/brush wash water. Application by brush, roller or spray. Good opacity and adhesion. Alkali resistant. Drying method coalescence. Drying time 30 to 40 mins. and is recoatable when touch dry. This will depend on the temperatures when applying. Nail heads and hinges etc. must be painted with a rust inhibiting primer before applying the acrylic primer undercoat. Do not apply under wet or frosty conditions. Alkyd gloss paint: Gloss finish (oil based).The final coating in the paint system applied over a well prepared and dry undercoat. A very tough flexible coating. Drying method is oxidation. A non reversible coating. It has good weather resistance. It can be applied over interior & exterior prepared wood, plaster & metal surfaces. It has a high film former low pigment ratio. Thinner turps or white spirit. Suitable for hot water radiators. Drying time Touch dry- 4-6 hrs. Recoating time 16-24 hrs. an be applied by brush, roller or spray. Acrylic gloss Acrylic gloss paint is a hard wearing finish. It has poor flow and gloss properties compared to oil paint. It drys quickly, has low odour and can be recoated in 2 hours. Brush wash is water. It will withstand frequent washing, and is non reversible It does not yellow like solvent based paints. The great benefit of acrylics is that the complete system can be applied the same day.

Painting and Decorating Phase 2

Revision 1.0 September 2007

Module 2 Unit 3

Gloss Paint Systems

Types of paint coating.

Convertible coating (non reversible film) A coating when drying, and changing from a liquid to a solid state goes through a complete chemical change. It cannot be brought back to its original state by the use of its thinners. Non convertible coating (reversible film) Some coatings are formed by dissolving a resin in a solvent (shellac in methylated spirit). On application of the coating the solvent evaporates leaving the resin in its original on the surface. No chemical change has taken place. The coating can be reversed to the liquid state by the application of the solvent

Painting terms

Cissing: When a paint or varnish coating fails to form a continuous film on the surface it has been applied to. The paint gathers in some places and recedes in others. Flaking: Paint loosing it adhesion on the substrate it has been applied to and peeling away from the surface. It can be caused by trapped moisture, a powdery surface dirty surface poor abrading etc. Flow: The ability of a coating to level out and spread into a smooth film. Paints that have good flow usually level out uniformly with few brush or roller marks. Opacity: The covering or hiding power of paint Viscosity: The fluid thickness of a product. Viscosity is often referred to as consistency. The higher the viscosity, the thicker the fluid. How thick or thin the paint is. Saponification: When oil paint is applied to an alkaline surface e.g. concrete it is attacked and converted to a soapy substance. The oil paint should be preceded by the use of an alkali resisting primer.

Painting and Decorating Phase 2

Revision 1.0 September 2007

Module 2 Unit 3

Gloss Paint Systems

1.4

Effects of White Spirit in Paints

White spirit is a colourless thinner for oil paints that evaporates completely as the paint dries. Its function is to reduce the viscosity of the paint, thereby making it easier to apply and to assist primers to penetrate wood and other absorbent surfaces such as building boards plaster etc. While thinning of paint is important, over-thinning can cause reduction of gloss, poor opacity and weakening of the paint system leading to early breakdown especially if used outdoors. It is always important to read the manufacturers instructions for the thinning of their product.

1.5

Function of 50/50s in oil based paints

The application of a mixture of 50% undercoating and 50% gloss is sometimes preferred by some painters to assist the flow of undercoats or to first coat over a well rubbed down surface in good condition. It takes the dryness out of the undercoating and gives a nice base after rubbing down for a gloss finish.

1.6

Sequence, Application & Brushes for Oil Based Paints

Reference Unit 3.1.7. The application of paint by brush even to a small area such as a plain panel must be carried out in a methodical way if a high quality finish is to be achieved. Depending on the size of the panel a 2 or 2 brush will be suitable. The paint having been adjusted to the correct viscosity and a good quality worn bristle or synthetic brush selected, the application can commence.

Bristle brush: Charge the brush well with paint and spread it evenly over an area at one end of the panel. Recharging the brush, begin to apply to the next section and so on until the panel is completed keeping the wet edges alive at all times. Finish by crossing using some pressure to complete the even spreading of the paint and finally laying off using a light pressure in one direction the length of the panel.

Painting and Decorating Phase 2

Revision 1.0 September 2007

Module 2 Unit 3

Gloss Paint Systems

The paint should be applied quickly and evenly before setting up commences. It is important that a full coating of paint is applied so do not brush out the paint too much as a wet coat of 50 microns will dry down to 25 microns. If the panel is a moulded one then a second brush is required, generally a 1 in order to paint the moulding. Firstly paint the moulding using the 1 brush. Paint applied to mouldings with a large brush will run as too much paint will have been applied to a small area. Next fill in the panel and then paint the top and bottom rails finishing by painting the two stiles. When a good quality and properly adjusted paint film is applied it offers great durability. If badly applied it is inclined to run, sag, show brush marks and dry patches

Painting and Decorating Phase 2

Revision 1.0 September 2007

Module 2 Unit 3

Gloss Paint Systems

2.0

High Gloss Finish Using Water Based Paints

Key Learning Points Sequence, application and brushes required for water based paints

2.1

Water based paints

To paint any size surface successfully the selecting the correct size brushes is all important so that work can progress speedily and efficiently. Water based paints dry quickly so the paint must be applied evenly and laid off at a steady pace. Keeping the wet edge alive (workable) is a key element to good finishing so where paint overlaps should not be obvious. There can be little time for application at times due to the temperature of room being high. Patent additives can be added to the finishing paint to slow the setting up of the paint allowing time for application. They also help the paint to flow reducing the risk of brush marks. Selecting the correct size brushes is important so that too much or too little paint will be applied. Synthetic brushes are best for the application of acrylic paints as bristles absorbs water causing them to swell distorting the brush. Apply paint to small areas such as mouldings with a 1 fitch to avoid overloading a small area resulting in runs Good finishing is achieved when the correct film thickness is applied, the paint brushed on evenly crossed and laid off with care. Applying too much paint will result in runs, brush marks and when dry wrinkling will occur. Applying too little paint will result in misses, dry spots, flashing and lack of gloss or satin of the finish. Rubbing down with worn abrasives or sanding pads between coats is essential for good adhesion and grit free finish.

Synthetic filament brush

Painting and Decorating Phase 2

Revision 1.0 September 2007

Module 2 Unit 3

Gloss Paint Systems

3.0 High Gloss Finish on Previously Painted wood surfaces

3.1 Advantages of wet abrasion

If flatting down has to be carried to smoothen a poor surface wet abrading with wet or dry abrasive is best. A grade such as 120 or 180 can cut down a surface quickly leaving it smooth and ready for painting. Wet abrading can also be carried out when repainting old gloss painted surfaces to assist adhesion using a finer grade such as 400. It is a dust free method of abrasion which is of great benefit to the painter. Wet abrading should only be carried out on well hardened coatings. When preparing previously painted surfaces prior to painting it is important that washing with white spirit is very important on areas around handles hand rails newel posts etc. as these are areas that contain grease from handling and offer poor adhesion if not attended to. Skirtings and architraves should be well rubbed down any surface defects made good and the complete surface undercoated with some gloss paint or additive added to help its flow. When dry a full coat of gloss can be applied. Denibbing Surfaces Prior to Painting: New plaster surfaces carry small pieces of plaster on the surface and they must be removed by dry scraping before painting. Previously painted plastered surfaces may be slightly gritty and this can be removed by sanding . This is made easier by using a sanding pole. This activity is known as denibbing. Previously painted oil paint surfaces can be denibbed by dry or wet sanding.

Pole sanding tool

Sanding block

Painting and Decorating Phase 2

Revision 1.0 September 2007

Module 2 Unit 3

Gloss Paint Systems

4.0

4.1

Sequence for Painting A Panelled Door

Correct sequence when painting flush and panelled door

Panelled door Mouldings 2. Panels 3 Muntins 4. Rails 5 Stiles Painting doors: Where possible all door fittings should be removed to enable the painter to paint underneath them and so achieve a clean and satisfactory finish. Cover the floor area under the door and wedge in an open position. The covering has two purposes To keep the floor clean. To avoid picking up dirt on the brush when painting the bottom rail

When the painting of the door is complete clean and replace the fittings.

Painting and Decorating Phase 2

Revision 1.0 September 2007

Module 2 Unit 3

Gloss Paint Systems

Panelled doors: Begin by painting a panel moulding and then its panel and continue the same procedure with the remaining panels Next paint the two muntins, followed by the top rail lock rail and bottom rail. Finally paint the edge and the two stiles. It is important to feather edges as you progress from panel to panel and keep the wet edge alive. Also care when brushing stiles and edges to avoid fatty edges. Avoid having fatty edges on the arises as they stay soft and are unsightly. Flush panelled Door:

Flush panelled Door Painting a flush panelled door is more straightforward than painting a panelled one. Divide the door visually into six parts and complete each section fully before moving on to the next one and so on as in above diagram.

Painting and Decorating Phase 2

10

Revision 1.0 September 2007

Module 2 Unit 3

Gloss Paint Systems

4.2

Cleaning and Storing Brushes.

Cleaning and maintaining brushes. The paint brush is the most important tool in the professional painters tool kit and proper use care and cleaning are very important. Brushes used in oil paint can be kept suspended in a water pot for a short period of time. The excess paint should be knocked out on a flat board before placing them in the water pot. It is better practice to rinse them out in white spirit so that paint does not accumulate around the stock. Bristle brushes should be washed out in the thinners of the paint being used and the same applies to synthetic filaments. If the synthetic brush has been used in acrylic paint or any water paint wash out in warm water or warm soapy water. A brush comb is a useful tool to use regularly to help clean through the centre of the brush. It also helps with straightening the filling. After washing thoroughly again spin dry by hand or with spinner. Never tap or strike the brush on a hard surface to remove old paint etc. as this action can loosen the setting in the ferrule. Comb through again to help reshape brush, and hang up to dry. Do not store brush standing on its tip as it will distort the shape of the brush. Brush keeper They can also be placed in a brush keeper which is designed to hang up the brush on hooks. The large keeper holds a number of brushes but small keepers can accommodate two brushes. A portable metal container fitted with hooks that brushes can be suspended from. They also have as a fixture a bottle and wick. The bottle is filled with a fluid which is transferred on to the wick and the strong fumes of the liquid are circulated in the container. The fume laden atmosphere keeps the brushes soft without the need to be immersed in water. The keeper must be kept covered at all times for it to be effective. This is a very handy piece of equipment when transporting brushes

4.3

Safe and Clean Working Practice

All work areas should at all times comply with Health and Safety regulations. Wet floors, tools and other equipment lying around, and general untidiness can be a serious safety and/or fire hazard. A sense of order is essential for a clean working environment. Untidy, dirty habits make it very difficult to produce high quality work. A proper system of storage should be in place and used. Another reason the workshop must be kept clean and uncluttered, is that some signboards will be at the preparation stage while others are being finished, and an orderly workplace is the most efficient way of doing this.

Painting and Decorating Phase 2

11

Revision 1.0 September 2007

Module 2 Unit 3

Gloss Paint Systems

4.4

Importance of Team Working

Reference Module 1734 Title: Teamwork, project management and team communication

Painting and Decorating Phase 2

12

Revision 1.0 September 2007

Module 2 Unit 3

Gloss Paint Systems

Summary

To achieve a good finish many elements play a part. Good quality tools and materials are essential as inferior ones can undo all the good preparation. It is essential to maintain a clean and an orderly system of working as this makes for a safer and dust free environment which is necessary for good finishing. A good example of this is the practice of setting aside a selection of brushes to be used only for the final coat.

Suggested Exercises

(i) (ii) Given a previously painted panelled door, architraves and skirting prepare and bring forward to a oil based gloss finish. Given a new plain plywood panel prepare and bring forward to a water based gloss finish.

Questions

Q. 1 Explain the following painting terms. (i) (ii) (iii) (iv) Q2 Q.3 Q.4 Cissing Saponification Opacity Viscosity

Explain reversible and non reversible coatings. Why wet abrade? What are the characteristics of oil based undercoating ?

Painting and Decorating Phase 2

13

Revision 1.0 September 2007

Module 2 Unit 3

Gloss Paint Systems

Suggested reading

BS EN 971-1:1996 Glossary of painting and decorating terms Paint manufacturers websites

Training Resources

Tool kit, panel x 2, undercoating and gloss (oil and water based), abrasive paper, Paint brushes, white spirit, flush door, paint kettles, panelled door, strainer, classroom and workshop facilities, notes/information sheets

Painting and Decorating Phase 2

14

Revision 1.0 September 2007

FS Learning Innovation Unit Apt. 2 43/49 Mespil Road Dublin 4

You might also like

- Floor Coatings and Industrial Paint SpecificationsDocument18 pagesFloor Coatings and Industrial Paint Specificationsagama1188No ratings yet

- M3U2Document16 pagesM3U2agama1188No ratings yet

- M2U2Document19 pagesM2U2agama1188No ratings yet

- Outdoor LightingDocument11 pagesOutdoor Lightingagama1188No ratings yet

- M4U3Document15 pagesM4U3agama1188No ratings yet

- M4U2Document31 pagesM4U2agama1188No ratings yet

- M4U1Document14 pagesM4U1agama1188No ratings yet

- Painting and DecoratingDocument21 pagesPainting and DecoratingZahidKhanNo ratings yet

- Silver Brazing Technical TipsDocument1 pageSilver Brazing Technical Tipsagama1188No ratings yet

- Mat SwitchDocument1 pageMat SwitchSameer NandanNo ratings yet

- Appliance Plumbing FixtureDocument3 pagesAppliance Plumbing Fixtureagama1188No ratings yet

- 0507TheThree PhaseAcInductionMotorDocument2 pages0507TheThree PhaseAcInductionMotoragama1188No ratings yet

- Non Contact AC Power MonitorDocument1 pageNon Contact AC Power MonitorRev. MatthewNo ratings yet

- Home Appliance Repair Guide Circle1983Document4 pagesHome Appliance Repair Guide Circle1983agama1188No ratings yet

- Product Type Δ T = Td: Source: Hundy, Trott and Welch. Refrigeration and Air Conditioning 4th Ed. (2008)Document3 pagesProduct Type Δ T = Td: Source: Hundy, Trott and Welch. Refrigeration and Air Conditioning 4th Ed. (2008)agama1188No ratings yet

- Measureing Pressure Drop: How and When To Change FiltersDocument1 pageMeasureing Pressure Drop: How and When To Change Filtersagama1188No ratings yet

- INST231 Sec2Document76 pagesINST231 Sec2agama1188No ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Computer-Supported Studying StoriesDocument22 pagesComputer-Supported Studying Storiesagama1188No ratings yet

- Digital Communications Lab ExperimentsDocument0 pagesDigital Communications Lab Experimentsagama1188No ratings yet

- Full Wave Rectifier Characteristics LabDocument36 pagesFull Wave Rectifier Characteristics LabTushar Kush100% (4)

- INST232 Sec1Document89 pagesINST232 Sec1agama1188No ratings yet

- Workshop On Computers For Management: True or FalseDocument0 pagesWorkshop On Computers For Management: True or Falseagama1188No ratings yet

- Ieee TemplatesDocument8 pagesIeee TemplatesfuzulihameedNo ratings yet

- Transistor Amplifiers: Biasing and Small Signal ModelDocument58 pagesTransistor Amplifiers: Biasing and Small Signal ModelRahul MishraNo ratings yet

- EDC2Document79 pagesEDC2Anurag AllaNo ratings yet

- BJT DCDocument19 pagesBJT DCagama1188No ratings yet

- Lecture Notes For Analog ElectronicsDocument54 pagesLecture Notes For Analog Electronicsmom028No ratings yet

- Common Emitter Amplifier: S.No Name of The Component/ Equipment Specifications QtyDocument0 pagesCommon Emitter Amplifier: S.No Name of The Component/ Equipment Specifications Qtyagama1188No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Java Interview Questions: Interfaces, Abstract Classes, Overloading, OverridingDocument2 pagesJava Interview Questions: Interfaces, Abstract Classes, Overloading, OverridingGopal JoshiNo ratings yet

- ms3 Seq 01 Expressing Interests With Adverbs of FrequencyDocument3 pagesms3 Seq 01 Expressing Interests With Adverbs of Frequencyg27rimaNo ratings yet

- 12.1 MagazineDocument44 pages12.1 Magazineabdelhamed aliNo ratings yet

- College Wise Form Fillup Approved Status 2019Document4 pagesCollege Wise Form Fillup Approved Status 2019Dinesh PradhanNo ratings yet

- Vegan Banana Bread Pancakes With Chocolate Chunks Recipe + VideoDocument33 pagesVegan Banana Bread Pancakes With Chocolate Chunks Recipe + VideoGiuliana FloresNo ratings yet

- Excel Keyboard Shortcuts MasterclassDocument18 pagesExcel Keyboard Shortcuts MasterclassluinksNo ratings yet

- Battery Genset Usage 06-08pelj0910Document4 pagesBattery Genset Usage 06-08pelj0910b400013No ratings yet

- Toshiba l645 l650 l655 Dabl6dmb8f0 OkDocument43 pagesToshiba l645 l650 l655 Dabl6dmb8f0 OkJaspreet Singh0% (1)

- Summer Internship ReportDocument135 pagesSummer Internship Reportsonal chandra0% (1)

- Consumer Behavior Paper PLDTDocument6 pagesConsumer Behavior Paper PLDTAngeline Santiago100% (2)

- The Future of Indian Economy Past Reforms and Challenges AheadDocument281 pagesThe Future of Indian Economy Past Reforms and Challenges AheadANJALINo ratings yet

- Marrickville DCP 2011 - 2.3 Site and Context AnalysisDocument9 pagesMarrickville DCP 2011 - 2.3 Site and Context AnalysiskiranjiNo ratings yet

- What Is Love? - Osho: Sat Sangha SalonDocument7 pagesWhat Is Love? - Osho: Sat Sangha SalonMichael VladislavNo ratings yet

- Autos MalaysiaDocument45 pagesAutos MalaysiaNicholas AngNo ratings yet

- ROCKET STOVE DESIGN GUIDEDocument9 pagesROCKET STOVE DESIGN GUIDEfrola5100% (2)

- Skin Yale University Protein: Where Does Collagen Come From?Document2 pagesSkin Yale University Protein: Where Does Collagen Come From?Ellaine Pearl AlmillaNo ratings yet

- Economic Impact of Tourism in Greater Palm Springs 2023 CLIENT FINALDocument15 pagesEconomic Impact of Tourism in Greater Palm Springs 2023 CLIENT FINALJEAN MICHEL ALONZEAUNo ratings yet

- FOCGB4 Utest VG 5ADocument1 pageFOCGB4 Utest VG 5Asimple footballNo ratings yet

- EE-LEC-6 - Air PollutionDocument52 pagesEE-LEC-6 - Air PollutionVijendraNo ratings yet

- The Insanity DefenseDocument3 pagesThe Insanity DefenseDr. Celeste Fabrie100% (2)

- Introduction To Computing (COMP-01102) Telecom 1 Semester: Lab Experiment No.05Document7 pagesIntroduction To Computing (COMP-01102) Telecom 1 Semester: Lab Experiment No.05ASISNo ratings yet

- Compound SentenceDocument31 pagesCompound Sentencerosemarie ricoNo ratings yet

- Write a composition on tax evasionDocument7 pagesWrite a composition on tax evasionLii JaaNo ratings yet

- BI - Cover Letter Template For EC Submission - Sent 09 Sept 2014Document1 pageBI - Cover Letter Template For EC Submission - Sent 09 Sept 2014scribdNo ratings yet

- Pale Case Digest Batch 2 2019 2020Document26 pagesPale Case Digest Batch 2 2019 2020Carmii HoNo ratings yet

- Ejercicio 1.4. Passion Into ProfitDocument4 pagesEjercicio 1.4. Passion Into ProfitsrsuaveeeNo ratings yet

- Aladdin and the magical lampDocument4 pagesAladdin and the magical lampMargie Roselle Opay0% (1)

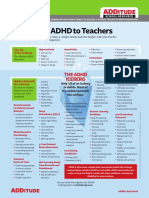

- Explaining ADHD To TeachersDocument1 pageExplaining ADHD To TeachersChris100% (2)

- Leku Pilli V Anyama (Election Petition No 4 of 2021) 2021 UGHCEP 24 (8 October 2021)Document52 pagesLeku Pilli V Anyama (Election Petition No 4 of 2021) 2021 UGHCEP 24 (8 October 2021)Yokana MugabiNo ratings yet

- ACS Tech Manual Rev9 Vol1-TACTICS PDFDocument186 pagesACS Tech Manual Rev9 Vol1-TACTICS PDFMihaela PecaNo ratings yet