Professional Documents

Culture Documents

Fowler Sanitizes Caps With Pulsed Light

Uploaded by

bradylintonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fowler Sanitizes Caps With Pulsed Light

Uploaded by

bradylintonCopyright:

Available Formats

Fowler Sanitizes Caps with Pulsed Light Innovative design has allowed Fowler to move away from sanitizing

caps with chemicals and, instead, sanitize caps with pulsed light. Fowler Products is the exclusive North American distributor of Claranor pulsed light sanitizing systems. Claranor is an advanced full spectrum light technology that eliminates the need for chemical sanitizing of caps, cups, and films. Fowler is powered by Pro Mach, a provider of integrated packaging products and solutions for food, beverage, household goods, pharmaceutical, and other diverse consumer and industrial companies. Through three business units and related divisions, Pro Mach provides equipment, training, installation, and parts in primary packaging, end-of-line packaging, and identification and tracking. The Fowler division has created the Claranor pulsed light sanitizing system to achieve maximum throughput. The Claranor pulsed light system removes the use of chemicals from the sanitizing process and rinses water in favor of a compact, long life, and energy efficient system that is as effective as the chemical system. Until recently, flavored waters, extended shelf life milk, and other dairy based drinks required caps to be sanitized using corrosive chemicalshydrogen peroxide or other peroxide based chemicals. Because these chemical systems increase the footprint and operational cost of the filling and capping line as well as increasing the plants water footprint, Fowler now uses a technology that is safer and . In addition, using the Claranor pulsed light for sanitizing caps is more effective than systems based upon continuous UV light. A test was completed using Aspergillus niger, the spray inoculated at 5.3 105 CFU per object, one flash of the Claranor pulsed light system resulted in a 5.1 log reduction and total decontamination after two flashes. The Claranor light pulse lasts only three tenths of a millisecond so the cap material itself does not absorb heat. The Claranor system treats up to 25 caps per second with varying throughput depending on the size and configuration of the cap. Ideal for flat caps, sports caps, five gallon caps, and caps with aluminum foil, this system is designed with precision and attention to detail. The Claranor pulsed light sanitizing is designed to be applied to new capping machine installation, though businesses with concerns regarding packaging operations with sustainability, workplace safety, or environmental concerns will opt for a retrofit to replace their existing chemical based cap sanitizing systems. This system is a safe alternative to chemical based cap sanitizing. Features on the Claranor pulsed light sanitizing include less floor space requirements, water cost reductions, and a pencil-sized bulb for 10 million flashes, which is enough to treat up to 500 million caps. With advanced technology, Fowler Products has created a method of safe cap sanitizing. Fowler specializes in manufacturing high-speed capping machinery and cap sorting and feeding systems including the Fowler high speed bottle rinsing and air cleaning machines and the Claranor pulsed light sterilizing systems for caps, cups, and films. Fowlers machinery can be used in the beverage, food, pharmaceutical, chemical, personal care, household goods, and distilled spirits industries.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ICT-CHS Grade 9Document6 pagesICT-CHS Grade 9LILEBELLE BALDOVENo ratings yet

- CITI BankDocument504 pagesCITI Banksekhar_g5332No ratings yet

- Aero EngineDocument118 pagesAero EngineTarun Choudhary100% (1)

- Startup ShutdownDocument4 pagesStartup ShutdownPit_mkluNo ratings yet

- Crusher House OperationDocument21 pagesCrusher House Operationratan das0% (1)

- ASTM E407-07 Standard Practice For Microetching Metals and AlloysDocument22 pagesASTM E407-07 Standard Practice For Microetching Metals and AlloysRifqiMahendraPutra100% (3)

- MAM100 User ManualDocument23 pagesMAM100 User Manualsteve@air-innovations.co.za100% (5)

- RT-1000 Terex, RT-100 TonDocument14 pagesRT-1000 Terex, RT-100 TonMaximo CC100% (1)

- Amine Gas Sweetening Systems PsDocument3 pagesAmine Gas Sweetening Systems Pscanada_198020008918No ratings yet

- Comparative Thermal Analysis of Fin of I.C. Engine With Extensions IJERTV6IS040377 PDFDocument8 pagesComparative Thermal Analysis of Fin of I.C. Engine With Extensions IJERTV6IS040377 PDFAhmad FaizalNo ratings yet

- Uwiciit Brochure v42Document2 pagesUwiciit Brochure v42Javian CampbellNo ratings yet

- ACCF - CSR Reconciliation-Darrang-18-08-20Document7 pagesACCF - CSR Reconciliation-Darrang-18-08-20Hunny VermaNo ratings yet

- 3948Document20 pages3948Jigneshkumar PatelNo ratings yet

- BILL A: Extra Low VoltageDocument9 pagesBILL A: Extra Low VoltagevijayxkumarNo ratings yet

- GoedhartVCI P 2012 en Version1 IDocument24 pagesGoedhartVCI P 2012 en Version1 IRodrigo GonçalvesNo ratings yet

- Cement Invoice No. For TCDocument3 pagesCement Invoice No. For TCAzhar ShaikhNo ratings yet

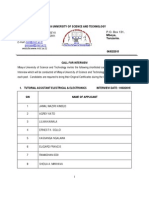

- Call For Interview Phase V - Mbeya University.Document13 pagesCall For Interview Phase V - Mbeya University.Rashid BumarwaNo ratings yet

- Module 2 - Important Theory Portions: - Friction - Characteristics of FrictionDocument8 pagesModule 2 - Important Theory Portions: - Friction - Characteristics of FrictionHima SNo ratings yet

- History of Information Technology: PremechanicalDocument5 pagesHistory of Information Technology: PremechanicalMichael RamogaNo ratings yet

- GX15 #12 Console (Jenkins) PDFDocument75 pagesGX15 #12 Console (Jenkins) PDFAnonymous fiWm7O2No ratings yet

- Annexure-I: 1. Safety Precaution Used in Laboratory LevelDocument36 pagesAnnexure-I: 1. Safety Precaution Used in Laboratory Levelraghu sweetdreamsNo ratings yet

- LG P503 SVC Eng 101008Document199 pagesLG P503 SVC Eng 101008MaxAllgeruNo ratings yet

- #Omega DPG409Document3 pages#Omega DPG409Cyrix.OneNo ratings yet

- 21 UK Catalogo Primaled GBDocument12 pages21 UK Catalogo Primaled GBluc1902No ratings yet

- Effect of Tillage and Crop Roration On Pore Size DistributionDocument12 pagesEffect of Tillage and Crop Roration On Pore Size DistributionWubetie MengistNo ratings yet

- Earthquake Resistance of Buildings With A First Soft StoreyDocument9 pagesEarthquake Resistance of Buildings With A First Soft StoreyZobair RabbaniNo ratings yet

- Indian Water Purifier Market (Water - India2005@yahoo - Com)Document16 pagesIndian Water Purifier Market (Water - India2005@yahoo - Com)Uday EdapalapatiNo ratings yet

- Asentria Public - 48VDC - or - 24VDC - Power - Card - Wiring - InstructionsDocument4 pagesAsentria Public - 48VDC - or - 24VDC - Power - Card - Wiring - Instructionsaelmai70No ratings yet

- Solid Fuel Boiler Control Standard 2: Version 1.0) Version 1.0) Version 1.0) Version 1.0)Document26 pagesSolid Fuel Boiler Control Standard 2: Version 1.0) Version 1.0) Version 1.0) Version 1.0)Ana Odzaklieska Krste SmileskiNo ratings yet

- 3-D Finite Element Modeling in OpenSees For Bridge - Scoggins - ThesisDocument54 pages3-D Finite Element Modeling in OpenSees For Bridge - Scoggins - Thesisantonfreid100% (2)