Professional Documents

Culture Documents

AC 25.1529-1A Instructions For Continued Airworthiness of Structural Repairs On Transport Airplanes

Uploaded by

Ladislao PazmanyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AC 25.1529-1A Instructions For Continued Airworthiness of Structural Repairs On Transport Airplanes

Uploaded by

Ladislao PazmanyCopyright:

Available Formats

U.S.

Department of Transportation Federal Aviation Administration

Advisory Circular

Date: 11/20/07 Initiated by: ANM-100 AC No: 25.1529-1A

Subject: INSTRUCTIONS FOR

CONTINUED AIRWORTHINESS OF STRUCTURAL REPAIRS ON TRANSPORT AIRPLANES 1. PURPOSE.

a. This advisory circular (AC) provides instructions to ensure the continued airworthiness of structural repairs on certain transport category airplanes. The intent of this AC is to ensure that damage tolerant structure will remain damage tolerant after it has been repaired. This AC applies to transport category airplanes operating under Title 14, Code of Federal Regulations (CFR), parts 91, 125, and 135, and to transport airplanes operating under parts 121 and 129 that have a passenger seating capacity of less than 30 passengers and a maximum payload capacity of less than 7,500 pounds. Instructions for ensuring the continued airworthiness of structural repairs on transport airplanes operating under parts 121 and 129 that have a passenger seating capacity of 30 or more, or a maximum payload capacity of 7,500 pounds or more, are provided in AC 120-93, Damage Tolerance Inspections for Repairs and Alterations. AC 120-93 applies to transport airplanes that are required to comply with 121.1109 and 129.109. b. This AC addresses the approval procedures to follow when making structural repairs to structure certificated under the damage tolerance requirements of 25.571, Amendment 25-45 or later, and to type designs with Supplemental Inspection Documents (SIDs) which were based on these criteria. The methods provided herein are not the only means acceptable for showing compliance with the applicable portions of 25.1529 and Appendix H of part 25. The Federal Aviation Administration (FAA) will consider other methods of compliance the applicant may elect to present. 2. APPLICABILITY.

a. The guidance provided in this document is directed to airplane manufacturers, modifiers, civil aviation authorities, and FAA transport airplane type certification engineers and their designees. b. Like all advisory circular material, this AC is not, in itself, mandatory, and does not constitute a regulation. It describes an acceptable means, but not the only means, for showing compliance with the requirements for transport category airplanes. The FAA will consider other

11/20/07

AC 25.1529-1A

methods of demonstrating compliance that an applicant may elect to present. While these guidelines are not mandatory, they are derived from extensive FAA and industry experience in determining compliance with the relevant regulations. On the other hand, if we become aware of circumstances that convince us that following this AC would not result in compliance with the applicable regulations, we will not be bound by the terms of this AC, and we may require additional substantiation or design changes as a basis for finding compliance. c. This material does not change, create any additional, authorize changes in, or permit deviations from, regulatory requirements. 3. CANCELLATION. Advisory Circular 25.1529-1, Instructions for Continued Airworthiness of Structural Repairs on Transport Airplanes, dated 8/1/1991, is canceled. 4. RELATED DOCUMENTS. a. Title 14, Code of Federal Regulations (14 CFR): Section 1.1 Title Definitions and Abbreviations, General Definitions Type Design Instructions for Continued Airworthiness and Manufacturers Maintenance Manuals Having Airworthiness Limitations Sections Damage-Tolerance and Fatigue Evaluation of Structure Instructions for Continued Airworthiness Instructions for Continued Airworthiness

21.31(c) 21.50

25.571

25.1529 Appendix H to Part 25 43.16 Appendix A to Part 43 b. Advisory Circulars:

Airworthiness Limitations Major Alterations, Major Repairs, and Preventive Maintenance

(1) AC 25.571-1C, Damage Tolerance and Fatigue Evaluation of Structure, dated 4/29/98.

11/20/07

AC 25.1529-1A

(2) AC 120-93, Damage Tolerance Inspections for Repairs and Alterations, dated 11/20/07. 5. BACKGROUND. The current industry procedure for repairing structural elements is to first classify the repair as either major or minor in accordance with the definitions set forth in 1.1 and Appendix A to part 43. The FAA approval procedures depend on the classification of the repair. The structure is then restored to the original certification status; either safe-life, fail-safe, or damage tolerant, and approved in accordance with established procedures. The definitions of major and minor have historically been subject to widely varying application by maintenance and inspection personnel. In order to standardize the application of the term major repair, the FAA published a list of parts and types of repairs considered major in Civil Aeronautics Manual (CAM) 18 in 1953. This was later adopted as Appendix A to part 43. This standardized list of major repairs has, in some cases, resulted in the classification of minor repairs as major simply because the list has not been updated to include evolving airplane design and construction techniques and it is not practical to tailor the list to individual airplane models. There is no attempt in this AC to redefine the terms major or minor as defined in parts 1 and 43 of the CFR. Rather, the intent of this AC is to ensure damage tolerant structure will remain damage tolerant after it has been repaired. The advent of damage tolerant design in modern transport category airplanes further complicated the approval procedures for repairs by introducing the need for additional testing and/or analysis in order to assess the long term effects of repairs on damage tolerant structure. Although the repairs may be structurally sound and airworthy when completed, it is not practical in many instances to complete the damage tolerance evaluation for long term airworthiness prior to returning the airplane to service. This necessitates an interim repair approval where the repair is found to be structurally sound relative to static strength but has not been analyzed for long term airworthiness effects. The final approval of the repair is made shortly thereafter and before long term fatigue effects are manifested. This AC provides guidance to airplane manufacturers and to those authorized to repair structures, in cases where this two-phase approval process is necessary. 6. DEFINITION OF TERMS. a. Damage tolerance means that the structure has been evaluated to ensure that should serious fatigue, corrosion, or accidental damage occur within the operational life of the airplane, the remaining structure can withstand reasonable loads without failure or excessive structural deformation until the damage is detected. b. Fail-safe means the structure has been evaluated to assure that catastrophic failure is not probable after fatigue failure or obvious partial failure of a single, principal structural element. c. Safe-life means that the structure has been evaluated to be able to withstand the repeated loads of variable magnitude expected during its service life without detectable cracks. d. Primary structure is structure that significantly contributes to the carrying of flight,

11/20/07

AC 25.1529-1A

ground, or pressure loads. It is also known as a structurally significant item (SSI). e. Principal structural elements (PSE) are those elements of primary structure which contribute significantly to carrying flight, ground, and pressurization loads, and whose failure could result in catastrophic failure of the airplane. f. Single load path is where the applied loads are eventually distributed through a single member, the failure of which would result in the loss of the structural capability to carry the applied loads. g. Multiple load path is identified with redundant structures in which (with the failure of individual elements) the applied loads would be safely distributed to other load-carrying members. 7. GUIDANCE. Appendix H to part 25 specifies the general requirements for the preparation of instructions for continued airworthiness as required by 25.1529. The following guidance is to be used in conjunction with Appendix H and other related regulations. a. Structural Repair Manual. The applicant should include in the maintenance instructions required by Appendix H, paragraph H25.3 (b), a structural repair manual (SRM) which describes the types of structural repairs anticipated in service. This SRM should be reviewed and approved by the FAA. b. Principal Structural Elements. The SRM should identify all PSEs and primary structure requiring approved repair data. Examples of PSEs may be found in AC 25.571-lC, Damage Tolerance and Fatigue Evaluation of Structure, dated 4/29/98. c. Repair Documentation. Any repair to a PSE or primary structure, including the removal of cracks and corrosion, requires some form of approval whether deemed "major" or "minor" under the definition of part 1 and the provisions of part 43. The SRM should provide criteria for determining if the repair warrants FAA engineering approval. In general, repair to a PSE or primary structure requires FAA engineering approval. Such approval is usually accomplished by the FAA, a designated engineering representative (DER), or Special Federal Aviation Regulations (SFAR) 36 authorized staff. d. Substantiating Repairs. Additionally, the SRM should provide guidance to repairers as to what substantiating data is necessary to show that the repair complies with certification requirements. This guidance should address repairs to PSEs and primary structure for which no FAA-approved or acceptable data currently exists. It should identify the applicable certification requirements and describe acceptable methods for demonstrating compliance. The SRM must tell the repairer that FAA approval is required for such repairs. e. Two Stage Structural Evaluation. (1) Applicants may elect to allow two-stage repair approval in which the basic structural evaluation shows that the repair will meet immediate and short term strength

11/20/07

AC 25.1529-1A

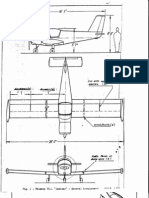

requirements (ultimate strength) but a more extensive investigation is required to show long-term strength requirements. If the applicant elects this option it must schedule the completion of the evaluation such that the airplane is not subjected to the risk of structural failure due to fatigue in the interim. For example, a two-stage evaluation may be recommended where; (i) A static structural strength evaluation is made prior to release of the airplane into service with a stated time for completion of the damage tolerance evaluation, and (ii) A damage tolerance evaluation of the repair is made within the prescribed time period after this interim release. The final evaluation must reflect any changes in the related inspection program, including the threshold, interval, and inspection procedure. (2) Final repair approval should not be made until a damage tolerance evaluation has been completed and has shown that the repair is adequate to assure continued airworthiness. The time period established for completion of the approval should be based on technical, logistic, and recordkeeping considerations. Due to the logistics and recordkeeping requirements and the ability of the operator to realistically track followon technical approval programs, a time period for completion of the approval process that does not exceed 12 months is generally adequate for most structural repairs. This time period is justified based on the assumed inherent crack free performance of structure designed to maintain its initial strength level for the lifetime of the structure. (3) Procedures must be established by the operator as agreed upon by the manufacturer, with approval from the cognizant aircraft certification office, which would assure timely completion of the approval process. These procedures should also provide for audits to ensure that interim repairs are finalized as scheduled. f. Special Qualifications. Guidance should be provided with regard to the qualifications of persons evaluating and approving repairs made to certain PSEs which have special design considerations. For example, a particular design may include certain PSEs having damage tolerant structure requiring a person who has comprehensive knowledge of the specific design philosophy, loading spectrum, and fracture mechanics techniques used in that particular design. Due to these qualifications of the specialist, responsibility for the assessment may be restricted to staff members of the airframe manufacturer, certain DERs, the FAA, or certain SFAR 36 engineering staff. The FAA aircraft certification offices should provide guidance in regard to qualifications of personnel. g. Logic Diagram. The logic diagram in Figure 1, below, is provided to assist in the determination of when FAA engineering approval is required for a repair to damage tolerant structure. The decision process begins when it has been determined that structural damage has occurred.

11/20/07

AC 25.1529-1A Figure 1 - How to Determine if FAA Engineering Approval is Required

Structural Damage Has Occurred

LOGIC DIAGRAM Determination of When FAA Engineering Approval Is Required For a Repair to Damage Tolerant Structure

Is There An Approved SRM Procedure? No Is There An Existing FAA Approved Procedure? No Does Damage Affect A PSE Item?

Yes

Repair Per SRM

Yes

Repair per Approved Procedure

Yes

No Does Repair Affect Other Major Repair Items CFR 1.1? No Repair Does Not Require FAA Approval Repair Requires FAA Approval

Yes

11/20/07 The following guidance is offered for use with the logic diagram:

AC 25.1529-1A

(1) Determine if the repair can be accomplished using standard methods defined in the SRM for the particular airplane. These standard repair methods may be simple or complex, for example: (i) Blend out - local. (ii) Replacement with identical part. (iii) Oversize attachment. (iv) Reduction of edge distance. (2) For damage not covered by an SRM procedure, determine if an FAA approved repair exists or if other means of repair acceptable to the FAA exists, for example: (i) FAA approved repair. (ii) Service bulletin (FAA or DER approved). (iii) All operators letter (FAA or DER approved). (iv) SFAR 36 repair previously approved. (3) Once it has been determined that the damage or repair does not affect PSE, then it must be determined whether it affects other criteria in the major repair definition of 1.1; i.e., systems, weight and balance, aerodynamics, or airplane performance. (4) If it has been determined that a repair must be submitted for FAA approval, and cannot be shown to have prior approval or other acceptable data, it may be approved by the FAA, a DER, or an SFAR 36 authority. Signed by Ali Bahrami Manager, Transport Airplane Directorate Aircraft Certification Service

You might also like

- Teori6 Aircraft AgingDocument27 pagesTeori6 Aircraft AgingRifki FirnandoTPPU 1No ratings yet

- AC 25.571-1D DTA GuidanceDocument41 pagesAC 25.571-1D DTA GuidanceRickNo ratings yet

- Defense Technical Information Center Compilation Part NoticeDocument20 pagesDefense Technical Information Center Compilation Part NoticeBala KrishnanNo ratings yet

- Pax To Cargo ConversionDocument3 pagesPax To Cargo ConversionLoveth Chidinma OgbonnaNo ratings yet

- Agard Ag 304Document68 pagesAgard Ag 304greatsteelNo ratings yet

- Repair Types, Procedures - Part I: Mohan M. Ratwani, Ph. DDocument23 pagesRepair Types, Procedures - Part I: Mohan M. Ratwani, Ph. DOho My worldNo ratings yet

- Simulating The Impact Behaviour of CompositeDocument15 pagesSimulating The Impact Behaviour of CompositeSchmetterling TraurigNo ratings yet

- Aeromat 2007 - MMPDS - 060407Document29 pagesAeromat 2007 - MMPDS - 060407luism2743No ratings yet

- Buckling and Postbuckling Analysis of A CFRP Stiffened Panel For ADocument7 pagesBuckling and Postbuckling Analysis of A CFRP Stiffened Panel For AOSCARDELTANo ratings yet

- Akka Conversion Cargo Oct 2020Document27 pagesAkka Conversion Cargo Oct 2020Salah Ali SalehNo ratings yet

- 06 Frame Surf Analy PAT301Document44 pages06 Frame Surf Analy PAT301Muhammad LutfiNo ratings yet

- Design Optimization of Stiffened Composite Panels With Buckling and Damage Tolerance ConstraintsDocument14 pagesDesign Optimization of Stiffened Composite Panels With Buckling and Damage Tolerance ConstraintslumpertNo ratings yet

- Workshop 11 PDFDocument22 pagesWorkshop 11 PDFJohan ConradieNo ratings yet

- Hyper SizerDocument16 pagesHyper SizerKamlesh Dalavadi100% (1)

- George Andrew Analysis of DA40Document36 pagesGeorge Andrew Analysis of DA40Trevor Leon100% (1)

- Damage TypesDocument15 pagesDamage TypesĐoàn Đình ĐôngNo ratings yet

- OffsetDocument22 pagesOffsetvinandaraNo ratings yet

- Hybrid and 2D DICDocument13 pagesHybrid and 2D DICNguyễn Văn ThườngNo ratings yet

- AMTE 214-2B Fail Safe: Submitted By: Rodriguez, John Mark MDocument6 pagesAMTE 214-2B Fail Safe: Submitted By: Rodriguez, John Mark MJohn Mark RodriguezNo ratings yet

- MSC Nastran 2020 Demonstration Problems Manual-Linear AnalysisDocument83 pagesMSC Nastran 2020 Demonstration Problems Manual-Linear AnalysiskadoNo ratings yet

- 11.1.1 Topology Optimization of An Automotive Control Arm Products: Abaqus/Standard Abaqus/CAEDocument5 pages11.1.1 Topology Optimization of An Automotive Control Arm Products: Abaqus/Standard Abaqus/CAEIrandokht NikshabaniNo ratings yet

- Postbuckling and Collapse AnalysisDocument8 pagesPostbuckling and Collapse AnalysisAtsis Papadopoulos100% (1)

- 2004-03-01 Actual vs. Effective Involute Tooth SizeDocument6 pages2004-03-01 Actual vs. Effective Involute Tooth Sizebee140676No ratings yet

- Boeing Hat Section StudyDocument17 pagesBoeing Hat Section StudyPrasanna KumarNo ratings yet

- Failure Theories ReviewDocument9 pagesFailure Theories ReviewAlex OliveiraNo ratings yet

- Workshop 4b Nonlin BucklingDocument30 pagesWorkshop 4b Nonlin BucklingRon RaeNo ratings yet

- ABAQUS Finite Element Analysis TutorialDocument41 pagesABAQUS Finite Element Analysis Tutorialmorad_cryNo ratings yet

- LOCAL ANALYSIS OF FASTENER HOLES USING LINEAR GAP TECHNOLOGYDocument24 pagesLOCAL ANALYSIS OF FASTENER HOLES USING LINEAR GAP TECHNOLOGYcbryant1990No ratings yet

- Frame Surface Model AnalysisDocument37 pagesFrame Surface Model AnalysisManasses juniorNo ratings yet

- MSC NASTRAN Linear Gap SeminarDocument21 pagesMSC NASTRAN Linear Gap SeminarOreste PrincipeNo ratings yet

- Post Buckling Structure Issue - Very Good OneDocument230 pagesPost Buckling Structure Issue - Very Good Oneprashanth_anNo ratings yet

- Model Beam Contact with Coincident NodesDocument12 pagesModel Beam Contact with Coincident Nodesaiyubi2100% (1)

- FullScaleTestingER JorgensenDocument30 pagesFullScaleTestingER JorgensenBrian PintoNo ratings yet

- A Symmary of Diagonal Tension Part 1 Methods and AnalysisDocument137 pagesA Symmary of Diagonal Tension Part 1 Methods and AnalysisVesa RäisänenNo ratings yet

- FRANC3D V7.4 Users GuideDocument191 pagesFRANC3D V7.4 Users GuidesrashmiiiscNo ratings yet

- Abaqus Answers Spring 1997Document4 pagesAbaqus Answers Spring 1997zmchen100% (1)

- Model Nonlinear Gap Element with Non-Coincident NodesDocument14 pagesModel Nonlinear Gap Element with Non-Coincident Nodesjjpr814367No ratings yet

- Riks (Arc-Length)Document24 pagesRiks (Arc-Length)great2007100% (1)

- Abaqus Fem Analysis of The Postbuckling Behaviour of Composite PDF E1094Document4 pagesAbaqus Fem Analysis of The Postbuckling Behaviour of Composite PDF E1094FabricioNo ratings yet

- Damage Tolerance Test Method Development For Sandwich Composites-AdamsDocument23 pagesDamage Tolerance Test Method Development For Sandwich Composites-AdamsAngel LagrañaNo ratings yet

- WingsDocument28 pagesWingsnakul_desh13No ratings yet

- CBUSHDocument4 pagesCBUSHBita MohajerniaNo ratings yet

- ABAQUS IntroDocument46 pagesABAQUS IntroMaroua MahouachiNo ratings yet

- f0 For Plastic BendingDocument4 pagesf0 For Plastic BendingbatmanbittuNo ratings yet

- Contact analysis in Nastran SOL101 using linear-gap elementsDocument10 pagesContact analysis in Nastran SOL101 using linear-gap elementsGowtham ReddyNo ratings yet

- Getting Started with MSC.Fatigue TutorialDocument24 pagesGetting Started with MSC.Fatigue TutorialFadzrul Hisyam BadarudinNo ratings yet

- Modul-Stiffness MethodDocument18 pagesModul-Stiffness MethodMohamad Zahir RazakNo ratings yet

- Commercial Aircraft Design Trends and Growth ProjectionsDocument60 pagesCommercial Aircraft Design Trends and Growth ProjectionsCamelia MunteanuNo ratings yet

- Gordon Kelly - 2004 - Joining of Carbon Fibre Reinforced Plastics For Automotive ApplicationsDocument36 pagesGordon Kelly - 2004 - Joining of Carbon Fibre Reinforced Plastics For Automotive ApplicationsDaniel MarquesNo ratings yet

- Calculation of Wing LoadsDocument55 pagesCalculation of Wing LoadsJony Oliver Lazo RamosNo ratings yet

- Workshop 14 Radiation Enclosures: WS14-1 NAS104, Workshop 14, March 2004 2004 MSC - Software CorporationDocument24 pagesWorkshop 14 Radiation Enclosures: WS14-1 NAS104, Workshop 14, March 2004 2004 MSC - Software Corporationaiyubi2No ratings yet

- AC_25_1529-1ADocument7 pagesAC_25_1529-1Amanolo garzon rNo ratings yet

- U.S. DOT Advisory Provides Instructions for Continued Airworthiness of Structural RepairsDocument6 pagesU.S. DOT Advisory Provides Instructions for Continued Airworthiness of Structural RepairsCandace FrankNo ratings yet

- Advisory Circular: U.S. Department of TransportationDocument10 pagesAdvisory Circular: U.S. Department of TransportationAlejandro MontealegreNo ratings yet

- AC 91-56B - Continuing Structural Integrity Program For Airplanes (SIDS)Document12 pagesAC 91-56B - Continuing Structural Integrity Program For Airplanes (SIDS)benNo ratings yet

- Structural Certification of External ModificationsDocument8 pagesStructural Certification of External ModificationsMarcus DragoNo ratings yet

- Policy on Bonded Repair Size LimitsDocument12 pagesPolicy on Bonded Repair Size LimitsStephen FornessNo ratings yet

- Continued Airworthiness of Composite Repairs To Primary Structures For Military AircraftDocument10 pagesContinued Airworthiness of Composite Repairs To Primary Structures For Military AircraftLuis Javier SantillanNo ratings yet

- US DOT Advisory Circular on Damage Tolerance and Fatigue EvaluationDocument11 pagesUS DOT Advisory Circular on Damage Tolerance and Fatigue EvaluationCandace FrankNo ratings yet

- Multi-Engine Oral Exam Guide: The comprehensive guide to prepare you for the FAA checkrideFrom EverandMulti-Engine Oral Exam Guide: The comprehensive guide to prepare you for the FAA checkrideRating: 5 out of 5 stars5/5 (4)

- Finite Element Modelling Techniques in MSC NASTRAN and LS DYNADocument172 pagesFinite Element Modelling Techniques in MSC NASTRAN and LS DYNAsreejit7777% (13)

- Guidance on Composite Material and Process SpecificationsDocument25 pagesGuidance on Composite Material and Process SpecificationsLadislao PazmanyNo ratings yet

- AC 23-19A Airframe Guide For FAR23 CertificationDocument93 pagesAC 23-19A Airframe Guide For FAR23 CertificationLadislao PazmanyNo ratings yet

- AC 23-9 Evaluation of Flight Loads On Small Airlpanes With T, V, +, or Y Empennage ConfigurationsDocument9 pagesAC 23-9 Evaluation of Flight Loads On Small Airlpanes With T, V, +, or Y Empennage ConfigurationsLadislao PazmanyNo ratings yet

- Compliance with Flutter RegulationsDocument32 pagesCompliance with Flutter RegulationsLadislao PazmanyNo ratings yet

- AC 23-8B Flight Test Guide App 1Document22 pagesAC 23-8B Flight Test Guide App 1Ladislao PazmanyNo ratings yet

- Ac23 13ADocument76 pagesAc23 13AZbor ZborNo ratings yet

- AC-23-8 ENSAIO EM VÔO Final-Part1Document174 pagesAC-23-8 ENSAIO EM VÔO Final-Part1Marcus DragoNo ratings yet

- Ac20 107BDocument37 pagesAc20 107BJoost ListNo ratings yet

- PL-1 SpecificationsDocument33 pagesPL-1 SpecificationsLadislao Pazmany100% (4)

- Pazmany's ProfileDocument6 pagesPazmany's ProfileLadislao PazmanyNo ratings yet

- Mertens-Duncanaviation - (2012) Legal InterpretationDocument3 pagesMertens-Duncanaviation - (2012) Legal InterpretationLuis Antonio HermozaNo ratings yet

- FAA Advisory Circular Explains Pilot Records Database and Pilot Records Improvement ActDocument136 pagesFAA Advisory Circular Explains Pilot Records Database and Pilot Records Improvement ActlocoboeingNo ratings yet

- FAR Parts 23, 25, 27 and 29 for Airworthiness StandardsDocument7 pagesFAR Parts 23, 25, 27 and 29 for Airworthiness StandardsAdrian AquinoNo ratings yet

- Bank Angle Impact On Climb GradientDocument7 pagesBank Angle Impact On Climb GradientPero PericNo ratings yet

- FAA Issues Emergency AD for Certain Learjet Spoiler AssembliesDocument6 pagesFAA Issues Emergency AD for Certain Learjet Spoiler AssembliesEliana Ayelen TruccoNo ratings yet

- Design and Performance of A Light Sport Airplane: Standard Specification ForDocument34 pagesDesign and Performance of A Light Sport Airplane: Standard Specification ForLois MeiraNo ratings yet

- Easa Ad Us-2021-08-12 1Document7 pagesEasa Ad Us-2021-08-12 1BahadorNo ratings yet

- FAA Form 8130-3 packing listDocument5 pagesFAA Form 8130-3 packing listFelipe HurtadoNo ratings yet

- Guidance Material For Instructor and Evaluator TrainingDocument61 pagesGuidance Material For Instructor and Evaluator TrainingMik Aeil100% (2)

- General Aviation's Contribution: To The U.S. EconomyDocument43 pagesGeneral Aviation's Contribution: To The U.S. Economysnappish1No ratings yet

- XL2 MMDocument1,610 pagesXL2 MMFoxTheHunter100% (1)

- Definitions - Runway PerformanceDocument89 pagesDefinitions - Runway PerformanceBruceNo ratings yet

- Aviation 2Document4 pagesAviation 2Huzaifa IftikharNo ratings yet

- P180 Airplane Flight Manual PDFDocument1,068 pagesP180 Airplane Flight Manual PDFlaurent jubeau100% (3)

- Faa Ead For 737sDocument4 pagesFaa Ead For 737sZerohedgeNo ratings yet

- Fatigue and Damage Tolerance in Airframe Structures: B. Vos (DO 39160)Document26 pagesFatigue and Damage Tolerance in Airframe Structures: B. Vos (DO 39160)flowerboyNo ratings yet

- Cirrus POH 2011Document498 pagesCirrus POH 2011enron_busterNo ratings yet

- Mechanic Privileges and LimitationsDocument9 pagesMechanic Privileges and Limitationsmauco lopezNo ratings yet

- Federal Aviation Administration regulations on aircraft design and performanceDocument178 pagesFederal Aviation Administration regulations on aircraft design and performanceadi9740No ratings yet

- A3EU Rev 44Document105 pagesA3EU Rev 44locoboeingNo ratings yet

- Part 145 Repair Station Ratings and ClassificationsDocument17 pagesPart 145 Repair Station Ratings and ClassificationsLucaNo ratings yet

- AD 2020-10-05 Collins FMSDocument9 pagesAD 2020-10-05 Collins FMSGeeNo ratings yet

- Preliminary Report of The Fatal Thomson Plane CrashDocument5 pagesPreliminary Report of The Fatal Thomson Plane CrashMatthew EnfingerNo ratings yet

- Operations Attachment 17 - FAA Interview SummariesDocument9 pagesOperations Attachment 17 - FAA Interview SummariesGFNo ratings yet

- Minimum Equipment List MEL Dornier 328-100 PDFDocument149 pagesMinimum Equipment List MEL Dornier 328-100 PDFmiguel ayala50% (2)

- FAR 21.197 & 21Document2 pagesFAR 21.197 & 21Mike AguirreNo ratings yet

- Chapter 5 Time Limits - Maintenance ChecksDocument220 pagesChapter 5 Time Limits - Maintenance ChecksHrishikesh NarasimhanNo ratings yet

- Thrush Type Certificate DataDocument12 pagesThrush Type Certificate Datatomay777100% (1)

- FAA Airworthiness Directive (FAA-2022-0145-0003)Document4 pagesFAA Airworthiness Directive (FAA-2022-0145-0003)Watertown Daily TimesNo ratings yet

- AirworpaDocument96 pagesAirworpaMd. Pabel AhmedNo ratings yet