Professional Documents

Culture Documents

E-4 Power Cycle Heaters and Deaerator PDF

Uploaded by

Subrata DasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

E-4 Power Cycle Heaters and Deaerator PDF

Uploaded by

Subrata DasCopyright:

Available Formats

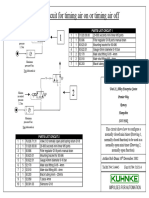

E - 4 POWER CYCLE HEATERS AND DEAERATOR

MOUDA STPP-II (2X660MW) / SOLAPUR STPP (2X660MW) / NABINAGAR STPP (3X660MW) / MEJA TPP (2X660MW) / RAGHUNATHPUR TPP-II (2X660MW) STEAM TURBINE GENERATOR PACKAGE

TECHNICAL SPECIFICATION SECTION-VI PART-B

CLAUSE NO.

POWER CYCLE HEATERS & DE-AERATOR

1.00.00

DEAERATORS:

Chemical Analysis

Mech. Properties

Impact

Hardness

Flattening

Flaring

UT

RT

MPI

DPT

Eddy Current

Helium Leak Test

SR

HT

Hydraulic

Pneumatic

Shell & Dished End

Y(a)

Y(g)

Y(a) Y

Y(e) Y

QUALITY ASSURANCE

2 Y(b) Y(b) Y(c) Y(c) Y Y

Fabrication/ Welding

a)

Edge Preparation/ Fillet Weld

Dimensions

b)

Butt Joints/ Branch Welding

Y Y

Y(d) Y

TECHNICAL SPECIFICATION SECTION-VI PART-B

3 Y

Complete Deaerator Y(f) Y(f) Y(f) Y(f)

Safety & Safety Relief Valve & other valves Y

Y(h)

WPS/PQR/WQR/App. Performance test

Mock up Test

MOUDA STPP-II (2X660MW) / SOLAPUR STPP (2X660MW) / NABINAGAR STPP (3X660MW) / MEJA TPP (2X660MW) / RAGHUNATHPUR TPP-II (2X660MW) STEAM TURBINE GENERATOR PACKAGE

TESTS/CHECKS

COMPONENTS/ACTIVITY

E4 : POWER CYCLE HEATERS & DE-AERATOR

PAGE 1 OF 3

CLAUSE NO.

2.00.00

HEATERS

TESTS/CHECKS

Chemical Analysis Mech. Properties Impact

Hardness Flattening Flaring UT

RT

MPI

DPT

Eddy Current

Helium Leak Test SR HT

Hydraulic

Pneumatic

Dimensions

WPS/PQR/WQR/App. Performance test Y Y

(I)

1 Y Y Y Y Y Y Y

(k)

Tube Sheet Y Y Y Y Y Y Y Y Y Y Y

Forging

Plates

Y(i) Y(j)

c Y Y(l) Y Y

Clading

QUALITY ASSURANCE

Shell Plates

Feed Nozzle Manhole forging

Y(k)

Y(i)

Welding / Fabrication Y(b) Y(b) Y(b) Y(b)

TECHNICAL SPECIFICATION SECTION-VI PART-B

Weld Edge Preparation

Back Chipping

Weld Joints Y(c) Y(c) Y Y Y

(c)

(i)

Butt

Y Y Y

(c)

Y Y Y Y Y Y Y Y

Y Y Y

Y Y Y

(ii)

Fillet

(iii)

Nozzle / Branch

E4 : POWER CYCLE HEATERS & DE-AERATOR

(iv)

Tube to tube sheet

Mock up Test

MOUDA STPP-II (2X660MW) / SOLAPUR STPP (2X660MW) / NABINAGAR STPP (3X660MW) / MEJA TPP (2X660MW) / RAGHUNATHPUR TPP-II (2X660MW) STEAM TURBINE GENERATOR PACKAGE

COMPONENTS/ACTIVITY

PAGE 2 OF 3

CLAUSE NO.

TESTS/CHECKS

MOUDA STPP-II (2X660MW) / SOLAPUR STPP (2X660MW) / NABINAGAR STPP (3X660MW) / MEJA TPP (2X660MW) / RAGHUNATHPUR TPP-II (2X660MW) STEAM TURBINE GENERATOR PACKAGE

Chemical Analysis

Mech. Properties

Impact

Hardness

Flattening

Flaring

UT

RT

MPI

DPT

Eddy Current

Helium Leak Test

SR

HT

Hydraulic

5 Y Y Y(q) Y(q) Y

)

Dished End & Hemi Head

Y(a) Y

Y(b) Y(b)

Y(e) Y(n) Y Y Y(o) Y(p) Y

Tubes

Tube expansion in tube sheet

Complete Heater

QUALITY ASSURANCE

3.00.00

(i) (j)

REMARKS FOR DEAERATORS AND HEATERS

TECHNICAL SPECIFICATION SECTION-VI PART-B

(a) (b) (c) (d)

(e) (f)

(k) (l) (m) (n) (o) (p) (q)

(g) (h)

After forming of plates. For dished end and Hemi head. DPT may be used as an alternate to MPI. UT/RT to be decided according to configuration/accessibility. (i) For plates (ii) For welding (iii) For wall thickness Including wall thickness (i) 100% RT/UT shall be carried out on bodies, bonnets, nozzle and stem of valves of HP heater. (ii) 100% DPT/MPI on machined surfaces of valve body, bonnet, stem, disc & springs. Outer surface (Dished end Knuckle Portion) Seat leakage Including Relieving Capacity-popping test at set and blow down pressure

Note : (1) (2)

Include ovality of holes, surface finish and size of holes. For cladding bond and clading thickness during bond check and after drilling For feed nozzle (pipes) For forgings After bending also Dimension to include wall thinning Both tube and shell side. After Hydro test drying and nitrogen filling to be done. As per the code. For HP Heater & Gland steam coolers the staturoy requirments as per IBR to be ensured and to be certification original to be furnished as per IBR statutory requirements. Quantum of Checks Shall be 100% Unless Otherwise Specified. Chem./Mech. shall be One/ per heat or HT batch.

Pneumatic

Dimensions

WPS/PQR/WQR/App. Performance test

Mock up Test

COMPONENTS/ACTIVITY

E4 : POWER CYCLE HEATERS & DE-AERATOR

PAGE 3 OF 3

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- HEI Standards For Steam Jet Vacuum Systems 5thDocument132 pagesHEI Standards For Steam Jet Vacuum Systems 5thCh Fai100% (12)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- HEI 2623-04 - Standards For Power Plant Heat Ex Changers 4thDocument88 pagesHEI 2623-04 - Standards For Power Plant Heat Ex Changers 4thvaibhav_kapoor100% (4)

- Condenser Performance SolutionsDocument12 pagesCondenser Performance SolutionsSubrata Das100% (1)

- Funke Shell Tube He eDocument24 pagesFunke Shell Tube He eSubrata DasNo ratings yet

- SteamTurbine Brochure MidDocument20 pagesSteamTurbine Brochure MidSubrata Das100% (1)

- Microprotol ManualDocument92 pagesMicroprotol ManualSubrata DasNo ratings yet

- 800 MW R&D ComparisionDocument1 page800 MW R&D ComparisionSubrata DasNo ratings yet

- Condenser Performance SolutionsDocument12 pagesCondenser Performance SolutionsSubrata Das100% (1)

- Comparision of Feed Water Heater DATA PROVIDE BY TPHX 30-11-10 PDFDocument1 pageComparision of Feed Water Heater DATA PROVIDE BY TPHX 30-11-10 PDFSubrata DasNo ratings yet

- Strategy Adopted For Indigenous ManufactureDocument13 pagesStrategy Adopted For Indigenous ManufactureSubrata DasNo ratings yet

- D888 137950-1Document12 pagesD888 137950-1Subrata DasNo ratings yet

- 02 - Deaerator (Spray-Tray Type) - GA PDFDocument1 page02 - Deaerator (Spray-Tray Type) - GA PDFSubrata DasNo ratings yet

- HEI 2624-03 - Tyay Type Deaerators 7thDocument51 pagesHEI 2624-03 - Tyay Type Deaerators 7thSubrata Das100% (3)

- Metric Plain Washers: American National StandardDocument16 pagesMetric Plain Washers: American National StandardSubrata Das100% (2)

- HEI 2854-00 - Liquid Ring Vacuum Pump 2ndDocument25 pagesHEI 2854-00 - Liquid Ring Vacuum Pump 2ndSubrata Das100% (3)

- Film Condensation Model in The Presence of Non-Condensable GasesDocument41 pagesFilm Condensation Model in The Presence of Non-Condensable GasesSubrata DasNo ratings yet

- 00212-1e8501-01.pdf (Legends)Document1 page00212-1e8501-01.pdf (Legends)Subrata DasNo ratings yet

- Experimental Study of Direct Contact Condensation of Steam in Turbulent Duct FlowDocument157 pagesExperimental Study of Direct Contact Condensation of Steam in Turbulent Duct FlowSubrata DasNo ratings yet

- SEA-CURE Vs Ti Prop Comparisons-MetricDocument33 pagesSEA-CURE Vs Ti Prop Comparisons-MetricSubrata DasNo ratings yet

- 47 56Document10 pages47 56kali highNo ratings yet

- Various Types of Faults in Turbine, GeneratorDocument10 pagesVarious Types of Faults in Turbine, Generatorchanchalk007No ratings yet

- Flow Control ValvesDocument9 pagesFlow Control Valvesaryan patilNo ratings yet

- Steel Flange DimensionsDocument3 pagesSteel Flange DimensionssazidalamNo ratings yet

- P700 Series MAXPUMP P500 Series: Diaphragm Pump Manual BookDocument11 pagesP700 Series MAXPUMP P500 Series: Diaphragm Pump Manual BookJefril SiruNo ratings yet

- New PapersDocument2 pagesNew PapersKripan SR SukrithamNo ratings yet

- M15-Gas Turbine Engine-WatermarkDocument172 pagesM15-Gas Turbine Engine-WatermarkvalNo ratings yet

- Ricambi Compatibili Con Il Prodotto: Codice Descrizione MarchioDocument3 pagesRicambi Compatibili Con Il Prodotto: Codice Descrizione MarchiobobNo ratings yet

- Cleancut R-Valve PDFDocument2 pagesCleancut R-Valve PDFbruce lianNo ratings yet

- Flashback ArrestorDocument6 pagesFlashback ArrestorahmedNo ratings yet

- US Chevron Spec. PSV - Sizing and Selection of Pressure Relief ValvesDocument20 pagesUS Chevron Spec. PSV - Sizing and Selection of Pressure Relief Valves울프No ratings yet

- Armstrong Is 2 Stainless Steel ConnectorDocument2 pagesArmstrong Is 2 Stainless Steel ConnectorpandahiuNo ratings yet

- Technical Requirements For Plumbing Works in Buildings eDocument118 pagesTechnical Requirements For Plumbing Works in Buildings eclementmwwong6387No ratings yet

- High Pressure HandbookDocument144 pagesHigh Pressure HandbookErika Castillo NievesNo ratings yet

- 1 - Laminar and Turbulent Flow - MITWPU - HP - CDK PDFDocument13 pages1 - Laminar and Turbulent Flow - MITWPU - HP - CDK PDFAbhishek ChauhanNo ratings yet

- 428C-System Operation-Piston Pump (Implement and Steering)Document10 pages428C-System Operation-Piston Pump (Implement and Steering)yoga_jpbmbm100% (1)

- AscoDocument2 pagesAscoyanjiayuNo ratings yet

- SBS5311 1718 Lab Refrigeration Cycle PDFDocument6 pagesSBS5311 1718 Lab Refrigeration Cycle PDFرولا العمرNo ratings yet

- World Class Manufacturer of Check Valves: Spring-Assisted, Non-Slam, Axial Flow, Silent Check ValvesDocument6 pagesWorld Class Manufacturer of Check Valves: Spring-Assisted, Non-Slam, Axial Flow, Silent Check Valvesashumishra007No ratings yet

- Anderson Anderson: Service and Operation ManualDocument19 pagesAnderson Anderson: Service and Operation ManualDiego SecoNo ratings yet

- Weld Shop: Daily Production Report (Plan Vs Actual) July'13Document11 pagesWeld Shop: Daily Production Report (Plan Vs Actual) July'13Saurabh ShuklaNo ratings yet

- 2.7 Valve Block Oil: 567802 Ref Part No Description - 08 NotesDocument2 pages2.7 Valve Block Oil: 567802 Ref Part No Description - 08 NotesPrinceSadhotraNo ratings yet

- Mini Timer CircuitDocument1 pageMini Timer CircuitSaeed QahremaniNo ratings yet

- Geared Drive Mixer: Mobile: +91 9820268595Document1 pageGeared Drive Mixer: Mobile: +91 9820268595Anil SharmaNo ratings yet

- Centrifugal Pump Troubleshooting ChecklistDocument8 pagesCentrifugal Pump Troubleshooting Checklistab_s5036No ratings yet

- RMS Inlet Pressure Calculation TheoryDocument22 pagesRMS Inlet Pressure Calculation TheoryRajesh SarkarNo ratings yet

- BAC Evaporative CondensersDocument12 pagesBAC Evaporative CondensersKONARASKI1982No ratings yet

- Msge Motion Systems Listenpreise Gultig Ab 15-01-2021Document6,256 pagesMsge Motion Systems Listenpreise Gultig Ab 15-01-2021HendraNo ratings yet

- Ansul: Inergen 150 Bar SystemsDocument140 pagesAnsul: Inergen 150 Bar SystemsDaryl HeeralalNo ratings yet