Professional Documents

Culture Documents

3 Brinell Test

Uploaded by

Anwar HossainOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3 Brinell Test

Uploaded by

Anwar HossainCopyright:

Available Formats

TITLE OBJECTIVE THEORY

: Brinell Hardness Test : To determine the hardness of materials using Brinell hardness test :

The Brinell hardness test was one of the most widely used hardness tests with a fixed load that its indentation is proportional to the materials hardness. Hardness is a measure of a materials resistance to localized plastic deformation. By varying the test force and ball size, nearly all metals can be tested. Brinell hardness values are considered test force independent as long as the ball size/test force relationship is the same. The Brinell number, normally ranges from HB 50 to HB 750 for metals. The depth or size of the resulting indention is measured, which in turn is related to a hardness number; the softer the material, the larger and deeper is the indention, and the lower the hardness index number. Hardness test is performed more frequently than other mechanical test because it is simple, inexpensive and most important, its nondestructive test. The BHN is calculated according to the following formula:

Where, HB F D d

= Brinell hardness number = Imposed load (kg) = Diameter of the spherical indenter (mm) = Diameter of resulting indenter impression (mm)

From Brinell hardness test, another mechanical properties of material will be obtained, which is tensile strength, Tensile strength = (3.45 x HB) MPa Or Tensile strength = (500 x HB) psi APPARATUS : i. ii. iii. A Brinell desktop device. Mild Steel and Aluminium plate. Measurement apparatus (ruler, caliper, divider, etc)

EXPERIMENTAL PROCEDURE : 1. Winded up pressure in the pressure cylinder until the screw rise about 5cm. 2. Replaced the pressure plate with Brinell test unit (10mm steel ball). 3. Screwed the lower plate in position. 4. Positioned the steel test piece on the lower pressure plate, so that the center of the steel ball is at least 20mm from the edge. 5. Winded up the pressure to 10kN slowly. 6. Hold the load pressure for about 15 seconds. 7. Measured the diameter of the indentation using the magnifying lens. 8. The experiment using the other test pieces were repeated. 9. The tensile strength of the specimens are calculated. RESULTS Material Diameter of Brinell hardness Tensile strength of the Indentation,d(mm) number, HB(N/mm2) material (MPa) Stainless steel 5.40 19.34 Copper 4.26 6.76

DISCUSSION i.

: A 10mm diameter Brinell hardness indenter produced an indentation 2.50mm diameter in a steel alloy when a load of 1000kg was used. Computer the HB of this material. HB = 2(1000 x 10N) (3.142)(10mm)[10mm (10mm2 2.5mm2)1/2] = 20000N / 9.977 = 2004.58 N/mm2

ii.

What will be the diameter of an indentation to yield a hardness of 300 HB when 500kg load is used? 300 HB = 300 300 300 300 = = = = 2(500x10N) (10)[10mm (102 d2)1/2] 10000 10 [10 (10 d)] 10000 100 10 (10 d) 10000 100 100 + 10d 10000 10d

10 d = 10000 300 d = 33.33 10(3.142) d = 10.47mm

CONCLUSION :

REFERENCE

You might also like

- Appendix G Crane Safety Attachment A Pre Lift PlanDocument2 pagesAppendix G Crane Safety Attachment A Pre Lift PlanSyed Waqhas0% (1)

- Worm and Worm WheelDocument2 pagesWorm and Worm Wheelzacoss70% (10)

- Worm and Worm WheelDocument2 pagesWorm and Worm Wheelzacoss70% (10)

- Design Sheet for Armature of D-C GeneratorDocument11 pagesDesign Sheet for Armature of D-C GeneratorNoykols GRncNo ratings yet

- MCG3341 Midterm W2016 wSOLS PDFDocument12 pagesMCG3341 Midterm W2016 wSOLS PDFStefanGraczyk100% (1)

- Welding ATWDocument62 pagesWelding ATWARPIT MATHURNo ratings yet

- Pressure Test - Hydrostatic and Pneumatic Test RequirementsDocument6 pagesPressure Test - Hydrostatic and Pneumatic Test RequirementslorenzoNo ratings yet

- Bolting NewDocument6 pagesBolting Newsam_roy124No ratings yet

- Welding Material Control ProcedureDocument12 pagesWelding Material Control ProcedureWalter RuedaNo ratings yet

- Rockwell Hardness Test ExplainedDocument5 pagesRockwell Hardness Test ExplainedUsama Tahir100% (1)

- SAF 034 Crane Check ListDocument1 pageSAF 034 Crane Check ListAbn BKNo ratings yet

- Hardness Tester PortableDocument2 pagesHardness Tester Portablealfachemy100% (1)

- ANMAN CatalogueDocument5 pagesANMAN CatalogueLukman ZakariyahNo ratings yet

- Fire Extinguisher Selection ChartDocument1 pageFire Extinguisher Selection ChartPranoti JoshiNo ratings yet

- Piping General SpecificationDocument6 pagesPiping General Specificationcitra puspita sari100% (1)

- Test Plan WorkshopDocument24 pagesTest Plan WorkshopĐại NamNo ratings yet

- PACKING TITLEDocument10 pagesPACKING TITLEJohn NainggolanNo ratings yet

- Webbing Sling - SWLDocument4 pagesWebbing Sling - SWLChandrasekhar SonarNo ratings yet

- MPI GuideDocument17 pagesMPI Guidejaga67No ratings yet

- Emergency Warden Training For ADDocument20 pagesEmergency Warden Training For ADsetiawanaji407No ratings yet

- Bolt preloading and tensioning notesDocument6 pagesBolt preloading and tensioning notesBishwajyoti DuttaMajumdarNo ratings yet

- A) SS 536: 2008, Code of Practice For The Safe Use of Mobile CranesDocument18 pagesA) SS 536: 2008, Code of Practice For The Safe Use of Mobile CranesMainrajNo ratings yet

- Rigging BookDocument53 pagesRigging BookAhmed KhaledNo ratings yet

- Mordec-Catalogue 2011 MayDocument83 pagesMordec-Catalogue 2011 Maykiiru88100% (1)

- Hand SafetyDocument59 pagesHand SafetybenonNo ratings yet

- Product Selection Guide: Tube & Clamp ScaffoldDocument10 pagesProduct Selection Guide: Tube & Clamp ScaffoldGanesh Eshwar100% (1)

- Bs 1806 1989Document22 pagesBs 1806 1989Kishor Jadhav100% (2)

- Three Crane Accidents Caused by Improper RiggingDocument2 pagesThree Crane Accidents Caused by Improper RiggingSubbarao Mallampalli100% (1)

- Techsonic EZ III Rev 4 092010 PDFDocument70 pagesTechsonic EZ III Rev 4 092010 PDFandresgomez10No ratings yet

- EN 15151-1 enDocument1 pageEN 15151-1 enMulyana Ibex100% (1)

- Slings, Rigging and Lifting EquipmentDocument11 pagesSlings, Rigging and Lifting Equipmentgshdavid0% (1)

- General or Cold PTWDocument2 pagesGeneral or Cold PTWVijayakumar KarunanidhiNo ratings yet

- Method of Statement PDFDocument7 pagesMethod of Statement PDFSakib AyubNo ratings yet

- Penguard ZP AO - English (Uk) - Issued.06.12.2007Document3 pagesPenguard ZP AO - English (Uk) - Issued.06.12.2007Mohamed FaragNo ratings yet

- Health and Safety in Fabrication and Welding Work BookDocument12 pagesHealth and Safety in Fabrication and Welding Work BookPrakash JoshiNo ratings yet

- Bench SawDocument4 pagesBench SawimranNo ratings yet

- OHSE Basic Requirement-COHSEMP (Update Ausgust 2018)Document94 pagesOHSE Basic Requirement-COHSEMP (Update Ausgust 2018)Sri Eko100% (1)

- Lifting Sequence Boiler Steel StructureDocument18 pagesLifting Sequence Boiler Steel StructureXwerty BoxNo ratings yet

- Aac Spec 377003Document25 pagesAac Spec 377003JakesNo ratings yet

- Job Hazard Analysis: Generic Jha For Blasting & Painting WorksDocument7 pagesJob Hazard Analysis: Generic Jha For Blasting & Painting WorksReynaldo PesqueraNo ratings yet

- Bending Moment Capacity of PipesDocument13 pagesBending Moment Capacity of Pipess3201696No ratings yet

- MIDCO Lifting Manual SOWDocument47 pagesMIDCO Lifting Manual SOWMoetaz MohamedNo ratings yet

- Disclosure To Promote The Right To InformationDocument15 pagesDisclosure To Promote The Right To InformationjaganNo ratings yet

- Hydrogen Sulfide ProtocolDocument32 pagesHydrogen Sulfide Protocolmashangh100% (1)

- Base PlateDocument4 pagesBase Platejatin kalraNo ratings yet

- PPL-PVS-023 - Rev1 - Barge Calculation During Transportation On SeaDocument80 pagesPPL-PVS-023 - Rev1 - Barge Calculation During Transportation On SeaThanh Anh MaiNo ratings yet

- En Allround Delekatalog 2017Document68 pagesEn Allround Delekatalog 2017Hanafiah RozaliNo ratings yet

- NCDOT WPS for Double Bevel Groove WeldsDocument3 pagesNCDOT WPS for Double Bevel Groove Weldsfarshid KarpasandNo ratings yet

- Fall ArrestersDocument1 pageFall ArrestersTrust EmmaNo ratings yet

- Project Proposal Wind MillDocument8 pagesProject Proposal Wind MillAbdul BasitNo ratings yet

- RA For Assessment For Lifting OperationsDocument19 pagesRA For Assessment For Lifting OperationsMohamedSaidNo ratings yet

- Material Handling SOPDocument1 pageMaterial Handling SOPRajesh Sharma100% (1)

- "Total Hse Solution in Project Construction Sites": Welcome To Presentation OnDocument15 pages"Total Hse Solution in Project Construction Sites": Welcome To Presentation OnAkhilesh Kumar SinghNo ratings yet

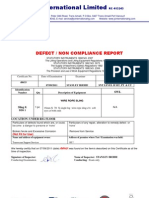

- Defect / Non Compliance ReportDocument12 pagesDefect / Non Compliance ReportMichael OkwuwaNo ratings yet

- HACCP Blank Form 3Document1 pageHACCP Blank Form 3kristinemaemutiaNo ratings yet

- Project: Bbs For No of Bars Weight of Steel Set Nos Total No Cutting Length Total LengthDocument2 pagesProject: Bbs For No of Bars Weight of Steel Set Nos Total No Cutting Length Total LengthkavithaNo ratings yet

- Piping Engineering All Codes and StandardDocument17 pagesPiping Engineering All Codes and Standardomkar parabNo ratings yet

- OSHA Man Basket User ManualDocument9 pagesOSHA Man Basket User Manualwalid EttihNo ratings yet

- Dynamic and Static Balancing of Rolls - How, Why and WhenDocument2 pagesDynamic and Static Balancing of Rolls - How, Why and WhenAbolfazl KhakiNo ratings yet

- Hardness Test-LOAYDocument7 pagesHardness Test-LOAYBin IbrahimNo ratings yet

- Brinell Hardness TestDocument21 pagesBrinell Hardness TestenginearswebNo ratings yet

- Brinell Hardness Testing PresentationDocument17 pagesBrinell Hardness Testing PresentationAldi Zuldiansyah100% (1)

- Exp.6 Brinell Hardness TestDocument5 pagesExp.6 Brinell Hardness TestG. Dancer Gh0% (1)

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesFrom EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNo ratings yet

- Mesaieed Brochure 2019Document11 pagesMesaieed Brochure 2019Anwar HossainNo ratings yet

- Engineering Drawing: Project PresentationDocument16 pagesEngineering Drawing: Project PresentationAnwar HossainNo ratings yet

- Welding Process DemonstrationDocument4 pagesWelding Process DemonstrationAnwar HossainNo ratings yet

- Mark Scheme (Results) January 2010: GCE Applied ICT (6953/01) The Knowledge WorkerDocument12 pagesMark Scheme (Results) January 2010: GCE Applied ICT (6953/01) The Knowledge WorkerAnwar HossainNo ratings yet

- Mechanical LAbDocument1 pageMechanical LAbAnwar HossainNo ratings yet

- Study of The Optical Properties of Poly (Methyl Methacrylate) (PMMA) Doped With A New Diarylethen CompoundDocument10 pagesStudy of The Optical Properties of Poly (Methyl Methacrylate) (PMMA) Doped With A New Diarylethen CompoundHuỳnh Minh KhôiNo ratings yet

- Essential Soil Tests for Building FoundationsDocument6 pagesEssential Soil Tests for Building FoundationsJustin MusopoleNo ratings yet

- FALLSEM2018-19 - MEE1004 - ETH - MB309 - VL2018191003741 - Reference Material I - Fluid Mechanics-3 PDFDocument69 pagesFALLSEM2018-19 - MEE1004 - ETH - MB309 - VL2018191003741 - Reference Material I - Fluid Mechanics-3 PDFSivaram PeramNo ratings yet

- Rock Stress Measurement MethodsDocument50 pagesRock Stress Measurement MethodschouszeszeNo ratings yet

- Lesson 1. Atomic Number and Synthesis of New ElementsDocument22 pagesLesson 1. Atomic Number and Synthesis of New ElementsMary Angeline L. BatacNo ratings yet

- BSNL JTO Sample Paper-3Document100 pagesBSNL JTO Sample Paper-3ramesh_balakNo ratings yet

- Energy For ProductivityDocument65 pagesEnergy For ProductivityNurettinAlpNo ratings yet

- Bifilar SuspensionDocument9 pagesBifilar SuspensionUmer ZamanNo ratings yet

- Rack and Pinion Gear DesignDocument32 pagesRack and Pinion Gear DesignmattgrubbsNo ratings yet

- 9 ContactmodelingDocument56 pages9 Contactmodelinganirudh666No ratings yet

- Introduction to ICP-MS for Elemental AnalysisDocument32 pagesIntroduction to ICP-MS for Elemental AnalysisShreeya Sethi GroverNo ratings yet

- FR4 3Document3 pagesFR4 3Elyse Fawohodie Kwadwo100% (5)

- 1982 - Mcelhaney - The Use of Differential Scanning Calorimetry and Differential Thermal Analysis in Studies of Model and Biological MembranesDocument31 pages1982 - Mcelhaney - The Use of Differential Scanning Calorimetry and Differential Thermal Analysis in Studies of Model and Biological MembranesymiyazyNo ratings yet

- NDT Syllabus NIT TrichyDocument17 pagesNDT Syllabus NIT Trichykhizer mohamedNo ratings yet

- Book ListDocument18 pagesBook ListazizbinnaserNo ratings yet

- Mitigation of Thermal Cracking in Massive FoundationsDocument7 pagesMitigation of Thermal Cracking in Massive Foundationssravan_rubyNo ratings yet

- MANU PPT - PPTX 2Document13 pagesMANU PPT - PPTX 2Karan JoshiNo ratings yet

- CM Monthly Test Schedule & SyllabusDocument1 pageCM Monthly Test Schedule & Syllabusprachir1501No ratings yet

- F-0606 - Standard Test Method For Determining The Mechanical Properties of Externally and Internally Threaded Fasteners, Washers, and RivetsDocument12 pagesF-0606 - Standard Test Method For Determining The Mechanical Properties of Externally and Internally Threaded Fasteners, Washers, and RivetsEwan SutherlandNo ratings yet

- Compressibility Z-Factor (Dranchuk-Abu-Kassem Method) : DisclaimerDocument4 pagesCompressibility Z-Factor (Dranchuk-Abu-Kassem Method) : DisclaimermrezzaNo ratings yet

- Mechanical Properties of Biological TissuesDocument8 pagesMechanical Properties of Biological TissuesHitendra SonkarNo ratings yet

- PV NRT: PM RT DRT PDocument19 pagesPV NRT: PM RT DRT PRyle ArbonNo ratings yet

- Engg Mech and Strength of MaterialsDocument73 pagesEngg Mech and Strength of MaterialsClaire NecesitoNo ratings yet

- Domino MagnificationDocument13 pagesDomino MagnificationYoceli RecobaNo ratings yet

- Calibration Curve of MBDocument140 pagesCalibration Curve of MBSandip KadoliNo ratings yet

- Reynolds NumberDocument15 pagesReynolds NumberZzPumpkingNo ratings yet

- Unveiling The Secrets of String TheoryDocument2 pagesUnveiling The Secrets of String Theorybic1973No ratings yet