Professional Documents

Culture Documents

OSHA Hard Hat Standards

Uploaded by

Raffer Asis MorañoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OSHA Hard Hat Standards

Uploaded by

Raffer Asis MorañoCopyright:

Available Formats

OSHA Standards for Wearing a Hard Hat

The Occupational Safety and Health Administration (OSHA), the agency for enforcing workplace safety laws, provides standards to protect workers from possible dangers at the workplace. For the construction industry, one of those protections is the OSHA standards for wearing a hard hat.

Head Protection Standard

According to the OSHA 1926.100(a) standard, "Employees working in areas where there is a possible danger of head injury from impact, or from falling or flying objects, or from electrical shock and burns, shall be protected by protective helmets."

Responsibilities

The "Duty of Care" principle means companies need to plan for the prevention of accidents at worksites. Under this standard, an employer must initially evaluate the activities of its employees and the surrounding activities on the job site and determine whether these hazards require the need for a hard hat to be worn. Employees who are obligated to wear a hard hat can be penalized under OSHA regulations for failing to wear the hat.

Performance

OSHA relies on the American National Standards Institute (ANSI) Z89.1-1997 guideline for compliance regarding hard hats. This ANSI statute recognizes three classes of hard hats, each which must withstand blows to the head and exposure to a variety of electrical impacts. The head wear must be tested for penetration, flammability resistance and water absorption.

Optional Test Criteria

Three optional test criteria are used by manufacturers of protective helmets based on ANSI Z89.1-2009. Reverse donning tests measure performance whether the hard hat is worn frontward or backwards. Low temperature tests show whether the hard hat meets perfomance requirements to -30 C (-22 F). High visibility testing indicates the hard hat meets requirements for high visibility colors.

Exemptions

In 1978 OSHA provided an exemption from wearing hard hats for employees who are members of the Old Order Amish or Sikh Dharma Brotherhood religious communities. In 1993, the Religious Freedom Restoration Act created OSHA standards for wearing a hard hat for employers and employees with specific

personal religious convictions. In such cases, the employer will not enforce wearing a hard hat, will instruct workers about the hazards of not wearing a hard hat and will contact OSHA.

HARD HAT FACTS

Q. What is the service life of my hard hat? A. The hard hats are designed with high quality, wear-resistant materials but it WILL NOT last forever. The protective properties of the helmet WILL be degraded by exposure to many common work environments, such as temperature extremes, chemical exposure, sunlight and normal daily wear and tear. The following is a recommend replacement schedule: Hard Hat Suspension - replace after NO MORE THAN 12 months; Entire Hard Hat - replace after NO MORE THAN 5 years. Remember that these are MAXIMUM useful service life guidelines. Wear or damage noticed during a regular inspection MUST be the determining factor for possible earlier replacement. In any case, ALWAYS replace the hard hat after it has withstood impact or penetration. Q. There is a date code on the inside of my hard hat is this when the service life starts? A. A hard hats service life starts when it is placed in service. This date should be recorded in the helmet, either on the ANSI label or with the use of a date of service label. The "date code" stamped on the inside of your hard hat refers to the date of manufacture, not the starting date for useful service. Q. I have a suspension from a manufacturer other than the original manufacturer, can I use it? A. NEVER attempt to interchange suspensions from one hat manufacturer to another. Use only the appropriate replacement parts from the original manufacturer. If you do not know who manufactured your hard hat you will need to replace the entire hard hat. Q. Can I wear my hard hat backwards? A. This depends on the manufacturer of your hard hat. If the suspension attachment points on your hard hat are the same from front to back, the suspension can be reversed and the cap worn with the brim facing the rear and still meet the requirements of the applicable protective headwear standard. Be sure that the suspension has been reversed so that the nape strap is in the rear. Many hard hat manufactures now offer swing-style suspensions that allow for you to quickly reverse the direction of your hard hat. Q. Can I paint my hard hat? A. Never paint a hard hat. Paint may chemically attack and damage the hard hats shell, thereby reducing the degree of protection originally provided. Q. Can I put anything in the space between the hard hat shell and suspension?

A. Items such as gloves, cigarettes and earplugs should NEVER be stored between the suspension and the shell. This space is needed when the shell and suspension absorbs the energy of an impact. Such objects in this space can transmit large forces to the head and neck, resulting in serious injury or death.

You might also like

- An Instructional Aid For Occupational Safety and Health in Mechanical Engineering Design: Enter asset subtitleFrom EverandAn Instructional Aid For Occupational Safety and Health in Mechanical Engineering Design: Enter asset subtitleNo ratings yet

- Don't Be Hard-Headed - Replace Aging Hard HatsDocument4 pagesDon't Be Hard-Headed - Replace Aging Hard HatsishamNo ratings yet

- Safety Helmet ShibDocument4 pagesSafety Helmet Shibkarchinmoy1995No ratings yet

- Head Protection (Hard Hats) : Training On The Use of Hard Hats in The WorkplaceDocument20 pagesHead Protection (Hard Hats) : Training On The Use of Hard Hats in The WorkplaceArvind SinghNo ratings yet

- Hard Hat RequirementsDocument6 pagesHard Hat RequirementsYussi WaluyoNo ratings yet

- Personal Protective EquipmentDocument19 pagesPersonal Protective EquipmentpoojaupesNo ratings yet

- ANSI Z89.1 MANUAL Hard Hat PDFDocument2 pagesANSI Z89.1 MANUAL Hard Hat PDFDeden SanusiNo ratings yet

- Personal Protective EquipmentDocument20 pagesPersonal Protective EquipmentpoojaupesNo ratings yet

- Osha Book PDFDocument76 pagesOsha Book PDFTahir MasoodNo ratings yet

- Hard HatsDocument2 pagesHard HatsraphilyNo ratings yet

- Hard Hat SafetyDocument2 pagesHard Hat SafetyMery EllisNo ratings yet

- Sfty Group 3 - Ppe - Head ProtectionDocument13 pagesSfty Group 3 - Ppe - Head ProtectionLance AngeloNo ratings yet

- Personal Protective Equipment Day 2Document37 pagesPersonal Protective Equipment Day 2OsamaAlaasamNo ratings yet

- Special Note To Helmet UsersDocument51 pagesSpecial Note To Helmet UsersEspín CompeticiónNo ratings yet

- Personal Protective EquipmentDocument24 pagesPersonal Protective EquipmentDominick Bas100% (4)

- Health, Safety and Risk Management: Fourth Year Lec.3Document6 pagesHealth, Safety and Risk Management: Fourth Year Lec.3mohammed naeemNo ratings yet

- Personal Protective Equipment for Welding SafetyDocument8 pagesPersonal Protective Equipment for Welding Safetyerika garciaNo ratings yet

- Eye Safety Guide for WorkersDocument5 pagesEye Safety Guide for WorkerstipuNo ratings yet

- The Requirement For PPEDocument40 pagesThe Requirement For PPECtstrphyNo ratings yet

- General Safety Rules For Steel Fabricators AISCDocument55 pagesGeneral Safety Rules For Steel Fabricators AISCEdison BecerraNo ratings yet

- Manual ENG Gp5x1Document12 pagesManual ENG Gp5x1Sassa ArcszNo ratings yet

- Ui-Rfaz-006-101 Ansi Helmet Eng-Esp V2Document2 pagesUi-Rfaz-006-101 Ansi Helmet Eng-Esp V2trialnaqueraNo ratings yet

- 4a. Protective ClothingDocument32 pages4a. Protective ClothingsarahNo ratings yet

- ©consultnet Limited 1Document132 pages©consultnet Limited 1John DenverNo ratings yet

- 6 OSHA Personal Protective Equipment (2004)Document202 pages6 OSHA Personal Protective Equipment (2004)belshaNo ratings yet

- PPE Training-InitialDocument46 pagesPPE Training-InitialAnonymous 1wDPsonNo ratings yet

- ARC WELDING SAFETY TIPSDocument16 pagesARC WELDING SAFETY TIPSScott NorrisNo ratings yet

- CNX 2-11-13 PpeDocument29 pagesCNX 2-11-13 PpeMichael KovachNo ratings yet

- Norma SnellDocument44 pagesNorma SnellNathaly GarciaNo ratings yet

- Eye and Face ProtectionDocument2 pagesEye and Face ProtectionAbu LeoNo ratings yet

- Hard Hat Safety TipsDocument2 pagesHard Hat Safety TipsWelma JohnsonNo ratings yet

- Safety GlassesDocument7 pagesSafety GlassesReki SwandanaNo ratings yet

- PPE ReportDocument22 pagesPPE ReportJhiGz Llausas de Guzman100% (1)

- PPE for Roofing IndustryDocument5 pagesPPE for Roofing IndustryÁineNo ratings yet

- Slide Osha PpeDocument12 pagesSlide Osha PpeNurzaidah AdnanNo ratings yet

- Part I - 03 Personal Protective Equipment (PPE)Document10 pagesPart I - 03 Personal Protective Equipment (PPE)Muhammad RizwanNo ratings yet

- EIM-10-WK-7-8Document6 pagesEIM-10-WK-7-8ivyeNo ratings yet

- Head Protection: Identifying HazardsDocument1 pageHead Protection: Identifying HazardsElton HasanajNo ratings yet

- Amor, Module 3 (BOSH)Document3 pagesAmor, Module 3 (BOSH)jerkNo ratings yet

- Eye Protection at WorkDocument4 pagesEye Protection at WorkHarits PamitranNo ratings yet

- World Health OrgansationDocument17 pagesWorld Health OrgansationYash AroraNo ratings yet

- Mod-1 - SJ - Val May 2020 - Ppe & Chemical SafetyDocument16 pagesMod-1 - SJ - Val May 2020 - Ppe & Chemical SafetyL JayanthiNo ratings yet

- FIA Driver Safety EquipmentDocument7 pagesFIA Driver Safety EquipmentLê Thành NhơnNo ratings yet

- 08a. TUV - COSH PPEDocument74 pages08a. TUV - COSH PPERYAN JOSEPH QUIMONo ratings yet

- Tool Box Talk: Eye ProtectionDocument1 pageTool Box Talk: Eye ProtectionEtibar AliyevNo ratings yet

- SDS NLBX 5934693Document2 pagesSDS NLBX 5934693Joey Cross fxNo ratings yet

- CM PR 16Document11 pagesCM PR 16omkarsonawane517No ratings yet

- HelmetDocument5 pagesHelmetSmita Sawant BholeNo ratings yet

- Delta School of Trades Welding Handbook by Norman J. AshleyDocument164 pagesDelta School of Trades Welding Handbook by Norman J. Ashleyamin_corporationNo ratings yet

- Eye and Face Protection PFDocument31 pagesEye and Face Protection PFAwalludin Pandu NegaraNo ratings yet

- Day 3 PPE (Handout)Document10 pagesDay 3 PPE (Handout)mike camsNo ratings yet

- Basics of Ppe TrainingDocument46 pagesBasics of Ppe TrainingAmhier Ong MokamadNo ratings yet

- Personal Protective EquipmentDocument6 pagesPersonal Protective EquipmentMariezen FernandoNo ratings yet

- All Employees Must Wear Appropriate ClothingDocument3 pagesAll Employees Must Wear Appropriate ClothingEsanka FernandoNo ratings yet

- PERSONAL PROTECTIVE EQUIPMENT Is Considered The Least Satisfactory Method in TheDocument14 pagesPERSONAL PROTECTIVE EQUIPMENT Is Considered The Least Satisfactory Method in TheAizen SousukeNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Workplace Vocabulary for Esl Students: With Exercises and TestsFrom EverandWorkplace Vocabulary for Esl Students: With Exercises and TestsNo ratings yet

- Power Carving Manual, Updated and Expanded Second Edition: Tools, Techniques, and 22 All-Time Favorite ProjectsFrom EverandPower Carving Manual, Updated and Expanded Second Edition: Tools, Techniques, and 22 All-Time Favorite ProjectsRating: 4 out of 5 stars4/5 (1)

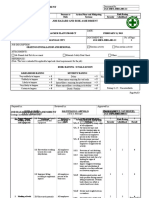

- Seismic Analyis Description DL Length (M) Width (M) Thickness (M) N Weight (W) Slab 23.5 Beam Column Total WeightDocument1 pageSeismic Analyis Description DL Length (M) Width (M) Thickness (M) N Weight (W) Slab 23.5 Beam Column Total WeightRaffer Asis MorañoNo ratings yet

- Estate Settlement GuidelinesDocument4 pagesEstate Settlement GuidelinesOfel TactacNo ratings yet

- SAnalysis IIDocument1 pageSAnalysis IIRaffer Asis MorañoNo ratings yet

- SAnalysis IIDocument1 pageSAnalysis IIRaffer Asis MorañoNo ratings yet

- Electric Motor Controls TutorialDocument24 pagesElectric Motor Controls Tutorialvijai daniel100% (4)

- Otis EscalatorDocument2 pagesOtis Escalatorratnasekhar_g100% (1)

- RC Design PDFDocument58 pagesRC Design PDFZerihun IbrahimNo ratings yet

- GAM DistributionOfLoads 2 Horizontal TorsionDocument48 pagesGAM DistributionOfLoads 2 Horizontal TorsionFelipe Carrasco Durán100% (1)

- SlabDocument66 pagesSlabRaffer Asis MorañoNo ratings yet

- How To Design A Junction in Civil 3DDocument30 pagesHow To Design A Junction in Civil 3DRaffer Asis MorañoNo ratings yet

- History of Housing Development in The PhilDocument5 pagesHistory of Housing Development in The PhilAries Vincent Vengco Felipe83% (6)

- Acco DobDocument1 pageAcco DobRaffer Asis MorañoNo ratings yet

- Location and Sizing of PumpDocument1 pageLocation and Sizing of PumpRaffer Asis MorañoNo ratings yet

- FallPrevention2014 QuickCard PDFDocument2 pagesFallPrevention2014 QuickCard PDFRaffer Asis MorañoNo ratings yet

- Brand NamesDocument2 pagesBrand NamesReigneth VillenaNo ratings yet

- Estate Settlement GuidelinesDocument4 pagesEstate Settlement GuidelinesOfel TactacNo ratings yet

- History of Housing Development in The PhilDocument5 pagesHistory of Housing Development in The PhilAries Vincent Vengco Felipe83% (6)

- Manual For ProsecutorsDocument51 pagesManual For ProsecutorsArchie Tonog0% (1)

- Item Description Amount I Concreting WorksDocument2 pagesItem Description Amount I Concreting WorksRaffer Asis MorañoNo ratings yet

- Cad Standard ManualDocument23 pagesCad Standard ManualNoly TicsayNo ratings yet

- Soil StrengthDocument2 pagesSoil StrengthRaffer Asis MorañoNo ratings yet

- Quick Card: What You Need To KnowDocument2 pagesQuick Card: What You Need To KnowRaffer Asis MorañoNo ratings yet

- Use of Lscape2Document1 pageUse of Lscape2Raffer Asis MorañoNo ratings yet

- PC ColDocument1 pagePC ColRaffer Asis MorañoNo ratings yet

- ConvectionDocument1 pageConvectionRaffer Asis MorañoNo ratings yet

- ConvectionDocument1 pageConvectionRaffer Asis MorañoNo ratings yet

- WoodDocument6 pagesWoodRaffer Asis MorañoNo ratings yet

- ESDocument1 pageESRaffer Asis MorañoNo ratings yet

- A T S Automatic Transfer SwitchDocument1 pageA T S Automatic Transfer SwitchRaffer Asis MorañoNo ratings yet

- HSE IMS System ManualDocument172 pagesHSE IMS System Manualdzelig0% (1)

- Operating Instruction: MAN Industrial Diesel Engines D2862 LE221/223/231/233Document86 pagesOperating Instruction: MAN Industrial Diesel Engines D2862 LE221/223/231/233Camilo PuentesNo ratings yet

- Responsible Research Managing Health and Safety in Research Advice GuideDocument36 pagesResponsible Research Managing Health and Safety in Research Advice Guidegato locoNo ratings yet

- Scott Alcohol Antibacterial Wipe SDS PDFDocument10 pagesScott Alcohol Antibacterial Wipe SDS PDFVinieysha LoganathanNo ratings yet

- BSBLDR502 DiplomaDocument41 pagesBSBLDR502 DiplomaSaba MateenNo ratings yet

- Synerquest-Public Training Schedule For 2013Document2 pagesSynerquest-Public Training Schedule For 2013robinrubinaNo ratings yet

- SDS CPVC CementDocument2 pagesSDS CPVC CementAhmad AnthonyNo ratings yet

- Dow Corning Corporation Material Safety Data SheetDocument8 pagesDow Corning Corporation Material Safety Data SheetvkmsNo ratings yet

- IG1 Element 2Document30 pagesIG1 Element 2Shah Wali UllahNo ratings yet

- Occupational Hazards in Textile IndustryDocument20 pagesOccupational Hazards in Textile IndustryShilpa ChaubeyNo ratings yet

- Arcelor Metal Coated Steel SheetsDocument11 pagesArcelor Metal Coated Steel SheetskhurshedlakhoNo ratings yet

- Safety Data Sheet: Ranco-Sil (TM) Fused Silica (NA)Document8 pagesSafety Data Sheet: Ranco-Sil (TM) Fused Silica (NA)Peter GelburdNo ratings yet

- 02 04 AMM Daily HSE Statistics Report AprDocument1 page02 04 AMM Daily HSE Statistics Report AprPT. ANUGRAH MIRAN MANDIRINo ratings yet

- MSDS for Carpet SpotterDocument7 pagesMSDS for Carpet Spotteraudi 2022No ratings yet

- Chieftain 1400 Operations Manual Revision 3.4 (English) - 1Document434 pagesChieftain 1400 Operations Manual Revision 3.4 (English) - 1Steven Dolan88% (8)

- The Complete Guide To: First Aid at WorkDocument9 pagesThe Complete Guide To: First Aid at WorkmuneerpmhNo ratings yet

- Action Checklist WISE COVID - 0505Document7 pagesAction Checklist WISE COVID - 0505j brotherNo ratings yet

- Occupational Health and Safety Scored Test AnswersDocument4 pagesOccupational Health and Safety Scored Test AnswersHisburn BermudezNo ratings yet

- NCEMA 6000 EnglishDocument60 pagesNCEMA 6000 EnglisheastNo ratings yet

- Standards Monitoring Self-AssessmentDocument17 pagesStandards Monitoring Self-AssessmentNuepe Manuel Jr.No ratings yet

- JGS SHES JHRA 001 13 Grating Installation and RemovalDocument2 pagesJGS SHES JHRA 001 13 Grating Installation and Removalarnel sungkip100% (2)

- The Existence & Application of Digital Technologies in Promoting Health & Safety in The South African Construction IndustryDocument67 pagesThe Existence & Application of Digital Technologies in Promoting Health & Safety in The South African Construction IndustryShaariq JoosubNo ratings yet

- IEEE Guide For Motor Control Centers Rated Up To and Including 600 V AC or 1000 V DC With Recommendations Intended To Help Reduce Electrical HazardsDocument47 pagesIEEE Guide For Motor Control Centers Rated Up To and Including 600 V AC or 1000 V DC With Recommendations Intended To Help Reduce Electrical HazardsSuman SahaNo ratings yet

- 1 (MPH) MPHOHLO Safety PolicyDocument1 page1 (MPH) MPHOHLO Safety PolicyLwandziso DlaminiNo ratings yet

- EMPLOYABILITY SKILLS - Semester 2 Module 1. Entrepreneurship SkillsDocument8 pagesEMPLOYABILITY SKILLS - Semester 2 Module 1. Entrepreneurship SkillsSumit RoyNo ratings yet

- Prevecan 2009 EnglishDocument150 pagesPrevecan 2009 EnglishatipometroNo ratings yet

- NeboshPractical GudianceDocument5 pagesNeboshPractical GudianceAmb Patrick Oghate0% (1)

- Module 4 - Housekeeping (Occupational Safety)Document20 pagesModule 4 - Housekeeping (Occupational Safety)Sam100% (1)

- T-MEET 001 004 Basic OSH Module 5 5a Occupationa Health Facility Safety MGT SystemDocument52 pagesT-MEET 001 004 Basic OSH Module 5 5a Occupationa Health Facility Safety MGT SystemFranz ObcenaNo ratings yet