Professional Documents

Culture Documents

Scada

Uploaded by

Sander TimmermansOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scada

Uploaded by

Sander TimmermansCopyright:

Available Formats

PT.

TRIPATRA Engineers and Constructors

Appendix A Scope of Work

APPENDIX A SCOPE OF WORK 1. GENERAL The Scope of Work is to specify the extended of the work of the Subcontractor by clarifying in detail the respective work supply responsibilities of Subcontractor and TPEC. The Sub-contractor shall be responsible to perform Pipeline Works in accordance with the requirements and conditions as stipulated in this Scope of Work and Appendix B Split of Work. In performing the work, Subcontractor shall be responsible to: Furnish all labor, construction equipment support, tools and necessary consumables. Perform environmental compliance and monitoring activities in accordance with all applicable regulations. Obtain the necessary permits required to construct the work from related government and/or institution or land owner (i.e. Railway crossing, main Road Crossing, etc)

For the purpose of the proposal, the Bill of Quantity as defined in Appendix C shall be used as reference only. 2. DESCRIPTION OF WORK 2.1. Engineering Requirements General This section covers the requirements of the buried 8 NGL pipeline from the Extraction Plant, Prabumulih Barat to Pulau Layang. The extent of the pipeline scope discussed here is from the mating outlet flange of the pig launcher at Prabumulih Barat to the inlet mating flange of the pig receiver at Pulau Layang. SUB-CONTRACTOR shall complete the engineering and detail of the 8 NGL pipeline utilizing the Design Criteria, drawings, specifications, data sheets, and other pertinent information furnished by TPEC. Engineering shall include final survey, detail engineering, field engineering, preconstruction survey and as-built surveying of the pipeline routes, and all construction engineering and analysis required for safe and acceptable installation and operation of the pipeline.

Page 1 of 12

PT. TRIPATRA Engineers and Constructors

Appendix A Scope of Work

SUB-CONTRACTOR shall review and generate the Design Basis and all other information furnished by TPEC and shall propose to TPEC any changes required to complete and finalize the engineering and detail engineering of all pipelines. Design Codes The pipeline within SUB-CONTRACTORs scope shall be designed and installed in accordance with the latest edition of the ASME codes as follows: pipeline from pig launcher inside NGL Extraction Plant Prabumulih Barat to Pig Receiver inside existing fence-line of Sungai Gerong Refinery, ASME B 31.4. Pipeline Disposition The pipeline shall be buried 1,5 meter minimum depth below ground level from top of pipe [TOP] for straight installation, while 2.0 meters from TOP for crossing from the Pig Launcher at Prabumulih Barat to Pig Receiver at Pulau Layang. Pipeline Routings COMPANY has indicated a preliminary routing and alignment sheets for the pipeline, which lies within the existing Pertamina pipelines ROW. SUB-CONTRACTOR shall provide, for TPEC/COMPANY approval prior to construction, final Pipeline Alignment Sheets. The alignment sheets shall include additional information including the following: Location of pipe within the ROW Plans and profile of existing ground surface Class locations. Buoyancy control measures Erosion control measures Line pipe information such as wall thickness, coatings, etc. Cathodic Protection and AC Mitigation details Final location of block valves Location of hot induction bends Location of additional mechanical protection such as concrete coating, where the pipeline is susceptible to 3rd party damage Location of special construction techniques Landowner information Pipeline Crossings

Page 2 of 12

PT. TRIPATRA Engineers and Constructors

Appendix A Scope of Work

There are pipeline crossings that are shown on the preliminary Pipeline Alignment Sheets. These crossings may include but are not limited to rivers, streams, railroads, highways, public and private roads, ditches, ponds, and utilities. SUB-CONTRACTOR shall prepare a Crossing List for the pipeline describing the type of each crossing and any special construction techniques or considerations required. Sub-Contractor shall design and construct all railroad and road crossings to meet the requirements of local regulations and API RP 1102: Steel Pipelines Crossing Railroads and Highways. Sub-Contractor shall determine the location and frequency of pipeline markers. At a minimum pipeline markers shall be installed on each side of each river, public road, railroad and highway that is crossed. The pipeline markers shall be in accordance with local regulations (MIGAS Standard 300.K/38/M.PE/1997) and API RP 1109: Marking Liquid Petroleum Pipeline Facilities, and shall be approved by TPEC/COMPANY. Cathodic Protection and AC Mitigation Systems SUB-CONTRACTOR shall complete final detail engineering to install cathodic protection systems for pipelines based on the soil characteristics including electrical resistively and pipeline protective coating information. Test stations shall be installed on regular intervals not exceeding 1 kilometer [HOLD] along the pipeline routes and where foreign lines are crossed. Additional test stations shall also be installed at each cased road and railway crossing. Permanent protection for the 8 NGL pipeline shall be provided by ground well anode impressed current system. If this cannot be provided within six months of the line installation, SUB-CONTRACTOR shall design and install temporary galvanic anode systems based on a two-year design life. The anode system shall be based on a 20-year design life. Insulation joints shall be installed to isolate the pipeline from the main facilities per Project Drawings. At some locations, the pipeline may be adjacent or near to existing or planned overhead high voltage AC power systems. These areas may include sections of parallelism, crossings and discontinuities. The pipelines and appurtenances may be exposed to possible hazardous AC conditions. In these locations the pipelines will require AC interference evaluation and subsequent mitigation. The design shall be finalized by SUB-CONTRACTOR subjected to TPEC and/or COMPANY approval. SUB-CONTRACTOR shall coordinate its activities with the power transmission authority and obtain all necessary information from the authority to finalize the design.

Page 3 of 12

PT. TRIPATRA Engineers and Constructors

Appendix A Scope of Work

Launcher/Receiver Facilities For the pig launchers and receivers indicated on the Project Drawings, SUBCONTRACTOR shall complete final detail engineering to install the facilities. 2.2. Transportation of Line Pipe SUB-CONTRACTOR shall be responsible for transportation all line pipe and pipeline accessories supplies by TPEC from TPEC warehouse to Pipeline location. The transportation method is subject to TPEC and/or COMPANY approval. Detailed specifications for the line pipe and coating provide by TPEC. 2.3. Installation of Pipe Lines The Pipe lines between the Prabumulih and Pulau Layang shall be installed in accordance with the final approved alignment sheets and corridor drawings. SUBCONTRACTOR shall complete all Work required to place the pipelines in operation, including construction, installation of specified appurtenances, testing, tie-ins, cleaning, pre-commissioning, site restoration, and submittal of as-built data and other documentation, all in accordance with the Contract Documents. Included, but not limited to, as part of its Work, SUB-CONTRACTOR shall: Comply with the provisions of Tender Documents/Contract Survey, as required, to re-establish and maintain the alignment centerline as defined by the Project Drawings; to locate and identify all above and below ground obstructions; and to support construction activities in accordance with the specifications. Clear, grade and prepare right-of-way, including topsoil separation, rock removal and construction of access roads required to move equipment, material and personnel to work areas. Provide and install temporary exclusion fencing along the right-of-way for environmentally restricted areas. Excavate ditch, including rock excavation and dispose of rock to approved sites. Daylight existing pipelines as necessary to verify location. Provide material and install ditch plugs in accordance with specifications. Install shoring or sheet piling where required for protection of personnel or to allow a free working area. Construction shall be in accordance with applicable regulations, and SubContractor shall provide all required permits. Field bend pipe to fit ditch. Install induction bends to fit ditch where field bending cannot be performed.

Page 4 of 12

PT. TRIPATRA Engineers and Constructors

Appendix A Scope of Work

Develop and qualify welding procedures and qualify welders for TPEC and/or COMPANY approval prior to work execution. Weld the pipeline pipe utilizing a qualified process. Back-weld and/or back-bevel heavy wall pipes, valves, fittings, etc. as required. Provide and apply specified coatings to field joints, buried valves, fittings, piping and other bare metal surfaces, and make necessary repairs to coating damage in accordance with the specifications. Provide holiday detection inspection of all coatings, including factory applied coatings, SUB-CONTRACTOR applied field joints and coatings on buried valves, fittings, piping, etc. Furnish and place material for bedding and padding of pipe in the ditch. Lower-in the pipeline. Provide special construction for crossing seismic faults, existing pipelines, power cables, transmission lines, and other foreign utilities. Provide and install TPEC and/or COMPANY approved rock shield or suitable mechanical pipe protection where padding materials are not readily available. Install crossings of highways, roads, railroads, drainage ditches, streams, and rivers as shown on the alignment sheets. Install required temporary traffic bypasses. Drain ponds as required and coordinate draining activities with the landowners. Design for approval and install concrete set-on or bolt-on weights or weight coating as required. Design for approval, manufacture and install screw anchors and or penetration earth anchors as required. Make pipeline tie-ins. Fabricate temporary hydrostatic test headers, as required. Hydrostatically pressure tests the test headers and related fabrications prior to use. Gauge and clean completed test sections following lowering-in operations and prior to final hydrostatic testing. Provide all hydrotest materials (including chemicals, if required) and equipment, and a written plan for Hydrostatic Testing the pipelines and related facilities. Perform Hydrostatic pressure testing of the pipelines and facilities.

Page 5 of 12

PT. TRIPATRA Engineers and Constructors

Appendix A Scope of Work

Provide pipeline survey for progress measurements at one hundred (100) meter intervals. Backfill and construct settlement berms over the pipeline in accordance with the specifications. Design for approval, provide and place concrete anchors, foundations and supports. Design for approval, provide and install pipeline alignment and aerial markers and warning signs. Collect as-built data to accurately document the completed installation of pipeline and related facilities and provide as-built drawings, including drawings of all pipeline crossings. Perform clean-up, final grading, erosion control, and restoration of the pipeline right of way. Clean up and restore material storage and soil stockpile sites and all other temporary facility sites.

2.4.

Cathodic Protection System Install all cathodic protection and AC mitigation as required and approved by TPEC and/or COMPANY. Install test lead stations and bond test leads to existing pipeline systems during construction.

2.5.

Instrumentation Works SUB-CONTRACTOR shall be responsible for installation of SCADA System, Telecommunication equipments for SCADA system and field instrumentation along pipeline. The WORKS shall be in accordance with the TPECS specification, procedure and drawing. The WORKS shall include the following, but not limited to: Transportation materials from TPECS warehouse to site. Unpacking work. Installation all of the components of SCADA Systems and Telecommunication equipments for SCADA (SCADA Panel, Solar Panel & Battery, and Radio Antenna). Setting and installing all of the components of Field Instrumentation to be mention on BoQ.

Page 6 of 12

PT. TRIPATRA Engineers and Constructors

Appendix A Scope of Work

Assist and support SCADA system vendor. Termination work for all wires of cable through cable gland that are to be terminated to terminal points in equipment that to be installed. Installation of cable tray and support fabrication. Pulling Cable. Tubing works Installation, Fabrication of field instrument support Touch up painting Finishing and grouting at associated foundation Cleaning works inside/outside equipment. Assist testing and pre commissioning Other related works required for implementation of works in accordance with Technical documents and drawing. Red Mark up drawing

2.6.

Installation above Ground Facilities Above ground facilities associated with the pipelines between the Extraction Plant Prabumulih and Pulau Layang shall be designed installed in accordance with final approved installation drawings. SUB-CONTRACTOR shall complete all Work required to place the associated facilities in a condition ready for operation, including construction, installation of specified appurtenances, testing, tie-ins, cleaning, pre-commissioning, site restoration, and submittal of as-built data and other documentation, all in accordance with the Tender Documents. For the above-ground facilities, SUB-CONTRACTOR shall perform the general elements of Work mentioned above such as site preparation, material handling and transportation, security, survey, as-builting, cleanup and restoration. Also included, but not limited to, as part of its Work, SUB-CONTRACTOR shall: Install launcher/receivers and mainline valve assemblies and associated facilities as required by the Project Drawings. Any other facilities such as foundations and supports, and structures requiring detailed drawing shall be provided by the SubContractor as part of its engineering package as required by the Project Drawings.

Page 7 of 12

PT. TRIPATRA Engineers and Constructors

Appendix A Scope of Work

Construct access roads as required to move equipment, material, and personnel to work areas and for permanent access to the sites. Provide finish grade with walkways in traveled areas and maintenance platforms for access to valves, equipment, and instruments as required. Install area lighting and grounding. Mount and function test valve actuators. Paint aboveground facilities in accordance with approved Specifications. Design for approval, provide materials as required, and install warning signs. Provide and install permanent fencing for above-ground facilities such as pipeline shutdown valves as indicated in pipeline documents.

2.7.

Special Design and Construction Requirements (i) Pipeline Spread Methods of construction are at the SUB-CONTRACTOR's option as long as the SUB-CONTRACTOR provides sufficient equipment and manpower to support construction efforts in order to complete the project within the defined schedule milestones and that existing pipelines and adjacent structures and facilities are not adversely impacted. (ii) Buoyancy Control The terrain across which the pipelines will be constructed is agricultural, subject to seasonal flooding, and may have ground water near the surface with weak soil conditions. Therefore, the specific soils geotechnical evaluation of this area may impact the design and construction techniques. SUB-CONTRACTOR shall investigate the soils in this area for use in engineering design. Analysis for requirement of buoyancy control measures shall be performed for the entire length of the pipeline route and will be calculated by TPEC base on result of soil investigation by SUB CONTRACTOR. The construction method may require special techniques that utilize mini-spreads working off a work pad 5-6 m wide built with imported fill material, use of swamp buggies to string pipe, ditching with clams and backhoes, etc. SUB-CONTRACTOR shall provide, install, and remove their work pads. SUB-CONTRACTOR shall provide details for locations anticipated for the installation of the work pad. TPEC will submit to COMPANY an engineering design for pipe buoyancy control base on Soil Investigation by SUB-CONTRACTOR for COMPANY approval.

Page 8 of 12

PT. TRIPATRA Engineers and Constructors

Appendix A Scope of Work

(iii) Pipeline Right-of-Way Existing Pipelines on the selected ROW between the Extraction Plant and Pulau Layang are installed on land controlled by Pertamina. SUB-CONTRACTOR shall submit requests for additional temporary workspace, all access roads, stockpile yards and any other work areas required for all construction related activities at least 30 days in advance. For pipelines installed outside COMPANY controlled land, the situation in regard to landowners is as follows: For pipeline tracks that are on land that is owned by a local or national government body, COMPANY will have an agreement with the owner for use of the land for installation of the pipeline, including access over such land. Where SUB-CONTRACTOR wants to temporarily use or gain access across any privately owned land adjacent to or in addition to any government owned land, it is SUB-CONTRACTORs sole responsibility to acquire the rights to the use of such land. SUB-CONTRACTOR may not permit the pipeline track to deviate from government owned land onto privately owned land without the advance written approval of COMPANY. SUB-CONTRACTOR is to be aware that such approval may take a significant amount of time and SUB-CONTRACTOR shall not be granted schedule relief due to these delays. For pipeline tracks that are across privately owned land, COMPANY will have procured a right of way. Where SUB-CONTRACTOR wants to temporarily use or gain access across any privately owned land adjacent to or in addition to any COMPANY owned right of way, it is SUB-CONTRACTORs sole responsibility to acquire the rights to the use of such land. SUB-CONTRACTOR may not permit the pipeline track to deviate from the COMPANY owned right of way onto privately owned land without the advance written approval of COMPANY. SUB-CONTRACTOR is to be aware that such approval may take a significant amount of time and SUB-CONTRACTOR shall not be granted schedule relief due to these delays. SUB-CONTRACTOR shall be responsible for ensuring that all temporary workspace and access has been obtained prior to beginning construction. SUBCONTRACTOR shall provide proof of temporary workspace agreements with landowners to COMPANY prior to commencing work. SUB-CONTRACTOR shall be responsible for compensating land owners and business owners for damages incurred during construction. (iv) Planning and Notification SUB-CONTRACTOR shall submit, within Seven (7) days of Contract award, an execution schedule and plan outlining SUB-CONTRACTORs planned

Page 9 of 12

PT. TRIPATRA Engineers and Constructors

Appendix A Scope of Work

construction progression along the entire pipeline right-of-way. This plan shall be time specific, shall detail planned construction progression by reference to existing sites and kilometer posts and shall meet COMPANYs milestone requirements. SUB-CONTRACTOR shall provide to TPEC and/or COMPANY at least Seven (7) days written notice of its need to have specific portions of the route made available for the purposes of mobilizing personnel and equipment for installing the pipeline or related facilities. Such notices shall be submitted to COMPANY on a weekly basis during the execution of the contract. (v) Site Obstructions SUB-CONTRACTOR shall be responsible for the removal of all obstructions from the right-of-way. SUB-CONTRACTOR, at his own cost, shall be responsible for making all arrangements and for gaining any approvals necessary to remove such obstructions, and for the relocation of any such obstructions, if required. (vi) Field Joint Coating The field joint coatings will be in accordance with the project field joint coating stated in the project specification. The field joint coating shall be performed by a Sub-Contractor with proven experience in, and records for, applying field joint coating on onshore pipelines with three layer polypropylene corrosion coating. The field joint coating Sub-Contractor shall be approved by TPEC/COMPANY.

3. MATERIAL Tripatra will provide all permanent material excluding steel material for pipe support. Sub-Contractor shall provide steel material for pipe support and temporary material such as gasket for hydro test, temporary Pig Launcher and Receiver, temporary spool, etc. For the bid purposes, Sub-contractor shall provide steel material based on bill of quantity stated in the Schedule of Price Appendix C.

4. INSTALLATION OF SUB-CONTRACTORS TEMPORARY BUILDING AND FACILITIES The Sub-contractors temporary works to be performed by Sub-contractor shall include the direct temporary work necessary to perform WORKS as well as the indirect common temporary work. TPEC shall have the rights, at any time, to inspect them and instruct to meet the requirement of the CONTRACT, countrys laws and regulations, etc., and the Sub-contractor shall obey the instruction and rectify them at his own cost, if so instructed.

Page 10 of 12

PT. TRIPATRA Engineers and Constructors

Appendix A Scope of Work

The Sub-contractor shall submit his plan and drawings of temporary facilities for TPECs approval. The Sub-contractor commences the TEMPORARY WORKS only after obtaining such approval from TPEC. The Sub-contractor shall be responsible for maintaining the TEMPORARY WORKS and for demobilization of them promptly after the completion of related works subject to TPECs approval.

5. PROCUREMENT OF EQUIPMENT AND MATERIAL TO BE SUPPLIED BY SUB-CONTRACTOR The Sub-contractor shall purchase and supply all necessary materials, equipment, apparatus, tools, machinery, and appliances or things of whatsoever nature required for completion of the works. The Sub-contractor shall perform all necessary procurement services including, but not limited, to the procurement, quality control, schedule control, packing, transportation, FOB charge, and insurances under full responsibility and expenses of the Sub-contractor in order to supply the materials, equipment, and construction equipment within this scope.

6. TRANSPORTATION AND STORING OF MATERIALS AND EQUIPMENT SUPPLIED BY SUB-CONTRACTOR The Sub-contractor shall carry out transportation work to the Sub-contractor's storage, unloading, unpacking, checking and storing, and material handling during storage and transportation to the work site of all materials and equipment to be supplied by the Subcontractor.

7. ARRANGEMENT OF CONSTRUCTION EQUIPMENT The Sub-contractor shall operate, maintain in safe and best operating condition, and manage the Construction Equipment during the whole construction period of the works under the full responsibility and expenses of the Sub-contractor. The Sub-contractor shall provide the fuel, oil and lubricants for the Construction Equipment.

8. INSPECTION OF CONSTRUCTION EQUIPMENT In order to assure that the construction equipment and such machinery as welding machine, grinding machine, portable drill, crane, etc. to be furnished by the Subcontractor area in safe and best operating condition, fit for the intended use and suitable for the safe and efficient performance of the WORKS, the Sub-contractor shall conduct

Page 11 of 12

PT. TRIPATRA Engineers and Constructors

Appendix A Scope of Work

such inspection and tests as required by industry practice, SAFETY PROCEDURE and by laws and regulations under witness by TPEC.

9. QUALITY ASSURANCE AND QUALITY CONTROL TEST AND INSPECTION The Sub-contractor shall ensure that the works shall be performed in accordance with: Approved construction drawings. TPECs and/or COMPANY Engineering Specifications. Applicable Codes and Standards. TPECs and/or COMPANY Quality Assurance and Quality Control plan.

10. SECURITY AND SAFETY Sub-contractor shall maintain security and safety during the works period according to the Security and Safety Procedure provided by TPEC. All lost of material, labor and equipments during works period due to accidents or other causes shall be Sub-contractors responsibility.

11. SITE CLEANING Sub-contractor shall clear all the areas mentioned above after completion of works and meet the specification requirements approved by TPEC.

12. OTHER Sub-contractor is not permitted to give part or all of the works to another Sub-contractor or other party. Should the Sub-contractor wish to use the services of another Subcontractor for the specific work scope/activity, prior written permission from TPEC shall be obtained.

Page 12 of 12

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Marine Operations, Design and Fabrication: DNV-OS-H102Document35 pagesMarine Operations, Design and Fabrication: DNV-OS-H102architectintxNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Bargepresentation ModelDocument1 pageBargepresentation ModelSander TimmermansNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Specs CPCMDocument2 pagesSpecs CPCMSander TimmermansNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- 4 TerminologyDocument1 page4 TerminologySander TimmermansNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Quality Assurance Nigeria LNGDocument1 pageQuality Assurance Nigeria LNGSander TimmermansNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Water Management Challenges in The NetherlandsDocument8 pagesWater Management Challenges in The NetherlandsSander TimmermansNo ratings yet

- Softwood Sizes: Moisture ContentDocument0 pagesSoftwood Sizes: Moisture ContentSander TimmermansNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- SLX Sliding Door SystemDocument16 pagesSLX Sliding Door SystemSander TimmermansNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Statewide Alcohol and or Drug Involved 27DEC2023Document1 pageStatewide Alcohol and or Drug Involved 27DEC2023Live 5 NewsNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Making The Most of Alarms As A Safety Layer of ProtectionDocument16 pagesMaking The Most of Alarms As A Safety Layer of ProtectionAli AbbasovNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Job Hazard Analysis Template .Docx Version 1Document2 pagesJob Hazard Analysis Template .Docx Version 1Tarik SenaneNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- DMLCIIDocument2 pagesDMLCIIVu Tung LinhNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- ASMI-OSHMS-PR-13 - OSH Performance Monitoring ProcedureDocument9 pagesASMI-OSHMS-PR-13 - OSH Performance Monitoring ProcedureJHUPEL ABARIALNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- AusNet Services - Supporting Technical Document - AMS 10-24 Asset Renewal Planning Guide - 29 October 2020Document52 pagesAusNet Services - Supporting Technical Document - AMS 10-24 Asset Renewal Planning Guide - 29 October 2020Djim. NOUBARANo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Vertically Suspended, Can Pump Sulzer PDFDocument221 pagesVertically Suspended, Can Pump Sulzer PDFAntonio Rivera100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Astm D3549Document4 pagesAstm D3549Ashraf Tomizeh50% (2)

- Ayala Malls Work Permit for Hot WorksDocument3 pagesAyala Malls Work Permit for Hot WorksRalph Adrian MielNo ratings yet

- WSH Guidelines - Landscape and Horticulture ManagementDocument35 pagesWSH Guidelines - Landscape and Horticulture Managementlwin_oo2435No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- MSDS TGDocument7 pagesMSDS TGPuskesmas Tambakboyo TubanNo ratings yet

- Series: User'S Manual Design and MaintenanceDocument359 pagesSeries: User'S Manual Design and MaintenanceĐại Vỹ ĐinhNo ratings yet

- Interactive Short Cut Method For Pressure Vessel Design Based On Asme CodeDocument8 pagesInteractive Short Cut Method For Pressure Vessel Design Based On Asme Codelatino_heartNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Procedia Sept 2019Document276 pagesProcedia Sept 2019Md Razali AbuNo ratings yet

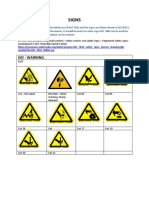

- Safety LabelsDocument12 pagesSafety LabelsJonathan JonesNo ratings yet

- Safe Use, Maintenance and Inspection of Suspended Work PlatformsDocument3 pagesSafe Use, Maintenance and Inspection of Suspended Work PlatformsshoaibNo ratings yet

- D6883-Standard Practice For Manual Sampling of Stationary Coal From Railroad Cars, Barges, Trucks, or StockpilesDocument5 pagesD6883-Standard Practice For Manual Sampling of Stationary Coal From Railroad Cars, Barges, Trucks, or StockpilesPradjnaParamitaMichele100% (1)

- Midterm - Lesson 5Document5 pagesMidterm - Lesson 5Baucas, Rolanda D.No ratings yet

- GOMO Complete Document December 2022Document309 pagesGOMO Complete Document December 2022Luana Marchiori100% (1)

- Improving Financial Stewardship and Service Delivery at Moi Kadzonzo Girls SecondaryDocument12 pagesImproving Financial Stewardship and Service Delivery at Moi Kadzonzo Girls SecondaryDorothy Otieno100% (3)

- Catalogo Rod&CasingDocument70 pagesCatalogo Rod&Casingtomas caputoNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- AN100.EN002 The Circuit Supervision For VAMP40 VAMP130 VAMP135 VAMP140 and VAMP150Document144 pagesAN100.EN002 The Circuit Supervision For VAMP40 VAMP130 VAMP135 VAMP140 and VAMP150Razvan MaresNo ratings yet

- Occupational Health and Safety Management in Manufacturing IndustriesDocument7 pagesOccupational Health and Safety Management in Manufacturing IndustriesAhmed GuevaraNo ratings yet

- 20624pf Ac Plant Keratin PF Ghs Sds v12Document9 pages20624pf Ac Plant Keratin PF Ghs Sds v12Ali SARINo ratings yet

- ACS Rules For Offshore Fixed Platform InstallationDocument31 pagesACS Rules For Offshore Fixed Platform Installationsaeed ghafooriNo ratings yet

- Noman Saeed Khan: Al Dhabi Contracting LLC) - Abu DhabiDocument3 pagesNoman Saeed Khan: Al Dhabi Contracting LLC) - Abu DhabiShery TentionNo ratings yet

- SDS for Transcal N Heat Transfer FluidDocument9 pagesSDS for Transcal N Heat Transfer FluidAgung PratamaNo ratings yet

- Ge6075 Professional Ethics PDFDocument40 pagesGe6075 Professional Ethics PDFKrish RNo ratings yet

- Opto Triac RapidosDocument6 pagesOpto Triac RapidosAnonymous oEoCVNhu7HNo ratings yet

- Unit 1 PPE. Student..docx2Document3 pagesUnit 1 PPE. Student..docx2ShindyNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)