Professional Documents

Culture Documents

Guide Atmospheric Testing Confined Spaces

Uploaded by

Anonymous 4ylE57C6Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Guide Atmospheric Testing Confined Spaces

Uploaded by

Anonymous 4ylE57C6Copyright:

Available Formats

Application Note AP-206

rev 4 wrh.04-06

Guide To Atmospheric Testing In Confined Spaces

This application note is intended to provide general

information and to act as a reminder of the dangers

associated with atmospheric hazards in a confined

space. It outlines the following:

What is a confined space?

Atmospheric hazards found in a confined space.

RAE Systems products for confined space entry.

What Is a Confined Space?

The confined space entry standard was established by

OSHA 29CFR 1910.146 in April of 1993. The

standard was developed to provide a defined work

plan for confined space

entry. Confined space

entries are part of a daily

routine throughout the

industrial workplace.

A Confined Space Is Defined As a Space That:

Is large enough for an employee to enter and

perform work.

Has limited or restricted means for entry or exit.

Is not designed for continuous human

occupancy.

A Permit-Required Confined Space Is Defined As:

A confined space, plus one of the following:

Contains, or has a known potential to contain, a

hazardous atmosphere.

Contains material with the potential for

engulfment.

Has an internal design that could entrap or

asphyxiate the entrant.

Contains any recognized safety or health hazard.

Examples of confined spaces:

Storage tanks and vessels

Sewers and manholes

Underground utility vaults

Agriculture silos

Railcar tanks

Marine vessel tanks

Tunnels

Grain elevators

Atmospheric Hazards in Confined Spaces

Atmospheric hazards in a confined space are those

that expose entrants to a risk such as death,

entrapment, injury, or acute illness from one or more

of the following causes:

Oxygen

An atmospheric oxygen concentration below 19.5% (oxygen

deficiency), or above 23.5% (oxygen enrichment).

Potential Effects of Oxygen Enriched

and Deficient Atmospheres

Oxygen

Content

(% by Vol.)

Effects and Symptoms

(At Atmospheric Pressure)

>23.5% Oxygen enriched, extreme fire hazard

20.9% Oxygen concentration in normal air

19.5% Minimum permissible oxygen level

15% to 19% Decreased ability to work strenuously;

may impair coordination and may

cause early symptoms for persons of

coronary, pulmonary or circulatory

problems

10% to 12% Respiration further increases in rate

and depth; poor judgment, blue lips

8% to 10% Mental failure, fainting,

unconsciousness, ashen face, nausea,

and vomiting

6% to 8% Recovery still possible after four to

five minutes.

50% fatal after six minutes.

Fatal after eight minutes.

4% to 6% Coma in 40 seconds, convulsions,

respiration ceases, death

These values are approximate and vary, due to

an individuals state of health and physical

activity.

1

RAE Systems Inc.

3775 N. First St., San J ose, CA 95134-1708 USA

Phone: +1.888.723.8823

Email: raesales@raesystems.com

Web Site: www.raesystems.com

Application Note AP-206

rev 4 wrh.04-06

Combustible Gases

A flammable gas or vapor in excess of 10% of its

lower explosive limit (LEL) yet still remaining below

the upper explosive limit UEL).

Lower Explosive Limit (LEL) Vs.

Upper Explosive Limit (UEL)

A

i

r

C

o

m

b

u

s

t

i

b

l

e

s

(Too lean to burn) (Too rich to burn)

LEL UEL

The lowest concentration (air-fuel mixture) at

which a gas can ignite is called lower explosive

limit (LEL). Concentrations below this limit are

too lean to burn.

The highest concentration that can be ignited is

its upper explosive limit (UEL). Above that

concentration, the mixture is too rich to burn.

The Fire Tetrahedron

For combustion to occur, there must be four elements:

1. Fuel

2. Oxygen to support

combustion

3. Heat or a source of

ignition

4. Chain reaction, i.e.,

the above three must

be present in such

proportions as to allow a

flame to propagate.

This is called the fire tetrahedron (formerly known as

the fire triangle). If any of the four elements are

missing, combustion cannot occur. The fourth

element, chain reaction, means that not any mixture

of fuel and oxygen can sustain a flame if heated. The

proportions must allow a flame to propagate. For

normal air, this means that the fuel concentration

must be between the LEL and the UEL.

Combustible Gas - Percent By Volume

RAE Systems one- to five-gas VRAE surveying

monitors read out in both % LEL and % by volume.

For example the LEL of methane is 5% by volume,

and the UEL is 15% by volume. When a confined

space reaches 2.5% methane by volume this would be

equal to 50% LEL. (5% methane by volume would

be 100% LEL.) Between 5 to 15% by volume, a

spark could cause an explosion.

Different gases have different % by volume concen-

trations to reach 100% LEL. Some examples are:

Propanes LEL is 2.1% by volume; Pentanes LEL is

1.5% by volume; Hexanes LEL is 1.1% by volume

and gasolines LEL is 1.3% by volume.

Toxic Gases

An atmospheric concentration of any toxic compound

above the permissible exposure limit established by

OSHA, NIOSH or ACGIH. Here are examples of

common toxic gases found in a confined space.

Toxic Gas TWA STEL Ceiling IDLH

Ammonia 25 ppm 35 ppm -- 500 ppm

Carbon

monoxide

25 ppm --

200

ppm

1,500

ppm

Chlorine 0.5 ppm 1 ppm -- 30 ppm

Hydrogen

cyanide

-- --

4.7

ppm

50 ppm

Hydrogen

sulfide

10 ppm 15 ppm -- 300 ppm

Nitric oxide 25 ppm -- -- 100 ppm

Sulphur

dioxide

2 ppm 5 ppm -- 100 ppm

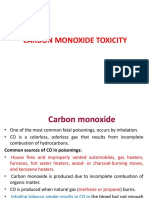

Life-Threatening Effects: CO and H

2

S

Effects Of Carbon Monoxide Exposure

ppm Time Effects & Symptoms

35 8 hours Permissible Exposure

Level

200 3 hours Slight headache,

discomfort

400 2 hours Headache, discomfort

600 1 hours Headache, discomfort

1000 to 2000 2 hours Confusion, discomfort

1000 to 2000 1/2 to 1 hour Tendency to stagger

1000 to 2000 30 Slight heart palpitations

2000 to 2500 30 Unconsciousness

4000 >1 hour Fatal

2

RAE Systems Inc.

3775 N. First St., San J ose, CA 95134-1708 USA

Phone: +1.888.723.8823

Email: raesales@raesystems.com

Web Site: www.raesystems.com

Application Note AP-206

rev 4 wrh.04-06

Effects Of Hydrogen Sulfide Exposure

ppm Time Effects & Symptoms

10 8 hour Permissible exposure level

50 to 100 1 hour Mild eye and respiratory

irritition

200 to 300 1 hour Marked eye and respiratory

irritation

500 to 700 1/2-1 hour Unconsciousness, death

>1000 Minutes Unconsciousness, death

Monitoring Confined Spaces for Atmospheric

Hazards

Monitoring the air inside a confined space is required

prior to entering. Testing a confined space for

atmospheric hazards should be done remotely before

entering, and should be done in this order:

Oxygen. Ensure that proper oxygen levels are

present.

Combustible gases. Ensure that combustible

gases are not present.

Toxic Gases. Ensure that toxic gases are below

the OSHA permissible exposure limit. Common

toxic gases in a confined space could be

hydrogen sulfide (H

2

S) and carbon monoxide

(CO), but other toxic compounds could be

present. RAE Systems offers monitors to

evaluate all these gases either individually or

simultaneously.

In a confined space, it is important to take samples at

the top, middle, and bottom to locate varying

concentrations of gases and vapors. Highly

concentrated gases can accumulate at the top or

bottom of a confined space depending on whether

they are less or more dense than air. Dilute gases and

vapors in the ppm range distribute evenly throughout

a confined space. It is especially important to sample

at a distance from the opening because air intrusion

near the entrance can give a false sense of adequate

oxygen presence.

As the remote air monitoring is completed and the

area is safe for entry, confined space entry permits

should be completed and followed. After the initial

entry, monitoring the air in the confined space should

be continuous. A confined space entry attendant or

hole watch should carry out the continuous

monitoring. Conditions in a confined space can

change without warning, due to leakage, toxic vapor

release, or disturbing the contents of the space.

Air Intrusion Layer

Dilute gases and vapors

or concentrated gas with

O

2

depletion

Liquids or concentrated

gases and vapors

Before entering the confined space, take samples at several levels,

and after entering, monitor the space continuously because

conditions can change.

Monitors for Confined Space Entry

RAE Systems offers the latest and most innovative

monitors available for Confined Space Entry (CSE).

Datalogging is an option on all our multi-gas

monitors.

QRAE, Confined Space Entry Monitor

The Q-RAE CSE Monitor is pre-set as an easy to use

tool to comply with the atmospheric testing required

by OSHA 29CFR 1910.146. The Q-RAE offers the

flexibility to work effectively in a confined space

while remaining protected from combustibles,

hydrogen sulfide, carbon monoxide, and high or low

oxygen levels.

Oxygen Concentration

OSHA acceptable levels are between 19.5% and

23.5%. The MultiRAE has preset alarms (low,

19.5%, and high, 23.5%) which are user selectable,

to warn of a hazardous condition.

Combustible Gases

Concentrations must be below 100% of the LEL.

The MultiRAE has a pre-set alarm at 10% LEL of

combustible gases, and a high alarm set at 20%

LEL. These alarm set points are user selectable.

Toxic Gases:

Alarms are preset at the OSHA permissible

exposure limit. The MultiRAE has pre-set alarms

for H

2

S at 10 ppm, low alarm, and 20 ppm, high

alarm. CO alarms are at 35 ppm low alarm and 200

ppm, high alarm. These alarm set points are user

selectable. The MultiRAE also offers several other

toxic gas sensors.

3

RAE Systems Inc.

3775 N. First St., San J ose, CA 95134-1708 USA

Phone: +1.888.723.8823

Email: raesales@raesystems.com

Web Site: www.raesystems.com

Application Note AP-206

rev 4 wrh.04-06

MultiRAE Toxic Gas Monitor With PID

The MultiRAE is an excellent personal protection

monitor. It combines the traditional security of

standard electrochemical and catalytic sensors with

the next generation, broad-band protection of a

photoionization detector (PID). Unlike the QRAE,

this monitor offers a wide variety of interchangeable

toxic sensors supplementable with a PID for

applications such as confined space entry.

VRAE One to Five, Toxic Gas Surveyer

The VRAEs powerful internal pump, combined with

RAE Systems wide selection of toxic sensors,

presents a highly effective, continuous surveying

monitor. The VRAE can monitor combustibles in

percent of LEL or in percent by volume.

ToxiRAE Single-Gas Monitors

RAE Systems also offers a complete line of single-

gas monitors for confined space entry applications.

Additional information:

Federal Register

29 CFR 1910.146 Permit Required Confined Spaces

for General Industry

http://cos.gdb.org

OSHA

U.S. Department of Labor

http://www.osha-slc.gov

OSHA Regulations (Standards - 29 CFR) - 1910.146

- Permit-required confined spaces.

www.osha-slc.gov/OshStd_data/

1910_0146.html

OSHA Regulations (Standards - 29 CFR) - 1910.146

App C - Examples of Permit-required Confined

Space Programs.

www.osha-slc.gov/OshStd_data/

1910_0146_APP_C.html

OSHA Regulations (Standards - 29 CFR) - 1910.146

App A - Permit-required Confined Space Decision

Flow Chart.

www.osha-slc.gov/OshStd_data/

1910_0146_APP_A.html

Disclaimer:

This application note contains only a general

description of atmospheric testing in a confined space

and equipment used to monitor a confined space.

Under no circumstances should a confined space be

entered or monitoring equipment used except by

qualified and trained personnel, and after all

instructions have been carefully read and understood

and all precautions followed.

4

RAE Systems Inc.

3775 N. First St., San J ose, CA 95134-1708 USA

Phone: +1.888.723.8823

Email: raesales@raesystems.com

Web Site: www.raesystems.com

You might also like

- Fire ResistanceDocument30 pagesFire ResistanceLesego MatojaneNo ratings yet

- Fire Resistance TestDocument2 pagesFire Resistance TestJaleel ClaasenNo ratings yet

- General: Insulated Aluminium CladdingDocument5 pagesGeneral: Insulated Aluminium Claddingeccos3338No ratings yet

- Unit4.Protective Coats 4 CivilDocument5 pagesUnit4.Protective Coats 4 CivilengineeringchemistryNo ratings yet

- Valve and pipe isometric diagram legendDocument1 pageValve and pipe isometric diagram legendnagarajhebbarNo ratings yet

- FEpoxy BoxDocument2 pagesFEpoxy BoxJamie ClarkNo ratings yet

- Insulation Materials Study Compares Cellulose Fiber and EPSDocument36 pagesInsulation Materials Study Compares Cellulose Fiber and EPSnamrytNo ratings yet

- Protect Ives TotalDocument58 pagesProtect Ives TotalengineeringchemistryNo ratings yet

- Sys 02Document1 pageSys 02arjunprasannan7No ratings yet

- Comment TTT-02 FillableDocument13 pagesComment TTT-02 FillableRichard ReiersenNo ratings yet

- 1 PDFDocument93 pages1 PDFRomart BarosaNo ratings yet

- Hot-Dip Galvanizing Process ExplainedDocument18 pagesHot-Dip Galvanizing Process Explainedsample use100% (1)

- Corrosion Failure From Water-Soluble Contaminants On AbrasivesDocument6 pagesCorrosion Failure From Water-Soluble Contaminants On Abrasivesyo_lobehotmailcom100% (1)

- Unit II - Study Materials On Energy Conversion MaterialsDocument25 pagesUnit II - Study Materials On Energy Conversion Materialsronnie1992No ratings yet

- Chapter 6 MetalDocument34 pagesChapter 6 Metalsisay gemNo ratings yet

- 2.electrochemical CorrosionDocument2 pages2.electrochemical CorrosionSahil VishwakarmaNo ratings yet

- CV Paimschi Adrian CVDocument5 pagesCV Paimschi Adrian CVIoana OanceaNo ratings yet

- H DG Corr ProtectionDocument16 pagesH DG Corr ProtectionNicolasNo ratings yet

- Insulation KitDocument8 pagesInsulation KitmohsenNo ratings yet

- Investigating Failure - Elevated Water Tank Coating Warranty RepairsKTA-TatorDocument6 pagesInvestigating Failure - Elevated Water Tank Coating Warranty RepairsKTA-TatorNsidibe Michael Etim100% (1)

- Duplex SystemDocument9 pagesDuplex Systemnightmanmx100% (1)

- Corrosion Types in Naval Materials ScienceDocument13 pagesCorrosion Types in Naval Materials ScienceMad Max100% (1)

- Zinc Coating ProcessDocument15 pagesZinc Coating ProcessMOHD SALMANNo ratings yet

- EFC No.62-2012 Testing Tribocorrosion of Passivating Materials Supporting ResearDocument215 pagesEFC No.62-2012 Testing Tribocorrosion of Passivating Materials Supporting ResearWHWENNo ratings yet

- Wet Storage Stain On Galvanized SteelDocument8 pagesWet Storage Stain On Galvanized SteelDino PedutoNo ratings yet

- Guidelines On Electrochemical Corrosion Measurements: European Federation of Corrosion PublicationsDocument62 pagesGuidelines On Electrochemical Corrosion Measurements: European Federation of Corrosion PublicationsjithukNo ratings yet

- Thermal Ceramics - Marine - and - OffshoreDocument6 pagesThermal Ceramics - Marine - and - OffshoremubeennavazNo ratings yet

- Corrosion Performance of 3CR12 SteelDocument16 pagesCorrosion Performance of 3CR12 SteelMashudu Ramovha100% (1)

- Fire StoppingDocument3 pagesFire StoppinggfdgdNo ratings yet

- FIRETEX Passive Fire Protection Brochure PDFDocument6 pagesFIRETEX Passive Fire Protection Brochure PDFPop Andrei IonutNo ratings yet

- Multifrequency Electromagnetic Data Interpretation for Subsurface CharacterizationFrom EverandMultifrequency Electromagnetic Data Interpretation for Subsurface CharacterizationNo ratings yet

- Surface Preparation Standards - ComparasionDocument4 pagesSurface Preparation Standards - ComparasiontaiNo ratings yet

- BS en 12068.1999Document33 pagesBS en 12068.1999yy20100% (1)

- Protective Coat Surface PreparationsDocument6 pagesProtective Coat Surface Preparationsengineeringchemistry0% (1)

- ROCKWOOL RockTech B (Blanket) Series LR PDFDocument2 pagesROCKWOOL RockTech B (Blanket) Series LR PDFWasawat JoongjaiNo ratings yet

- JPCL ReportDocument13 pagesJPCL ReportShahzaib AbbasiNo ratings yet

- CuiDocument6 pagesCuiأحمد صبحىNo ratings yet

- Ballast TK HempelsDocument15 pagesBallast TK HempelsGeorgios PapakostasNo ratings yet

- 부식 en12944Document10 pages부식 en12944ksjin0226No ratings yet

- Wind EnergyDocument25 pagesWind EnergySayak KarmakarNo ratings yet

- TTP 28 HDocument18 pagesTTP 28 HDongNo ratings yet

- 10-1 PaintDocument5 pages10-1 PaintdetteheartsNo ratings yet

- Corrosion Control PDFDocument48 pagesCorrosion Control PDFAnkit SinghNo ratings yet

- 2010 SummerDocument16 pages2010 SummerRa'oufAli-zadeh100% (1)

- Chartek 1709Document4 pagesChartek 1709devangmajithiaNo ratings yet

- CUI Risk Factors on Insulated PipingDocument21 pagesCUI Risk Factors on Insulated PipingRenan Soares KieferNo ratings yet

- Rti Brochure Searox Technical Guidelines - Int EngDocument116 pagesRti Brochure Searox Technical Guidelines - Int EngEzzaty ShafiqaNo ratings yet

- FBE Testleri - DeFelskoDocument54 pagesFBE Testleri - DeFelskoÖzgür TuştaşNo ratings yet

- Polyaspartic Webinar Protective and MarineDocument47 pagesPolyaspartic Webinar Protective and MarinequimizaNo ratings yet

- Painting of Structure Piping Equipment 22Document5 pagesPainting of Structure Piping Equipment 22Saurabh Kumar VermaNo ratings yet

- 2018Document16 pages2018asfaruk2556No ratings yet

- 7.3 Calculation of PFP ThicknessDocument10 pages7.3 Calculation of PFP ThicknessmaheshbandhamNo ratings yet

- Practical Assessment: Identify Equipment and Answer QuestionsDocument1 pagePractical Assessment: Identify Equipment and Answer QuestionsBOBNo ratings yet

- P&ID Basics: Understanding Piping and Instrumentation DiagramsDocument9 pagesP&ID Basics: Understanding Piping and Instrumentation DiagramsUps YamNo ratings yet

- Corrosion and Corrosion Control: An Introduction to Corrosion Science and EngineeringFrom EverandCorrosion and Corrosion Control: An Introduction to Corrosion Science and EngineeringNo ratings yet

- Overall Aspects of Non-Traditional Glasses: Synthesis, Properties and ApplicationsFrom EverandOverall Aspects of Non-Traditional Glasses: Synthesis, Properties and ApplicationsNo ratings yet

- AP-206 Confined SpaceDocument4 pagesAP-206 Confined SpaceshaheerNo ratings yet

- Training MaterialDocument31 pagesTraining MaterialAlan EdhilsNo ratings yet

- Authorized Gas Testing Course Provides Safety TrainingDocument106 pagesAuthorized Gas Testing Course Provides Safety Trainingജിനാദ് അബ്ദുസ്സലാം100% (6)

- July 2020Document7 pagesJuly 2020Anonymous 4ylE57C6No ratings yet

- Sample CVDocument1 pageSample CVAnonymous 4ylE57C6No ratings yet

- Dec 2019Document8 pagesDec 2019Anonymous 4ylE57C6No ratings yet

- Dec 2019Document7 pagesDec 2019Anonymous 4ylE57C6No ratings yet

- Replace Alarm Printers with Prilog Alarm LoggerDocument2 pagesReplace Alarm Printers with Prilog Alarm LoggerAnonymous 4ylE57C6No ratings yet

- CLS 1 MotorDocument34 pagesCLS 1 MotorAnonymous 4ylE57C6No ratings yet

- Mepc 10749Document35 pagesMepc 10749Anonymous 4ylE57C6No ratings yet

- MCERTIFI HEATDocument6 pagesMCERTIFI HEATAnonymous 4ylE57C6No ratings yet

- 01 Master Responsibilities PDFDocument1 page01 Master Responsibilities PDFAnonymous 4ylE57C6No ratings yet

- Metamanual DG ShippingDocument6 pagesMetamanual DG ShippingAnonymous 4ylE57C60% (1)

- Mca Applied Heat 2017Document16 pagesMca Applied Heat 2017Anonymous 4ylE57C6No ratings yet

- SEABOURN PRIDE Power Restoration SequenceDocument2 pagesSEABOURN PRIDE Power Restoration SequenceAnonymous 4ylE57C6No ratings yet

- Vacuum System Upgrade ProjectDocument2 pagesVacuum System Upgrade ProjectAnonymous 4ylE57C6No ratings yet

- Mca Applied Heat 2017Document16 pagesMca Applied Heat 2017Anonymous 4ylE57C6No ratings yet

- Sample CVDocument1 pageSample CVAnonymous 4ylE57C6No ratings yet

- Sample CVDocument1 pageSample CVAnonymous 4ylE57C6No ratings yet

- Top shipping companies contact detailsDocument6 pagesTop shipping companies contact detailsprasadcshettyNo ratings yet

- SESCON feedwater & steam pressure regulator limitsDocument1 pageSESCON feedwater & steam pressure regulator limitsAnonymous 4ylE57C6No ratings yet

- Adonia SchedsDocument1 pageAdonia SchedsAnonymous 4ylE57C6No ratings yet

- Marine Officer Exam Notes Oral Questions E-booksDocument4 pagesMarine Officer Exam Notes Oral Questions E-booksAnonymous 4ylE57C6100% (1)

- Answering DGSA Exam QuestionsDocument3 pagesAnswering DGSA Exam QuestionsPedroTorres88No ratings yet

- How To - Aux Engine HFO To DO Change and BackDocument2 pagesHow To - Aux Engine HFO To DO Change and BackAnonymous 4ylE57C6No ratings yet

- Maritime SchoolsDocument172 pagesMaritime SchoolsAnonymous 4ylE57C6100% (1)

- Marine ShelfDocument20 pagesMarine ShelfAnonymous 4ylE57C6No ratings yet

- Marine Reciprocating CompressorsDocument3 pagesMarine Reciprocating CompressorsAnonymous 4ylE57C6No ratings yet

- Induction Cooker Manual TCL 1821Document4 pagesInduction Cooker Manual TCL 1821prakashinaibsNo ratings yet

- Fuel Pump - Marine EngineerDocument5 pagesFuel Pump - Marine EngineerAnonymous 4ylE57C6No ratings yet

- Checklliistfor ISMDocument2 pagesChecklliistfor ISMAnonymous 4ylE57C6No ratings yet

- Class 1 Sea TimeDocument2 pagesClass 1 Sea TimeAnonymous 4ylE57C6No ratings yet

- Duct BurnersDocument23 pagesDuct BurnersMartín Diego MastandreaNo ratings yet

- Physics 207 Lecture 22: Ideal Fluid Flow, Bernoulli's PrincipleDocument13 pagesPhysics 207 Lecture 22: Ideal Fluid Flow, Bernoulli's PrincipleAdithyaNo ratings yet

- OLEDreport PDFDocument26 pagesOLEDreport PDFStanimir YordanovNo ratings yet

- Energetics Lab - ChemDocument5 pagesEnergetics Lab - Chemvaibhav100% (1)

- This Document Certifies That: Precision Polymer Engineering Limited (PPE)Document2 pagesThis Document Certifies That: Precision Polymer Engineering Limited (PPE)JuanNo ratings yet

- Prepared by Miss Unnati .M. Patel F.Y.M Pharm (Pqa) by DR A.D.Kulkerni Mpharm (Pharmaceutics)Document29 pagesPrepared by Miss Unnati .M. Patel F.Y.M Pharm (Pqa) by DR A.D.Kulkerni Mpharm (Pharmaceutics)Fatima VessaliusNo ratings yet

- Practical of Chemistry PDFDocument377 pagesPractical of Chemistry PDFrajesh971No ratings yet

- Materials of Construction For Pressure VesselsDocument59 pagesMaterials of Construction For Pressure VesselsVimin Prakash90% (10)

- Agitated Nutsche Filter & Dryer (ANF/ANFD) : EquipmentsDocument8 pagesAgitated Nutsche Filter & Dryer (ANF/ANFD) : EquipmentsJiril JacobNo ratings yet

- Steel Forgings, Carbon and Alloy, For General Industrial UseDocument10 pagesSteel Forgings, Carbon and Alloy, For General Industrial UseRed RedNo ratings yet

- I ObjectivesDocument3 pagesI ObjectivesEdelyn Dimatulac TorrelizaNo ratings yet

- Urine Analysis I: Chemical Examination: Lenka Fialová & Martin VejražkaDocument9 pagesUrine Analysis I: Chemical Examination: Lenka Fialová & Martin VejražkaGeffrey S. QuilalaNo ratings yet

- Methods For Diffusion Welding The Superalloy Udimet 700Document9 pagesMethods For Diffusion Welding The Superalloy Udimet 700Enary SalernoNo ratings yet

- Chapter 02Document199 pagesChapter 02351brendan83% (6)

- Solid Hollow Plug PDFDocument3 pagesSolid Hollow Plug PDFSandra DevannyNo ratings yet

- Dwnload Full Chemistry in Context 9th Edition Amer Solutions Manual PDFDocument35 pagesDwnload Full Chemistry in Context 9th Edition Amer Solutions Manual PDFezrak2martin100% (9)

- Spring 2013 Lecture 2 - 4Document15 pagesSpring 2013 Lecture 2 - 4XiuQingNo ratings yet

- What Are Some of The Best Interview Questions Asked For A Mechanical Engineering Student - Quora PDFDocument17 pagesWhat Are Some of The Best Interview Questions Asked For A Mechanical Engineering Student - Quora PDFPavansatya AdabalaNo ratings yet

- Ideal Vapor Compression Refrigeration CycleDocument9 pagesIdeal Vapor Compression Refrigeration CycleStephanie ParkNo ratings yet

- ApcolDocument25 pagesApcolJAGADISH PADHYNo ratings yet

- Appendix A & CDocument7 pagesAppendix A & CAmr HeshamNo ratings yet

- Astm D 388Document6 pagesAstm D 388Julian MonroyNo ratings yet

- Saranya IJPSRDocument8 pagesSaranya IJPSRBhavana GangurdeNo ratings yet

- Mep 1 1Document58 pagesMep 1 1Amisha GuptaNo ratings yet

- MBN 10494-2 2016-03Document12 pagesMBN 10494-2 2016-03cmorabitoNo ratings yet

- Carbon Monoxide PoisoningDocument22 pagesCarbon Monoxide PoisoningSunilNo ratings yet

- Cartridge Heaters FIREROD ImmersionDocument3 pagesCartridge Heaters FIREROD ImmersionEliasNo ratings yet

- Pipebook ADocument2 pagesPipebook APRAKASH PANDEYNo ratings yet

- PhysicsBowl 2002Document14 pagesPhysicsBowl 2002satishirish3938No ratings yet

- NIC Components NMO SeriesDocument3 pagesNIC Components NMO SeriesNICCompNo ratings yet