Professional Documents

Culture Documents

Bracing Connection

Uploaded by

rajedmaglinteOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bracing Connection

Uploaded by

rajedmaglinteCopyright:

Available Formats

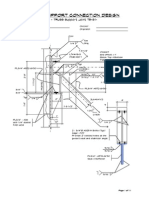

Design Calculation for Bracing Connection - Joint SWF-SF10

1.) LAYOUT

HSS8X8X1/4

10" 9"

3/16" 3/16" 3/16" 3/16" 8" 8" Typ

5" 8.0

2

HSS8X8X1/2

1'-2 1/2" 10 7/8" 3/16" 3/16" 5" 4. 4" 4" Typ

PL 0.375 - A36 HSS8X4X1/8

2.)

REQUIRED STRENGTHS: Member 1: Axial Load, Ta Axial Load, Ca Member 2: Axial Load, Ta Axial Load, Ca Shear Load, Va

= =

10.0 10.0

kips (Tension) kips (Compression)

= = =

10.0 10.0 10.0

kips (Tension) kips (Compression) kips

3.)

MATERIAL & GEOMETRIC PROPERTIES: Member 1: Size: Fy Fu B HT A

HSS8X4X1/8 = 46 = 58 4.00 = 8.00 = 2.70 =

ASTM A500 Gr. B ksi ksi in in in

Page 1 of 10

Design Calculation for Bracing Connection - Joint SWF-SF10

t Member 2: Size: Fy Fu B HT A t Member 3: Size: Fy Fu B HT A t Gusset Plate: Fy Fu tgusset Width, W Depth, H 4.) BRACE CONNECTION MEMBER 1: Brace to Gusset Plate Weld: Electrode Class Fu Fv = = = = = = = = = = = = = = = = = E700XX = 0.116 in

HSS8X8X1/2 = 46 = 58 8.00 = 8.00 = 13.50 = 0.465 =

ASTM A500 Gr. B ksi ksi in in in in

HSS8X8X1/4 = 46 = 58 8.00 = 8.00 = 7.10 = 0.233 =

ASTM A500 Gr. B ksi ksi in in in in ASTM 36 ksi ksi in in in

= = = = =

36 58 3/8 16 28

Nominal Tensile Strength of Weld 70.00 Ksi Allowable Weld Shear Strength 0.6 Fu / 2 21.00 Ksi Size of Weld 0.1875 in. (Use 0.1250 in. for calculation)

w Pw

Shear Capacity of 1/8" weld per Linear Inch 0.707 * Fv * w (0.707 * 21 * 0.125) 1.856 Kips/in Length of Weld 4.00 in. Weld Shear Capacity Pw * 4 L2 29.694 Kips

L1 Vw

Vw

>

10.00

Kips

(OK)

Page 2 of 10

Design Calculation for Bracing Connection - Joint SWF-SF10

Tension Yielding of the Brace: Rn/ = = = Capacity from 'Limit State of Tension Yielding of Brace' Fyb * Ag1 1.67 74.37 kips 10.00 kips (OK) >

Tension Rupture of the Brace: Rn/ Capacity from 'Limit State of Tension Rupture of Brace' Fub * Ae = 2.00 where: 4.00 in = (Length of Weld in HSS) L B H x U An Ae = = = = = = = = = = 8.00 4.00 in in (Width of HSS Section) (Height of HSS Section) =

(B2 + 2 * B * H) / (4 * (B + H)) 2.667 in 1 - (x / L) 0.333 Ag1 - 2 * (tp + 0.0625) * t1 2.599 in U * An 0.866 25.12 kips in > 10.00 kips (OK)

Rn/

Whtimore Section L= L= 2 lw tan 30 + B 8.619 in 0.000 0.000 in in = 1.67 B= 4.00 in

Whitmore width in Vertical Member = Whitmore width in Horizontal Member =

Check tension yielding on the Whitmore section Rn = Fy Aw Rn = 36 x [ ( 8.619 - 0 - 0 ) x 0.375 ] Rn = Rn/ 116.35 = kips 69.67 kips > 10.00

kips

(OK)

Check block shear rupture of the gusset Rn = Nominal Block Shear Strength of Gusset ( =2)

Page 3 of 10

Design Calculation for Bracing Connection - Joint SWF-SF10

2 x Min[ (0.6 x Fu x Anv + Ubs x Fu x Ant); (0.6 x Fy x Agv + Ubs x Fu x Ant) ] Where: Ubs = 1.0 Ant = Net Area with Tension Resistance = Bbrace x tgusset = 1.50 in

2

Agv = Gross Area with Shear Resistance = 2 x lw x tgusset = 3.00 in

2

Anv = Net Area with Shear Resistance = Rn/ = 3.00 75.90 in

2

kips

>

10.00

kips

(OK)

Plate Buckling of Connection Plate Ap = = = = = = = = = = = Effective Plate Cross-sectional Area L*t 3.232 in Plate Unbraced Length of Whitmore Section 4.28 in. Effective Length Factor 1.200 Radius of Gyration t / 3.464 0.108 in. 47.443 > 25

Lcr

K Lcr/r

From Specification E3 Fe = = Fcr = ()*E/(KL/r) 127.16 ksi

>

0.44*Fy = 15.84 ksi

[0.658^(Fy/Fe)]*Fy 31.98 ksi Allowable Strength in Compression Ap * Fcr 1.67 61.89 kips > 10.00 kips (OK)

Rn/

= =

MEMBER 2:

Page 4 of 10

Design Calculation for Bracing Connection - Joint SWF-SF10

Brace to Gusset Plate Weld: Electrode Class Fu = = = = = w = = = = = = = = = = = = = = = E700XX

Nominal Tensile Strength of Weld Ksi 70.00 tan-1( 10.00 10.00 0.7854 rad deg 45

Size of Weld 0.1875 in.

(Use

0.1250 in. for calculation)

Fv

Allowable Weld Shear Strength 0.6 Fu / 2 21.00 Ksi Shear Capacity of 1/8" weld per Linear Inch 0.707 * Fv * w (0.707 * 21 * 0.125) 1.856 Kips/in ( 10 + 10 ) 14.1421 kips Length of Weld 8.00 in. 7.07107 kips (See attached Calcs)

Pw

P/2

Tension Yielding of the Brace: Rn/ = = = Capacity from 'Limit State of Tension Yielding of Brace' Fyb * Ag3 1.67 371.86 kips > 10.00 kips (OK)

Tension Rupture of the Brace: Rn/ Capacity from 'Limit State of Tension Rupture of Brace' Fub * Ae = 2.00 where: L = (Length of Weld in HSS) 8.00 in B H x = = = 8.00 8.00 in in (Width of HSS Section) (Height of HSS Section) =

(B2 + 2 * B * H) / (4 * (B + H))

Page 5 of 10

Design Calculation for Bracing Connection - Joint SWF-SF10

= U = = = = = = 3.000 1 - (x / L) 0.625 Ag3 - 2 * (tp + 0.0625) * t3 in 13.093 U * An 8.183 kips in

An

Ae

in > 10.00 kips (OK)

Rn/

237.31

Whtimore Section L= L= 2 lw tan 30 + B 17.238 in 0.000 4.700 in in = 1.67 B= 8.00 in

Whitmore width in Vertical Member = Whitmore width in Horizontal Member =

Check tension yielding on the Whitmore section Rn = Fy Aw Rn = 36 x [ ( 17.238 - 0 - 4.7 ) x 0.375 ] Rn = Rn/ 169.26 = kips kips > 10.00

101.35

kips

(OK)

Check block shear rupture of the gusset Rn = = Nominal Block Shear Strength of Gusset ( =2)

2 x Min[ (0.6 x Fu x Anv + Ubs x Fu x Ant); (0.6 x Fy x Agv + Ubs x Fu x Ant) ] Where: Ubs = 1.0 Ant = Net Area with Tension Resistance = Bbrace x tgusset = 3.00 in

2

Agv = Gross Area with Shear Resistance = 2 x lw x tgusset = 6.00 in

2

Anv = Net Area with Shear Resistance = Rn/ = 6.00 151.80 in

2

kips

>

10.00

kips

(OK)

Page 6 of 10

Design Calculation for Bracing Connection - Joint SWF-SF10

Plate Buckling of Gusset Plate Ap = = = = = = = = = = = Effective Plate Cross-sectional Area L*t 6.464 in Plate Unbraced Length of Whitmore Section 1.00 in. Effective Length Factor 1.200 Radius of Gyration t / 3.464 0.108 in. 11.085 < 36 25 ksi

Lcr

K Lcr/r

Thus Fcr = Fy = Rn/ = =

Allowable Strength in Compression Ap * Fcr 1.67 139.35 kips > 10.00 kips (OK)

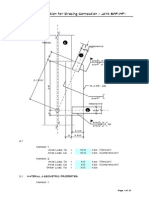

Gusset Plate to Colum:

A V2 L2 T2 e1 C1V L1 C1H V2 T2

C1

Solving for component forces: C1H = = 10 (1) [ (1.37) + (1) ] 5.9 kips

Page 7 of 10

Design Calculation for Bracing Connection - Joint SWF-SF10

C1V = = T2 V2 e1 L1 L2 L L = = = = = = = L1 5 (1.37) [ (1.37) + (1) ] 8.1 10.0 10.0 5.26 14.5 4.5 + L2 19.0 kips kips kips in in in

in

The normal stress is, ft = P/L + 3M/L

The in-plane stress is, fv = V/L

Consider section A-A P = = = = T2 - C1V 1.9

kips

C1V x e1 kip-in 42.5

then, ft and, V

0.454

kip/in

= = =

C1H + 15.9 0.837

V2 kips kip/in

(Diagonal force may reverse)

fv

The resultant is, f = = [ (0.454) + (0.837) ] 0.952 kip/in

Check weld size Fv = = = = = Allowable Weld Shear Strength 0.6 Fexx / 2 [ Fexx = 70ksi] 21.00 Ksi tan 0.837 0.454 61.4987 deg

)

Page 8 of 10

Design Calculation for Bracing Connection - Joint SWF-SF10

= w = = = = = = = 1.073 rad Size of Weld 0.1875 in.

(Use

0.1250 in.

for calculation)

Pw

Shear Capacity of 1/8" weld per Linear Inch 1.5 0.707 * Fv * w * (1.0 + 0.50 sin ) (0.707 * 21 * 0.125) * (1.412) 2.620 Kips/in 5.241 Kips/in > 0.95 Kips/in (OK)

2 Pw

Check plate stress fa = fa = fv = fv = ft tgusset 1.211 fv tgusset 2.231 = ksi = ksi < 0.45 0.375 < 0.84 0.38

0.6Fy/ = Fy/ =

( = 1.67) 22 ksi ( = 1.5) 14 ksi (OK) (OK)

Check HSS wall Force component perpendicular to HSS wall Ft = ft x L = 8.63 kips

HSS wall capacity Rn/ = [ Fy t2 / (1- tp/B)] [ (2N/B + 4(1 -tp/B)0.5 ) Qf] Fy t tp B N Qf Rn/ = = = = = = = 46 0.465 3/8 8.00 19.0 1 kips > 8.63 kips (OK) ( = 1.5)

where:

60.2138

Page 9 of 10

AISC 13th Edition Manual Table 8-5

Coefficients C for Eccentrically Loaded Weld Groups

Input:

kl = l = e x = al = = weld size, w = Fexx = C1 = P = Specs = 8 8 5.000 45 1/8 70 1.00 in in in degrees ksi kips l kl in e x =al P

7.07 ASD

where:

P = D = l = a = ex = C = C1 = required force, P u or P a , kips number of sixteenths-of-an-inch in the fillet weld size characteristic length of weld group, in. e x /l horizontal component of eccentricity of P with respect to centroid of weld group, in. weld group coefficient electrode strength coefficient (1.0 for E70XX electrodes)

Results:

C =

3.16

Available strength of a weld group, Rn/, is determined with C C1 D l Rn/ = (1/) = Setting Rn/ = P, D min = D min = P / C C1 l 0.560 l min = l min = P / C C1 D 2.240 in ( = 2.00)

Conclusion: Since Dmin = 0.56 < 2 (1/16's) Weld is adequate! and l min = 2.24 < 8 in.,

Page 10 of 10

You might also like

- E-Cat35xt014 Xtro PhantomsDocument32 pagesE-Cat35xt014 Xtro PhantomsKari Wilfong100% (5)

- 2018 International Swimming Pool and Spa CodeDocument104 pages2018 International Swimming Pool and Spa CodeEngFaisal Alrai100% (3)

- SlabsOnGrade - Ppthandout ACI 360Document7 pagesSlabsOnGrade - Ppthandout ACI 360Ivan Pacompia Calcina50% (2)

- Practice Problems For Modulus and Logarithm Section-I: FiitjeeDocument8 pagesPractice Problems For Modulus and Logarithm Section-I: FiitjeePratham SharmaNo ratings yet

- PCA Rectangular - Tank Design ExampleDocument15 pagesPCA Rectangular - Tank Design ExampleConrad Otieno100% (4)

- Column Beam Seismic ConnectionDocument8 pagesColumn Beam Seismic ConnectionPrakash Singh RawalNo ratings yet

- Connection Design Standard Document PDFDocument47 pagesConnection Design Standard Document PDFclam2014No ratings yet

- End Plate Type Shear Connection-ASD-2Document10 pagesEnd Plate Type Shear Connection-ASD-2sitehabNo ratings yet

- Connection - Foundation To PileDocument5 pagesConnection - Foundation To PileSandesh Kumar100% (1)

- HSS ThroughPlateBucklingDocument60 pagesHSS ThroughPlateBucklingandyhrNo ratings yet

- Design of Composite Beam With Formed Steel DeckDocument2 pagesDesign of Composite Beam With Formed Steel DeckKhắc ĐăngNo ratings yet

- 4.T&Angle-Brace Connection (M Project) - 0618Document49 pages4.T&Angle-Brace Connection (M Project) - 0618Omprakash KhodkeNo ratings yet

- Rean'S Building 5/24/2002 Angle Plate Design: Framed Beam ConnectionDocument11 pagesRean'S Building 5/24/2002 Angle Plate Design: Framed Beam ConnectionrbalmodalNo ratings yet

- Welded Splice Connection-R2Document33 pagesWelded Splice Connection-R2Anonymous cG5MyHM100% (1)

- HSS Flange Plate Moment Connection - Temporary SteelDocument9 pagesHSS Flange Plate Moment Connection - Temporary SteelrajedmaglinteNo ratings yet

- HSS Cap Plate ConnectionDocument7 pagesHSS Cap Plate ConnectionlavignenoeNo ratings yet

- Flust-Extended End Plate ConnectionDocument8 pagesFlust-Extended End Plate ConnectionamachmouchiNo ratings yet

- Brace ConnectionDocument10 pagesBrace ConnectionAhmed Ben HmidaNo ratings yet

- 10 HOR. BRACE CONNECTION BRACE L90x90x6 - GUSSET PLT.Document114 pages10 HOR. BRACE CONNECTION BRACE L90x90x6 - GUSSET PLT.Asaru DeenNo ratings yet

- Bolted Moment ConnectionDocument18 pagesBolted Moment ConnectionAlpha50% (2)

- Aisc Chevron BraceDocument42 pagesAisc Chevron Bracegvlanusha100% (1)

- Ub 254 Fin Plate To Column Web - LRFDDocument10 pagesUb 254 Fin Plate To Column Web - LRFDihpeterNo ratings yet

- Design of Raft SlabDocument6 pagesDesign of Raft SlabVenkatesha HebbarNo ratings yet

- Structural Steelwork ConnectionsDocument4 pagesStructural Steelwork Connectionstheunknown076No ratings yet

- Extended Fin Plate Connection - LRFDDocument22 pagesExtended Fin Plate Connection - LRFDkalpanaadhiNo ratings yet

- Single Clipconn Bolt Weld 13Document28 pagesSingle Clipconn Bolt Weld 13Nguyen Duc CuongNo ratings yet

- Moment ConnectionDocument7 pagesMoment Connectionkashyap_structuralNo ratings yet

- Column Splice 356 x368x129 Column - WeldDocument4 pagesColumn Splice 356 x368x129 Column - WeldNiraj Shinde100% (1)

- Problem SetsDocument69 pagesProblem SetsAnnagrazia ArgentieriNo ratings yet

- Welded Moment Connection PDFDocument22 pagesWelded Moment Connection PDFRajasekar MeghanadhNo ratings yet

- Column W10x49 2L6x4x1/2 BraceDocument4 pagesColumn W10x49 2L6x4x1/2 BraceDario Federico Noguez GonzalézNo ratings yet

- Design of Moment ConnectionDocument2 pagesDesign of Moment ConnectionDushyantha Jayawardena100% (1)

- Connection Design GuidelinesDocument4 pagesConnection Design GuidelinesABDUL REHMANNo ratings yet

- RC Stair SlabsDocument3 pagesRC Stair SlabsAssad Mohammed AliNo ratings yet

- End Plate Connection Design Per AISCDocument5 pagesEnd Plate Connection Design Per AISCAdam Michael GreenNo ratings yet

- End Plate Beam To Column Moment ConnectionDocument84 pagesEnd Plate Beam To Column Moment Connectionakshay chauhanNo ratings yet

- 033 - Flight Planning Monitoring - QuestionsDocument126 pages033 - Flight Planning Monitoring - QuestionsEASA ATPL Question Bank100% (4)

- Design of End Plate ConnectionDocument2 pagesDesign of End Plate ConnectionAndro RebuyasNo ratings yet

- Piling RequirementsDocument80 pagesPiling Requirementsthusi67% (3)

- Bracing Connection RefDocument5 pagesBracing Connection Refsukarma acharyaNo ratings yet

- Bracing ConnectionDocument15 pagesBracing ConnectionrajedmaglinteNo ratings yet

- Corrosion Protection of Steel BridgesDocument0 pagesCorrosion Protection of Steel Bridgesrajedmaglinte100% (1)

- Double Angle CleatsDocument6 pagesDouble Angle CleatsKaushal KishoreNo ratings yet

- Truss Support Connection Design T5-S1Document11 pagesTruss Support Connection Design T5-S1rajedmaglinteNo ratings yet

- Truss Support Connection Design T5-S1Document11 pagesTruss Support Connection Design T5-S1rajedmaglinteNo ratings yet

- AnchorageDocument8 pagesAnchorageRicha MunjalNo ratings yet

- Wood Armer Equations 553Document2 pagesWood Armer Equations 553Balaji VenkateswaranNo ratings yet

- EC3 - Fin Plate Connection Design ChecksDocument5 pagesEC3 - Fin Plate Connection Design Checkssuman_civilNo ratings yet

- W14x43 To HSS6x6x1 - 2 Moment ConnDocument21 pagesW14x43 To HSS6x6x1 - 2 Moment ConnrajedmaglinteNo ratings yet

- Twisting Momentsin Two-Way SlabsDocument6 pagesTwisting Momentsin Two-Way SlabsProfessor Dr. Nabeel Al-Bayati-Consultant Engineer100% (2)

- SmartBeam Composite Castellated Beam DesignDocument2 pagesSmartBeam Composite Castellated Beam Designirne83100% (2)

- Filled Composite ColumnDocument1 pageFilled Composite ColumnAlphaNo ratings yet

- 4 Anchor Bolts Base PlateDocument285 pages4 Anchor Bolts Base Platetitir bagchiNo ratings yet

- AISC-34 Gusset PlateDocument4 pagesAISC-34 Gusset PlateMartin Cristobal CupitayNo ratings yet

- Four Bolt Unstiffened End PlateDocument7 pagesFour Bolt Unstiffened End PlateRnD2013No ratings yet

- Design - Calculation - For - Bracing - Connection 1 PDFDocument10 pagesDesign - Calculation - For - Bracing - Connection 1 PDFLian Jia JieNo ratings yet

- Beam Aisc LRFDDocument7 pagesBeam Aisc LRFDsocrates00701227100% (1)

- Unbraced LengthsDocument8 pagesUnbraced LengthsZoran MilutinovicNo ratings yet

- A325 and Class 8.8Document3 pagesA325 and Class 8.8rajedmaglinte100% (1)

- Sample Shear ConnectionDocument1 pageSample Shear ConnectionmaheshbandhamNo ratings yet

- RAM Connection Input With CommentsDocument6 pagesRAM Connection Input With CommentsAhmed Saeed OokaNo ratings yet

- Bolted Connection of An Angle Brace in Tension To A Gusset PlateDocument9 pagesBolted Connection of An Angle Brace in Tension To A Gusset PlateshamshiriNo ratings yet

- Haunched Moment Connection AISC360-10Document5 pagesHaunched Moment Connection AISC360-10osman_sultanNo ratings yet

- Trash Rack Design of Compression Member As Per Is 800-2007Document12 pagesTrash Rack Design of Compression Member As Per Is 800-2007D SRINIVASNo ratings yet

- 6-Bracing Connection - TDocument2 pages6-Bracing Connection - TMUTHUKKUMARAMNo ratings yet

- Connection TypesDocument22 pagesConnection TypesWilliam FoxNo ratings yet

- Bolted Connection Angle Brace TensionDocument2 pagesBolted Connection Angle Brace TensionRajib MaharjanNo ratings yet

- Rule of Thumb Concrete DesignDocument54 pagesRule of Thumb Concrete DesignrunkirNo ratings yet

- Antonov 225 - The Largest - Airliner in The WorldDocument63 pagesAntonov 225 - The Largest - Airliner in The WorldFridayFunStuffNo ratings yet

- GlobalDocument24 pagesGloballaleye_olumideNo ratings yet

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part2-Breakout Strength in TensionDocument6 pagesConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part2-Breakout Strength in TensionVenu GopalNo ratings yet

- Angle Flex SeatDocument3 pagesAngle Flex Seatitissa INGENIERIANo ratings yet

- Beam Design For Moment, Shear & TorsionDocument6 pagesBeam Design For Moment, Shear & TorsionRajendra BadjatyaNo ratings yet

- W12x30 Beam To BeamDocument6 pagesW12x30 Beam To BeamWin ThanNo ratings yet

- Ltil LRN Eb Ezee.:, Clean. Postholes, in Concre, Le !Document2 pagesLtil LRN Eb Ezee.:, Clean. Postholes, in Concre, Le !rajedmaglinteNo ratings yet

- Structural Engineer 2009 Top Performers ListDocument3 pagesStructural Engineer 2009 Top Performers ListrajedmaglinteNo ratings yet

- Haydon TC Wrench InfoDocument11 pagesHaydon TC Wrench InforajedmaglinteNo ratings yet

- Chap 3-Structural Bolts PDFDocument45 pagesChap 3-Structural Bolts PDFAndang85No ratings yet

- WireRopeRailingEngSection ADocument16 pagesWireRopeRailingEngSection ArajedmaglinteNo ratings yet

- SP Slab PresentationDocument19 pagesSP Slab PresentationrajedmaglinteNo ratings yet

- Spslab Manual PDFDocument251 pagesSpslab Manual PDFrajedmaglinteNo ratings yet

- FootingsDocument2 pagesFootingsrajedmaglinteNo ratings yet

- Brace ConnectionDocument8 pagesBrace ConnectionrajedmaglinteNo ratings yet

- Steel Connection Formulas - Tension CheckDocument1 pageSteel Connection Formulas - Tension CheckrajedmaglinteNo ratings yet

- Hilti HIT-200 System Replaces HIT-HY 150Document3 pagesHilti HIT-200 System Replaces HIT-HY 150rajedmaglinte100% (1)

- Hilti HIT-200 System Replaces HIT-HY 150Document3 pagesHilti HIT-200 System Replaces HIT-HY 150rajedmaglinte100% (1)

- Beam DesignDocument1 pageBeam DesignrajedmaglinteNo ratings yet

- Column TiesDocument1 pageColumn TiesrajedmaglinteNo ratings yet

- Forged Steel Clevis: Caution: Never Exceed The Working Load LimitDocument1 pageForged Steel Clevis: Caution: Never Exceed The Working Load LimitrajedmaglinteNo ratings yet

- HLC Vs KWIK CON IIDocument2 pagesHLC Vs KWIK CON IIrajedmaglinteNo ratings yet

- FootingsDocument2 pagesFootingsrajedmaglinteNo ratings yet

- 3in DeckDocument1 page3in DeckrajedmaglinteNo ratings yet

- Bracing ConnectionDocument10 pagesBracing ConnectionrajedmaglinteNo ratings yet

- Chapter 1Document20 pagesChapter 1Li YuNo ratings yet

- Topics For AssignmentDocument2 pagesTopics For AssignmentniharaNo ratings yet

- Amazon Tax Information InterviewDocument2 pagesAmazon Tax Information Interviewasad nNo ratings yet

- Consumer Price SummaryDocument5 pagesConsumer Price SummaryKJ HiramotoNo ratings yet

- Iot Practical 1Document15 pagesIot Practical 1A26Harsh KalokheNo ratings yet

- Dhulikhel RBB PDFDocument45 pagesDhulikhel RBB PDFnepalayasahitya0% (1)

- Vedic Town Planning ConceptsDocument17 pagesVedic Town Planning ConceptsyaminiNo ratings yet

- WP05 - ACT 01 - Development 1909Document53 pagesWP05 - ACT 01 - Development 1909ramesh9966No ratings yet

- Case 1394 Moteur 1 2Document36 pagesCase 1394 Moteur 1 2ionel ianosNo ratings yet

- 面向2035的新材料强国战略研究 谢曼Document9 pages面向2035的新材料强国战略研究 谢曼hexuan wangNo ratings yet

- Anin, Cris Adrian U. Experiment Water Flirtation ELECTIVE 103Document2 pagesAnin, Cris Adrian U. Experiment Water Flirtation ELECTIVE 103Cris Adrian Umadac AninNo ratings yet

- Problem Solving Questions: Solutions (Including Comments)Document25 pagesProblem Solving Questions: Solutions (Including Comments)Narendrn KanaesonNo ratings yet

- Updated PDPDocument540 pagesUpdated PDPnikulaaaasNo ratings yet

- 1and5.microscopes, Specializedstem Cells, Homeostasis - Answer KeyDocument1 page1and5.microscopes, Specializedstem Cells, Homeostasis - Answer KeyMCarmen López CastroNo ratings yet

- Role of Quick Response To Supply ChainDocument15 pagesRole of Quick Response To Supply ChainSanuwar RashidNo ratings yet

- Where Business Happens Where Happens: SupportDocument19 pagesWhere Business Happens Where Happens: SupportRahul RamtekkarNo ratings yet

- Lite Indicator Admin ManualDocument16 pagesLite Indicator Admin Manualprabakar070No ratings yet

- What Are The Challenges and Opportunities of ResearchingDocument5 pagesWhat Are The Challenges and Opportunities of ResearchingmelkyNo ratings yet

- Standards Guide 1021 1407Document8 pagesStandards Guide 1021 1407Anjur SiNo ratings yet

- Engineering Economics1Document64 pagesEngineering Economics1bala saiNo ratings yet

- Law MCQ 25Document3 pagesLaw MCQ 25nonoNo ratings yet

- UTM Firewalls: AR3050S and AR4050SDocument8 pagesUTM Firewalls: AR3050S and AR4050SChristian Javier Lopez DuranNo ratings yet

- Dr. Muhammad Mumtaz: Thesis TitleDocument10 pagesDr. Muhammad Mumtaz: Thesis TitleDr. Muhammad MumtazNo ratings yet