Professional Documents

Culture Documents

A Micro Electro Mechanical Model For Polarization Swithing of Ferroelectric Materials

Uploaded by

王轩Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Micro Electro Mechanical Model For Polarization Swithing of Ferroelectric Materials

Uploaded by

王轩Copyright:

Available Formats

PII:

Acta mater. Vol. 46, No. 15, pp. 53035311, 1998 # 1998 Acta Metallurgica Inc. Published by Elsevier Science Ltd. All rights reserved Printed in Great Britain S1359-6454(98)00207-9 1359-6454/98 $19.00 + 0.00

A MICRO-ELECTRO-MECHANICAL MODEL FOR POLARIZATION SWITCHING OF FERROELECTRIC MATERIALS

W. CHEN and C. S. LYNCH{

School of Mechanical Engineering, Georgia Institute of Technology, Atlanta, GA 30332, U.S.A. (Received 16 September 1997; accepted 5 June 1998) AbstractFerroelectric and ferroelastic switching are the major source of nonlinearity and hysteresis in ferroelectric materials subjected to high electric eld or mechanical stress. A computational micromechanics model for polycrystalline ferroelectric ceramics is developed based on consideration of the constitutive behavior of single crystals. This model simulates the tetragonal and the rhombohedral crystal structures. Saturation of the linear piezoelectric eect is included. Interaction between dierent grains in the polycrystalline ceramic is considered. A switching criterion is developed that accounts for dierent energy levels associated with 908 and 1808 switching for the tetragonal structure (or 70.58, 109.58, and 1808 for the rhombohedral structure). Experimental results on 8/65/35 PLZT are simulated and a parametric study of the eects of crystal structure, intergranular interaction, and phase transformation is performed. # 1998 Acta Metallurgica Inc. Published by Elsevier Science Ltd. All rights reserved.

1. INTRODUCTION

Electro-active ceramics are widely used as sensors and actuators. This class of materials includes piezoelectrics, ferroelectrics, electrostrictors and phase changers. Applications include active damping, precision positioning, structural control, and noise control. Many applications require the largest possible strain and force. This results in their operation at high stress and electric elds, in which the electro-active ceramics show strong nonlinearity and hysteresis. These properties can be seen in the electric displacement vs electric eld curves and strain vs electric eld curves measured on 8/65/35 lead lanthannina zirconate titanate (PLZT) ceramics [1]. The hysteresis loops are the result of ferroelectric switching. When the electric eld is higher than the coercive eld (Ec), the polarization direction is reoriented. A ferroelastic material is one in which the direction of polarization can be reoriented by an applied stress eld. For a 8/35/65 PLZT, when the stress level is higher than the coercive stress (sc), polarization switching occurs. Nonlinearity and hysteresis may limit the performance of electro-ceramic actuators. Very large strain materials such as phase changing lead lanthanum stannate zirconate titanate (PLSnZT) [2] ceramics and lead zinc niobate (PZN) single crystals [3] are under development for large strain actuator applications, but nonlinearity and hysteresis as well as intergranular cracking in ceramics are often associated with the larger strain. In

{To whom all correspondence should be addressed.

antiferroelectric PLSnZT, application of strong electric elds induces a ferroelectric phase [2]. PZN single crystals change their structures from rhombohedral to tetragonal, or vice versa in response to large electric eld [3]. The coupling of stress and electric eld is suciently complicated so that it is dicult to accurately describe the multiaxial nonlinearity and hysteresis at the macroscopic level. A framework for the nonlinear theory of ferroelectrics has been developed based on the general thermodynamics theory [47]. Recently, a relatively simple macroscopic constitutive model was developed [8], but it is limited to one-dimensional uniaxial loading. Micro-electro-mechanics models give insight into the phenomena that give rise to hysteresis and, with this understanding, may give insight into how to control hysteresis and cracking phenomena. In previous micro-electro-mechanics work, Hwang et al. [9] used a Preisach hysteresis model to simulate each grain of a ceramic. A work energy criterion was used to determine the critical loading level at which polarization switching occurs. The contribution of each grain to the macroscopic strain and polarization of the ceramic was calculated by averaging over all grains. A similar approach was used by Chan and Hagood [10]. The previous models did not consider several phenomena. Models based on a tetragonal crystal structure were used to simulate rhombohedral materials. The dierences between the tetragonal structure and rhombohedral structure are considered in this work. In this work, dierent energy levels associated with 908 and 1808 switching for the tetragonal structure (or 70.58, 109.58, and 1808 switching for the rhom-

5303

5304

CHEN and LYNCH: SWITCHING OF FERROELECTRIC MATERIALS

bohedral structure) are considered. These energy levels could be obtained by tting the experimental results on ferroelectrics. The model presented here has extended previous models by considering tetragonal and rhombohedral crystal structures, local constitutive laws for individual grains, dierent switching criteria for 908 and 1808 switching, interaction eects between grains, and phase transitions driven by electric eld and mechanical stress. The development begins with consideration of the rhombohedral and tetragonal perovskite type crystal structures of ferroelectric single crystals. The constitutive behavior of single crystals governs the behavior of ceramics. At small eld levels the constitutive behavior is linear but not isotropic, which is governed by piezoelectric constitutive laws. At high eld levels in the polarization direction, the piezoelectric eect saturates. At high eld levels in other directions, the directions of spontaneous polarization and strain can be switched by an applied electric eld or mechanical stress [1, 11]. Ferroelectric and ferroelastic polarization switching together with linear eects are the source of the buttery shaped strain vs electric eld curves and the corresponding electric displacement vs electric eld loops [12]. Phase changes between the tetragonal and rhombohedral structures are considered in this model. Other phase changes such as antiferroelectric-to-ferroelectric (AFF) could readily be implemented. Ceramics are modeled as many randomly oriented grains. A global coordinate system is used to describe the applied loads and local coordinate systems are used to describe the crystallographic orientation of each grain. The local coordinate systems are xed relative to the global coordinate system. The possible polarization directions are dened relative to the local coordinate system. When the polarization direction switches, local piezoelectric and elastic tensors are rotated to a new direction. Each grain has single crystal anisotropic non-linear constitutive behavior. The response of each grain is computed in local coordinates. The macroscopic response of the ceramic is computed from the volume average of the local response of each grain. Polarization switching does not occur homogeneously in single crystals. The mechanism is the nucleation and growth of domains, and the mobility of domain walls has a large eect on the constitutive behavior of the crystal. This model smears smaller length scale eects such as domain wall motion into the single crystal constitutive behavior. Grains interact with each other and with the globally applied stress and electric elds. The intergranular interaction is modeled using a simplied approximation of an inclusion in a matrix, with the matrix having the volume average properties of the other grains. The model can be used to explore the eects of physical properties and interactions on the micro-

mechanical scale, with observed macroscopic material properties. Micromechanical properties include intergranular interactions, texture in the granular orientations, crystal structure eects, switching between structures (as is believed to occur in PZT compositions near morphotropic boundaries), and constitutive behavior such as ferroelectrics with a saturating piezoelectric eect, quadratic electrostriction with saturation and structural phase changes with associated volume changes. This work begins by simulating the results of a series of experiments performed on ceramic rhombohedral 8/65/35 PLZT. This is followed by a parametric study that explores the eects of intergranular interaction, crystal structure, and phase transformation on the hysteresis loops of ferroelectric ceramics.

2. MODEL DESCRIPTION

2.1. Crystal structure Development of this model begins with consideration of the rhombohedral and tetragonal perovskite type crystal structures for ferroelectric grains. The tetragonal and the rhombohedral crystal structures allow the polarization to occur toward six face centers and the eight corners of the unit cell. Under small loads, the polarization of the grain undergoes a reversible change which is proportional to the loading level in one of two ways: (i) an applied stress deforms the crystal structure, resulting in a relative displacement of the positive and negative ions; (ii) an applied electric eld changes the relative displacement of the positive and negative ions, inducing deformation of the crystal. These are the linear piezoelectric eects. At high eld levels in the polarization direction, the piezoelectric eect saturates. At high eld levels in other directions, the central ion is moved to another possible site, and the direction of spontaneous polarization is switched. 2.2. Constitutive behavior of single crystals The individual grains are modeled as linear piezoelectric with ferroelectric and ferroelastic switching, and saturation of the piezoelectric eect at high eld levels. This constitutive behavior is described by

p s eij ee ij eij eij p s Dm D d m Dm Dm X

1 2

Superscripts e, p, and d indicate elastic, piezoelectric, and dielectric components. es ij is the spontaneous strain, and Ds the spontaneous electric m displacement. 2.2.1. Linear constitutive behavior. The elastic, dielectric, and piezoelectric components, with stress and electric eld as free variables, are described by

CHEN and LYNCH: SWITCHING OF FERROELECTRIC MATERIALS

5305

the following equations: elij ee ij ep ij sijkl skl dnij En 3 4

d Dlm Dp m Dm dmkl skl emn En

where superscript l refers to linear, sijkl is the elastic compliance, dnij the piezoelectricity, En the electric eld, and emn the dielectric permittivity. Indices vary from 1 to 3. Summation on repeated indices is implied. Since the constitutive behavior is implemented at the single crystal scale, and general tensor calculations are performed, anisotropic crystal properties are readily implemented. Simulations presented in this work are performed with the elastic compliance and dielectric permittivity considered isotropic, and the piezoelectricity tensor transversely isotropic. In this case, sijkl and emn are given by sijkl 1# # dik djl dij dkl Y Y emn edmn 5 6

reorientation, through either ferroelectric or ferroelastic switching, results in a change of the spontaneous strain. This is a major source of nonlinearity and hysteresis. 2.2.4. Switching between structures (TETRH, AFF). Phase changes between the tetragonal and rhombohedral structures are known to occur in some materials. To accommodate this behavior, the electric eld and/or mechanical stress are allowed to drive the structures from tetragonal to rhombohedral, or vice versa. These phase changes are governed by a minimization of the energy of the system. The phase transformation is simulated by allowing the polarization of the crystal to be switched to any of the possible 14 tetragonal and rhombohedral directions. Other phase changes such as AFF can be implemented by changing the polarization (phase) switching laws. Such switching laws should account for the volume change from the antiferroelectric state to the ferroelectric state that occurs in materials like PLSnZT. 2.3. Grain orientation eects Ceramics consist of many randomly orientated grains. Each grain is modeled as a uniformly polarized cell that has a spontaneous polarization and a spontaneous strain. Inhomogeneities in the local electric and stress elds are ignored so that each grain is subjected to the same loading conditions. A global coordinate system is xed in space. A local coordinate system is assigned to each grain. The orientation of the local coordinate system relative to the global coordinate system is dened in terms of nine direction cosines x j aji Xi 8 where aij cos yij are the direction cosines between the local and the global coordinate system and the subscripts refer to Cartesian coordinate directions. The yij are specied by three randomly generated Euler angles. The polarization direction of each grain is dened in its local coordinate system. The unit cell elongates in the direction of polarization and contracts in the directions perpendicular to it for both structures. 2.4. Switching laws with intergranular interaction The switching law for each grain should account for the dierent energy levels associated with 908 and 1808 switching for the tetragonal structure, or 109.58, 70.58, and 1808 switching for the rhombohedral structure. These energy levels are associated with the nucleation and propagation energies of each type of domain wall. The ferroelectric/ferroelastic switching law described for single crystals must be modied to account for discontinuities in the spontaneous polarization and strain from grain to grain. These discontinuities are accommodated by local stress and local electric eld. The local

where Y is Young's modulus, n is Poisson's ratio, and e the dielectric permittivity. The piezoelectricity tensor has a principal direction that aligns with the polarization direction in each grain. The nonzero components of the piezoelectric tensor include d113, d223, d311, d322, and d333. The x3-axis, parallel to the polarization direction, is the transverse isotropic symmetric axis of the piezoelectricity tensor. Polarization reorientation results in a direction change of the anisotropic elastic, dielectric, and piezoelectricity tensors. When the polarization direction switches, the principal directions of the piezoelectricity tensor are rotated to those associated with the new polarization direction. 2.2.2. Saturation of the linear piezoelectric eect. Experimental data indicate that when a large applied electric eld is in the direction of polarization, the linear piezoelectric eect saturates. This is described by & d E a if ep esa nij n ij ij p eij 7 p sa esa if e b e ij ij ij where esa ij is the magnitude of the saturation strain, Ea are the components of the applied electric eld. n 2.2.3. Ferroelectric and ferroelastic switching. When the electric or stress eld is higher than the coercive eld and it is not in the polarization direction, ferroelectric or ferroelastic switching occurs. The magnitude of spontaneous strain and electric displacement remain constant during switching, but their directions change. One of the principle directions of strain is always aligned with the polarization and the magnitude of strain in this direction is positive, i.e. elongation. Non-1808 polarization

5306

CHEN and LYNCH: SWITCHING OF FERROELECTRIC MATERIALS

stress and electric eld increase the energy of the system. These intergranular interactions can be approximated as inclusions in a linear piezoelectric matrix. The problem of the spherical piezoelectric inclusion has been solved by Benveniste [13] and Huang [14]. Their solutions are too computationally intensive to be implemented because many thousands of inclusion problems would have to be solved to simulate the response of a ceramic. In this work, details of the interactions between each grain and matrix are not explicitly considered. Rather, they are approximated by considering the dierences between the spontaneous polarization and spontaneous strain of the grains and the remanent polarization and strain of the ceramic. Equation (9) is used to approximate the interaction energies between each grain and the ceramic matrix

e UI U D I UI D I

dened as W DUI r2D0 E0 15 where DUI is the change of interaction energy which is given as

2 1 DUI U I UI

16

where D0 is the value of the spontaneous polarization, E0 the magnitude of the critical electric eld at which the polarization switching occurs if only the electric eld is applied to a single crystal grain. Since the energy necessary to move dierent kinds of domain walls diers, E0 must be given dierent values associated with 908 and 1808 switching for the tetragonal structure, or 70.58, 109.58, and 1808 switching for the rhombohedral structure. E0 is also a material dependent parameter. 2.5. Local response to applied loads The global coordinate system is used to describe the applied stress and electric eld. At each time step in the computation, components of the applied stress and electric eld are computed in each of the local coordinate systems. The switching criterion of equation (15) is checked for every grain and for every possible polarization direction to see if switching will occur. If more than one switching direction can occur, the direction which maximizes the lefthand side of equation (15) is chosen. If more than one such direction exists, one of them is chosen randomly. In the computational process, the increment of loading at each step is limited in size, thus only a few grains change their polarization directions in each step. After all possible polarization switches have occurred, the piezoelectric tensor of each grain is rotated to the new polarization direction. Next the strain and electric displacement of each grain are computed from constitutive equations (1) and (2) in the local coordinate system. 2.6. Global response to applied loads The macroscopic response of the ceramic is computed from the volume average response of each grain. The strain and polarization of each grain are computed, and then rotated to the global system and averaged. The global strain and electric displacement are updated only at the end of each loading increment. After the global response has been determined, i.e. the remanent polarization and remanent strain have been computed, the applied loads are incremented and the local response is recomputed.

3. RESULTS AND DISCUSSIONS

where U is the interaction energy due to the mismatch of electric displacement, and U e I is the interaction energy due to the mismatch of strain between the grain and the matrix. McMeeking and e Hwang [15] have shown that U D I and U I can be approximated by c1 s s r D Dr UD 10 I i Di Di 2e i Ue I c2 Y s s r e er ij eij eij 2 ij 11

where c1 and c2 are parameters, which would be chosen so that the computational results are in best s agreement with the experimental data. Ds i , eij are the spontaneous electric displacements and strains r of each grain, respectively. Dr i , eij are the remanent electric displacements and strains of the matrix, which are the average values over all grains. The work done by the external forces during polarization switching is given by W Ei DDi sij Deij where DDi Di2 Di1

2 1 Deij e ij eij

12

13 14

where DDi is the change in the spontaneous polarization, and Deij the change in spontaneous strain during switching. Superscript (1) indicates the present value, while superscript (2) indicates the new value if polarization switching occurs. The contribution of elastic strain and electric displacement to the work and interaction energy are assumed to be relatively small in comparison with that of spontaneous strain and electric displacement. When the sum of the work done and the reduction of interaction energy exceed a critical value, polarization switching occurs. Thus the switching criterion is

3.1. Simulations of the behavior of 8/65/35 PLZT The results of a series of experiments perfomed on ceramic rhombohedral 8/65/35 PLZT [1] are simulated. Data include strainelectric eld hysteresis vs stress, electric displacementelectric eld hys-

CHEN and LYNCH: SWITCHING OF FERROELECTRIC MATERIALS

5307

teresis vs stress, and stress vs strain, and stress vs electric displacement measured at zero electric eld. Input parameters are chosen so that the computational results are in agreement with the data. Since 1808 switching does not change the spontaneous strain, the sharp tail and negative strain observed in experiments are due to 70.58 (or 109.58) switching following by another 70.58 (or 109.58). It suggests that 70.58 or 109.58 switching is preferred over 1808 switching in this material. Therefore, the energy level for 70.58 and 109.58 switching should be smaller than that for 1808 switching. In the 70X5 simulation, E 180 is used to favor 70.58 0 5E 0 X5 X5 switching. The value E 70 E 109 0X1 MVam 0 0 is chosen, so that the simulated coercive eld is in agreement with the measured one (Ec 0X36 MVam). D0 0X3 Cam2 and e0 0X0039 are used to get remanent polarization (Dr 0X24 Cam2 ) and remanent strain (er 0X0014) at zero stress and electric eld. The saturation strain,

esa ij 0X0687, gives good simulated results at high electric eld levels. The interaction energy factors, c1=0.03, c2=0.005, are used to get a sharp shape of the strainelectric eld curve. Piezoelectric coecients are selected as d333 d113 1X0 109 maV to match the slope of the strainelectric eld curve. 3.1.1. Simulated e33E3 hysteresis loops vs stress. Initially the material is in the paraelectric state with zero electric displacement and strain. When an electric eld above the coercive eld is applied, the sample switches to the polarized state. After several cycles, a stable hysteresis loop develops [Fig. 1(a)]. At zero stress, the simulation results show the sudden decrease of strain during switching, but negative strains are not obtained. At 10 and 30 MPa compressive stress, the simulations give the same value of negative strain as the data. At higher stress levels, the remanent strain steadily decreases and the curves are shifted downward and become atter. Elastic deformation and ferroelectric/ferroelastic

Fig. 1. Comparison of simulated and measured longitudinal strain and polarization subjected to an electric cycle: (a) strain vs electric eld at various compressive stress levels; (b) electric displacement vs electric eld at dierent compressive stress levels.

5308

CHEN and LYNCH: SWITCHING OF FERROELECTRIC MATERIALS

switching contribute to this change. The higher stress level decreases the coercive eld and encourages the polarization to switch to 70.58 (or 109.58) directions. After the rst 70.58 (or 109.58) switching, the stress tends to keep the polarization in these directions and hinder further switching. A much higher loading level is necessary to make the second 70.58 (or 109.58) switch. 3.1.2. Simulated D3E3 hysteresis loops vs stress. The simulated electric displacment vs electric eld hysteresis loops are very close to the data at all stress levels [Fig. 1(b)]. The compressive stress decreases the remanent polarization. At 10 MPa, a higher electric eld is needed to complete the switching. At 30 MPa, the electric eld is not able to fully repole the material. 3.1.3. Simulated s3 vs e33 curve. The polarized ceramic is subjected to uniaxial compressive stress parallel to the direction of polarization and the stressstrain curve [Fig. 2(a)] is simulated. The measured remanent strain at zero stress is smaller than seen in the simulation. This is because the model does not include ageing (time dependent eects), but the material does. Initially, the response of the ceramic is due to the linear elastic and piezoelectric eect. When the coercive stress is reached, the material starts to depole. When the stress has reached 35 MPa, the switching is nearly complete and the stressstrain behavior becomes linear elastic. The unloading slope is the same as the loading slope. When the sample is unloaded to zero, the

nal strain is negative relative to the unpoled state due to 70.58 and 109.58 switching. 3.1.4. Simulated s3 vs D3 curve. The stresselectric displacement curve [Fig. 2(b)] is measured during the stress/strain test. The shape of the stresselectric displacement curve is similar to that of the stressstrain curve. The initial measured remanent polarization is smaller than the simulated one due to ageing. After the maximum amount of ferroelastic switching has occurred, although the strain reaches a high negative level, a positive remanent polarization still exists in the ceramic. The unloading slope has the same sign, but a dierent value than that of the initial loading slope. When the specimen is unloaded to zero, the simulated remanent polarization is smaller than the measured one. 3.2. Parametric study A parametric study is performed to investigate the eects of dierent parameters on material behavior. All of the results are normalized by E 90 0 (or X5 E 70 for rhombohedral), P0, e0, and s0. Since stress 0 can drive only 908 (or 70.58, 109.58) switching, s0 is given by s0

X5 P0 E 90 P0 E 70 0 0 or s0 X e0 e0

17

Fig. 2. Comparison of simulated and measured longitudinal strain and polarization subjected to a stress cycle: (a) stress vs strain; (b) stress vs electric displacement curve.

Eects on the material behavior are examined by varing individual parameters. First, intergranular interaction eects are studied. Next, the eects of tetragonal and the rhombohedral structures are examined, and a morphotropic boundary material is simulated. Finally, the model is used to validate a macroscopic law for the evolution of the piezoelectric coecients during switching. 3.2.1. Intergranular interaction eects. Electric displacement vs electric eld and strain vs electric eld hysteresis loops are simulated with interaction (c1=0.05, c2=0.025) and without interaction (c1=c2=0) (Fig. 3). The interaction between each single grain and the matrix plays an important role in the constitutive behavior. The interaction energy initially increases the coercive electric eld by discouraging polarization switching. However, after the electric displacement and strain change sign, the interaction energy encourages further switching. This results in a sharp tail in the strainelectric eld curve at zero stress [Fig. 3(a)]. At zero stress, the coercive electric eld with interaction energy is about 1.5 times higher than that without. If c1 and c2 are decreased, these dierences are decreased. When the stress level is increased, the dierence becomes less signicant. Interaction does not change the shape, but widens the electric displacement vs electric eld loops because more energy needs to be overcome [Fig. 3(b)]. The switching saturates at the same electric eld level for these two cases.

CHEN and LYNCH: SWITCHING OF FERROELECTRIC MATERIALS

5309

Fig. 3. Comparison of simulated results with or without interaction energy eect at dierent zero compressive stress level and twice the coercive stress level: (a) strain vs electric eld; (b) electric displacement vs electric eld.

dierent stress levels. The results are very similar for these two crystal structures. The tails in the strain vs electric eld curves computed from the rhombohedral structure are a little shorter than those from the tetragonal at zero stress [Fig. 5(a)]. The coercive eld of the rhombohedral structure is a little smaller than the tetragonal. When the stress is increased, the dierences become smaller. The electric displacement vs electric eld curves at dierent stress levels are almost the same for these two ceramics [Fig. 5(b)]. The curves obtained from these two structures are so close that we may conclude that the dierences between the crystal structures do not have much inuence on the nonlinear behavior or the hysteresis of ferroelectric materials. 3.2.3. Eect of phase changes. A morphotropic boundary composition is simulated by allowing switching into either tetragonal or rhombohedral sites. The results show the tails disappear when both tetragonal and rhombohedral sites are available [Fig. 6(a)]. The remanent strain at zero electric eld is higher for the mixed phase, since more polarization directions (all 14 possible tetragonal and rhombohedral directions) are possible, and the polarization can be aligned more closely with a given direction. Similarly, the remanent polarization of the mixed phase material is higher than tetragonal or rhombohedral alone [Fig. 6(b)]. 3.2.4. Check of phenomenological law. The constitutive law is applied to every grain in the local coordinate system so that the response of each

A fully polarized ceramic subjected to a stress cycle at zero electric eld is simulated and stress strain and stresselectric displacement curves are plotted (Fig. 4). The intergranular interaction does not aect the stressstrain behavior signicantly [Fig. 4(a)], but the coercive eld for depolarization is increased. However, the shapes of stresselectric displacement curves are changed dramatically by interaction [Fig. 4(b)]. When the compressive stress reaches a very high level, the remanent polarization of the ceramic reaches a minimum positive value. Next, the stress is unloaded to zero. If no interaction energy is present, the following tensile stress does not repolarize the material because there is equal probability of the polarization switching to a positive or negative 908 direction. Since the positive remanent polarization tends to make the grains align in one direction to minimize the potential energy of the ceramic, the tensile stress repolarizes the ceramic when the stress exceeds the coercive stress level and the interaction eect is implemented. This gives the stressstrain hysteresis loop [Fig. 4(b)]. 3.2.2. Eects of tetragonal and rhombohedral crystal structures. The same parameters with interaction are used for tetragonal and rhombohedral ceramics and strain vs electric eld and electric displacement vs electric eld hysteresis loops are generated at

Fig. 4. Comparison of simulated results at zero electric eld with or without interaction energy eect: (a) stress vs strain; (b) stress vs electric displacement.

5310

CHEN and LYNCH: SWITCHING OF FERROELECTRIC MATERIALS

is poled by a large electric eld, it shows a strong piezoelectric eect. The value of the piezoelectricity tensor is related to the remanent polarization. An approximate relationship between the piezoelectricity tensor and the remanent polarization is that the value of the piezoelectricity tensor is proportional to the remanent polarization [1], i.e. dijk dijk Dr Dr s 18

where dijk is the piezoelectric coecient of the fully poled polycrystalline ceramic, Dr the current value of the remanent polarization, and Dr s the fully poled saturation magnitude of the remanent polarization of the ceramic. Several simulated compressive stresses are applied to fully poled ceramic to obtain dierent remanent polarizations. An electric eld is then applied and d333 is obtained. An approximately linear relationship between d333 and Dr is found at dierent polarization levels (Fig. 7). The approximate equations for other components of the piezoelectricity tensor can be checked in the same way. It appears that equation (18) is a reasonable approximation for the piezoelectricity tensor during switching.

4. CONCLUDING REMARKS

A computational model based on micromechanics has been developed to simulate the nonlinear behavior of ferroelectric ceramics. The ceramics were

Fig. 5. Comparison of simulated results for tetragonal and rhombohedral structures: (a) strain vs electric eld; (b) electric displacement vs electric eld.

grain can be evaluated. This makes it possible to use anisotropic material properties and track their change during switching. Since the macroscopic response of the ceramic is completely determined by the properties of grains, this model is very useful in testing macroscopic phenomenological constitutive laws that include switching eects. A macroscopic equation used for the piezoelectricity tensor is tested. Initially the unpoled ceramic is macroscopically isotropic and has no piezoelectric properties (piezoelectricity tensor is zero). When the material

Fig. 6. Eect of phase changes driven by electric eld: (a) strain vs electric eld; (b) electric displacement vs electric eld.

CHEN and LYNCH: SWITCHING OF FERROELECTRIC MATERIALS

5311

results give us important information that will be used to guide the development of multiaxial, nonlinear, hysteretic phenomenological constitutive law for ferroelectric materials.

Acknowledgements We gratefully acknowledge funding for this work by an oce of Naval Research Young Investigator award #N0014-96-1-0711 and by a National Science Foundation CAREER award, NSF #CMS9702169. Fig. 7. d333 vs remanent polarization (Dr) Approximate linear relationship is found. curve. REFERENCES 1. Lynch, C. S., Acta metall. mater., 1996, 44, 4137. 2. Pan, W. Y. and Cross, L. E., Antiferroelectric to ferroelectric switching in lead zirconia titanate stannate ceramics, Proceedings of the 6th IEEE Symposium on the Application of Ferroelectrics, Lehigh University, 8 11 June 1986, p. 648. 3. Park, S. E. and Shrout, R. T., J. Mater. Res. Innovations, 1997, 1, 20. 4. Bassiouny, E., Ghaleb, A. F. and Maugin, G. A., Int. J. Engng Sci., 1988, 26, 1279. 5. Bassiouny, E., Ghaleb, A. F. and Maugin, G. A., Int. J. Engng Sci., 1988, 26, 1297. 6. Bassiouny, E. and Maugin, G. A., Int. J. Engng Sci., 1989, 27, 975. 7. Bassiouny, E. and Maugin, G. A., Int. J. Engng Sci., 1989, 27, 989. 8. Kamlah, M. et al., Macroscopic description of the nonlinear electro-mechanical coupling in ferroelectrics, in Smart Structures and Materials 1997: Mathematics and Control in Smart Structures, SPIE, 1997, pp. 144 155. 9. Hwang, S. C., Lynch, C. S. and McMeeking, R. M., Acta metall. mater., 1995, 43, 2073. 10. Chan, K. H. and Hagood, N. W., Proc. SPIE Smart Structures and Materials, Vol. 194, ed. N. W. Hagood, 1994, p. 2190. 11. Jae, B., Cook, W. R. and Jae, H., Piezoelectric Ceramics. Academic Press, London, 1971. 12. Cao, H. C. and Evans, A. G., J. Am. Ceram. Soc., 1993, 76, 896. 13. Benveniste, Y., J. appl. Phys., 1992, 72, 1086. 14. Huang, J. H., J. appl. Phys., 78, 6491. 15. McMeeking, R. M. and Hwang, S. C., Ferroelectrics, 1997, 200, 151.

considered as an aggregate of many grains which were modeled as single domain with switching. A linear saturation model was applied to each unit cell. The strain and electric displacement of each grain were obtained by computing the linear components and spontaneous components in a local coordinate system. The macroscopic response was obtained by averaging over all grains. A switching criterion that accounts for the interaction between grains and the dierent energy levels necessary to move 908 (70.58, 109.58) and 1808 domain walls was implemented in this model. When 908, 70.58 switching is favored, the simulation results better t the rhombohedral experimental data. This implies that it is easier to move 908, 70.58 domain walls than 1808 domain walls. A parametric study was performed using this model. The results suggest the interaction energy has inuence on the hysteresis loops of ferroelectric materials, especially under mechanical loading. The crystal structures, tetragonal or rhombohedral, do not have a signicantly dierent eect on the nonlinearities in material behavior. Morphotropic boundary materials were simulated. They show higher remanent strain and polarization. This model is capable of predicting the behavior of ferroelectric materials under multiaxial loading (mechanical and/or electrical). The

You might also like

- Applications of Ferroelectric Ceramic MaterialsDocument40 pagesApplications of Ferroelectric Ceramic Materialssamir_kumar_40% (1)

- Piezo Ceramic TutorialsDocument50 pagesPiezo Ceramic Tutorialscal2_uniNo ratings yet

- Resumen de Piezo Ceramic TutorialsDocument29 pagesResumen de Piezo Ceramic TutorialsCarlos BustamanteNo ratings yet

- Piezo Ceramic TutorialsDocument51 pagesPiezo Ceramic TutorialsCarlos BustamanteNo ratings yet

- Revsed ChaptersDocument84 pagesRevsed ChaptersPow dowtowNo ratings yet

- Fracture Behaviors of PiezoelectricmaterialsDocument41 pagesFracture Behaviors of PiezoelectricmaterialsJoão JacintoNo ratings yet

- International Journal of Solids and Structures: R. Jayendiran, A. ArockiarajanDocument12 pagesInternational Journal of Solids and Structures: R. Jayendiran, A. ArockiarajanMani PrakashNo ratings yet

- Li 2018Document19 pagesLi 2018Eduardo SaavedraNo ratings yet

- Effects of Uniaxial Prestress On The Ferroelectric Hysteretic Response of Soft PZT PDFDocument8 pagesEffects of Uniaxial Prestress On The Ferroelectric Hysteretic Response of Soft PZT PDFAlan SoulieNo ratings yet

- tmp9087 TMPDocument28 pagestmp9087 TMPFrontiersNo ratings yet

- Giant Single-Molecule Anisotropic Magnetoresistance at Room TemperatureDocument7 pagesGiant Single-Molecule Anisotropic Magnetoresistance at Room TemperaturejuliosilvaNo ratings yet

- R. Gonzalez-Ferez and P. Schmelcher - Rovibrational Spectra of Diatomic Molecules in Strong Electric Fields: The Adiabatic RegimeDocument11 pagesR. Gonzalez-Ferez and P. Schmelcher - Rovibrational Spectra of Diatomic Molecules in Strong Electric Fields: The Adiabatic RegimeImasmzNo ratings yet

- Fundamentals of Piezoelectricity and its ApplicationsDocument9 pagesFundamentals of Piezoelectricity and its Applicationssurendranath jadhavNo ratings yet

- AllenspachDocument26 pagesAllenspachRobin PlüschNo ratings yet

- Crystals 09 00132Document3 pagesCrystals 09 00132Rishu KhuranaNo ratings yet

- (2017) Cremer, P., Heinen, M., Menzel, A.M., Löwen, H.Document14 pages(2017) Cremer, P., Heinen, M., Menzel, A.M., Löwen, H.Fattah Maulana AlanNo ratings yet

- Flexomagnetoelectric Interaction in Cubic Tetragonal and Orthorhombic CrystalsDocument14 pagesFlexomagnetoelectric Interaction in Cubic Tetragonal and Orthorhombic Crystalsb_m_tanyginNo ratings yet

- Piezoelectric Materials and ApplicationsDocument5 pagesPiezoelectric Materials and Applications21-035 Mahes Deo Raynaldi TurnipNo ratings yet

- Aerospace: Modeling Plasma Via Electron Impact IonizationDocument25 pagesAerospace: Modeling Plasma Via Electron Impact IonizationProjesh BasuNo ratings yet

- S0031918X18020084 PDFDocument2 pagesS0031918X18020084 PDFtyoNo ratings yet

- Atoms of None of The Elements Ionize While Atoms of Inert Behavior SplitDocument25 pagesAtoms of None of The Elements Ionize While Atoms of Inert Behavior SplitIdontspeakeNo ratings yet

- Carlos A. Arango, William W. Kennerly and Gregory S. Ezra - Classical and Quantum Mechanics of Diatomic Molecules in Tilted FieldsDocument15 pagesCarlos A. Arango, William W. Kennerly and Gregory S. Ezra - Classical and Quantum Mechanics of Diatomic Molecules in Tilted FieldsMddl2aNo ratings yet

- Strongly Correlated MaterialDocument77 pagesStrongly Correlated MaterialHabib Rizqa KarimaNo ratings yet

- Ca-V YIG Duong2019Document11 pagesCa-V YIG Duong2019Duong Nguyen PhucNo ratings yet

- Spintronics PDFDocument49 pagesSpintronics PDFGokaran ShuklaNo ratings yet

- An Overview of The Structure and Magnetism of Spinel FerriteDocument15 pagesAn Overview of The Structure and Magnetism of Spinel FerriteCosty VirlanNo ratings yet

- Electromigration in Cu InterconnectsDocument13 pagesElectromigration in Cu InterconnectsDr. Arijit RoyNo ratings yet

- Mesoscale Simulation of Ferro Uid Structure: Yimin Xuan, Meng Ye, Qiang LiDocument9 pagesMesoscale Simulation of Ferro Uid Structure: Yimin Xuan, Meng Ye, Qiang LiShafqat HussainNo ratings yet

- Anisotropic ExchangeDocument4 pagesAnisotropic ExchangeNyiam HlubNo ratings yet

- Philosophical Magazine Letters: Phase-Field Model For Ferromagnetic Shape-Memory AlloysDocument10 pagesPhilosophical Magazine Letters: Phase-Field Model For Ferromagnetic Shape-Memory AlloyseidelsayedNo ratings yet

- Planar Crack Analysis in Magnetoelectroelastic MediumDocument19 pagesPlanar Crack Analysis in Magnetoelectroelastic MediumManda Ramesh BabuNo ratings yet

- JAP083908 SpinDIsorderDocument10 pagesJAP083908 SpinDIsorderalibbbsudeNo ratings yet

- 2016 AlbayrakDocument7 pages2016 AlbayrakTuğçe AkkurtNo ratings yet

- Aerosol Science and TechnologyDocument11 pagesAerosol Science and TechnologyOscar Ruben Castillo NavaNo ratings yet

- Thorsten Hansen, Vladimiro Mujica and Mark A. Ratner - Cotunneling Model For Current-Induced Events in Molecular WiresDocument7 pagesThorsten Hansen, Vladimiro Mujica and Mark A. Ratner - Cotunneling Model For Current-Induced Events in Molecular WiresGomsajNo ratings yet

- A Remarkable Transformation of Magnetic Resonance Spectra As A Result of A Mutual Influence of Coexisting Para-And Ferromagnetic PhasesDocument15 pagesA Remarkable Transformation of Magnetic Resonance Spectra As A Result of A Mutual Influence of Coexisting Para-And Ferromagnetic Phaseschvar80No ratings yet

- Seventeen, Jun 2011Document6 pagesSeventeen, Jun 2011emediageNo ratings yet

- A Coupled Electro-Hydrodynamic Numerical Modeling of Droplet Actuation by ElectrowettingDocument8 pagesA Coupled Electro-Hydrodynamic Numerical Modeling of Droplet Actuation by Electrowettingmypassion59No ratings yet

- Chapter 2 - MVPOMsDocument9 pagesChapter 2 - MVPOMsSkintone PhotographyNo ratings yet

- Neutron and NeutronDocument10 pagesNeutron and Neutronsamuel_07No ratings yet

- Chapter 4-Piezoelectric CeramicsDocument33 pagesChapter 4-Piezoelectric Ceramicssantsex111No ratings yet

- Failure Mode, Ferroelastic Behavior and Toughening Effect of Bismuth Titanate Ferroelectric Ceramics Under Uniaxial Compression LoadDocument11 pagesFailure Mode, Ferroelastic Behavior and Toughening Effect of Bismuth Titanate Ferroelectric Ceramics Under Uniaxial Compression Load张鹏No ratings yet

- Tuning Magnetic Properties of Diamagnetic MoleculesDocument35 pagesTuning Magnetic Properties of Diamagnetic MoleculesRishu KhuranaNo ratings yet

- Piezoelectric CeramicsDocument12 pagesPiezoelectric CeramicsLin JieNo ratings yet

- Modeling Electrospinning of Nanofibers Using Boundary Element MethodDocument14 pagesModeling Electrospinning of Nanofibers Using Boundary Element Methodandres alfraro cerazoNo ratings yet

- Also Known As The Transistor. Shockley, Bardeen and Brattain Received The Nobel Prize in Physics in 1956 For Research Regarding The TransistorDocument16 pagesAlso Known As The Transistor. Shockley, Bardeen and Brattain Received The Nobel Prize in Physics in 1956 For Research Regarding The TransistoryouminbuluoNo ratings yet

- PHD SCDocument2 pagesPHD SCArshad PathanNo ratings yet

- H.J.A.Molegraaf - Magnetoelectric Effects in Complex OxidesDocument5 pagesH.J.A.Molegraaf - Magnetoelectric Effects in Complex OxidesFreudensteinitzNo ratings yet

- Podgorni 2016 GePbMnTe TranspDocument7 pagesPodgorni 2016 GePbMnTe TranspVasyl SlynkoNo ratings yet

- 211-2022-Chen2022 Article ElectricallyDrivenMotionDestruDocument8 pages211-2022-Chen2022 Article ElectricallyDrivenMotionDestru刘璐恺No ratings yet

- Structure and Dynamics of Electrorheological FluidsDocument20 pagesStructure and Dynamics of Electrorheological FluidsShaik Saheb ShaikNo ratings yet

- Ferro ElectricityDocument6 pagesFerro Electricity33noe100% (1)

- Keywords: Piezoelectric Effect, Ferroelectricity, Actuators, SensorsDocument33 pagesKeywords: Piezoelectric Effect, Ferroelectricity, Actuators, Sensorsamrendra kumarNo ratings yet

- Invariant Plane StrainDocument7 pagesInvariant Plane StraininekNo ratings yet

- What Is A Dielectric Material?Document13 pagesWhat Is A Dielectric Material?Joel DanlamiNo ratings yet

- I. Turek Et Al - Exchange Interactions, Spin Waves, and Transition Temperatures in Itinerant MagnetsDocument36 pagesI. Turek Et Al - Exchange Interactions, Spin Waves, and Transition Temperatures in Itinerant MagnetsTellusz4532No ratings yet

- Adaptive Actuator Nonlinearity Compensation For Multivariable SystemsDocument20 pagesAdaptive Actuator Nonlinearity Compensation For Multivariable Systems王轩No ratings yet

- Inverse Iteration Method For Finding EigenvectorsDocument4 pagesInverse Iteration Method For Finding Eigenvectors王轩No ratings yet

- Adaptive Control of Plants With Unknown HysteresesDocument13 pagesAdaptive Control of Plants With Unknown Hystereses王轩No ratings yet

- Adaptive Control of A Hysteretic Structural SystemDocument7 pagesAdaptive Control of A Hysteretic Structural System王轩No ratings yet

- Rayleigh's and Ritz's vibration methodsDocument18 pagesRayleigh's and Ritz's vibration methodsBensingh DhasNo ratings yet

- On The Use of Characteristic Orthogonal Polynomials in The Free Vibration Analysis of Rectangular Anisotropic Plates With Mixed Boundaries and Concentrated MassesDocument15 pagesOn The Use of Characteristic Orthogonal Polynomials in The Free Vibration Analysis of Rectangular Anisotropic Plates With Mixed Boundaries and Concentrated Masses王轩No ratings yet

- A Unified Framework For Modeling Hysteresis in Ferroic MaterialsDocument40 pagesA Unified Framework For Modeling Hysteresis in Ferroic Materials王轩No ratings yet

- A Comprehensive Micro Nanamechanical Drift Modeling and Compensation For NanorobotsDocument15 pagesA Comprehensive Micro Nanamechanical Drift Modeling and Compensation For Nanorobots王轩No ratings yet

- A Domain Wall Model For Hysteresis in Piezoelectric MaterialsDocument27 pagesA Domain Wall Model For Hysteresis in Piezoelectric Materials王轩No ratings yet

- Modal Analysis of MDOF Forced Undamped SystemsDocument11 pagesModal Analysis of MDOF Forced Undamped Systems王轩No ratings yet

- A Survey of Control Issues in NanopositioningDocument22 pagesA Survey of Control Issues in Nanopositioning王轩No ratings yet

- Finite Element Analysis and Genetic AlgorithmDocument293 pagesFinite Element Analysis and Genetic AlgorithmAnonymous 1BdR0EQgbu100% (1)

- A Survey of Modeling and Control of Piezoelectric ActuatorsDocument20 pagesA Survey of Modeling and Control of Piezoelectric Actuators王轩No ratings yet

- Technique For Estimating Natural FrequenciesDocument4 pagesTechnique For Estimating Natural Frequencies王轩No ratings yet

- Baseline Design of The SUNRISE TelescopeDocument1 pageBaseline Design of The SUNRISE Telescope王轩No ratings yet

- Model Reduction of Second Order SystemsDocument23 pagesModel Reduction of Second Order Systems王轩No ratings yet

- Characteristic Solutions For The Statics of RepetitiveDocument17 pagesCharacteristic Solutions For The Statics of Repetitive王轩No ratings yet

- Master - Thesis Vibrations of Thin Plate With Piezoelectric Actuator Theory and ExperimentsDocument160 pagesMaster - Thesis Vibrations of Thin Plate With Piezoelectric Actuator Theory and Experiments王轩No ratings yet

- Comparison of Methods For Developing Dynamic Reduced Models For Design OptimizationDocument6 pagesComparison of Methods For Developing Dynamic Reduced Models For Design Optimization王轩No ratings yet

- Basic Wavefront Aberration Theory For Optical MetrologyDocument13 pagesBasic Wavefront Aberration Theory For Optical Metrology王轩No ratings yet

- Evolutionary Piezoelectric Actuators Design OptimisationDocument14 pagesEvolutionary Piezoelectric Actuators Design Optimisation王轩No ratings yet

- Master Thesis Shape Control of Composite Structures With Optimally Placed Piezoelectric PatchesDocument93 pagesMaster Thesis Shape Control of Composite Structures With Optimally Placed Piezoelectric Patches王轩No ratings yet

- First Light of The 6.5-m MMT Adaptive Optics SystemDocument9 pagesFirst Light of The 6.5-m MMT Adaptive Optics System王轩No ratings yet

- Towards 1st Light of The 6.5m MMT Adaptive Optics System WithDocument9 pagesTowards 1st Light of The 6.5m MMT Adaptive Optics System With王轩No ratings yet

- Thermal Performance Enhancement of Adaptive Optics by Use of ADocument14 pagesThermal Performance Enhancement of Adaptive Optics by Use of A王轩No ratings yet

- The 20-20 Telescope-MCAO Imaging at The Individual and Combined FociDocument10 pagesThe 20-20 Telescope-MCAO Imaging at The Individual and Combined Foci王轩No ratings yet

- Simulation of Closed-Loop Wavefront Reconstruction For Multi-Conjugete Adaptive Optics On Giant TelescopesDocument12 pagesSimulation of Closed-Loop Wavefront Reconstruction For Multi-Conjugete Adaptive Optics On Giant Telescopes王轩No ratings yet

- MMT Adaptive Secondary-Performance Evaluation and Field TestingDocument12 pagesMMT Adaptive Secondary-Performance Evaluation and Field Testing王轩No ratings yet

- Progress of The OWL 100-Rn Telescope Conceptual DesignDocument10 pagesProgress of The OWL 100-Rn Telescope Conceptual Design王轩No ratings yet

- BCE 314L (Hydraulics) ULO 4 SIM SDLDocument19 pagesBCE 314L (Hydraulics) ULO 4 SIM SDLJollibee ChickenjoyNo ratings yet

- Design of Power ScrewsDocument5 pagesDesign of Power ScrewsShaswatNo ratings yet

- SIMSOLID Validation Manual Release 1 1 PDFDocument66 pagesSIMSOLID Validation Manual Release 1 1 PDFadigraduNo ratings yet

- Chapter 2Document28 pagesChapter 2nurulselangorNo ratings yet

- Journal of The Mechanics and Physics of Solids: Ryan S. Ginder, William D. Nix, George M. PharrDocument11 pagesJournal of The Mechanics and Physics of Solids: Ryan S. Ginder, William D. Nix, George M. PharrRaj Jung MahatNo ratings yet

- Node Nodal Degrees of Freedom: 1. The Definition of The Finite Element Method (FEM)Document32 pagesNode Nodal Degrees of Freedom: 1. The Definition of The Finite Element Method (FEM)KomarudinNo ratings yet

- CH 1Document11 pagesCH 1AlaaNo ratings yet

- Finite Element Plane Solids AnalysisDocument101 pagesFinite Element Plane Solids Analysistesfaye gurmesaNo ratings yet

- Couplings - Balancing Tutorial & "New Developments in Gas Turbine Couplings"Document19 pagesCouplings - Balancing Tutorial & "New Developments in Gas Turbine Couplings"Christopher ShawNo ratings yet

- Building Technology 2 - Building Structures - Lecture (September 8 15 - 2017) Part 2Document432 pagesBuilding Technology 2 - Building Structures - Lecture (September 8 15 - 2017) Part 2Jeff YaoNo ratings yet

- Control, Structure and Syntax of Calculations. Information On The Project. Process of CalculationDocument13 pagesControl, Structure and Syntax of Calculations. Information On The Project. Process of CalculationM Jobayer AzadNo ratings yet

- Design of The Toggle JackDocument30 pagesDesign of The Toggle Jackkoanakist91% (11)

- Steel Design - LRFD Bolted Connections TutorialDocument4 pagesSteel Design - LRFD Bolted Connections TutorialFernando PizarroNo ratings yet

- Fluid Mechanics d203Document302 pagesFluid Mechanics d203Vignesh SundaramNo ratings yet

- Basics of Stress Analysis of Underground Piping in Caesar IIDocument4 pagesBasics of Stress Analysis of Underground Piping in Caesar IIiaftNo ratings yet

- Especificaciones Tecnicas DP 5.5 FH R2 PDFDocument1 pageEspecificaciones Tecnicas DP 5.5 FH R2 PDFDiego Fabian Ruiz VacaflorNo ratings yet

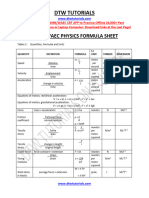

- DTW Tutorials 135 Physics Formula SheetDocument16 pagesDTW Tutorials 135 Physics Formula Sheetggold0934No ratings yet

- Nortje Desiree 2002 PDFDocument328 pagesNortje Desiree 2002 PDFAtul KulkarniNo ratings yet

- HSFG Bolts PDFDocument12 pagesHSFG Bolts PDFmcwong_98No ratings yet

- Dynamic of Bow RotorDocument20 pagesDynamic of Bow Rotormh1999No ratings yet

- Construction and Building Materials: S. Jeeva Chithambaram, Sanjay KumarDocument8 pagesConstruction and Building Materials: S. Jeeva Chithambaram, Sanjay KumarKartickPaiNo ratings yet

- Tension Anchors1.3 - Rock BoltsDocument5 pagesTension Anchors1.3 - Rock Boltsibnmessaoud10No ratings yet

- Strength of Material Question BankDocument11 pagesStrength of Material Question BankTec nicaNo ratings yet

- Asphalt ReinforcementDocument27 pagesAsphalt ReinforcementE Hammam El MissiryNo ratings yet

- Lode Dependences Pressure-Sensitive Materials For Isotropic ElastoplasticDocument9 pagesLode Dependences Pressure-Sensitive Materials For Isotropic Elastoplasticaasc1981No ratings yet

- Chapter ThreeDocument35 pagesChapter ThreeMerawi TilahunNo ratings yet

- Caea Ugm2012 NL BP PDFDocument75 pagesCaea Ugm2012 NL BP PDFAvinashRaiNo ratings yet

- Jamt D 23 04087Document38 pagesJamt D 23 04087Anand PaulNo ratings yet

- A Drilling Guide To Shales and Related Borehole ProblemsDocument41 pagesA Drilling Guide To Shales and Related Borehole ProblemsNitul DoleyNo ratings yet

- Code Based Fatigue Life Prediction and Validation of Pressure Vessel StressesDocument9 pagesCode Based Fatigue Life Prediction and Validation of Pressure Vessel StressesAdrian StoicescuNo ratings yet