Professional Documents

Culture Documents

Basic Paver Eng

Uploaded by

Ericsson ViaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Basic Paver Eng

Uploaded by

Ericsson ViaCopyright:

Available Formats

Paver Introduction

Canopy Engine hood Dashboard Foldable hopper

Main Parts of Paver > PLC

Remote control and screed operator position Conveyor

Screed Push roller Leveling arm Crawler chain Crawler direct drive Leveling cylinder

PLC - Programmable Logic Control Dashboard

Fuses LCD Display Control Unit

PLC Dashboard

Emergency Switch

Foil Keyboard Steering Potentiometer Driving Speed Potentiometer

Single Lever Control of Driving Direction

PLC Dashboard

PLC Dashboard

PLC Dashboard

PLC Dashboard

PLC Fuses

PLC Fuses

PLC Fuses

10

PLC Fuses

11

PLC Relays

12

Display

13

Display

14

Display

15

Display

16

Display

17

Display

18

Display

19

Display

20

Display

21

Display

22

Display

23

Display

24

Display

25

Display

26

Emergency Function

27

Emergency Function

28

Emergency Function

29

Remote Control > PLC

30

Canopy

Main Parts of Paver > Conventional

Engine hood Foldable hopper Dashboard

Remote control and screed operator position Conveyor

Screed Push roller Leveling arm Steering wheels Leveling cylinder Wheeled propulsion drive

31

Conventional Dashboard

32

Conventional Dashboard

33

Conventional Dashboard

34

Conventional Dashboard

35

Conventional Fuses

36

Conventional Dashboard

37

Conventional Fuses

38

Conventional Fuses

39

Conventional Relays

40

Remote Control > Conventional

41

Material Flow Control > Conventional

42

Screed Control > PLC + Conventional

93

93a

Option 94

43

Engine Diagnostic > PLC + Conventional

44

Engine Diagnostic > PLC

45

Engine Diagnostic > Conventional

46

Engine Diagnostic > Conventional

47

Engine Diagnostic > Conventional

48

Engine Diagnostic > PLC + Conventional

49

Engine > Battery Main Switch

50

Operation

51

Transportation

52

Transportation

53

Transportation

54

Transportation > Towing

55

Transportation > Towing

56

Safety Devices

57

Safety Devices

58

Danger Zones

59

Location of Instruction Labels

60

Location of Instruction Labels

61

Maintenance

62

Maintenance

63

Maintenance

64

Maintenance

65

Maintenance

66

Maintenance

67

Maintenance

68

Maintenance

69

Maintenance

70

Maintenance

71

Maintenance

72

Maintenance

73

Order No.: 532.000.45

Maintenance

V- Belt Version

74

Flexion power (read from the bottom to the top)

Maintenance

Rubber ring

Toothed V- Belt Version

Deflexion (read from the bottom to the top) Belt flexion

Generator 17KVA: - Flexion power min.: 101,4N - Flexion power max.: 110,6N - Belt flexion : ca. 9,9mm Generator 20KVA: - Flexion power min.: 72,4N - Flexion power max.: 79,0N - Belt flexion : ca. 5,4mm Generator 17KVA: - Flexion power min.: 92,2N - Flexion power max.: 100,5N - Belt flexion : ca. 5,4mm

75

Maintenance

76

Maintenance

77

Maintenance

78

Maintenance

79

Maintenance

80

Maintenance

81

Maintenance

82

Maintenance

83

Maintenance

84

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- AL4 TransmissionDocument59 pagesAL4 Transmissionericsolver97% (62)

- Alfa Romeo RZ-SZ Spare Parts PDFDocument41 pagesAlfa Romeo RZ-SZ Spare Parts PDFMiguel CamachoNo ratings yet

- John Deere 450 Service Sec WatDocument20 pagesJohn Deere 450 Service Sec Watchris98% (45)

- Service Manual 2014 HD Dyna Service Manual 99481-14 (Preview)Document6 pagesService Manual 2014 HD Dyna Service Manual 99481-14 (Preview)Amip FolkNo ratings yet

- Triumph TR7 TR8 Parts CatalogueDocument392 pagesTriumph TR7 TR8 Parts CatalogueWolfoniNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Massey-Ferguson-Tractor-Transmission-Parts CatalogueDocument24 pagesMassey-Ferguson-Tractor-Transmission-Parts Catalogueableni50% (2)

- CAT TH560B TelehandlerDocument16 pagesCAT TH560B TelehandlerZeck100% (2)

- Tabla Blow by MotoresDocument1 pageTabla Blow by MotoresEricsson Via100% (1)

- Tabla Blow by MotoresDocument1 pageTabla Blow by MotoresEricsson Via100% (1)

- 6HEUIDocument27 pages6HEUIEricsson Via100% (1)

- Ga 16Document142 pagesGa 16Ericsson Via90% (10)

- Ga 16Document142 pagesGa 16Ericsson Via90% (10)

- D8TDocument20 pagesD8TFelix Juan Valentin Paucar MamaniNo ratings yet

- Volvo FM Product BrochureDocument36 pagesVolvo FM Product BrochureShane LinNo ratings yet

- Starters Alternators 2023 2025Document1,348 pagesStarters Alternators 2023 2025Асен ВасилевNo ratings yet

- Modified Fiat Bogie Presentation 4Document56 pagesModified Fiat Bogie Presentation 4kr_abhijeet7235658767% (3)

- AIR SUSPENSION SYSTEM EXPLAINEDDocument7 pagesAIR SUSPENSION SYSTEM EXPLAINEDSridhar DineshNo ratings yet

- In: Fuzzy Logic Techniques For Autonomous Vehicle NavigationDocument26 pagesIn: Fuzzy Logic Techniques For Autonomous Vehicle NavigationEricsson ViaNo ratings yet

- Monthly expense report breakdownDocument1 pageMonthly expense report breakdownEricsson ViaNo ratings yet

- Service Manual Model: Lm-U1050a, Lms-U1050Document57 pagesService Manual Model: Lm-U1050a, Lms-U1050SAMSOON27100% (3)

- Basic Paver EngDocument84 pagesBasic Paver EngEricsson ViaNo ratings yet

- Fitting 4C4892Document2 pagesFitting 4C4892Ericsson ViaNo ratings yet

- Service Manual Model: Lm-U1050a, Lms-U1050Document57 pagesService Manual Model: Lm-U1050a, Lms-U1050SAMSOON27100% (3)

- GA16 Nissan Sentra Timing MarkDocument5 pagesGA16 Nissan Sentra Timing MarkAndy Ngo50% (2)

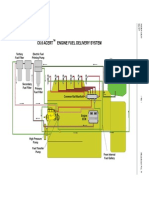

- C6.6 Acert Engine Fuel Delivery System: Electric Fuel Priming Pump Tertiary Fuel FilterDocument1 pageC6.6 Acert Engine Fuel Delivery System: Electric Fuel Priming Pump Tertiary Fuel FilterEricsson ViaNo ratings yet

- Equipos Muestreo SosDocument2 pagesEquipos Muestreo SosEricsson ViaNo ratings yet

- KTM RC 250 RDocument2 pagesKTM RC 250 Rpverma4622100% (1)

- HuangDocument25 pagesHuangCastro A. GerardoNo ratings yet

- Retenes VolvoDocument2 pagesRetenes VolvoCristhop HerNo ratings yet

- River Valley News Shopper, December 13, 2010Document40 pagesRiver Valley News Shopper, December 13, 2010Pioneer GroupNo ratings yet

- Understanding Automobile Industry Trends Using SMA AnalysisDocument95 pagesUnderstanding Automobile Industry Trends Using SMA AnalysisPâvan Ñaga Sai MämidiNo ratings yet

- Virtual Dynamic Events of BAJA SAEINDIA 2022Document11 pagesVirtual Dynamic Events of BAJA SAEINDIA 2022BIMAL XAVIOURNo ratings yet

- SCV DciDocument14 pagesSCV DcitrifemilNo ratings yet

- CTR Ball JointDocument19 pagesCTR Ball JointTan JaiNo ratings yet

- 3 Heavy Vehicle Inspection ChecklistDocument5 pages3 Heavy Vehicle Inspection ChecklistODALYS ALEJANDRA RAMIREZ PALOMONo ratings yet

- Bravo Service Manual Part 2Document622 pagesBravo Service Manual Part 2Geraldine Bailey100% (1)

- Spare Parts Catalogue for Avenger DTS-i 200cc MotorcycleDocument46 pagesSpare Parts Catalogue for Avenger DTS-i 200cc Motorcyclevisugue_26No ratings yet

- (Ownership Thread) : Honda Dio, Activa and Aviator - Page 95Document4 pages(Ownership Thread) : Honda Dio, Activa and Aviator - Page 95cadoNo ratings yet

- McLaren F1Document19 pagesMcLaren F1FelixNo ratings yet

- Truck & Bus: Spare Parts Catalogue 2017Document49 pagesTruck & Bus: Spare Parts Catalogue 2017كـروري كـشخةةNo ratings yet

- New 8x4 Dump Truck With 371HP EngineDocument2 pagesNew 8x4 Dump Truck With 371HP EngineYusuf ZukarnaNo ratings yet

- Online Technical Bulletin: Automatic Transmission Service GroupDocument2 pagesOnline Technical Bulletin: Automatic Transmission Service Groupsrg58398No ratings yet

- Corolla 2011 ManualDocument19 pagesCorolla 2011 ManualPrayoga AjaNo ratings yet

- Kia Carnival 2021Document18 pagesKia Carnival 2021Technology InformerNo ratings yet

- Mercedes Technical Training 287 Ho 01 Electrical Climate Control Fah 10-05-04Document5 pagesMercedes Technical Training 287 Ho 01 Electrical Climate Control Fah 10-05-04carl100% (46)

- Jack Stands ArticleDocument4 pagesJack Stands ArticledenperkinsNo ratings yet