Professional Documents

Culture Documents

Electrical Technology Experiment.

Uploaded by

Joseph KavinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Electrical Technology Experiment.

Uploaded by

Joseph KavinCopyright:

Available Formats

A Generator is a device which converts mechanical energy into electrical energy. WORKING PRINCIPLE A.

C Generator works on the principle of electromagnetic induction (motional emf). In generator an induced emf is produced by rotating a coil in a magnetic field. The flux linking the coil changes continuously hence a continuous fluctuating emf is obtained. CONSTRUCTION

A.C Generator consists of the following parts. Powerful field magnet with concave poles. Armature: It is a rectangular coil of large number of turns of wire wound on laminated softiron core of high permeability and low hysteresis loss. Slip rings: The ends of the coil are joined to two separate copper rings fixed on the axle (S1 & S2). Carbon brushes: Two carbon brushes remain pressed against each of the rings which form the terminals of the external circuit.

WORKING: In order to determine the magnitude and direction of induced e.m.f, let us consider the different positions of the coil which has N turns of wire. In one revolution following positions can be considered.

When initially coil is vertical, the length arms AC and BD are moving parallel to the lines of force maximum number of lines link the coil, but rate of change of flux is zero, hence emf is zero. As the coil moves from this position, sides AC and BD begin to cut the lines of force and induced emf is setup till it is maximum when the coil is horizontal. It has rotated 90o, 1st quarter is completed. Further rotation decreases the value of emf, until at the end of 2nd quarter, when coil is vertical, it has rotated 180o, the emf is again zero. As the coil rotates further from position 3 to position 4, an emf is again induced, but in reverse direction, because AC and BD are cutting the magnetic lines in opposite direction. The reverse emf reaches to ve peak value at the end of 3rd quarter. The coil is horizontal and angle of rotation is 270o. On further rotation, the emf again decreases and becomes zero when the coil returns back to its original position after rotating 360o. This shows that the coil of generator produces induced emf which reverse its direction 2*f times in one cycle. Where f = frequency of rotation of coil.

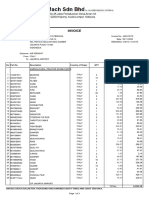

POLITEKNIK SULTAN AZLAN SHAH.

JJ 102 : ELECTRICAL TECHNOLOGY.

JOSEPH KAVINDEENATH A/L HARINDRANATH. 15DKM13F1078. MUHD SAMEER BIN KADER IBRAHIM 15DKM13F1026. ARUNAAN A/L CHINGA RAJA 15DKM13F1084.

An AC generator in its most basic form, has these components: * Rotor - an armature wound with wire coils * Slip Rings - part of the rotor / armature, connected to the wire coils * Brushes - part of the frame, ride in contact with the slip rings * Field (stator) - magnetic field for the rotor / armature. This can be either a permanent magnet or an electromagnet. The rotating armature spins the wire coils through the field. The changing (alternating) field seen by the wires induces a corresponding alternating current that is picked up by the brushes from the slip rings. When an electromagnet is used for the field, the alternator's output can be regulated by simply changing the field current. A feedback system monitors output voltage and controls the field coil to regulate the output to the correct voltage. There are variants on this setup where the rotor and stator reverse roles. For example, an automotive alternator supplies DC current to the rotor through slip rings. The rotor makes a rotating magnetic field which induces current in the fixed stator coils, which in turn makes the AC output. In a car system this this is then rectified into DC by a set of diodes, for an AC system the current is taken as-is. The "rotating bridge" (brushless) style of AC generator couples AC to the rotor through a rotary transformer to power the rotating field. This AC is then rectified into DC right on the rotor by a bridge diode set, which then energizes the rotor coils. The energized rotor makes a rotating field which is then picked up the the stator coils as AC. The rotating bridge setup eliminates the slip rings, a key wear item in gensets.

You might also like

- Physics PprojectDocument6 pagesPhysics PprojectSuman DasNo ratings yet

- DC Generators: by B.Shilpa Reddy Asst - Professor, EEE DeptDocument5 pagesDC Generators: by B.Shilpa Reddy Asst - Professor, EEE DeptAnonymous FzZcDyNo ratings yet

- Unit 1 Co1Document31 pagesUnit 1 Co1Gokul anandNo ratings yet

- Prepared by Anmol R. SinghDocument12 pagesPrepared by Anmol R. Singhdynamic_sNo ratings yet

- Physcis Ac Generator ReportDocument15 pagesPhyscis Ac Generator ReportVishal HirrtikNo ratings yet

- Introduction of Ac GeneratorDocument10 pagesIntroduction of Ac Generatorprince395100% (1)

- Types of AlternatorsDocument12 pagesTypes of AlternatorsHamoudRazaMazherNo ratings yet

- Unit 3 Three Phase Alternator PDFDocument38 pagesUnit 3 Three Phase Alternator PDFPalak JioNo ratings yet

- DC GeneratorDocument3 pagesDC GeneratorDurga SampathNo ratings yet

- DC GeneratorDocument35 pagesDC GeneratorMohammed Jalaluddin RayeenNo ratings yet

- Electrical Assignment 15-12-2018Document15 pagesElectrical Assignment 15-12-2018Mudasir SahoNo ratings yet

- EEE-183, DC Generators, Working PrinciplesDocument21 pagesEEE-183, DC Generators, Working PrinciplesPiyas ChowdhuryNo ratings yet

- Ac GeneratorDocument20 pagesAc GeneratorRiya BadhaniNo ratings yet

- Ac & DC Generators NotesDocument9 pagesAc & DC Generators NotesShadyNo ratings yet

- Construction and Working Principle of DC GeneratorsDocument3 pagesConstruction and Working Principle of DC Generatorsharishkarthik.7799No ratings yet

- PrincipleDocument3 pagesPrincipleTehmeen AnwarNo ratings yet

- Module 3 - Genrators FinDocument62 pagesModule 3 - Genrators FinaliyumaidamisaNo ratings yet

- Module 3 - GenratorsDocument50 pagesModule 3 - GenratorsaliyumaidamisaNo ratings yet

- Notes For CIA-IIDocument15 pagesNotes For CIA-IIhariNo ratings yet

- Unit IIIDocument9 pagesUnit IIIhariNo ratings yet

- Unit-V: Synchronous Generators and Synchronous MotorsDocument9 pagesUnit-V: Synchronous Generators and Synchronous MotorsPasupuleti Venkata RamanaNo ratings yet

- 1) Explain The Constructional Details of A DC Machine?: Electrical Machines - I Unit - Iv 1Document31 pages1) Explain The Constructional Details of A DC Machine?: Electrical Machines - I Unit - Iv 1abcd sripathiNo ratings yet

- Research About DC GeneratorsDocument6 pagesResearch About DC GeneratorsjemahbabesNo ratings yet

- Arc Welding PPT FinishDocument50 pagesArc Welding PPT FinishmahendraNo ratings yet

- DC GeneratorDocument11 pagesDC GeneratorTaha khan100% (1)

- cos d sin d d d: NBA t NBA t Φ N VDocument2 pagescos d sin d d d: NBA t NBA t Φ N VchrismarieayopNo ratings yet

- Emf Equation of A DC Generator (Page No: 2.9)Document11 pagesEmf Equation of A DC Generator (Page No: 2.9)Poornima SubramanianNo ratings yet

- DC Machine & Ac MachineDocument19 pagesDC Machine & Ac MachineSankara nathNo ratings yet

- DC Generator2021Document28 pagesDC Generator2021Maysara BalakiNo ratings yet

- Ac GeneratorDocument18 pagesAc GeneratorPrathune KailashNo ratings yet

- Rotating Machines and Transformers Unit 2 DC GENERATOR CLASS NOTESDocument70 pagesRotating Machines and Transformers Unit 2 DC GENERATOR CLASS NOTESSEDHURAJA SNo ratings yet

- Electrical GenetorDocument14 pagesElectrical GenetorHarry WinstonNo ratings yet

- Unit IIDocument194 pagesUnit IIMuniyasamyNo ratings yet

- Synchronous Generator or AC Generator or AlternatorDocument6 pagesSynchronous Generator or AC Generator or AlternatorMd. Latifur RahmanNo ratings yet

- DC & AC Machines and Speed ControlDocument53 pagesDC & AC Machines and Speed ControlInsane Clown Prince60% (5)

- AC Generator 3rjwDocument2 pagesAC Generator 3rjwZafar Khan Niazi NiaziNo ratings yet

- AC GeneratorDocument37 pagesAC GeneratorS. Dinesh KumarNo ratings yet

- Chapter 8 - Electrical, Starting, and Ignition SystemsDocument213 pagesChapter 8 - Electrical, Starting, and Ignition SystemsKim RioverosNo ratings yet

- D C Machines-IntroductionDocument25 pagesD C Machines-Introductionprashanth6876050% (2)

- FY7W04 Electrical Module 1 Lesson 12Document30 pagesFY7W04 Electrical Module 1 Lesson 12chudyaceNo ratings yet

- FINAL ET NOTES-5 UnitsDocument121 pagesFINAL ET NOTES-5 Unitsbapiraju saripellaNo ratings yet

- How Does An AC Generator WorkDocument3 pagesHow Does An AC Generator WorkPrincess Diane GravidesNo ratings yet

- DC Generators-I PDFDocument29 pagesDC Generators-I PDFPraneetha InumarthiNo ratings yet

- Application of DC Shunt MotorDocument5 pagesApplication of DC Shunt MotorPrajwal Deep RaiNo ratings yet

- Ac HoDocument22 pagesAc HoFrank MujuniNo ratings yet

- Chapter2-1 - Overview of DC MachinesDocument40 pagesChapter2-1 - Overview of DC MachinesTabi4every175% (4)

- Alternator ToyotaDocument5 pagesAlternator ToyotaAYON_MSNNo ratings yet

- Basic Operation and Constructional Features of A DC Machine AreDocument28 pagesBasic Operation and Constructional Features of A DC Machine AreBrijesh PrasadNo ratings yet

- Generator Principle: InductionDocument28 pagesGenerator Principle: InductionDiptoNo ratings yet

- POWER SUPPLY SYSTEM. ServicesDocument76 pagesPOWER SUPPLY SYSTEM. ServicesnwanabossNo ratings yet

- Unit IiDocument25 pagesUnit Iistoryteller9059517061No ratings yet

- Pricipio Básico de Funcionamiento Del AlternadorDocument5 pagesPricipio Básico de Funcionamiento Del AlternadorJasonNo ratings yet

- Unit 1 BEEDocument29 pagesUnit 1 BEEnagendra maddulaNo ratings yet

- Japh Thymodynamics (Assignment)Document3 pagesJaph Thymodynamics (Assignment)abdulmajeedabdussalam09No ratings yet

- Fundamental of Electrical Engineering EMT 113/4 DC MachinesDocument64 pagesFundamental of Electrical Engineering EMT 113/4 DC Machinesluiz pauloNo ratings yet

- ELE290 Chapter 6Document21 pagesELE290 Chapter 6imfendiNo ratings yet

- EEE2104 Basic AC Electrical Generators 0411MMXXIDocument52 pagesEEE2104 Basic AC Electrical Generators 0411MMXXIKISAKYE MOSESNo ratings yet

- DCAC ModuleDocument19 pagesDCAC ModuleDHEMI ALAWINo ratings yet

- Ei6402 - Electrical Machines: Unit I D.C. MachinesDocument30 pagesEi6402 - Electrical Machines: Unit I D.C. MachinesDhanush BhaiNo ratings yet

- A New System of Alternating Current Motors and Transformers and Other EssaysFrom EverandA New System of Alternating Current Motors and Transformers and Other EssaysRating: 5 out of 5 stars5/5 (1)

- Word For English PoliteknikDocument1 pageWord For English PoliteknikJoseph KavinNo ratings yet

- Objective For Gas WeldingDocument1 pageObjective For Gas WeldingJoseph KavinNo ratings yet

- Welding ReportDocument3 pagesWelding ReportJoseph KavinNo ratings yet

- Welding ReportDocument3 pagesWelding ReportJoseph KavinNo ratings yet

- Ca2 Power Amplifier: Product Description CA2 FeaturesDocument2 pagesCa2 Power Amplifier: Product Description CA2 FeaturessimonNo ratings yet

- Course Outline of CSE 211 PDFDocument4 pagesCourse Outline of CSE 211 PDFSafialIslamAyonNo ratings yet

- Time Displacement Machine PDFDocument16 pagesTime Displacement Machine PDFAlexander Avilés GuerraNo ratings yet

- Datasheet Andrena 12V25Ah: Lightweight PowerDocument2 pagesDatasheet Andrena 12V25Ah: Lightweight PowerMayur DeokarNo ratings yet

- Lta Gs (Lifting)Document11 pagesLta Gs (Lifting)Chan NaingNo ratings yet

- Jlo Engines Rockwell L-227 L-230 L-252-l Jp-7710 IplDocument8 pagesJlo Engines Rockwell L-227 L-230 L-252-l Jp-7710 Ipljim1961No ratings yet

- Jak418172 (Air To Jak)Document3 pagesJak418172 (Air To Jak)FaisalhafidzNo ratings yet

- Panasonic+sa-Akx34ph Akx34pnDocument126 pagesPanasonic+sa-Akx34ph Akx34pnAndres Florentin Pizarro LazarteNo ratings yet

- Electrical BOQDocument22 pagesElectrical BOQSAI ASSOCIATENo ratings yet

- DIO-1616H-PE: Opto-Isolated Digital I/O For PCI Express 16 CH TypeDocument2 pagesDIO-1616H-PE: Opto-Isolated Digital I/O For PCI Express 16 CH TypeVictor HemzNo ratings yet

- SCI1500A: Crawler Crane 150 Tons Lifting CapacityDocument34 pagesSCI1500A: Crawler Crane 150 Tons Lifting CapacityUpendra KumarNo ratings yet

- Manual JukeDocument345 pagesManual JukeMosta GartusNo ratings yet

- Typesofmemory UpdatedDocument8 pagesTypesofmemory UpdatedErmin SehicNo ratings yet

- MS2 IpmDocument101 pagesMS2 Ipmgionguyen0% (1)

- Thread Manufacturing Processes PDFDocument26 pagesThread Manufacturing Processes PDFStefan Istratescu100% (2)

- Inalsa Vacuum Cleaner Gusto Pro-1200W With Powerful Blower Function and 1.5L Reusable Cloth Dust Bag, Powerful 16KPA Suction, Lightweight & Compact, (Red - Black) - Amazon - in - Home & KitchenDocument7 pagesInalsa Vacuum Cleaner Gusto Pro-1200W With Powerful Blower Function and 1.5L Reusable Cloth Dust Bag, Powerful 16KPA Suction, Lightweight & Compact, (Red - Black) - Amazon - in - Home & Kitchentvis MusicNo ratings yet

- HSN CodeDocument13 pagesHSN CodeDeepak GuptaNo ratings yet

- 714-52 Mifare ID Reader: With Selectable OutputsDocument7 pages714-52 Mifare ID Reader: With Selectable OutputsSergio Landete ExpositoNo ratings yet

- ZF Axles Adn Transmissions ProductsDocument44 pagesZF Axles Adn Transmissions ProductsMarek WyszatyckiNo ratings yet

- Samsung RF22K9381SR RefrigeratorDocument220 pagesSamsung RF22K9381SR Refrigeratorhoward.deiner1674No ratings yet

- E7 TiempoDocument12 pagesE7 TiempoJonatan Arango Gomez67% (3)

- Torque-Air Brake FittingsDocument2 pagesTorque-Air Brake Fittingsyoga_jpbmbmNo ratings yet

- Manual Railduino v1.3 Update 14112016 enDocument23 pagesManual Railduino v1.3 Update 14112016 enAngelo DottoreNo ratings yet

- LG 42PQ30 Block DiagramDocument2 pagesLG 42PQ30 Block DiagrammakotoNo ratings yet

- Sony TVC LCD Ke 32ts2uDocument99 pagesSony TVC LCD Ke 32ts2uGiada SpaccarotellaNo ratings yet

- SV-520/550 Instruction ManualDocument32 pagesSV-520/550 Instruction ManualLe DuNo ratings yet

- LFE Desicant Dryer ManualDocument12 pagesLFE Desicant Dryer ManualNaveen KumarNo ratings yet

- +2.7 V To +5.5 V, I C Interface, Voltage Output, 8-Bit Digital-To-Analog ConverterDocument26 pages+2.7 V To +5.5 V, I C Interface, Voltage Output, 8-Bit Digital-To-Analog ConverterJoão Paulo Lucas BarbosaNo ratings yet

- N. Tesla.: 46 7, 2-, 4-4 (He/ea& 9a (AuDocument5 pagesN. Tesla.: 46 7, 2-, 4-4 (He/ea& 9a (Auhix256No ratings yet

- BAE PVS Cell Engl 2012 12 PDFDocument2 pagesBAE PVS Cell Engl 2012 12 PDFCARLOS ANDRES SARMIENTO CUEVASNo ratings yet