Professional Documents

Culture Documents

Ds2211 Hil Io Board Dspace Catalog 2008

Uploaded by

Ram Krishan SharmaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ds2211 Hil Io Board Dspace Catalog 2008

Uploaded by

Ram Krishan SharmaCopyright:

Available Formats

Modular Hardware

DS2211 HIL I/O Board

The basis for almost any hardware-in-the-loop simulation system

Key Features

Base I/O hardware for dSPACE Simulator Ideally suited to all kinds of hardware-in-the-loop simulation Unrivaled in engine, powertrain, and vehicle dynamics applications

Simulates and measures all engine signals (for up to 8 cylinders) Signal conditioning for automotive signals up to 42 V Supports 2-voltage systems NEW: Cascadable for up to 96 cylinders

Description

Key Benets The DS2211 HIL I/O Board is the central I/O board for hardware-in-the-loop simulation, especially in the eld of automotive electronics. The DS2211 HIL I/O Board is tailored to the simulation and measurement of automotive signals, particularly for engine and vehicle dynamics applications, and combines a variety of typical HIL I/O signals on one board. It also contains signal conditioning for automotive signals up to 42 V.

Building an HIL Simulator Together with a processor board (the DS1005 PPC Board or the DS1006 Processor Board), the DS2211 HIL I/O Board constitutes the hardware core of dSPACE Simulator. The processor board performs the calculation of the real-time model, for example, of an engine, while the DS2211 measures and stimulates all the required I/O signals. The simulator can be expanded from 8-cylinder up to 96 cylinders by using two or more DS2211 HIL I/O Boards.

Angle-Synchronous Signals

Angular Processing Unit The DS2211 HIL I/O Board features a unique angular processing unit which supports highspeed generation and measurement of crank angle-related signals to simulate engines up to 29,000 rpm.

Angle-Synchronous Cascading For tougher I/O requirements, several boards, for example, several DS2211s, can be cascaded. The boards operate angle-synchronously if their time base connectors are connected. One DS2211 board acts as the time base (angle master), and the other boards read out its time base, which allows signals to be generated and measured angle-synchronously on several boards. The same applies to the DS4002 Timing and Digital I/O Board (p. 360) and the DS5001 Digital Waveform Capture Board (p. 386), which can both be connected to the time base, too. See p. 347 for an application example.

342

2008 Catalog 2008 dSPACE Technologiepark 25 33100 Paderborn Germany info@dspace.de www.dspace.com

DS2211 HIL I/O Board

Technical Details

Parameter General Specication

Angular processing unit (APU) to handle all crankshaft-angle-related signals

(ignition, injection, crankshaft, camshaft, etc.)

1 crankshaft signal output (programmable analog and digital waveforms) Max. 4 camshaft signal outputs (2 with programmable analog and digital output

plus 2 with digital output only, shared with 2 digital outputs)

Complex comparator functionality support for ignition and injection signals Time-base connector

Slave processor

DSP (digital signal processor)

I/O subsystem based on Texas Instruments TMS320VC33 DSP 150 MHz clock rate 13.3 ns cycle time 32 kilowords plus 2 kilowords on-chip RAM 16 kilowords dual-port RAM (towards PHS bus)

Interrupt controller

6 angle position interrupts (can be set at any engine position in 0.01 degree

increments)

1 CAN controller interrupt 1 serial interface (universal asynchronous receiver and transmitter) interrupt

Angular processing unit (APU) A/D channels

Angular resolution Speed range Speed resolution Channels Resolution Conversion time1) Input voltage range Offset error Gain error Input impedance

0.011 crank angle 29,000 rpm 0.112 rpm 16 differential A/D channels (multiplexed) 14 bits 1.1 s per channel 0 60 V, differential inputs 10 mV 0.5 % > 1 M 20 D/A channels with individual ground sense line 0 10 V

D/A channels

Channels Output voltage range

(with internal reference, or ratiometric with 5 10 V external reference)

Sense lines allow differential outputs with DACx2) output swing -10 V ... +12 V

from system ground Resolution Settling time Analog outputs

12 bits 20 s (full scale to 1 LSB) 1 crankshaft signal (angular processing unit) 2 camshaft signals (angular processing unit) 4-channel wheel speed or 4-channel knock signal generation (based on DSP);

up to 8 knock signals per cycle

4 additional analog waveform outputs (from DSP, no sense line, 10 V)

Output current Offset error Gain error Slave DSP DAC Settling time Output voltage range Output current Transformer outputs

1)

5 mA 5 mV 0.5 % (with internal reference) 10 s (full scale to 1 LSB) 10 V 5 mA 20 V (transformer output mode) 10 V (DC output mode) 5 mA

Output voltage range Output current

2)

Speed and timing specications describe the capabilities of the hardware components and circuits of dSPACE products. Depending on the software complexity, the attainable overall performance can deviate signicantly from the hardware specication. Output swing referenced to ground, when DACx is connected to a potential other than GND.

343

Catalog 2008 dSPACE Technologiepark 25 33100 Paderborn Germany info@dspace.de www.dspace.com 2008

Modular Hardware

Parameter Resistive output channels Channels Topology Resistance range Resistance error Voltage range Output current range Power per channel Digital inputs Channels

Specication

10 channels 16-bit switched resistor ladder 15.8 1 M 2% or 3 , whichever is greater, with RESx pin within 5 V of system ground Each terminal must stay within 10 V of system ground Max. 80 mA Max. 250 mW Max. 24 PWM measurement inputs (16 inputs shared with digital inputs, 2 inputs

shared with injection inputs), up to 50 ns resolution, 0.01 Hz 100 kHz

Max. 16 digital inputs (all inputs shared with PWM measurement inputs) Max. 8 ignition inputs (2 inputs shared with auxiliary capture inputs), up to

64 sparks per event window, or up to 64 events buffered for continuous readout

Max. 8 injection inputs (2 inputs shared with PWM measurement inputs), up to

64 pulses per event-window, or up to 64 events buffered for continuous readout

Max. 2 auxiliary capture inputs (all inputs shared with ignition inputs) PWM measurement input channels can also be used for frequency measurement

Input voltage Threshold voltage level Input impedance Digital outputs Channels

0 +60 V 1 V 22.65 V or 23.8 V (dependent on I/O circuit) 390 k Max. 16 digital outputs (2 pins shared with digital camshaft signal outputs) 9 PWM outputs, resolution 16 bit, 0.01 Hz 100 kHz, push/pull outputs PWM outputs can also be used for square wave signal generation

External supply voltage

+5 V +60 V Supplied from two independent rails (VBAT1 and VBAT2) 2-voltage support for digital outputs, selectable pin-wise

Output current range Vout high, min. Vout low, max. Interfaces Serial interface

Max. 50 mA (VBATx 1.2 V) at +50 mA 0.4 V at -50 mA TL16C550C single UART (universal asynchronous receiver and transmitter) RS232, RS422 compatibility Up to 115.2 Kbaud (RS232) Up to 1 Mbaud (RS422)

CAN bus interface

2 CAN channels based on ST10F269 microcontroller ISO DIN 11898-2 CAN High-Speed standard Max. 1 Mbaud

Physical connections Host interface Physical characteristics Physical size Ambient temperature Power supply

I/O connection via 2 x 100 pin high-density connectors and a 50-pin female Sub-D

connector

One 8- or 16-bit ISA slot (power supply only) Requires three brackets (for I/O connectors) 340 x 125 x 61 mm (13.4 x 4.9 x 2.4 in) The board requires three brackets 0 55 C (32 131 F) +5 V 5%; 1.5 A +12 V 5%; 0.25 A typical (max. 0.5 A with load on all analog and transformer

outputs)

-12 V 5%; 0.2 A typical (max. 0.5 A with load on all analog and transformer

outputs)

Two VBAT rails (5 V 60 V DC) Each rail (VBATx): 0.05 A + load current on digital outputs VBATx has to be supplied from an external source.

344

2008 Catalog 2008 dSPACE Technologiepark 25 33100 Paderborn Germany info@dspace.de www.dspace.com

DS2211 HIL I/O Board

Order Information

Product DS2211 HIL I/O Board Order Number

DS2211

Relevant Software

Software Required

Real-Time Interface (RTI) (p. 146) Texas Instruments TMS320 Optimizing C Compiler

Order Number

RTI TMDC3243855_02 RTICAN_BS RTICANMM_BS

Optional

(p. 167) RTI CAN Blockset (p. 156)

RTI CAN MultiMessage Blockset (p. 156)

Block Diagram

345

Catalog 2008 dSPACE Technologiepark 25 33100 Paderborn Germany info@dspace.de www.dspace.com 2008

Modular Hardware

Graphical Programming

Using Real-Time Interface

Programming from MATLAB/Simulink/Stateow Programming and connecting to I/O is simple with our Real-Time Interface (p. 146), which enables you to program all your I/O graphically in Simulink, even the angular processing unit. For connection to the CAN bus, for example, the optional RTI CAN Blockset extends Real-Time

Interface for easy, graphical CAN conguration from Simulink. The blockset comprises CAN controller configuration and dialog-based parameterization of messages in receive and transmit modes (p. 156).

Simulating a 12-Cylinder EVT Engine

Application Example

The Challenge: Immense I/O HIL simulation of a 12-cylinder, 48-valve engine with an electromagnetic valve train (EVT) is a real challenge, especially as regards I/O. The engine ECU generates 12 injection signals plus 12 ignition signals. In addition, 4 valve signals are needed for each of the 12 cylinders to control the electromagnetic valve actuators. This means that if the engine is simulated, 72 signals generated by the ECU have to be captured anglesynchronously.

dSPACE Simulator

Cascading Several I/O Boards The DS2211 HIL I/O Board is designed to be the heart of such applications. The hardware can be cascaded via the Engine Position Bus, with further boards operating angle-synchronously. In this case, the dSPACE Simulator hardware consists of a further DS2211 and three DS5001 Digital Waveform Capture Boards. The DS2211s are ready to capture injection and ignition signals of 6 (up to 8) cylinders each, while each DS5001 provides 16 capture channels for the valve signals. One board is the time base (angle master) for the other boards, so that all signals can be generated and captured anglesynchronously. Another example in which you might need angle-synchronous signal capturing is a rail pressure actuator for direct injec tion gasoline engines.

346

2008 Catalog 2008 dSPACE Technologiepark 25 33100 Paderborn Germany info@dspace.de www.dspace.com

DS2211 HIL I/O Board

HIL Simulation of a 6-Cylinder Engine

A HIL System with Just Two Boards Together with a processor board (the DS1005 PPC Board or the DS1006 Processor Board), the DS2211 provides a compact, yet powerful dSPACE Simulator for hardware-in-the-loop simulation, for example, for function or system testing. Engine Position Based Signal Generation The processor board performs the calculation of an engine model and sends all the calculated engine data to the DS2211 (for example, engine speed, camshaft phase, and engine knock parameters). The DS2211 processes this data with an engine position accumulator that constantly calculates the engine position according to the current engine speed. With a 16-bit angle resolution and an engine speed resolution of 0.112 rpm, this engine position is the basis for all further signal generation.

Application Example

ECU

Engine I/O Performed by the DS2211 The DS2211 HIL I/O Board uses the engine position and other model parameters to generate all the required signals (for example, crankshaft, camshaft, and knock signals). To simulate the complexity of an engine, the signals have to be highly realistic so that they can be processed by the ECU. In parallel, the DS2211 reads out the ECUs reactions to the simulation (for example, ignition and injection signals), and preprocesses them for the real-time model running on the processor board.

Simulated crankshaft and camshaft signals.

The engine model is calculated by the processor board, while the DS2211 performs the challenging I/O tasks.

347

Catalog 2008 dSPACE Technologiepark 25 33100 Paderborn Germany info@dspace.de www.dspace.com 2008

You might also like

- DS1104 R&D Controller Board: SpaceDocument8 pagesDS1104 R&D Controller Board: SpaceViet NguyenNo ratings yet

- Dspace 1103Document8 pagesDspace 1103TimoMarxNo ratings yet

- TLV 320 Adc Stereo Evaluation Audio AmplifierDocument85 pagesTLV 320 Adc Stereo Evaluation Audio AmplifierJay VoraNo ratings yet

- Ds 11031Document6 pagesDs 11031Nch NMNo ratings yet

- Standard Cpus - Cpu 1214CDocument8 pagesStandard Cpus - Cpu 1214ClplplplpzNo ratings yet

- T100MD888+ PLC: Product DescriptionDocument2 pagesT100MD888+ PLC: Product DescriptionFelico AguirreNo ratings yet

- V350 35 R6 - Tech SpecDocument5 pagesV350 35 R6 - Tech Specchrobakpeter12345No ratings yet

- Ad 9863Document40 pagesAd 9863AkashKosgiNo ratings yet

- ACDC Pages 177-192 (Low Res) PDFDocument16 pagesACDC Pages 177-192 (Low Res) PDFmachevallieNo ratings yet

- 14-Bit, 160 Msps 2 Interpolating Dual Txdac+: Ⴛ/4Ⴛ/8Ⴛ D/A ConverterDocument52 pages14-Bit, 160 Msps 2 Interpolating Dual Txdac+: Ⴛ/4Ⴛ/8Ⴛ D/A Convertercbernal73No ratings yet

- DT9837 Series DatasheetDocument15 pagesDT9837 Series DatasheetJohann Montero100% (1)

- BLN 95 9041Document5 pagesBLN 95 9041marsh2002No ratings yet

- DS1103Document6 pagesDS1103studysmNo ratings yet

- Tda 10021 DatasheetDocument17 pagesTda 10021 DatasheetWilly DacoNo ratings yet

- Mitsubishi Ics (TV) : DD DD DDDocument15 pagesMitsubishi Ics (TV) : DD DD DDJoel MarvalNo ratings yet

- STA308A: Multichannel Digital Audio Processor With DDX™Document46 pagesSTA308A: Multichannel Digital Audio Processor With DDX™TURBOJATONo ratings yet

- Isppac 10: Features Functional Block DiagramDocument23 pagesIsppac 10: Features Functional Block DiagramFaiber CalderonNo ratings yet

- Fatek PLC ControlerDocument12 pagesFatek PLC ControlersdmitarNo ratings yet

- Data Sheet: DescriptionDocument2 pagesData Sheet: Descriptionxxmxxmxx666No ratings yet

- TSX Micro Hardware / System OverviewDocument31 pagesTSX Micro Hardware / System Overviewadvantage025No ratings yet

- ADMC201Document15 pagesADMC201Ariana Ribeiro LameirinhasNo ratings yet

- Dynamic Testing of Highspeed Adcs Part 2Document17 pagesDynamic Testing of Highspeed Adcs Part 2ketkyhuNo ratings yet

- Vision™ OPLC™: Technical SpecificationsDocument7 pagesVision™ OPLC™: Technical SpecificationsPaulo RobertoNo ratings yet

- Fioa0402u 16Document4 pagesFioa0402u 16mcsecNo ratings yet

- 10-Bit Digital-To-Analog Converters: Features DescriptionDocument22 pages10-Bit Digital-To-Analog Converters: Features Descriptionwolvering2009No ratings yet

- Atmel 11219 SmartEnergy ATSENSE-101-301-301H Datasheet4Document55 pagesAtmel 11219 SmartEnergy ATSENSE-101-301-301H Datasheet4Ivan BabicNo ratings yet

- TLC 59116 FDocument33 pagesTLC 59116 FhfuishNo ratings yet

- 200Document2 pages200ChevronelleNo ratings yet

- DSB-B350S Training ManualDocument46 pagesDSB-B350S Training Manualax63naNo ratings yet

- C8051F020 C8051F020 C8051F020 C8051F020: 8 0 5 1 C o R eDocument3 pagesC8051F020 C8051F020 C8051F020 C8051F020: 8 0 5 1 C o R eBeth PenaNo ratings yet

- Simatic S7-200 Micro PLC: Ordering Information DescriptionDocument13 pagesSimatic S7-200 Micro PLC: Ordering Information DescriptionfemalefaustNo ratings yet

- ControlSpace ESP-88Document6 pagesControlSpace ESP-88stranfirNo ratings yet

- Components of Modern User InterfacesDocument35 pagesComponents of Modern User Interfacesduke_doNo ratings yet

- Led Driver CatalogDocument13 pagesLed Driver CatalogarieldaviNo ratings yet

- Programmable Logic Controllers PDFDocument4 pagesProgrammable Logic Controllers PDFJosé HeinNo ratings yet

- Tda 1548Document20 pagesTda 1548Jennifer NealNo ratings yet

- DMA-22-01 - 02 Data Sheet E R21 20180209Document18 pagesDMA-22-01 - 02 Data Sheet E R21 20180209scrappy traderNo ratings yet

- DS8500Document7 pagesDS8500abdulmajeed_cetNo ratings yet

- Versa MaxDocument2 pagesVersa MaxEl latasNo ratings yet

- Pax Panel Meter by RedlionDocument36 pagesPax Panel Meter by RedlionJesus GarciaNo ratings yet

- Harmonic DDP Series CatalogDocument24 pagesHarmonic DDP Series CatalogElectromateNo ratings yet

- TI - Texas Instruments - Slyy041c - Programmable Logic Control (PLC) Solutions GuideDocument20 pagesTI - Texas Instruments - Slyy041c - Programmable Logic Control (PLC) Solutions GuideAnonymous R0s4q9X8No ratings yet

- Atmel Sam d21Document1,022 pagesAtmel Sam d21Spiinn PhattrakulNo ratings yet

- s7200 Data SheetDocument3 pagess7200 Data SheetVamsi KumarNo ratings yet

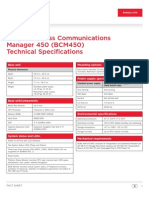

- Avaya Business Communications Manager 450 (BCM450) Technical SpecificationsDocument6 pagesAvaya Business Communications Manager 450 (BCM450) Technical Specificationsursus006No ratings yet

- 1758 pp002 - en PDocument2 pages1758 pp002 - en PNima MoaddeliNo ratings yet

- Stereo, Single-Supply 18-Bit Integrated DAC AD1859: SD Modulator With Triangular PDF DitherDocument16 pagesStereo, Single-Supply 18-Bit Integrated DAC AD1859: SD Modulator With Triangular PDF DitherSubir MaityNo ratings yet

- Ads 7870Document43 pagesAds 7870Moorthy VenkatachalamNo ratings yet

- TrustPLC KataloogDocument38 pagesTrustPLC KataloogNtscJNo ratings yet

- VSG 410Document7 pagesVSG 410jsrt234956No ratings yet

- RT USB3000: Technical Description and User Manual. Revision 4.1Document18 pagesRT USB3000: Technical Description and User Manual. Revision 4.1Carlos Alberto Viancha SalazarNo ratings yet

- Isel ControlerDocument18 pagesIsel Controlermihail91smNo ratings yet

- Opimod 8200Document84 pagesOpimod 8200UTC_ITSNo ratings yet

- Mini PLC PL-100 With 2 COM PortsDocument4 pagesMini PLC PL-100 With 2 COM PortsRapidtek controls Pvt LtdNo ratings yet

- LC320WXN Sca1Document43 pagesLC320WXN Sca1aldoNo ratings yet

- Delta DVP CatalogDocument39 pagesDelta DVP CatalogElectromateNo ratings yet

- DC Motor and GeneratorDocument78 pagesDC Motor and GeneratorRam Krishan Sharma100% (1)

- Baja2017 - Car Number - Mbaja & EbajaDocument7 pagesBaja2017 - Car Number - Mbaja & EbajaRam Krishan SharmaNo ratings yet

- 2016 EBaja SAE India RulesDocument84 pages2016 EBaja SAE India RulesRam Krishan SharmaNo ratings yet

- Aspee Vehicle Mounted Fogger Fog Atk 400dbDocument2 pagesAspee Vehicle Mounted Fogger Fog Atk 400dbRam Krishan SharmaNo ratings yet

- Supra Phase-II ListDocument2 pagesSupra Phase-II ListRam Krishan SharmaNo ratings yet

- Orange Engineering WorksDocument1 pageOrange Engineering WorksRam Krishan SharmaNo ratings yet

- 02 Intro To FOCDocument55 pages02 Intro To FOCRam Krishan SharmaNo ratings yet

- SD DataLoggerDocument1 pageSD DataLoggerSadikul FuadNo ratings yet

- Indian Baby Girl Name Starts With Letter CH - Yahoo! Answers IndiaDocument5 pagesIndian Baby Girl Name Starts With Letter CH - Yahoo! Answers IndiaRam Krishan SharmaNo ratings yet

- 7th Semester ElectricalDocument10 pages7th Semester ElectricalRam Krishan SharmaNo ratings yet

- H1 Training & Certification Process - Ver 1Document12 pagesH1 Training & Certification Process - Ver 1Ram Krishan SharmaNo ratings yet

- ProjectDocument6 pagesProjectRam Krishan SharmaNo ratings yet

- Albert, David - Quantum Mechanics and ExperienceDocument108 pagesAlbert, David - Quantum Mechanics and Experiencekarenhunt9583% (6)

- 8th Semester ElectricalDocument8 pages8th Semester Electricalvenkat04364904No ratings yet

- Tutorial Auto Code Generation For F2803x TargetDocument12 pagesTutorial Auto Code Generation For F2803x TargetRam Krishan SharmaNo ratings yet

- III Semester Electronics Numerical AnalysisDocument9 pagesIII Semester Electronics Numerical AnalysisSrikar MandalikaNo ratings yet

- BTech Chemical RevisedDocument46 pagesBTech Chemical RevisedRam Krishan SharmaNo ratings yet

- Elecrical SCHM Syllabus 3Document49 pagesElecrical SCHM Syllabus 3Shivakumar ChintapalliNo ratings yet

- Omega PID TunningDocument4 pagesOmega PID TunningOwaisNo ratings yet

- 4th Semester ElectricalDocument3 pages4th Semester ElectricalTony StarkNo ratings yet

- Abstracts in EnglishDocument11 pagesAbstracts in EnglishElaineNo ratings yet

- A Guide To Understanding Battery SpecificationsDocument3 pagesA Guide To Understanding Battery SpecificationswijayanataNo ratings yet

- 1st SemesterDocument5 pages1st SemesterRam Krishan SharmaNo ratings yet

- S Z Conv 1Document178 pagesS Z Conv 1Ram Krishan SharmaNo ratings yet

- A2L FileDocument5 pagesA2L FileRam Krishan Sharma100% (2)

- SimulatorHW MidSize dSPACE Catalog 2008Document4 pagesSimulatorHW MidSize dSPACE Catalog 2008Ram Krishan SharmaNo ratings yet

- AN713 - Controller Area Network (CAN) BasicsDocument9 pagesAN713 - Controller Area Network (CAN) BasicsRam Krishan SharmaNo ratings yet

- Standard Terminology For Vehicle Dynamics SimulationDocument14 pagesStandard Terminology For Vehicle Dynamics SimulationRam Krishan SharmaNo ratings yet

- Running IGSS As An Operator Part One - ScadaDocument9 pagesRunning IGSS As An Operator Part One - ScadaRam Krishan SharmaNo ratings yet

- A Guide To Understanding Battery SpecificationsDocument3 pagesA Guide To Understanding Battery SpecificationswijayanataNo ratings yet

- Chapter - 1-OOP ConceptsDocument63 pagesChapter - 1-OOP ConceptsMik ClashNo ratings yet

- Curriculum Vitae Aditya Tiwari Contact: +91-8308988815: Technical Skills and Programming ModulesDocument4 pagesCurriculum Vitae Aditya Tiwari Contact: +91-8308988815: Technical Skills and Programming ModulesShikha JainNo ratings yet

- Aca QBDocument9 pagesAca QBSherril VincentNo ratings yet

- Vaibbhav Taraate - Digital Logic Design Using Verilog - Coding and RTL Synthesis (2022)Document607 pagesVaibbhav Taraate - Digital Logic Design Using Verilog - Coding and RTL Synthesis (2022)SHANKAR PNo ratings yet

- Molly ABP#3 BDocument10 pagesMolly ABP#3 BMolly StolzNo ratings yet

- Network Report: SINETPLAN - Siemens Network PlannerDocument21 pagesNetwork Report: SINETPLAN - Siemens Network PlannerRenzo ZarsosaNo ratings yet

- DW1601 DW1702 DW1703 DW1705 DW1707 and DW1901 Release Notes CS WIN7 Combo 01 10 2014Document12 pagesDW1601 DW1702 DW1703 DW1705 DW1707 and DW1901 Release Notes CS WIN7 Combo 01 10 2014Abir BaidyaNo ratings yet

- 2.DataTypes Control Statements OperatorsDocument42 pages2.DataTypes Control Statements OperatorsKolachalama MythiliNo ratings yet

- User Manual-Stringing Machine-Pro's Pro Tomcat MT-400Document10 pagesUser Manual-Stringing Machine-Pro's Pro Tomcat MT-400kippcamNo ratings yet

- MBL LaptopDocument2 pagesMBL LaptopZ JazzNo ratings yet

- GE Proficy Programming Software RX3i PDFDocument19 pagesGE Proficy Programming Software RX3i PDFThanh BaronNo ratings yet

- Phusion Passenger Users Guide - Apache VersionDocument37 pagesPhusion Passenger Users Guide - Apache VersionvmukulNo ratings yet

- ARM Introduction & ArchitectureDocument33 pagesARM Introduction & ArchitectureSanjana PulapaNo ratings yet

- Rampage MB 48.4YW03.011 12241-1Document103 pagesRampage MB 48.4YW03.011 12241-1liliNo ratings yet

- Binary Decoder: Binary Decoders Are Another Type of Digital Logic Device That Has Inputs of 2-Bit, 3-Bit or 4-BitDocument7 pagesBinary Decoder: Binary Decoders Are Another Type of Digital Logic Device That Has Inputs of 2-Bit, 3-Bit or 4-BitJohn Brix BalisterosNo ratings yet

- Chapter 4: Preventive Maintenance and Troubleshooting: Instructor MaterialsDocument33 pagesChapter 4: Preventive Maintenance and Troubleshooting: Instructor MaterialsJose De PinaNo ratings yet

- Marble Point BIOS Update GuideDocument6 pagesMarble Point BIOS Update Guidecodigorojo2000No ratings yet

- Data SheetDocument26 pagesData SheetAnonymous CNSSoLI2wiNo ratings yet

- Mobile BankingDocument2 pagesMobile Bankingjagadish madiwalarNo ratings yet

- DS Chapter 3Document39 pagesDS Chapter 3Maddula PrasadNo ratings yet

- PHP Web DevelopmentDocument18 pagesPHP Web DevelopmentJiniya BipashaNo ratings yet

- Programming in C++ 2 MarksDocument24 pagesProgramming in C++ 2 MarksSudersan BalajiNo ratings yet

- 2021 Free B2C Commerce Developer CCD-102 Exam DumpsDocument11 pages2021 Free B2C Commerce Developer CCD-102 Exam DumpskaronbillNo ratings yet

- Parallel Implementation of Sobel Filter Using CUDADocument4 pagesParallel Implementation of Sobel Filter Using CUDAabed81No ratings yet

- Alv Drag & Drop Funcitonality On RowsDocument6 pagesAlv Drag & Drop Funcitonality On RowsMahender DonthulaNo ratings yet

- Oracle DBA Scripts PDFDocument4 pagesOracle DBA Scripts PDFAnonymous P3sQECw0% (1)

- WGWGTDocument477 pagesWGWGTsandeepNo ratings yet

- Huawei Ale-L21 c432b170 Upgrade Guideline v1.0Document7 pagesHuawei Ale-L21 c432b170 Upgrade Guideline v1.0Diego Uchiha DNo ratings yet

- Motionsuite Mp940 Machine Controller Hardware ManualDocument72 pagesMotionsuite Mp940 Machine Controller Hardware ManualJULIAN ANDRES ROJASNo ratings yet

- Chapter 3 Data RepresentationDocument23 pagesChapter 3 Data RepresentationVansh GuptaNo ratings yet