Professional Documents

Culture Documents

How To Dry A Refrigeration System?

Uploaded by

Pawan SehrawatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

How To Dry A Refrigeration System?

Uploaded by

Pawan SehrawatCopyright:

Available Formats

How to dry a refrigeration system?

1) Causes of moisture Several reasons may be responsible for the presence of moisture in a refrigeration system:

The drying of the circuit was not efficient enough during its manufacturing at the plant or at the installation on the field, A bad air tightness (moisture enters the circuit at each opening of the system), The hygroscopic aspect of the refrigerant and the oil, that is to say their capacity to absorb moisture of the ambient atmosphere POE oils are 10 times more hygroscopic than mineral oils, HFC refrigerants are 25 times more hygroscopic than C FC refrigerants.

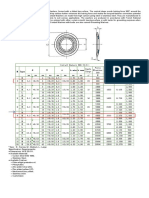

Hygroscopic aspects of mineral and polyol-ester oils, and some refrigerants

Hygroscopic aspect of mineral and polyol-ester oils

The absorption consists in making a substance (gas, liquid) get into another (gas, liquid, solid) and to keep it linked by attraction or chemical modification. On the other hand, adsorption is a surface phenomenon and it consists in fixing a molecule (gaseous or liquid) at the surface of a solid by the intermediate of attraction forces (reversible reaction) or chemical interaction.

2) The consequences of the presence of moisture

Within a refrigeration system, the presence of moisture can have several consequences: Blocking the expansion valve: creation of a ice cap

Damages to the brazed assembling: corrosion, the water trapped in the small gaps may turn into ice that makes the tubes burst

Oil hydrolysis In presence of moisture, the oil is chemically split (hydrolysis) and creates some organic acids:

These acids cause a corrosion of reactive metals, especially copper metals, and the creation of metallic sediments that may fill in the pipes. They are oil-soluble, their reaction is very slow and they are present in small quantity in the oil of the compressor. For POE oil (ester), a small quantity of moisture is enough to start the reaction of acid creation. This phenomenon is due to the reversibility of the reaction of ester oil manufacturing (esterification): Organic acid + alcohol ester + water Note : Organic acids may also be created during the decomposition of oil at high temperature in presence of air and oxidizing agents (oil oxidation).

Refrigerant degradation

The refrigerant are very stable chemically, even at high temperature. But it can still happen that in contact with moisture, the refrigerant chlorine and fluorine elements may react to create hydrochloric or hydrofluoric acids. For example, R-134a breaks down at high temperature to create hydrofluoric acid. This compound is present in the form of gas in the system and it is highly corrosive for metals and toxic for humans. These acids are highly reactive, water-soluble, and they may vaporize. They are considered as the most damaging acids for a refrigeration system.

3) The necessary precautions in order to avoid the introduction of moisture

In order to avoid any introduction of moisture inside a refrigeration system, a preventive treatment, realized properly in the rules, must be performed during the installation or a maintenance intervention: Plugging the pipes, Checking air tightness, Making vacuum, Storing the components, Adjusting the oil level with a depression pump, Monitoring moisture with a sight glass, Using a filter drier.

Filter drier is an essential component for the system protection. It has the capacity to catch the damaging elements for refrigerant and oil, before

they might cause non-reversible damages. The 3 main functions of the filter drier are: Adsorbing the residual moisture of the system or the moisture introduced in the circuit by refrigerant or oil, Neutralising the acids, Filtering solid contaminants.

A filtration element at the outlet of filter drier has the function to retain solid contaminants. On the other hand, moisture and acids are caught at the surface of molecular sieve and activated alumina : it is said they are adsorbed .

Molecular sieve is a synthetic compound of aluminum silicates. It is different from other adsorbents by its crystalline structure and the fix and uniform opening of its pores.

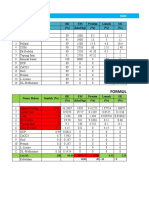

The volume and the size of the pores are important parameters: A big pore sieve will be a desiccator with a high capacity of adsorption for high moisture, A small pore sieve is more efficient for rather low moisture, When the pores are small enough, the sieve becomes selective regarding the big molecules, Thanks to its big internal area, the molecular sieve offers a very high capacity of adsorption: it is able to adsorb till 20% of its own weight in steam.

Activated alumina is a compound of aluminum oxides, extremely porous, amorphous and partially hydrated. Its chemical features enable it to ensure a perfect adsorption of acids coming from the chemical break down at high temperature of the refrigerant and the oil (hydrolysis-oxidation). Moisture adsorption: Adsorption capacity of molecular sieve = 3 times the one of activated alumin Acid retention: Adsorption capacity of activated alumina = 7 times the one of molecular sieve Filter drier is made of 70% molecular sieve and 30% activated alumina. The efficiency in moisture drying and acid neutralization is directly proportional to the volume of active chemical agents, present in the filter drier. It is important to detail that the filter design avoids any risk of solid particle release in the circuit. When choosing a brand of filter drier, remember that what is inside is what matters.

By: Pawan Sehrawat

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Psychromoist User GuideDocument10 pagesPsychromoist User GuidePawan SehrawatNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- SOP - Reliability AssessmentDocument12 pagesSOP - Reliability AssessmentPawan Sehrawat0% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- BulletinDocument18 pagesBulletinPawan SehrawatNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Conical Contact Washers NFE 25-511Document1 pageConical Contact Washers NFE 25-511Pawan SehrawatNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Standard Tightening TorqueDocument1 pageStandard Tightening TorquebalramkinageNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Engineering & Design: Geometric Dimensioning: SectionDocument34 pagesEngineering & Design: Geometric Dimensioning: SectionVinaya Almane DattathreyaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Jenny Gas Fired Steam Cleaner: Solving Individual Cleaning Problems WorldwideDocument2 pagesJenny Gas Fired Steam Cleaner: Solving Individual Cleaning Problems WorldwidePawan SehrawatNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- GN1 - Good Practice A4 DONEDocument10 pagesGN1 - Good Practice A4 DONEchris655No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Selecting Air Filters for Indoor Air QualityDocument11 pagesSelecting Air Filters for Indoor Air QualityPawan SehrawatNo ratings yet

- Fundamentals of GD&T With The Background of GD&TDocument50 pagesFundamentals of GD&T With The Background of GD&TRajasekaran VtNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Machines, Parts and Accessories CatalogDocument74 pagesMachines, Parts and Accessories CatalogPawan SehrawatNo ratings yet

- R134a PropertiesDocument2 pagesR134a PropertiesPawan SehrawatNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Steam Jenny ElectricDocument2 pagesSteam Jenny ElectricPawan SehrawatNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Steam Jenny ManualDocument48 pagesSteam Jenny ManualPawan SehrawatNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- GDT Spring 2010tDocument278 pagesGDT Spring 2010tYanaki HristovNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Introduction to Geometric Dimensioning and TolerancingDocument8 pagesIntroduction to Geometric Dimensioning and TolerancingPawan SehrawatNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Layered Process Audit FormDocument3 pagesLayered Process Audit FormPawan Sehrawat100% (7)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Laboratory Quality StandardsDocument74 pagesLaboratory Quality StandardsPawan Sehrawat100% (2)

- Natural ConvectionDocument7 pagesNatural ConvectionPeterNo ratings yet

- LPA MistakesDocument1 pageLPA MistakesPawan SehrawatNo ratings yet

- R134a Properties at - 6.7 Deg PDFDocument2 pagesR134a Properties at - 6.7 Deg PDFPawan SehrawatNo ratings yet

- Natural ConvectionDocument7 pagesNatural ConvectionPeterNo ratings yet

- Understanding LPA SystemDocument1 pageUnderstanding LPA SystemPawan SehrawatNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- LPA SystemDocument6 pagesLPA SystemPawan SehrawatNo ratings yet

- Kcn463hag BXXXDocument4 pagesKcn463hag BXXXPawan SehrawatNo ratings yet

- Pareto Diagram PDFDocument39 pagesPareto Diagram PDFPawan SehrawatNo ratings yet

- Importance of Moisture Free Refrigeration SystemDocument5 pagesImportance of Moisture Free Refrigeration SystemPawan SehrawatNo ratings yet

- Type 2 Switchgear CombinationDocument15 pagesType 2 Switchgear CombinationPawan SehrawatNo ratings yet

- General Safety Rules in HINDIDocument3 pagesGeneral Safety Rules in HINDIPawan Sehrawat67% (6)

- Liquid Soap ProcessDocument3 pagesLiquid Soap ProcessAnnette40% (5)

- PREOSDocument18 pagesPREOSLija BinuNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- KANDUNGAN ZAT MAKANAN BAHAN PAKAN UNGGASDocument5 pagesKANDUNGAN ZAT MAKANAN BAHAN PAKAN UNGGASIrma Rahayu NingrumNo ratings yet

- O Rings HandbookDocument292 pagesO Rings HandbookleocastarlenasNo ratings yet

- 6 MorDocument55 pages6 MorMadeline Delmo ArroyoNo ratings yet

- THG Hooks Forged Hooks Catalogue SheetDocument5 pagesTHG Hooks Forged Hooks Catalogue SheetjhonNo ratings yet

- Ceramic Nanoparticle SynthesisDocument40 pagesCeramic Nanoparticle SynthesisXavier Jones100% (1)

- Mühlen Sohn: Airslide FabricsDocument9 pagesMühlen Sohn: Airslide FabricsengfaridmalkNo ratings yet

- Chemistry Diagnostic TestDocument3 pagesChemistry Diagnostic TestJohn John RoacheNo ratings yet

- Michael - Sikora@navy - Mil: Check The Source To Verify That This Is The Current Version Before UseDocument29 pagesMichael - Sikora@navy - Mil: Check The Source To Verify That This Is The Current Version Before UseName24122021No ratings yet

- Influence of Plasticizers On The Properties of Natural Rubber Based CompoundsDocument10 pagesInfluence of Plasticizers On The Properties of Natural Rubber Based CompoundsRupin SaigalNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Mock Engineering MaterialsDocument6 pagesMock Engineering MaterialsJohn AsokNo ratings yet

- Operating Instructions and Maintain EdiDocument119 pagesOperating Instructions and Maintain EdiPhạm Quang HuyNo ratings yet

- Exp 2 CO2 Absorption-Effect of Solvent RateDocument6 pagesExp 2 CO2 Absorption-Effect of Solvent RateLil Wayne JrNo ratings yet

- Zinc Precipitation On Gold Recovery: February 2013Document19 pagesZinc Precipitation On Gold Recovery: February 2013Arief RHNo ratings yet

- Principles of Dairy Chemistry (PDFDrive)Document454 pagesPrinciples of Dairy Chemistry (PDFDrive)Abeer AbdelnaserNo ratings yet

- Lect 5 - Liquefaction - 2015 PDFDocument6 pagesLect 5 - Liquefaction - 2015 PDFAnonymous oqlnO8e100% (1)

- PyrometallurgyDocument3 pagesPyrometallurgyMojalefa MotloutsiNo ratings yet

- GCFGCGCFGFDGDocument15 pagesGCFGCGCFGFDGZabrinaRuizNo ratings yet

- Rubber Properties Chart PDFDocument1 pageRubber Properties Chart PDFArasarethina KumarNo ratings yet

- ks3 Acids and Alkalis Whats Your Idea PowerpointDocument11 pagesks3 Acids and Alkalis Whats Your Idea PowerpointManha abdellahNo ratings yet

- PDS Technofoam PT 01 - Hfc.Document2 pagesPDS Technofoam PT 01 - Hfc.Ahmed FoudaNo ratings yet

- WWW - Substech.com Dokuwiki Doku - PHP Id Steel Strip ProcesDocument7 pagesWWW - Substech.com Dokuwiki Doku - PHP Id Steel Strip Procesrahul srivastavaNo ratings yet

- Chapter 6 Thermochemistry: StudentDocument28 pagesChapter 6 Thermochemistry: StudentKing Ray TabalbaNo ratings yet

- Electrical Insulation Coating SpecificationDocument12 pagesElectrical Insulation Coating SpecificationMina RemonNo ratings yet

- Intergranular Corrosion - An Overview - ScienceDirect TopicsDocument14 pagesIntergranular Corrosion - An Overview - ScienceDirect TopicsRex RusselNo ratings yet

- Experiment 3 RdmeetingDocument4 pagesExperiment 3 RdmeetingDia SariNo ratings yet

- Metal Forming ProcessesDocument52 pagesMetal Forming ProcessesJoaNo ratings yet

- Importance of nucleic acidsDocument2 pagesImportance of nucleic acidsMyla Angelica AndresNo ratings yet

- 3 - D Printer Carbon Fiber Reinforced WithDocument17 pages3 - D Printer Carbon Fiber Reinforced With19 CH 056 Vaishali VivekNo ratings yet