Professional Documents

Culture Documents

SOP Compressed Gases

Uploaded by

Shamsol AriffinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SOP Compressed Gases

Uploaded by

Shamsol AriffinCopyright:

Available Formats

Standard Operating Procedure (SOP) Template

COMPRESSED GAS SAFETY Effective Date: 12/7/2011 Revised Date: 1/30/2012

INTRODUCTION A Standard Operating Procedure (SOP) describes how your lab will handle a hazardous chemical safely, including the amount and concentration you will use, how you obtain or create the working solution, and special handling procedures, engineering controls, and personal protective equipment. Chemical-specific SOPs are found on the EH&S website. Wake Forest Baptist Medical Center has created Standard Operating Procedures (SOPs) for several chemical hazard categories and some commonly-used chemicals. The SOP provides only standard information and requires customization for each lab. The Occupational Safety and Health Administration (OSHA) requires a written SOP for any work with hazardous chemicals in laboratories. There are additional requirements for SOPs for particularly hazardous substances, or PHSs. These SOPs are an important part of the Chemical Hygiene Plan. CATEGORIES OF COMPRESSED GASES (Hyperlink to each section below.) CATEGORIES DEFINITION OF GAS OF GASES INERT Gases that do not react with other materials at ordinary temperature and pressure. LIQUEFIED Gases which can become liquids at GASES normal temperatures when they are inside cylinders under pressure. They exist inside the cylinder in a liquid-vapor balance or equilibrium. Initially the cylinder is almost full of liquid, and gas fills the space above the liquid. As gas is removed from the cylinder, enough liquid evaporates to replace it, keeping the pressure in the cylinder constant. CORROSIVE Gases that corrode material or tissue with which they come in contact, or do so in the presence of water, are classified as corrosive. FLAMMABLE Gases that, when mixed with air at atmospheric temperature and pressure, form a flammable mixture at 13% or less by volume or have a flammable range in EXAMPLES argon, helium, neon and nitrogen Anhydrous ammonia, chlorine, propane, nitrous oxide and carbon dioxide

ammonia, hydrogen chloride, chlorine, Fluorine and methylamine acetylene, butane, ethylene, hydrogen, methylamine and vinyl chloride

1

Standard Operating Procedure (SOP) Template

COMPRESSED GAS SAFETY Effective Date: 12/7/2011 Revised Date: 1/30/2012

OXIDIZER

Toxic or Highly Toxic

REACTIVE

air of greater than 12% by volume regardless of the lower flammable limit. Oxidizing gases include any gases containing oxygen at higher than atmospheric concentrations (above 23-25 percent). A toxic or highly toxic gases containing a median lethal concentration (LC50) in air of 200 parts per million (ppm) by volume or less. Some pure compressed gases are chemically unstable. If exposed to slight temperature or pressure increases, or mechanical shock, they can readily undergo certain types of chemical reactions such as polymerization or decomposition. These reactions may become violent, resulting in fire or explosion. Some dangerously reactive gases have other chemicals, called inhibitors, added to prevent these hazardous reactions.

nitrogen oxides, Chlorine and Fluorine Gases Arsine, Boron Trifluoride, Bromine

acetylene, 1,3butadiene, methyl acetylene, vinyl chloride, tetrafluoroethylene and vinyl fluoride

GENERAL LAB RULES 1. No eating, drinking, smoking, handling contact lenses, or applying cosmetics in the laboratory. 2. Persons shall wear buttoned lab coat, long pants, safety glasses or goggles and appropriate gloves when working with hazardous chemicals. 3. Mouth pipetting is prohibited; mechanical pipetting devices are to be used at all times. 4. All procedures are performed carefully to minimize the creation of splashes or aerosols. 5. Wash hands after handling chemicals materials, after removing gloves, and before leaving the laboratory. 6. Plastic ware should be substituted for glassware whenever possible GENERAL SAFETY FOR COMPRESSSED GAS CYLINDERS Ensure that regulator pressure control valve is relieved (i.e., closed) before attaching to tanks.

2

Standard Operating Procedure (SOP) Template

COMPRESSED GAS SAFETY Effective Date: 12/7/2011 Revised Date: 1/30/2012

Close valves on gas cylinders when a system is not in use. Remove all pressure from regulators not currently used (by opening equipment valves downstream after the regulators are closed). Shut-off valves must not be installed between pressure relief devices and the equipment they are to protect. Use pressure relief valves in downstream lines to prevent high pressure buildup in the event that a regulator valve does not seat properly and a tank valve is left on. Relief valves should be vented to prevent potential buildup of explosive or toxic gases. Never allow flames or concentrated heat sources to come in contact with a gas cylinder. Never allow a gas cylinder to become part of an electrical circuit. Never partially open a tank valve to remove dust or debris from the cylinder inlet. Never use cylinder gas as compressed air. Pressurize regulators slowly and ensure that valve outlets and regulators are pointed away from all personnel when cylinder valves are opened. Cylinders which require a wrench to open the main valve shall have the wrench left in place on the cylinder valve while it is open. Use adequately sized wrenches (12 long) to minimize ergonomic stress when turning tight tank valves. Never apply excessive force when trying to open valves. Cylinders with stuck valves should be returned to suppliers to have valves repaired. Do not attempt to open a corroded valve; it may be impossible to reseal. Valves should only be opened to the point where gas can flow into the system at the necessary pressure. This will allow for quicker shutoff in the event of a failure or emergency. Use a cylinder cap hook to loosen tight cylinder caps. Never apply excessive force or pry off caps. Return to supplier to remove stuck caps. Keep piping, regulators and other apparatus gas tight to prevent gas leakage. Confirm gas tightness by using compatible leak test solutions (e.g., soap and water) or leak test instruments. Release pressure from systems before connections are tightened or loosened and before any repairs. Do not use Teflon tape on CGA fittings (straight thread) where the seal is made by metal-to-metal contact. Use of Teflon tape causes the threads to spread and weaken, increasing the likelihood of leaks. Never use adapters or exchange fittings between tanks and regulators. Fluorescent light can be used to check for grease or oil in regulators and valves. LABELING Cylinders should be marked with a clear label identifying the contents. No cylinder should be accepted without a proper label.

Standard Operating Procedure (SOP) Template

COMPRESSED GAS SAFETY Effective Date: 12/7/2011 Revised Date: 1/30/2012

Add Lab Specific Rules Here

PURPOSE Add Lab Specific Purpose Here

PHYSICAL HAZARDS

HEALTH HAZARDS

Standard Operating Procedure (SOP) Template

COMPRESSED GAS SAFETY Effective Date: 12/7/2011 Revised Date: 1/30/2012

PERSONAL PROTECTIVE EQUIPMENT EYE PROTECTION Safety glasses, goggles or face shields shall be worn during operations in which COMPRESSED GASES might contact the eyes (e.g., through vapors or splashes of solution). Ordinary (street) prescription glasses do not provide adequate protection. Adequate safety glasses must meet the requirements of the Practice for Occupational Education Eye and Face Protection (ANSI Z87.1-1989) and must be equipped with side shields. HAND PROTECTION Use disposable nitrile gloves when working with chemicals. Laboratory personnel should thoroughly wash hands with soap and water before and immediately upon removal of gloves. LAB COATS, ETC. Button lab coats, closed toed shoes, long pants and long sleeved clothing shall be worn when handling COMPRESSED GASES. Protective clothing shall be worn to prevent any possibility of skin contact with COMPRESSED GASES. CRYOGENICS Wear cryogenic gloves, safety glasses, and lab coat when handling and transporting cryogenic materials. Wear safety goggles, face shield and cryogenic apron (plus cryogenic gloves and lab coat) when working with any open container of liquefied gases (including when retrieving a specimen from a liquid nitrogen freezer). DESIGNATED AREA FOR USE AND CONTAINMENT DEVICES When possible, work with COMPRESSED GASES shall be done in the laboratory fume hood. When working with volatile, toxic chemicals, in limited amounts, Biological Safety Cabinets (BSC) Class II, Type A2 exhausted or Class II, Types B1and B2 BSCs exhausted to the outside can be used. All compressed gases should be stored in rooms with ventilation. The fume hoods sash must be in the position where a face velocity of 100 feet per minute is achieved. The BSC must be certified annually by a qualified outside vendor. Environmental Health and Safety certifies fume hoods annually and places a yellow sticker to indicate the date of certification and the proper sash height for achieving proper fume hood face velocity. Contact Engineering (716-4351) immediately if fume hood is malfunctioning. USE

Standard Operating Procedure (SOP) Template

COMPRESSED GAS SAFETY Effective Date: 12/7/2011 Revised Date: 1/30/2012

Leak testing should be performed each time after connecting a new cylinder. Check manufacturers recommendations on requirements for regulators gauge calibration and use periodically.

SPECIAL HANDLING PROCEDURES AND STORAGE REQUIREMENTS If Applicable - Store COMPRESSED GASES in a flammable storage cabinet. If Applicable - Peroxide hazard on concentrationdo not distill or evaporate without first testing for the presence of peroxidesdiscard or test for peroxides after 6 months. EM QUANT Peroxide test strips can be ordered through Fisher Scientific, catalogue #M100111 for testing for the presences of peroxides. Shall not be stored in exits or egress routes. Shall be stored within a well-ventilated area. Caps used for valve protection must always be securely fastened, unless the cylinder is being used. Cylinders should be stored away from locations that are continuously damp, subject to heat or mechanical and physical damage, and in a well-ventilated area. Compressed gas cylinders must be stored upright and secured with a chain or strap that is connected to a wall or bench mounted device. If tags are used that read FULL, IN USE, or EMPTY, the tags shall not be removed from the compressed gas cylinder. The label shall reflect the status of the cylinder. Oxygen Cylinders must be stored in a designated location that is labeled as such. Oxygen Cylinders must be physically segregated in storage as to FULL vs EMPTY.

Standard Operating Procedure (SOP) Template

COMPRESSED GAS SAFETY Effective Date: 12/7/2011 Revised Date: 1/30/2012

Empty cylinders should be labeled EMPTY and immediately returned to the storage area. EE cylinders (lecturer bottles) must not exceed a maximum quantity of 12 cylinder in an area. HANDLING Cylinders should always be transported with hand trucks equipped with the appropriate chains or straps to secure the cylinder during transport. Never drop, bang, or strike cylinders against each other nor against solid objects. Do not lift a cylinder by its cap; the cap or cylinder could come loose and cause harm. Anyone transporting cylinders should wear steel-toed shoes or at a minimum closed toe shoes. SEPARATION OF CYLINDERS BY HAZARD CLASS If storing more than one cylinder containing a different hazard classes then the cylinders must be separated by at least 20 feet (6.1 m). ENGINEERING CONTROLS Some storage areas are equipped with Oxygen sensors for ensuring oxygen levels do not drop below 19.5% oxygen and produce an IDLH immediately dangerous life and health situation. It is recommended that oxygen sensors be installed where liquid nitrogen is stored. In the event of an alarm from the sensors, do not access space, ensure door remains closed and contact Environmental Health and Safety at 716-9375 and Emergency Communication Center at 716-9111.

Add Lab Specific Special Handling/Storage Procedures

EMPLOYEE EXPOSURE MONITORING Users of COMPRESSED GASES are required to notify EH&S at 716-9375 so air sampling/monitoring may be performed to determine exposure level. Individuals planning a family or pregnant can contact EH&S for exposure determination, consultation, and recommendations. Exposure monitoring through EH&S is free of charge.

7

Standard Operating Procedure (SOP) Template

COMPRESSED GAS SAFETY Effective Date: 12/7/2011 Revised Date: 1/30/2012

CHEMICAL USE WITH ANIMALS Click here to enter text. Please consider alternative routes of exposure when handling animal bedding.

WASTE DISPOSAL Chemicals shall not be drain disposed unless prior approval is given by EH&S. Excess COMPRESSED GASES and all waste material containing COMPRESSED GASES must be placed in an unbreakable secondary container labeled with the following HAZARDOUS WASTE COMPRESSED GASES. Full containers of COMPRESSED GASES waste must be disposed of according to the EH&S Hazardous Waste Program. A Waste Ticket must be completed and submitted prior to disposing of COMPRESSED GASES through EH&S. In most cases, the compressed gas cylinder, including any unused gas, will be returned to the vendor from which the cylinder was purchased. If the vendor cannot be determined, contact EH&S at 716-9375 for disposal information. SPECIFIC COMPRESSED GAS SAFETY CATEGORIES OF GASES INERT - argon, helium, neon and nitrogen CATEGORIES OF GASES LIQUEFIED GASES Anhydrous ammonia, chlorine, propane, nitrous oxide and carbon dioxide PROPERTIES POTENTIAL HAZARDS

PROPERTIES Cryogenic materials are liquefied or solidified gases at low temperatures.

POTENTIAL HAZARDS They can cause tissue damage (frostbite), asphyxiation due to oxygen displacement, and potential explosion due to pressure buildup.

Standard Operating Procedure (SOP) Template

COMPRESSED GAS SAFETY Effective Date: 12/7/2011 Revised Date: 1/30/2012

CATEGORIES OF GASES CORROSIVE chlorine, hydrogen chloride, fluorine, hydrogen fluoride, hydrogen sulfide, carbon monoxide and carbon dioxide

PROPERTIES Contact EH&S, Fire and Life Safety Specialist at 716-9375 before ordering this category of gas.

POTENTIAL HAZARDS Metals become brittle when used in corrosive gas service, check equipment and lines frequently for leaks. A diaphragm gauge should be used with corrosive gases that would destroy a steel or bronze gauge. Check with gas supplier for recommended equipment. Remove regulators after use and flush with dry air or nitrogen.

CATEGORY OF GASES FLAMMABLE - acetylene, butane, ethylene, hydrogen, methylamine and vinyl chloride

PROPERTIES Hydrogen Gas - colorless, odorless, tasteless, flammable nontoxic gas. Contact EH&S, Fire and Life Safety Specialist at 716-9375 before ordering this category of gas.

POTENTIAL HAZARDS Forms a flammable mixture over a wide range of concentrations in air and requires a minimum ignition source. Detonation from a lowenergy ignition source is possible in hydrogen-air mixtures of 18-60% volume that are well mixed and confined.

Standard Operating Procedure (SOP) Template

COMPRESSED GAS SAFETY Effective Date:

CATEGORIES OF GASES OXIDIZER Fluorine Gas

12/7/2011

PROPERTIES

Revised Date:

PHYSICAL HAZARDS Corrosive to exposed tissues including upper and lower respiratory tracts, eyes, nose, and any other exposed mucous membranes. Penetrates deeply into body tissues and will continue to exert toxic effects unless neutralized.

1/30/2012

HANDLING AND STORAGE Fluorine reacts violently with many materials and decomposes to hydrofluoric acid on contact with moisture, so make sure to keep equipment dry.

Highly toxic, pale yellow gas. The most powerful oxidizing agent known, reacting with practically all organic and inorganic substances. Contact EH&S, Fire and Life Safety Specialist at 716-9375 before ordering this category of gas.

CATEGORIES OF GASES REACTIVE Contact EH&S, Fire and Life Safety Specialist at 716-9375 before ordering this category of gas.

EXAMPLES acetylene, 1,3butadiene, methyl acetylene, vinyl chloride, tetrafluoroethylene and vinyl fluoride

CATEGORIES OF GASES Toxic or Contact EH&S, Fire and Life Safety highly Toxic Specialist at 716-9375 before ordering this category of gas. EMERGENCY PROCEDURES Emergency Numbers: Fire and Medical Emergencies

EXAMPLES

716-9111 (9 + 911 for Friedberg campus)

10

Standard Operating Procedure (SOP) Template

COMPRESSED GAS SAFETY Effective Date: 12/7/2011 Revised Date: 1/30/2012

Principal Investigators Emergency Number Employee Health Hospital Emergency Room Environmental Health and Safety Laboratory Contact Information: Click here to enter text. Click here to enter text. Click here to enter text. 716-4801 716-9008 716-9375

Click here to enter text. Click here to enter text. Click here to enter text.

FIRST AID The nearest safety shower station is located: Insert text here The nearest safety eyewash is located: Insert text here If chemical exposure occurs, flush exposed area for 15 to 20 minutes using emergency eyewash station and/or safety shower. Call 716-9111 and describe the extent of injuries, chemical spilled and the amount. Keep people out of the area. Report all accidental exposures to Employee Health Services. Complete an online injury/illness report if there is an over-exposure to the chemical or if there is an accident involving the chemical. SPILL AND ACCIDENT PROCEDURES If the chemical spilled is considered a carcinogen, reproductive toxin or highly toxic chemical, contact 716-9111 and evacuate area immediately, regardless of spill amount. If you are unsure of type of chemical, contact 716-9111. For all other spills use the chart below for spill reporting and response: Chemical Spill Procedures PROPER SPILL RESPONSE Contact Environmental Health and Safety (7169375) and clean up spill using spill kit. Spill greater than 300 mL Do not attempt to clean up spill. Leave the Area and immediately report to WFBMC Security (716-9111). For Spills of any compressed gas, leave the area immediately and contact the Hazmat Team by

11

SPILL QUANTITY Spill less than 300 mL

Standard Operating Procedure (SOP) Template

COMPRESSED GAS SAFETY Effective Date: 12/7/2011 Revised Date: 1/30/2012

calling 716-9111 from a campus phone. Spills of cryogenic liquid can cause depletion of oxygen in the area. For spills over 1 liter (or smaller amounts in very small rooms), leave the area immediately and contact the Hazmat Team by calling 716-9111 from a campus phone. EH&S can monitor to ensure adequate oxygen concentration.

12

CERTIFICATION OF APPLICATION PLEASE READ THESE ITEMS AUTOMATICALLY BECOME A PART OF YOUR SOP 1. I understand that it is my responsibility to assure that all personnel working in my laboratory with any of these hazards are fully informed about their specific dangers, proper actions for safe use, steps to take in case of accidents, and are provided with all necessary safety equipment and instructions in its use. 2. I agree to follow the provisions of the Chemical Hygiene Plan. 3. I will ensure that all of my personnel attend Basic Lab Safety Training by EH&S prior to using chemical materials. 4. I agree to permit Representatives of WFSM Environmental Health and Safety to inspect the facilities where this work is being conducted. 5. All chemical waste will be disposed of through EH&S Chemical Waste Program. I understand that drain disposal is NOT allowed. 6. Chemical materials will be transported in closed containers. 7. Sharps and/or breakable plastic solid waste items will be placed in approved punctureresistant container, i.e., a sharps container. 8. As soon as possible, the Chemical Occupational Hygiene Officer will be notified in writing of any proposed changes in locations where chemical materials are stored or used. 9. Additional chemicals or changes in possession limits will be requested in writing from the Chemical Occupational Hygiene Officer. 10. Chemical materials will not be transferred to other Authorized Users without prior approval of the Chemical Occupational Hygiene Officer. 11. Chemical materials will not be shipped anywhere off campus without prior approval of the Chemical Occupational Hygiene Officer. 12. Secure chemicals (including waste) to prevent unauthorized access or removal. In addition, you must control and maintain constant surveillance of chemicals that are not in storage or are in use. This can be achieved by: 1) Locking refrigerators and/or storage cabinets, 2) Locking the laboratory when no one is present, and 3) Challenging unknown persons entering the laboratory. 13. I will notify the Chemical Occupational Hygiene Officer of my intent to leave WFUHS at least 60 days in advance. I will be responsible for disposing of my chemical materials inventory through EH&S Chemical Waste Program. First Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. Last Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. Click here to enter text. Signature

13

You might also like

- 10 Simple Solutions To Build Self EsteemDocument182 pages10 Simple Solutions To Build Self Esteemstudkhan100% (23)

- Fit For Duty PolicyDocument3 pagesFit For Duty PolicyScope Sameer PNo ratings yet

- The Sharper MindDocument301 pagesThe Sharper Mindlingus123100% (4)

- Proco Rat Distortion DIY SchemDocument1 pageProco Rat Distortion DIY SchemFer VazquezNo ratings yet

- Compressed Gas Cylinder SOPDocument4 pagesCompressed Gas Cylinder SOPAmber ChavezNo ratings yet

- PA Hidden FiguresDocument12 pagesPA Hidden FiguresJoya Jimenea GenzolaNo ratings yet

- Evoque Owners Club Manual PDFDocument258 pagesEvoque Owners Club Manual PDFmihai12moveNo ratings yet

- Spill Response Plan.Document2 pagesSpill Response Plan.Carlo March Notarte100% (1)

- Equipment Operating ProcedureDocument5 pagesEquipment Operating ProcedurezaizamNo ratings yet

- OHSDocument19 pagesOHSAshok PatelNo ratings yet

- Environment Health Safety Director in Huntsville AL Resume Ainsworth ThomasDocument2 pagesEnvironment Health Safety Director in Huntsville AL Resume Ainsworth ThomasAinsworthThomasNo ratings yet

- Bloodborn Pathogen ProgramDocument22 pagesBloodborn Pathogen Programsitimaezyaroh100% (1)

- PPE Hazard Assessment Certification FormDocument4 pagesPPE Hazard Assessment Certification FormHaleem Ur Rashid BangashNo ratings yet

- 4 Steps To Spill Response: Prevention: The Best SolutionDocument4 pages4 Steps To Spill Response: Prevention: The Best SolutionJuan Carlos Guerrero RNo ratings yet

- Sample PPE Policies: InstructionsDocument9 pagesSample PPE Policies: InstructionsrejilkumarNo ratings yet

- PPE PolicyDocument4 pagesPPE PolicyalbertNo ratings yet

- EHS Induction Training ModuleDocument19 pagesEHS Induction Training ModuleBhaskar ShuklaNo ratings yet

- Overhead Crane OperationDocument4 pagesOverhead Crane OperationDraj CahyaNo ratings yet

- Respiratory Protection - Harmonized - PolicyDocument26 pagesRespiratory Protection - Harmonized - PolicyZubaidi OthmanNo ratings yet

- SOP Compressed GasDocument4 pagesSOP Compressed GasSandeep ShettyNo ratings yet

- Service Manual Repair 552-557 PDFDocument3,278 pagesService Manual Repair 552-557 PDFSerg la RoshNo ratings yet

- Safe Operating Procedures Equipment MaintenanceDocument3 pagesSafe Operating Procedures Equipment Maintenancegustian141No ratings yet

- SOP - Material Handling and Safe Operation of E-Forklift in Finished Good WarehouseDocument11 pagesSOP - Material Handling and Safe Operation of E-Forklift in Finished Good WarehouseYashwantkumar ShivappaNo ratings yet

- Crash Course in Office 365:: How It Can Help You Grow Your BusinessDocument32 pagesCrash Course in Office 365:: How It Can Help You Grow Your BusinessEsrael Waworuntu0% (1)

- Hazard Communication Program 1Document4 pagesHazard Communication Program 1myo lwinNo ratings yet

- Fall Protection Plan: QPS Services - Occupational Health and Safety Management System Fall Protection Plan Page 1 of 8Document8 pagesFall Protection Plan: QPS Services - Occupational Health and Safety Management System Fall Protection Plan Page 1 of 8HeleenNo ratings yet

- Thermal Imaging Tech ResourceDocument20 pagesThermal Imaging Tech Resourceskimav86100% (1)

- PPE TrainingDocument16 pagesPPE TrainingRobert WrightNo ratings yet

- 07 101 Production Jack UpsDocument4 pages07 101 Production Jack UpsShamsol Ariffin100% (1)

- First Aid - Sample ProcedureDocument5 pagesFirst Aid - Sample ProcedureARSHI ASLAMNo ratings yet

- SOP 06 - Portable Tools and EquipmentDocument3 pagesSOP 06 - Portable Tools and EquipmentEdwins Gabrelle Hendrawan DalfadoNo ratings yet

- Heat Rate EpriDocument48 pagesHeat Rate EpritbfakhrimNo ratings yet

- Awareness On Working at HeightDocument3 pagesAwareness On Working at Heightsubhadipmanna8100% (1)

- Compressed GasDocument3 pagesCompressed GassherinNo ratings yet

- SOP - LatheDocument2 pagesSOP - LatheQuality PFPLNo ratings yet

- 1-Mock Drill Report of Aegis Gas On 16-01-2018Document3 pages1-Mock Drill Report of Aegis Gas On 16-01-2018Parth PatelNo ratings yet

- Safety Standard For Material Storage and HandlingDocument48 pagesSafety Standard For Material Storage and Handlingvinodh nairNo ratings yet

- Machineguardingsoptech 12Document1 pageMachineguardingsoptech 12api-200253170No ratings yet

- SWP Plasma Cutter AS532Document2 pagesSWP Plasma Cutter AS532Adet WildanNo ratings yet

- Safety TrainingDocument6 pagesSafety Trainingsvpriya233282No ratings yet

- OHS-17 Motor Vehicle SafetyDocument9 pagesOHS-17 Motor Vehicle SafetyAshok PatelNo ratings yet

- Utico FZC Work Instruction Manual Drilling MachineDocument2 pagesUtico FZC Work Instruction Manual Drilling MachineNAVANEETHNo ratings yet

- SOP-34 Ladders SafetyDocument3 pagesSOP-34 Ladders SafetyBoiler ScrubberNo ratings yet

- SG-14 Safety Guideline For Work On Electric Overhead Travelling (EOT) CraneDocument19 pagesSG-14 Safety Guideline For Work On Electric Overhead Travelling (EOT) CraneAbhishek GadatiaNo ratings yet

- MSDS - NitrogenDocument7 pagesMSDS - NitrogenSatish Kumar MauryaNo ratings yet

- 3786 Frequency & Severity Rates For Industrial InjuriesDocument30 pages3786 Frequency & Severity Rates For Industrial InjuriesVk Seshadri100% (1)

- Factory Compliance Check ListDocument5 pagesFactory Compliance Check ListvermaamanvermaNo ratings yet

- 22 Hand Tool SafetyDocument8 pages22 Hand Tool SafetyAlma Tomas-CafeNo ratings yet

- Pump and CompressorDocument26 pagesPump and CompressorShamsol AriffinNo ratings yet

- On Phase ChangesDocument28 pagesOn Phase Changesapi-313517608No ratings yet

- Operating Instructions Back Pressure Regulator Series: BPR: Holter RegelarmaturenDocument19 pagesOperating Instructions Back Pressure Regulator Series: BPR: Holter Regelarmaturenamin100% (2)

- DEE EHU-17-1-2 Chemical Management Procedure PDFDocument9 pagesDEE EHU-17-1-2 Chemical Management Procedure PDFFerijanto WahjudiNo ratings yet

- Personal Protective Equipment OHS-PROC-12: Tarong Energy Corporation Limited Corporate Business Procedure ForDocument17 pagesPersonal Protective Equipment OHS-PROC-12: Tarong Energy Corporation Limited Corporate Business Procedure ForSundarapandiyan Sundaramoorthy100% (2)

- Emergency Preparedness Training PlanDocument1 pageEmergency Preparedness Training PlanenviromunishNo ratings yet

- Fire Safety AuditDocument3 pagesFire Safety AuditAvijit SharmaNo ratings yet

- Personal Protective Equipment Hazard Assessment: Location: Conducted By: Date: Tasks Performed at This LocationDocument4 pagesPersonal Protective Equipment Hazard Assessment: Location: Conducted By: Date: Tasks Performed at This LocationAnge JuanNo ratings yet

- Safety ManualDocument31 pagesSafety ManualJosue Sandoval MenaNo ratings yet

- Tank Vessel HandbookDocument76 pagesTank Vessel HandbooklsgmzNo ratings yet

- 4 First Aid Box Inventory (White) 2020Document1 page4 First Aid Box Inventory (White) 2020lez2No ratings yet

- Welding Dissimilar MetalsDocument6 pagesWelding Dissimilar MetalsNitintak100% (1)

- Emergency and Action Plans-FormatsDocument12 pagesEmergency and Action Plans-Formatsanoushia alviNo ratings yet

- Signs of The End Times in Surat Al-KahfDocument260 pagesSigns of The End Times in Surat Al-KahfFatma SamNo ratings yet

- Machinery Inspection ChecklistDocument3 pagesMachinery Inspection ChecklistYuva samaj sewa TrustNo ratings yet

- Safety Engineer PDFDocument3 pagesSafety Engineer PDFخلف الله التوم0% (1)

- Factory Compliance ListDocument31 pagesFactory Compliance ListAnkit Kr MishraNo ratings yet

- Msds of OxygenDocument7 pagesMsds of OxygensahilchemNo ratings yet

- Operational Safety Guideline Gas Torch: Description of Work: Potential Hazards: Hazards With The Potential ToDocument2 pagesOperational Safety Guideline Gas Torch: Description of Work: Potential Hazards: Hazards With The Potential ToAcosta CharlesNo ratings yet

- EHS ManagerDocument3 pagesEHS Managerapi-121631565No ratings yet

- Basic Safety Program RulesDocument2 pagesBasic Safety Program RulesMattNo ratings yet

- JSA-AUST-HAL-PE-037 PS Rev - ACIDDocument7 pagesJSA-AUST-HAL-PE-037 PS Rev - ACIDIulian Costin IonNo ratings yet

- Written Lockout/Tagout Program University of South Carolina (Enter Department Name Here)Document13 pagesWritten Lockout/Tagout Program University of South Carolina (Enter Department Name Here)SaidNo ratings yet

- NOHSC 1005-1994 Hazardous Substances Model RegsDocument23 pagesNOHSC 1005-1994 Hazardous Substances Model RegsAdiguna DhanaNo ratings yet

- SF6 MSDSDocument7 pagesSF6 MSDSjaycarpioNo ratings yet

- Standard Operating Procedures: Type of SOP: PurposeDocument10 pagesStandard Operating Procedures: Type of SOP: PurposeArunkumar ChandaranNo ratings yet

- 530 - Dryers ManualDocument10 pages530 - Dryers Manualck19654840No ratings yet

- 10 Minutes To Success SUCCESS SHEET PDFDocument1 page10 Minutes To Success SUCCESS SHEET PDFDebby LafinaNo ratings yet

- Tank ProtectionDocument29 pagesTank ProtectionShamsol AriffinNo ratings yet

- Configuring Catalyst SwitchDocument22 pagesConfiguring Catalyst SwitchShamsol AriffinNo ratings yet

- ICND22S01L01Document12 pagesICND22S01L01Shamsol AriffinNo ratings yet

- ICND22S01L02Document9 pagesICND22S01L02Shamsol AriffinNo ratings yet

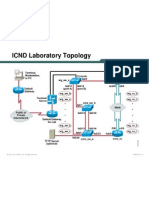

- ICND Laboratory Topology: © 2004 Cisco Systems, Inc. All Rights ReservedDocument3 pagesICND Laboratory Topology: © 2004 Cisco Systems, Inc. All Rights ReservedShamsol AriffinNo ratings yet

- ICND22S01L03Document15 pagesICND22S01L03Shamsol AriffinNo ratings yet

- CCNA INTRO1.0a Knet HiResDocument822 pagesCCNA INTRO1.0a Knet HiResShamsol AriffinNo ratings yet

- ICND Laboratory Topology: © 2004 Cisco Systems, Inc. All Rights ReservedDocument15 pagesICND Laboratory Topology: © 2004 Cisco Systems, Inc. All Rights ReservedShamsol AriffinNo ratings yet

- Installation Instructions For Cable Gland Type A2F: Certificate References: Sira 06 Atex 1097X Iecex Sir 06.0039XDocument9 pagesInstallation Instructions For Cable Gland Type A2F: Certificate References: Sira 06 Atex 1097X Iecex Sir 06.0039XShamsol AriffinNo ratings yet

- Certificate in Process Plant Layout Piping Design Engineering Institute PDFDocument3 pagesCertificate in Process Plant Layout Piping Design Engineering Institute PDFShamsol AriffinNo ratings yet

- CCNA INTRO1.0a Knet HiResDocument822 pagesCCNA INTRO1.0a Knet HiResShamsol AriffinNo ratings yet

- Welding Course by IemDocument2 pagesWelding Course by IemShamsol AriffinNo ratings yet

- Lab 9.1.5b Trunking With 802.1q: ObjectiveDocument8 pagesLab 9.1.5b Trunking With 802.1q: ObjectiveShamsol AriffinNo ratings yet

- Presure Testing GuidanceDocument15 pagesPresure Testing GuidanceShamsol AriffinNo ratings yet

- Be Strategic - New Version of The Hare & The TortoiseDocument40 pagesBe Strategic - New Version of The Hare & The TortoisesszmaNo ratings yet

- Lab 9.3.6 Configuring Inter-VLAN Routing: ObjectiveDocument7 pagesLab 9.3.6 Configuring Inter-VLAN Routing: Objectiveapi-3729796No ratings yet

- Configure Static VlanDocument7 pagesConfigure Static VlanShamsol AriffinNo ratings yet

- Configure Static VlanDocument7 pagesConfigure Static VlanShamsol AriffinNo ratings yet

- Xiaopan OS InstallationDocument6 pagesXiaopan OS InstallationMuhammad SyafiqNo ratings yet

- Marina Bay SandsDocument5 pagesMarina Bay SandsTauqeer A. BalochNo ratings yet

- Dn7064519 - Installing Flexi Cabinet For IndoorDocument63 pagesDn7064519 - Installing Flexi Cabinet For Indoorlettymc100% (1)

- Ruth Clark ResumeDocument2 pagesRuth Clark Resumeapi-288708541No ratings yet

- Imovie Presentation Rubric EfDocument1 pageImovie Presentation Rubric Efapi-239838395No ratings yet

- 243 RegulatorDocument24 pages243 RegulatorDavid Somogyi DovalNo ratings yet

- 8060056-ELIVAC Smart Vacuum Systems ENDocument8 pages8060056-ELIVAC Smart Vacuum Systems ENseimarfelipeNo ratings yet

- Sorona - Product InformationDocument4 pagesSorona - Product InformationchristianNo ratings yet

- Assessment PlanDocument2 pagesAssessment Planapi-282348214No ratings yet

- PDFDocument2 pagesPDFSalim AshorNo ratings yet

- Personal Data Sheet: Criminology Intern UnitDocument1 pagePersonal Data Sheet: Criminology Intern UnitJoseph RycheNo ratings yet

- Schlafhorst Texlab: Catalogue of ServicesDocument27 pagesSchlafhorst Texlab: Catalogue of ServicesvenkatspinnerNo ratings yet

- Kinematic Analysis of 5 Dof Lynx ArmDocument6 pagesKinematic Analysis of 5 Dof Lynx ArmsathyaNo ratings yet

- Vedic MathematicsDocument19 pagesVedic MathematicsyogeshNo ratings yet

- PKG 101 Principles of Packaging Quiz 1ADocument2 pagesPKG 101 Principles of Packaging Quiz 1AuknowgaryNo ratings yet

- '11!01!05 NEC Femtocell Solution - Femto Specific FeaturesDocument25 pages'11!01!05 NEC Femtocell Solution - Femto Specific FeaturesBudi Agus SetiawanNo ratings yet

- Altman Fall Winter 2012 Product Showcase FlyerDocument32 pagesAltman Fall Winter 2012 Product Showcase FlyerИлия ГеоргиевNo ratings yet

- Updated After 11th BoS Course Curriculum - B.tech CSEDocument120 pagesUpdated After 11th BoS Course Curriculum - B.tech CSEAnonymous 9etQKwWNo ratings yet

- ValvesDocument1 pageValvesnikhilNo ratings yet

- Mechanical and Micro Structure of MDF Processed MaterialDocument8 pagesMechanical and Micro Structure of MDF Processed MaterialSharath P CNo ratings yet