Professional Documents

Culture Documents

Coal Combustion Products

Uploaded by

mechanistOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Coal Combustion Products

Uploaded by

mechanistCopyright:

Available Formats

Material Fact Sheet

Coal Combustion Products

Introduction

Coal combustion products or CCPs are the materials that remain after burning coal to

generate electricity. There are a number of different CCPs, but the most important are fly

ash, bottom ash and flue gas desulfurization (FGD) materials. Fly ash and bottom ash are

primary composed of valuable industrial minerals such as alumina, silica, lime and iron

oxide. FGD is primarily composed of gypsum, the mineral used to make wallboard. CCPs

can used as a replacement for natural materials in construction, providing a quality product

while reducing costs. However, of the approximately 125 million tons of CCPs produced

each year, more than half goes into landfills. The goal of the IRC is to increase the appro-

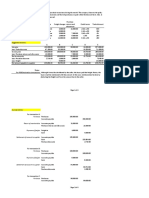

An SEM image of coal fly ash.

priate use of CCPs in construction, saving money and valuable landfill space.

Applications

Fly ash makes up the largest component of CCPs, with more than 70 million tons produced

each year. Fly ash is composed of very fine spherical particles that were removed from the

hot emission gases leaving the furnace where the coal is burned. The shape of the particles

and their composition make fly ash an excellent additive to concrete. The spherical shape

improves workability and decreases the permeability, while the minerals can improve the

long-term strength of the concrete. Similarly, the shape and chemistry of the ash lends itself

to use a fill material in flowable fill or controlled low strength material. Bottom ash is simi-

lar to fly ash in composition, but it is composed of heavier pieces that are collected from

grates beneath the furnace. The ash has coarse granular composition that makes it good for

use a coarse aggregate material. The bottom ash is strong and drains well, so it is often used

for road base, embankment and structural fill applications.

FGD materials are produced during the removal of sulfur dioxide (SO2) from gas emis-

sions produced by burning coal, as mandated by the 1990 Clean Air Act. There are many

different technologies for removing SO2, but in general an alkaline material like lime or

limestone is introduced into the flue gases to capture the SO2. The alkaline material reacts

with the SO2 gas to form calcium sulfate (gypsum), or calcium sulfite, which is usually

transformed into calcium sulfate. The primary use for FGD materials is the production of

wall board, which uses gypsum. In 2006, more than 7 million tons of FGD gypsum was

used to make wall board. In addition, FGD materials have been used in embankments and

as feedstock for cement production.

Environmental Benefits

Studies and research conducted or supported by Electric Power and Research Institute

(EPRI), government agencies, and universities indicates that the beneficial uses of coal

combustion products in highway construction have not been shown to present significant

risks to human health or the environment. But, as with many other common substances,

precautions and sound management practices should be applied when using coal ash in un-

encapsulated uses. Water and air are the two media most likely to be affected by coal ash or

coal ash constituents. Ingestion, inhalation, and skin contact are the ways that humans and

other living things could be exposed to coal ash. Other issues that may need to be addressed

are leaching of elements such as mercury and metals into ground water, contamination of

vegetation and the impact of other elements on the food chain, and air-borne dust. In most

cases, however, the way that coal ash is used, the engineering requirements for that use,

and the handling and management methods applied minimizes exposure to the ash.

For more information, see:

American Coal Ash Association

www.industrialresourcescouncil.org www.acaa-usa.org

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Bash Beginners GuideDocument173 pagesBash Beginners GuideCarin IoanaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- C Shell CookbookDocument60 pagesC Shell CookbookedwarzambranoNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Common Issues in DatastageDocument12 pagesCommon Issues in Datastagesunipulicherla100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- SitesDocument3 pagesSitesmechanistNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Analisa SNI 2007Document1 pageAnalisa SNI 2007Sandera SanNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 6.270 Robot Builders Guide 1Document255 pages6.270 Robot Builders Guide 1mechanistNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Lipfert - Etal - BiophysJ09-Quantitative Modeling and Optimization of Magnetic TweezersDocument10 pagesLipfert - Etal - BiophysJ09-Quantitative Modeling and Optimization of Magnetic Tweezersmechanist100% (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Optimal CO2 Capture and StorageDocument34 pagesOptimal CO2 Capture and Storagemechanist100% (2)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Ah-64a Apache Training CoursesDocument18 pagesAh-64a Apache Training Coursesmechanist100% (3)

- Flyash HTTP Geoinfo, NMT, Edu Publications Periodicals NMG 22 n2 FlyashDocument12 pagesFlyash HTTP Geoinfo, NMT, Edu Publications Periodicals NMG 22 n2 Flyashmechanist100% (2)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Fly Ash BricksDocument3 pagesFly Ash BricksmechanistNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- K. Subramanya - Engineering Hy-Hill Education (India) (2009) 76Document1 pageK. Subramanya - Engineering Hy-Hill Education (India) (2009) 76ramsinghmahatNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 31504647-Antenna System (On Tower) Installation Standard ModelDocument27 pages31504647-Antenna System (On Tower) Installation Standard ModelBadr AmerNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Perfil Clinico de Pacientes Con Trastornos de La Conducta AlimentariaDocument44 pagesPerfil Clinico de Pacientes Con Trastornos de La Conducta AlimentariaFrida PandoNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- GutsDocument552 pagesGutsroparts cluj100% (1)

- What Is E-CollaborationDocument7 pagesWhat Is E-CollaborationToumba LimbreNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Handout No. 03 - Purchase TransactionsDocument4 pagesHandout No. 03 - Purchase TransactionsApril SasamNo ratings yet

- North-South Railway Project - South LineDocument49 pagesNorth-South Railway Project - South LinesuperNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Baptismal DelayDocument20 pagesBaptismal DelayfiohdiohhodoNo ratings yet

- Education and Its LegitimacyDocument4 pagesEducation and Its LegitimacySheila G. Dolipas100% (6)

- A Child With Fever and Hemorrhagic RashDocument3 pagesA Child With Fever and Hemorrhagic RashCynthia GNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Culture NegotiationsDocument17 pagesCulture NegotiationsShikha SharmaNo ratings yet

- Republic of The Philippines Department of Education Deped Complex, Pasig City Science Iii K To 12 Curriculum Guide Planner / Budget of WorkDocument3 pagesRepublic of The Philippines Department of Education Deped Complex, Pasig City Science Iii K To 12 Curriculum Guide Planner / Budget of WorkLedie Lou Cetoy SuperalesNo ratings yet

- Exploded View: 22031050000281 RF-S218XAR1 Product Model Customer ModelDocument9 pagesExploded View: 22031050000281 RF-S218XAR1 Product Model Customer ModelPablo GuerraNo ratings yet

- AH Business-Management All 2011Document11 pagesAH Business-Management All 2011Sanam PuriNo ratings yet

- IRremote Library, Send & Receive Infrared Remote ControlDocument4 pagesIRremote Library, Send & Receive Infrared Remote ControlJayant SwamiNo ratings yet

- Three Moment Equation For BeamsDocument12 pagesThree Moment Equation For BeamsRico EstevaNo ratings yet

- Fastener Torque Charts: Phone: 1-800-558-2808 Fax: 1-800-553-8769Document2 pagesFastener Torque Charts: Phone: 1-800-558-2808 Fax: 1-800-553-8769KOMATSU SHOVELNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Dry Docking QuotationDocument4 pagesDry Docking Quotationboen jayme100% (1)

- Arithmetic Mean PDFDocument29 pagesArithmetic Mean PDFDivya Gothi100% (1)

- Thetford c250 InstallationDocument19 pagesThetford c250 InstallationCatalin Bejan100% (1)

- Frogs and ToadsDocument6 pagesFrogs and ToadsFaris AlarshaniNo ratings yet

- Term Paper - 2022964Document17 pagesTerm Paper - 2022964Md. Ahbab HasanNo ratings yet

- Term Paper Gender RolesDocument5 pagesTerm Paper Gender Rolesea8d1b6n100% (1)

- Otis C. Mitchell - Hitler-s-Stormtroopers-and-the-Attack-on-the-German-Republic-1919-1933 PDFDocument201 pagesOtis C. Mitchell - Hitler-s-Stormtroopers-and-the-Attack-on-the-German-Republic-1919-1933 PDFbodyfull100% (2)

- Can J Chem Eng - 2022 - Mocellin - Experimental Methods in Chemical Engineering Hazard and Operability Analysis HAZOPDocument20 pagesCan J Chem Eng - 2022 - Mocellin - Experimental Methods in Chemical Engineering Hazard and Operability Analysis HAZOPbademmaliNo ratings yet

- Final Project Part-3 Marketing PlanDocument8 pagesFinal Project Part-3 Marketing PlanIam TwinStormsNo ratings yet

- 实用多元统计分析Document611 pages实用多元统计分析foo-hoat LimNo ratings yet

- RP Poster FinalDocument1 pageRP Poster Finalapi-270795195No ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Lesson Plan - Organization and ManagementDocument5 pagesLesson Plan - Organization and ManagementBilly Joe80% (15)

- FPA 03-A.01 Permohonan Akreditasi LP LK LI LM PUP PBADocument595 pagesFPA 03-A.01 Permohonan Akreditasi LP LK LI LM PUP PBAabimanyubawonoNo ratings yet