Professional Documents

Culture Documents

Class D Audio Amplifier With Ferroxcube Gapped Toroid Output Filter

Uploaded by

ikaro181083Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Class D Audio Amplifier With Ferroxcube Gapped Toroid Output Filter

Uploaded by

ikaro181083Copyright:

Available Formats

Class D audio amplifier

with Ferroxcube

gapped toroid output filter

Application Note

The concept of a Class D amplifier has

been around for a long time, however

only fairly recently have they become

commonly used in consumer applica-

tions. Due to improvements in the

speed, power capacity and efficiency of

modern semiconductor devices, appli-

cations using Class D amplifiers have

become affordable for the common

person. The mainly benefit of this kind

of amplifier is the efficiency, the theo-

retical maximum efficiency of a class D

design is 100%, and over 90% is

achieve in practice.

Other benefits of these amplifiers are

the reduction in consumption, their

smaller size and the lower weight.

Their advantages are obvious in low

power battery operated personal

audio players and laptop computer.

However they are also progressively

displacing more traditional linear

designs in mainstream applications

such as home entertainment systems,

automotive sound systems, and pro-

fessional installations where high qual-

ity audio is important.

Audio Amplifiers

An electronic amplifier is a device for

increasing the current, voltage or

power of a signal. It does this, by tak-

ing power from a power supply and

controlling the output to match the

input signal shape but with larger

amplitude. And audio amplifier is spe-

cially design for reproducing audio fre-

quencies.

Amplifier circuits are classified as A, B,

AB and C for analog designs, and class

D and E for switching devices. For the

analog classes, each type defines which

proportion of the input signal cycle is

used to switch on the amplifying device:

Class A 100%

Class AB Between 50% and 100%

Class B 50%

Class C less than 50%

The letter D used to designate the class

D amplifier, is simply the next letter

after the C, and does not stand for dig-

ital. Class D and E are sometimes mis-

takenly defined as digital because the

output waveform superficially resem-

bles a pulse train of digital symbols.

Class D amplifiers

A class D amplifier is basically a

switching amplifier or pulse width

modulator (PWM from now on)

amplifier. In this kind of amplifier all

power devices are operated in on/off

mode, reducing the power losses in

the output devices significantly.

Class D amplifiers can be categorised

into two topologies; half bridge and full

Class D audio amplifier with Ferroxcube

gapped toroid output filter

bridge configuration. Each topology

has pros and cons. In brief, a half bridge

is potentially simpler, while a full bridge

is better in audio performance.The full

bridge topology requires two half-

bridge amplifiers, and thus more com-

ponents.

A Class D amplifier works in the same

way as a PWM power supply, except

that the reference signal is the audio

wave instead of the accurate voltage

reference.

Lets start with an assumption that the

input signal is a standard audio line level

signal.This audio line level signal is sinu-

soidal with a frequency ranging from 20

Hz to 20Khz. This signal is compared

with a high frequency triangle or saw-

tooth waveform to create the PWM

signal.The input signal is converted to a

sequence of pulses whose averaged

value is directly proportional to the

amplitude of the signal at that time.The

frequency of the pulses is typically ten

or more times the highest frequency of

interest in the input signal.

This PWM signal is then used to drive

the power stage, creating the amplified

digital signal, and finally a low pass filter

is applied to the signal to filter out the

PWM carrier frequency and retrieve

the sinusoidal audio signal. The result-

ing filtered signal is then an amplified

replica of the input.

CLASS D Audio Power

Amplifier with GAPPED

FERRITES

One of the most important parts in a

class D, audio power amplifier is the

output filter.The overall efficiency, reli-

ability and audio performance depends

on it. A reference circuit has been

modified in order to substitute an

inductor by a gapped ferrite.This com-

ponent is designed to behave with the

same performance as the first one.

Output Filter Design

The overall efficiency, reliability and

audio performance depend on the

quality and linearity of the output fil-

ter.The main goal of the output filter is

attenuation of the high frequency

switching component of the class D

amplifier while preserving the signals

in the audio band.

The order of the filter determines

how many poles exist at the same fre-

quency, with each order increasing the

attenuation above the cut-off frequen-

Figure 1: Block diagram of a Class D audio amplifier

Figure 2: Example of the transfer function of a

low pass filter over normalized frequency (f/fc).

Several order filters are shown.

cy by 20dB per decade.The switching

frequency of the amplifier can influ-

ence the choice of the filter order, the

higher the fs, the lower the order

required to achieve a given attenua-

tion within a specified passband. This

would seem to dictate the use of the

highest switching frequency possible.

The trade-off is that increasing fs

increases the switching losses and the

EMI, thus decreasing the efficiency of

the amplifier.

0 1 10

0.2 0.3 0.4 0.5 0.6 0.7 0.8 2.0 3.0 4.0 5.0 6.0 7.0 8.0

A second order LC filter is the com-

mon approach, as it is lossless and has

a 40dB/decade slope, allowing for a

reasonable rejection of the carrier if

the parameters of the filter and the

switching frequency itself are properly

designed.

The first thing to do is to design the

transfer function for the filter. Usually,

a Butterworth or similar frequency

response is chosen, with a cut-off fre-

quency slightly above the audio band

(30-60KHz). Have in mind that one of

the design parameters is the termina-

tion load, that is, the speaker imped-

ance. Usually, a typical 4 or 8 ohm

resistor is assumed, but that would

produce variations in the measured

frequency response in presence of dif-

ferent speakers.That must be compen-

sated for by means of proper feedback

network design. Some manufacturers

simply leave it that way, so the

response is strongly dependent on the

load. Surely a non-desirable situation.

More information about designing the

output filter as a function of the cut off

frequency and load impedance is pre-

sented in annex 2.

The output inductor withstands the

whole output current without satura-

tion, as well as keeps the energy for

the off cycle, as in any non-isolated

switching converter (Class-D half

bridge design is in fact analogous to a

buck converter, its reference voltage

being the audio signal).

The ideal inductor (in terms of linear-

ity) is an air-core one, but the size and

number of turns required for typical

Class-D operation makes it impracti-

cal, so a core has to be used in order

to reduce turns count and also pro-

vide a confined magnetic field that

reduces radiated EMI. It can be use

either powder cores or ferrite cores.

Ferrite cores, must have a gap where

energy is stored.Wire size should also

be carefully chosen to keep DC and

AC losses low (requiring thick wire).

Figure 3: Second order low pass filter structu-

re.

Figure 4: Saturation curve: ferrites have lower

saturation, but flat response, while powder

cores show high saturation with a continuous

slope.

Magnetic core

of the output filter

The linearity of the filter versus fre-

quency and output power strongly

influences the performance of the

amplifier and quality of the audio sig-

nal. Therefore, care has to be taken in

order to select the optimal magnetic

core at a reasonable cost.

Iron powder cores are the cheapest

solution, but the switching frequency

(several hundred kilohertz) is too high

to make them suitable for this applica-

tion.

Powder alloy cores are widely used,

mainly because they are very popular

as output chokes in DC/DC convert-

ers and SMPS.The drawback is that the

saturation curve is not flat, but with a

constant slope drop. To overcome this

problem the designer has to over

specify the product in the sense that

only a small region of the saturation

curve is used. Losses at high frequen-

cies are also a thread, implying the use

of low permeability materials wound

with some 30 to 50 turns.

E

f

f

e

c

t

i

v

e

P

e

r

m

e

a

b

i

l

i

t

y

Ferrite cores are the third option.

They have the lowest losses at high

frequencies, and though the saturation

is lower than in powder cores, the

curve is completely flat. This curve

allows the designer to optimize the

core volume and gap size to the

required energy to store. The result is

very low distortion with a low turns

count (10 to 25) and, finally, at the

most affordable cost.

A practical Class D audio amplifier has

been evaluated to measure the influ-

ence of the magnetic core on the dis-

tortion of the audio signal.The amplifi-

er is driven by an International

Rectifier IR2011S device, delivering up

to 500 + 500 watts peak.

The reference design

The reference design is the

IRAUDAMP1 from International Rec-

tifier. Complete details of the amplifier

can be found at International Rectifier

website, in this application we will

focus on the output low pass filter

design.

The switching frequency is 400 kHz;

this frequency will be modulated by

the low frequency audio signal through

the PWM (Pulse Width Modulator).

The MOSFETs (International Rectifier

IRFB23N15D) are driven by the

IR2011S high speed gate driver.

In the original design, the output filter

of each channel is made with an AVX

capacitor (BF074E0474J with 0.47uF)

and a Micrometals inductor core

(NPT0104, core T106-2). It has an

inductance value of 18 H and it is

wound with 37 turns of AWG18 mag-

net wire.This filter cut off frequency is

50 kHz (see annex 2 for details).

In one of the channels, the original

inductor has been replaced by a FER-

ROXCUBE TN26/11-3C20-A113. It

has also an inductance of 18 uH, but it

is only wound with 13 turns of the

same AWG18 wire.

Distortion and noise versus frequency

and power are the key parameters to

define the quality of an audio amplifier.

The following curves compare the

performance of the amplifier on each

channel, taking into account that the

only difference between them is the

magnetic material of the inductor and

the winding count.

The measuring equipment used to test

the amplifier performance is Audio

Precision System Two. This equipment

allows easy and fast measurements

under several conditions. It is widely

used in the audio industry. Each chan-

nel has been loaded with a 5 Ohms

resistive load.

This first graph shows the total har-

monic distortion and noise power

percentage versus the output power

of the amplifier. The percentage

increases with the output power due

to longer swing over the saturation

curves (see figure 4). Here we can see

that the performance of the ferrite is

similar and slightly better under high

power conditions.

Figure 5: International Rectifier IRAUDAMP1

demo board. Features 500W + 500W peak

stereo power, efficiency 93% at 1 kHz and

100 watts. Voltage supply 50 Volts (allowed

25 to 60). Compact size: 100 x 140 x 38

mm.

This second graph shows the same

parameter (total harmonic distortion

and noise percentage) over a frequen-

cy sweep over the audio spectrum at a

fixed output power (in this case 100

watts). Again, the same result shows a

Figure 6:

Distortion over

output power

percentage ver-

sus output

power comparing

powder alloy and

ferrite core

inductors.

Amplifier input

10 kHz, load: 5

Ohms, voltage

supply 50 Volts.

Figure 7:

Distortion over

output power

percentage ver-

sus frequency

comparing pow-

der alloy and

ferrite core

inductors.

Output power

100 watts, load 5

Ohms, voltage

supply 50 Volts

slightly better performance of the fer-

rite core over the powder core.

5 Loading, Vcc = 50V, 100W

Ferrite core design with

Ferroxcube gapped toroids

Ferroxcube offers a wide range of

standard gapped toroids fitting in this

application. The procedure shown

below is intended to help the design

engineer to choose the optimal (and

therefore the most cost effective)

product size and gap. It is important to

note that custom cores and gap sizes

are availble upon request.

The procedure starts with 2 basic

parameters: the inductance of the out-

put filter (see annex to calculate the

value out of the cut off frequency and

load impedance) and the maximum

current that will flow through the

inductor (derived from the maximum

power of the amplifier).

These parameters will be used to cal-

culate the energy stored in the induc-

tor:

E = L x I

2

, where L is the induc-

tance in H, I is the maximum cur-

rent in Amperes, and E is energy in J

The next parameter to be taken into

account is the size of the core in com-

bination with the amount of energy to

be stored in the inductor. In most of

the cases the size of the core is limit-

ed by the board layout and mechanical

constraints, so the designer has to

optimize the core to work in the sat-

uration limit.The following graphs help

to choose the right core able to stand

the power. For each core size it is

plotted the amount of energy capable

to be stored and the maximum AL fac-

tor of the core. In annex 1 plots for

every standard size can be found.

Note that it is possible to make cus-

tom sizes and custom AL factors upon

request.

After the selection of the core size

and AL factor, the next step is to cal-

culate the winding. The number of

turns is derived from the next rela-

tion:

where L is the inductance in H and

AL is in nH/T2, and N is the number of

turns.

The wire gauge is fixed by the maxi-

mum DC resistance allowed for the

inductor as well as by the current den-

sity that the wire can handle. DC

resistance can be estimated with the

following formula:

R = (1+OD-ID+2xH)xRLxN,

where R is the DC resistance of the

inductor in mOhm, OD, ID and H are

the outer, inner diameter and height

of the core in mm, RL is the resist-

ance per meter of the selected wire

gauge and N is the number of turns.

N =

L x 1000

A

L

Annex 1: I2L curves for

Ferroxcube gapped

toroids

The following graphs show the energy

storage capability of standard Ferroxcube

gapped toroids. There are more sizes and

AL values available and custom products

can be made upon request.

Product dimensions are described as

TN (toroid coated with Nylon) 13

(outer diameter) /7.5 (inner diameter)

/5 (height).

Annex 2:

Filter design basics

The most common and recommend-

able output filter is a simple second

order Butterworth filter.They count a

minimum number of components and

show optimal flatness response while

keeping a sharp cut off frequency.

The transfer function for a second

order Butterworth filter has to follow

this equation:

The cut off frequency for this filter is

located at w0=1 rad/sec, so we should

scale it by wc=2pfc, being fc the

desired cut off frequency:

The basic construction for such a filter

is:

Figure 8: Second order low pass filter.

Calculating the transfer function of the

circuit in the Laplace domain:

Now calculating the L and C values:

These equations show that the induc-

tor and capacitor values depend on

the loudspeaker impedance. Therefore

it is recommendable to have a switch

to choose between 4 or 8 Ohms. This

means that the inductor should have 2

windings in series, so the switch will

select the first winding for the low

inductance (and low impedance loud-

speaker) or both windings for the high

inductance filter.

Depending on the polarity of the

amplifier voltage supply (bipolar Vcc

or simple +Vcc) the output filter

should be implemented accordingly, as

shown in the following scheme:

Figure 10: Double inductor filter for simple

supply.

These equations and figures derive a

table with capacitance and inductance

values for several cut off frequencies

and loudspeaker impedance values.

fc (kHz) R (Ohm) L (H) L Half (H) C (F)

20 4 45 23 1.41

25 4 36 18 1.13

30 4 30 15 0.94

50 4 18 9 0.56

20 8 90 45 0.70

25 8 72 36 0.56

30 8 60 30 0.47

50 8 36 18 0.28

Figure 9: Simple filter with bipolar supply.

Figure 10: Double inductor filter for simple supply.

Core type AL (nH/T

2

) eff

TN13/5-3C20-A40 40 15% 90

TN13/5-3C20-A56 56 15% 125

TN13/5-3C20-A67 67 15% 147

TN13/5-3C20-A72 72 15% 160

TN13/5-3C20-A79 79 15% 173

Core type AL (nH/T

2

) eff

TN20/6.4-3C20-A68 68 15% 125

TN20/6.4-3C20-A81 81 15% 147

TN20/6.4-3C20-A87 87 15% 160

TN20/6.4-3C20-A96 96 15% 173

TN20/6.4-3C20-A109 109 15% 200

Core type AL (nH/T

2

) eff

TN17/6.4-3C20-A52 52 15% 90

TN17/6.4-3C20-A72 72 15% 125

TN17/6.4-3C20-A88 88 15% 147

TN17/6.4-3C20-A92 92 15% 160

TN17/6.4-3C20-A104 104 15% 173

Core type AL (nH/T

2

) eff

TN23/7.5-3C20-A65 65 15% 90

TN23/7.5-3C20-A90 90 15% 125

TN23/7.5-3C20-A106 106 15% 147

TN23/7.5-3C20-A115 115 15% 160

TN23/7.5-3C20-A124 124 15% 173

Core type AL (nH/T

2

) eff

TN26/11-3C20-A113 113 15% 90

TN26/11-3C20-A157 157 15% 125

TN26/11-3C20-A185 185 15% 147

TN26/11-3C20-A201 201 15% 160

TN26/11-3C20-A217 217 15% 173

Product range and

specifications

The cores are coated with Polyamide

11 (PA11), flame retardant in accor-

dance with UL94V-2, UL file number

E45228 (M).The inner and outer diam-

eters apply to the coated toroid.

Contacts are applied on the edge of

the toroid for isolation voltage test,

which is also the critical point for the

winding operation.

Core type

TN13/7.5/5 13 6.6 5.4 2.46 368 30.1 12.2 1.8 1500

TN17/11/6.4 17.5 9.9 6.85 2.24 787 42.0 42 3.7 1500

TN20/10/6.4 20.6 9.2 6.85 1.43 1330 43.6 43.6 6.9 2000

TN23/14/7.5 24 13 8.1 1.69 1845 55.8 55.8 9.0 2000

TN26/15/11 26.8 13.5 11.6 0.982 3700 60.1 60.1 19 2000

Outer

diameter

D (mm)

Inner

diameter

d (mm)

Core

factor

(mm

-1

)

Effective

volume

(mm

3

)

Effective

length

(mm)

Effective

area

(mm

2

)

Isolation

voltage

(V)

Mass

(g)

Height

H (mm)

Dimensions (mm) Effective parameters Other

Australia: Contact Ferroxcube Taiwan

Tel. +886 2 86650099, Fax: +886 2 86650145

Austria: Contact Ferroxcube Germany

Tel: +49 (040) 527 28 305, Fax: +49 (040) 527 28 306

Benelux: Contact Ferroxcube Germany

Tel: +49 (040) 527 28 302, Fax: +49 (040) 527 28 306

Bosnia: Contact Ferroxcube Italy

Tel: +39 02 241131 1 , Fax: +39 02 241131 11

Brazil: Richardson Electronics, Sao Paulo

Tel: +55 11 3845 6199, Fax: +55 11 3845 6199

Richardson Electronics, Rio de Janeiro

Tel: +55 21 521 4004, Fax: +55 21 521 5193

Canada east: Contact Ferroxcube USA

Tel: +1 978 579 7932, Fax: +1 978 579 9457

China: Ferroxcube Hong Kong

Tel: +852 2319 2740, Fax: +852 2319 2757

Ferroxcube South of China

Tel: +86 769 7382420, Fax: +86 769 7339561

Ferroxcube Suzhou

Tel: +86 512 68095048, Fax: +86 512 68097128

Colombia: Richardson Electronics

Tel: +57 1 636 1028, Fax: +57 1 636 1005

Croatia: Contact Ferroxcube Italy

Tel: +39 02 241131 1 , Fax: +39 02 241131 11

Czech Republic: Contact Ferroxcube Poland

Tel: +48 46 834 00 07, Fax: +48 46 834 00 35

Denmark: Contact Ferroxcube Sweden

Tel: +46 8 580 119 74, Fax: +46 8 580 121 60

Finland: Contact Ferroxcube Sweden

Tel: +46 8 580 119 74, Fax: +46 8 580 121 60

France: Ferroxcube France, NANTERRE

Tel: +33 (01) 5551 8422, Fax: +33 (01) 5551 8423

Germany: Ferroxcube Germany, HAMBURG

Tel: +49 (040) 527 28 302, Fax: +49 (040) 527 28 306

Greece: Contact Ferroxcube Italy

Tel: +39 02 241131 1 , Fax: +39 02 241131 11

Hungary: Contact Ferroxcube Poland

Tel: +48 46 834 00 07, Fax: +48 46 834 00 35

Indonesia: Contact Ferroxcube Singapore

Tel: +65 6244 7815, Fax: +65 6449 0446

Ireland: Contact Ferroxcube UK

Tel: +44 1706 830723, Fax: +44 1706 222638

Israel: Arrow\Rapac Ltd., PETACH TIKVA

Tel: +972 3 9203480, Fax: +972 3 9203443

Italy: Ferroxcube Italy, SESTO S. GIOVANNI (MI)

Tel: +39 02 241131 1 , Fax: +39 02 241131 11

Korea: Contact Ferroxcube Taiwan

Tel. +886 2 86650099, Fax: +886 2 86650145

Malaysia: Contact Ferroxcube Singapore

Tel: +65 6244 7815, Fax: +65 6449 0446

Mexico (excl. Baja): R.V. Componentes, Guadalajara, MX

Tel: +52 33 3641 9595, Fax: +52 33 3641 9898

Mexico (Baja): Contact Ferroxcube USA

Tel: +1 619 207 0061, Fax: +1 619 207 0062

New Zealand: Contact Ferroxcube Taiwan

Tel. +886 2 86650099, Fax: +886 2 86650145

Norway: Contact Ferroxcube Sweden

Tel: +46 8 580 119 74, Fax: +46 8 580 121 60

Philippines: Contact Ferroxcube Singapore

Tel: +65 6244 7815, Fax: +65 6449 0446

Poland: Ferroxcube Polska, SKIERNIEWICE

Tel: +48 46 834 00 07, Fax: +48 46 834 00 35

Portugal: Contact Hispano Ferritas, Spain

Tel: +34 (949) 247 153, Fax: +34 (949) 247 146

Serbia and Montenegro: Contact Ferroxcube Italy

Tel: +39 02 241131 1 , Fax: +39 02 241131 11

Singapore: Ferroxcube Singapore, SINGAPORE

Tel: +65 6244 7815, Fax: +65 6449 0446

Slovak Republic: Contact Ferroxcube Poland

Tel: +48 46 834 00 07, Fax: +48 46 834 00 35

Slovenia: Contact Ferroxcube Italy

Tel: +39 02 241131 1 , Fax: +39 02 241131 11

South-Africa: Contact Ferroxcube UK

Tel: +44 1706 830723, Fax: +44 1706 222638

Spain: Hispano Ferritas, GUADALAJARA

Tel: +34 (949) 247 153, Fax: +34 (949) 247 146

Sweden: Ferroxcube Sweden, JRFLLA

Tel: +46 8 580 119 74, Fax: +46 8 580 121 60

Switzerland: Contact Ferroxcube Germany

Tel: +49 (040) 527 28 305, Fax: +49 (040) 527 28 306

Taiwan: Ferroxcube Taiwan, TAIPEI

Tel. +886 2 86650099, Fax: +886 2 86650145

Turkey: Contact Ferroxcube Italy

Tel: +39 02 241131 1 , Fax: +39 02 241131 11

United Kingdom: Ferroxcube UK, CROYDON

Tel: +44 870 2418759, Fax: +44 870 2418761

United States: Ferroxcube USA, EL PASO (TX)

Tel: +1 915 599 2513/2328, Fax: +1 915 599 2555

For all other countries apply to closest regional sales office:

HAMBURG, Germany

Tel: +49 (040) 527 28 302, Fax: +49 (040) 527 28 306

e-mail: saleseurope@ferroxcube.com

EL PASO (TX), USA

Tel: +1 915 599 2513/2328, Fax: +1 915 599 2555

e-mail: salesusa@ferroxcube.com

TAIPEI, Taiwan

Tel. +886 2 86650099, Fax: +886 2 86650145

e-mail: salesasia@ferroxcube.com

Ferroxcube International Holding B.V. 2006

All rights are reserved. Reproduction in whole or in part is prohibited without the prior written consent of the copyright owner. The

information presented in this document does not form part of any quotation or contract, is believed to be accurate and reliable

and may be changed without notice. No liability will be accepted by the publisher for any consequence of its use. Publication the-

reof does not convey nor imply any license under patent- or other industrial or intellectual property rights.

Visit our web-site for the latest information on new products, application info

as well as updated phone- and fax numbers

Internet: www.ferroxcube.com

Printed in Spain 9930 030 00011 Date of Release: October 2006

FERROXCUBE - your global partner

www.ferroxcube.com

You might also like

- 200W Leach AmpDocument12 pages200W Leach AmpАлексей Андрияш100% (1)

- IRS2092 Stereo AmplifierDocument10 pagesIRS2092 Stereo AmplifierLuiz Clemente PimentaNo ratings yet

- 900W Class-D Next Generation Power Amplifier - Class D Amplifier CircuitDocument5 pages900W Class-D Next Generation Power Amplifier - Class D Amplifier CircuitK. RAJA SEKAR50% (2)

- 1500watts Power Amp.Document27 pages1500watts Power Amp.Dinah Nicole88% (16)

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsFrom EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsRating: 4 out of 5 stars4/5 (1)

- Shaper Gear CuttingDocument4 pagesShaper Gear Cuttingnevadablue100% (4)

- Transistor Switching and Sequential CircuitsFrom EverandTransistor Switching and Sequential CircuitsRating: 5 out of 5 stars5/5 (1)

- Class D Tutorial 606Document51 pagesClass D Tutorial 606luizcpimenta100% (1)

- Iraudamp6: 250W/8 X 2 Channel Class D Audio Power Amplifier Using The IRS20957S and IRF6785Document46 pagesIraudamp6: 250W/8 X 2 Channel Class D Audio Power Amplifier Using The IRS20957S and IRF6785jean grangeonNo ratings yet

- 600 Watt Mosfet Power Amplifier With PCBDocument3 pages600 Watt Mosfet Power Amplifier With PCBkirgar1No ratings yet

- Design and Prototyping Methods For Brushless Motors and Motor ControlDocument135 pagesDesign and Prototyping Methods For Brushless Motors and Motor Controlscardig0% (1)

- Yamaha xp7000 5000 Power Amplifier Service Manual PDFDocument92 pagesYamaha xp7000 5000 Power Amplifier Service Manual PDFRomlly Voice Elektro100% (3)

- 25 Permanent Magnet Motor Design PDFDocument39 pages25 Permanent Magnet Motor Design PDFbitconcepts60% (5)

- 300 Watt MOSFET Real HI-FI Power AmplifierDocument3 pages300 Watt MOSFET Real HI-FI Power AmplifierMiguel MejíaNo ratings yet

- 1000W Driver Power Amplifier Namec TEF - Electronic CircuitDocument3 pages1000W Driver Power Amplifier Namec TEF - Electronic CircuitK Raja SekarNo ratings yet

- Gemini - Amplifier XPM-600, 900, 1200 - Service ManualDocument24 pagesGemini - Amplifier XPM-600, 900, 1200 - Service Manualapi-371104550% (2)

- Circuit Power Audio Amplifier Stereo With TDA7293Document5 pagesCircuit Power Audio Amplifier Stereo With TDA7293Trường LongNo ratings yet

- 70 Watt MOSFET Audio AmplifierDocument5 pages70 Watt MOSFET Audio AmplifierJuan Sánchez LópezNo ratings yet

- 10A 70V SMPS For Power Amplifier - Electronic CircuitDocument2 pages10A 70V SMPS For Power Amplifier - Electronic CircuitK Raja SekarNo ratings yet

- Class D Tutorial 2Document17 pagesClass D Tutorial 2អំភ្លី សំលេង100% (1)

- Hi Fi Audio AmplifiersDocument90 pagesHi Fi Audio AmplifiersReagan92% (12)

- DK Tech PCB Audio Power Amplifier - Power Amp Part IIDocument9 pagesDK Tech PCB Audio Power Amplifier - Power Amp Part IIRene100% (1)

- 4500W High Power Class D Amplifier D4K5 Electronic CircuitDocument4 pages4500W High Power Class D Amplifier D4K5 Electronic CircuitK. RAJA SEKAR50% (2)

- 500 Watt AmplifierDocument2 pages500 Watt AmplifierIslami Punjabi Bayan SM Hadi0% (1)

- Class D Audio AmplifierDocument11 pagesClass D Audio AmplifierHenry Pal100% (1)

- JBL Class D Training WorkbookDocument24 pagesJBL Class D Training WorkbookGerardo Mendez CamarilloNo ratings yet

- D1KPro Schematic Ver.4aDocument2 pagesD1KPro Schematic Ver.4aWahyudi100% (2)

- First Watt F1 Service ManualDocument14 pagesFirst Watt F1 Service ManualasenmtNo ratings yet

- 1000w 2 Ohms Audio Power Amp r2 HDF X 2012 Rev 1.1Document7 pages1000w 2 Ohms Audio Power Amp r2 HDF X 2012 Rev 1.1Erwin MusliminNo ratings yet

- Class D Amplifier With Maximum Power Adjustable From 20W To 300WDocument13 pagesClass D Amplifier With Maximum Power Adjustable From 20W To 300Wramontv032428100% (1)

- Peavey-CS3000 - 4000 - 4080 AmpDocument7 pagesPeavey-CS3000 - 4000 - 4080 AmpJohnny Tenezaca DuarteNo ratings yet

- A HiFi Power AmpDocument15 pagesA HiFi Power AmpCopil Dement100% (4)

- Technics SAAX 54 SchematicsDocument11 pagesTechnics SAAX 54 Schematicsarmas1No ratings yet

- LYNX Audio Amplifier 275W 4 OhmiDocument11 pagesLYNX Audio Amplifier 275W 4 OhmiDanut777750% (2)

- Mitrc Refresher Answer Key Acoustics & BroadcastingDocument12 pagesMitrc Refresher Answer Key Acoustics & Broadcastingglenne gonzalesNo ratings yet

- High Quality Tone Control Circuit by Transistor Low NoiseDocument17 pagesHigh Quality Tone Control Circuit by Transistor Low NoiseJavier Güerino Palacios100% (1)

- ACCESSIBILITYDocument6 pagesACCESSIBILITYHarsh MandloiNo ratings yet

- Commands 3g 4G EricssonDocument8 pagesCommands 3g 4G EricssonSheyson Sanchez SuarezNo ratings yet

- High Power Switching Audio Power Amplifier With Symmetrical Topology and Digital ControlDocument3 pagesHigh Power Switching Audio Power Amplifier With Symmetrical Topology and Digital ControlPéter PAPPNo ratings yet

- 500w Car Audio Amplifier Circuit DiagramDocument39 pages500w Car Audio Amplifier Circuit DiagrammpcdfNo ratings yet

- Pioneer PWB 101Document4 pagesPioneer PWB 101elbocinero100% (1)

- 120 W X 2 Channel Class D Audio Power Amplifier Using IRS20955 and IRF6645Document43 pages120 W X 2 Channel Class D Audio Power Amplifier Using IRS20955 and IRF6645Domingo ArroyoNo ratings yet

- High Power Amplifier Matrix 1.4 - Electronic CircuitDocument5 pagesHigh Power Amplifier Matrix 1.4 - Electronic CircuitK Raja SekarNo ratings yet

- M.silverstein Power AmpDocument8 pagesM.silverstein Power AmpManny Silverstein100% (1)

- Ca 20Document5 pagesCa 20jhon130296No ratings yet

- 8 - Band - Stereo - Equalizer - PDF Filename UTF-8''8 Band Stereo EqualizerDocument14 pages8 - Band - Stereo - Equalizer - PDF Filename UTF-8''8 Band Stereo EqualizerAsmar Toussaint100% (1)

- Uppen FP 2200 PWR SMDocument49 pagesUppen FP 2200 PWR SMcoolruler40No ratings yet

- Speakers CircuitDocument3 pagesSpeakers CircuitSantosh TalankarNo ratings yet

- Class D AmplifierDocument5 pagesClass D AmplifierkothuraNo ratings yet

- 6n1 SPK Prot Rev 1.2B - With Basic Function How It WorksDocument34 pages6n1 SPK Prot Rev 1.2B - With Basic Function How It Worksអំភ្លី សំលេងNo ratings yet

- Ahuja SSA-250M Specifications & FeaturesDocument1 pageAhuja SSA-250M Specifications & Featuressecurekart50% (2)

- DIYAudio DIYAB Honey Badger Build Guide v1.0Document30 pagesDIYAudio DIYAB Honey Badger Build Guide v1.0Danh Pro100% (1)

- (Rlva) 1000w 2 Ohms Audio Power Amp r2 Rlva Se1 2012 Rev 1Document7 pages(Rlva) 1000w 2 Ohms Audio Power Amp r2 Rlva Se1 2012 Rev 1adirsom100% (1)

- Amplificador de 1000 Watts RMS para Montar. - Áudio e EletrônicaDocument2 pagesAmplificador de 1000 Watts RMS para Montar. - Áudio e EletrônicaK Raja SekarNo ratings yet

- Hafler p7000 Power Amplifier Service ManualDocument24 pagesHafler p7000 Power Amplifier Service ManualRomlly Voice ElektroNo ratings yet

- 1.7 KW 2 Single Channel Class D Audio Power Amplifier Using The IRS2092S and IRFB4227 1422001499Document39 pages1.7 KW 2 Single Channel Class D Audio Power Amplifier Using The IRS2092S and IRFB4227 1422001499Viorel Aldea0% (1)

- Here Are Many Applications For A Small, Adjust-: Active, Adjustable Audio Band-Pass FilterDocument9 pagesHere Are Many Applications For A Small, Adjust-: Active, Adjustable Audio Band-Pass FilterYuda AditamaNo ratings yet

- DIY Stereo Yiroshi Power Amplifier 1400W - Electronic CircuitDocument6 pagesDIY Stereo Yiroshi Power Amplifier 1400W - Electronic CircuitK Raja Sekar100% (3)

- Irs2092 25W 500WDocument42 pagesIrs2092 25W 500WKien TrungNo ratings yet

- BU120 - HTS-20revJ SM PDFDocument35 pagesBU120 - HTS-20revJ SM PDFcoolruler40100% (1)

- Power AmplifierDocument6 pagesPower AmplifierYen Hugo MirtoNo ratings yet

- Screwthread Standards For Federal ServicesDocument12 pagesScrewthread Standards For Federal Servicesikaro181083No ratings yet

- Screwthread Standards For Federal ServicesDocument12 pagesScrewthread Standards For Federal Servicesikaro181083No ratings yet

- High Speed Calorimeter: InstrumentDocument2 pagesHigh Speed Calorimeter: Instrumentikaro181083No ratings yet

- High Speed Calorimeter: InstrumentDocument2 pagesHigh Speed Calorimeter: Instrumentikaro181083No ratings yet

- High Speed Calorimeter: InstrumentDocument2 pagesHigh Speed Calorimeter: Instrumentikaro181083No ratings yet

- Screwthread Standards For Federal ServicesDocument12 pagesScrewthread Standards For Federal Servicesikaro181083No ratings yet

- Screwthread Standards For Federal ServicesDocument12 pagesScrewthread Standards For Federal Servicesikaro181083No ratings yet

- 060 John Petro Final PaperDocument12 pages060 John Petro Final Paperikaro181083No ratings yet

- Screwthread Standards For Federal ServicesDocument12 pagesScrewthread Standards For Federal Servicesikaro181083No ratings yet

- Thermoelectricity: Lessons in Electric Circuits, Volume 1, Chapter 9: "Electrical Instrumentation Signals"Document3 pagesThermoelectricity: Lessons in Electric Circuits, Volume 1, Chapter 9: "Electrical Instrumentation Signals"ikaro181083No ratings yet

- Stepper MotorsDocument3 pagesStepper Motorsikaro181083100% (1)

- The USB CNC Project Ported - Country LaboratoryDocument9 pagesThe USB CNC Project Ported - Country Laboratoryikaro181083100% (1)

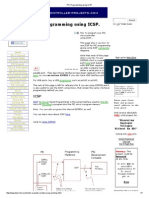

- PIC Programming Using ICSPDocument7 pagesPIC Programming Using ICSPikaro181083100% (1)

- PC Power Supply Repair Magazine Article 1996 WW PDFDocument4 pagesPC Power Supply Repair Magazine Article 1996 WW PDFAnthony GonzalesNo ratings yet

- ADC Value Sent On USB - Country LaboratoryDocument6 pagesADC Value Sent On USB - Country Laboratoryikaro181083No ratings yet

- Windmill Controller Logger Shield - Country LaboratoryDocument3 pagesWindmill Controller Logger Shield - Country Laboratoryikaro181083No ratings yet

- 4-Wire Resistance Measurement - DC CircuitsDocument4 pages4-Wire Resistance Measurement - DC Circuitsikaro181083100% (1)

- Automotive Alternator - Ac CircuitsDocument7 pagesAutomotive Alternator - Ac Circuitsikaro181083No ratings yet

- 11 SimonDocument7 pages11 Simonikaro181083No ratings yet

- Principles of Sigma-Delta Modulation For Analog-To-Digital ConvertersDocument71 pagesPrinciples of Sigma-Delta Modulation For Analog-To-Digital ConvertersGonzalo GarateguyNo ratings yet

- X Ray TestingDocument24 pagesX Ray Testingapi-27176519100% (6)

- Principles of Sigma-Delta Modulation For Analog-To-Digital ConvertersDocument71 pagesPrinciples of Sigma-Delta Modulation For Analog-To-Digital ConvertersGonzalo GarateguyNo ratings yet

- X Ray TestingDocument24 pagesX Ray Testingapi-27176519100% (6)

- MM74C00 - MM74C02 - MM74C04 Quad 2-Input NAND Gate - Quad 2-Input NOR Gate - Hex InverterDocument6 pagesMM74C00 - MM74C02 - MM74C04 Quad 2-Input NAND Gate - Quad 2-Input NOR Gate - Hex InverterPragnesh Hasmukhbhai GajjarNo ratings yet

- Datasheet Tip141Document4 pagesDatasheet Tip141ikaro181083No ratings yet

- TBAV70: Low Power Signal DiodesDocument4 pagesTBAV70: Low Power Signal Diodesikaro181083No ratings yet

- KA258/KA258A, KA358/KA358A, KA2904: Dual Operational AmplifierDocument12 pagesKA258/KA258A, KA358/KA358A, KA2904: Dual Operational Amplifierikaro181083No ratings yet

- Samsung GT-S5670 Galaxy Fit 08 Level 3 Repair - Block, PCB Diagam, Flow Chart of Troubleshooting PDFDocument56 pagesSamsung GT-S5670 Galaxy Fit 08 Level 3 Repair - Block, PCB Diagam, Flow Chart of Troubleshooting PDFAnonymous z9TtHkEaNo ratings yet

- Cleaning The EOS 5D MKII ViewfinderDocument21 pagesCleaning The EOS 5D MKII Viewfinderdeep42No ratings yet

- Internship Report of Muhammad Shehzad NadeemDocument16 pagesInternship Report of Muhammad Shehzad NadeemBilal Ali KhanNo ratings yet

- BF 246 ADocument5 pagesBF 246 ARey TiburonNo ratings yet

- Dliterx - 2 - 4 - Manuel en de FR Es It Ru PDFDocument131 pagesDliterx - 2 - 4 - Manuel en de FR Es It Ru PDFCatalin HoratiuNo ratings yet

- Projectmix Io User GuideDocument45 pagesProjectmix Io User GuideVincent Pellerin100% (1)

- Owner's Manual: DRM Digital Receiver DR111Document26 pagesOwner's Manual: DRM Digital Receiver DR111Nikolai PautovNo ratings yet

- Automatic Temperature ControllerDocument5 pagesAutomatic Temperature ControllerRaagha VigneshNo ratings yet

- Icom IC-F5400D OpS MAnDocument189 pagesIcom IC-F5400D OpS MAnMikeNo ratings yet

- HUAWEI U8860 SchematicDocument40 pagesHUAWEI U8860 Schematicausper01No ratings yet

- VT-4018Document39 pagesVT-4018Serp1972No ratings yet

- Turkcell U900 Trial Project Wireless Solution ApplicationDocument25 pagesTurkcell U900 Trial Project Wireless Solution ApplicationSangwani NyirendaNo ratings yet

- DCD 710aeDocument2 pagesDCD 710aearsmiataNo ratings yet

- Raised Cosine FilterDocument4 pagesRaised Cosine Filterneverdielv2No ratings yet

- Table of Electrical SymbolsDocument9 pagesTable of Electrical SymbolsmajaneNo ratings yet

- 3GPP Frequency Paramenter CalculationDocument13 pages3GPP Frequency Paramenter CalculationmamunNSN100% (1)

- Impulse: Operation ManualDocument8 pagesImpulse: Operation ManualRonggo SukmoNo ratings yet

- Electronic System Design LabDocument25 pagesElectronic System Design Labsramiz_1987No ratings yet

- Data Sheet: CB-3-GDU-NF-13Document2 pagesData Sheet: CB-3-GDU-NF-13rizkyNo ratings yet

- Hex Inverting Schmitt TriggerDocument8 pagesHex Inverting Schmitt Triggersuhaila38No ratings yet

- Deskjet 9Xx Maintenance and TroubleshootingDocument8 pagesDeskjet 9Xx Maintenance and TroubleshootingLucas Suelen Isabela JoaquimNo ratings yet

- Abstract:: E.E Department Tatung Institute of TechnologyDocument4 pagesAbstract:: E.E Department Tatung Institute of TechnologyragvshahNo ratings yet

- Data SheetDocument8 pagesData SheetRucelle Chiong GarcianoNo ratings yet

- SystemDocument8 pagesSystemmappy396458100% (1)

- Service: LCD-TVDocument98 pagesService: LCD-TVIsidro MendozaNo ratings yet

- AD820A-Low Power FET-Input Op AmpDocument17 pagesAD820A-Low Power FET-Input Op AmpR4PH431No ratings yet

- Microcell CalibrationDocument10 pagesMicrocell Calibrationprabhu0487No ratings yet