Professional Documents

Culture Documents

Amercoat 3279 Datasheet

Uploaded by

mekag94Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Amercoat 3279 Datasheet

Uploaded by

mekag94Copyright:

Available Formats

March 2012

Revision of June 2011

DESCRIPTION High Temperature Modified Silicone Aluminum

PRINCIPAL CHARACTERISTICS Resistant to dry temperature up to 1000F

Applied on prepared steel, stainless steel, or inorganic zinc

Does not require a heat cure

High solids formulation

VOC Compliant

Temperature Resistance

* Product should be sprayed in a mist coat/full coat technique when applying over inorganic zinc primers.

COLOR AND GLOSS Aluminum

Semi-gloss

BASIC DATA

Volume solids 55% 3%

VOC 3.45 lbs/gal (415 g/L)

Recommended

Dry film thickness (per coat) 0.75 2.0 mils; (15 35 microns)

1 or 2 coats

Theoretical Spread Rate @ 1 mil dft 497 ft

2

/ gallon

Components 1

Shelf Life 2 years from date of manufacture

SURFACE PREPARATION

Steel Remove weld spatter, protrusions, and laminations in steel. Grind welds smooth in

accordance with NACE RP-0178. Round off sharp edges. Remove all surface con-

taminants, oil and grease in accordance with SSPC SP-1.

Abrasive blast with an angular abrasive to an SSPC SP-10 cleanliness or higher.

Achieve a surface profile of 1.0-1.5 mils. Apply Amercoat 3279 as soon as possible

to avoid rusting of blasted surfaces.

Stainless Steel Abrasive blast with a hard angular abrasive to achieve a uniform and dense anchor

profile of 1.0-1.5 mils.

Inorganic Zinc Surfaces Surface must be clean, dry and free of zinc salts. A mist coat / full coat application

technique may be required to prevent application bubbling.

ENVIRONMENTAL CONDITIONS

Ambient temperatures* 32F to 104F (0C to 40C)

Material temperatures 50F to 90F (10C to 32C)

Relative humidity 0 85%

Surface temperature 32F to 104F (0C to 40C) Surface temperature must remain at least 5F above the

dew point temperatures.

General air quality Area should be sheltered from airborne particulates and pollutants. Provide shelter to

prevent wind from affecting spray patterns.

AMERCOAT

3279

page 1/3

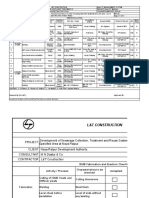

First coat Second Coat Temperature Resistance

Amercoat 3279

1.0 2.0 mils

N/A 1000F

Amercoat 3279

1.5 2.0 mils

Amercoat 3279

1.5 2.0 mils

750F

Dimetcote 9-series*

2.0 3.0 mils

Amercoat 3279

1.5 2.0 mils

750F

INSTRUCTIONS FOR USE

Mixing Mix with a pneumatic air mixing at moderate speeds to homogenize the container.

Airless spray 33:1 pump or larger, 0.017 fluid tip

Air spray Use a 2.0-2.6 mm fluid tip at approximately 40 psi fluid pressure. An agitated pressure

pot is recommended. Separate air and fluid regulators are essential. Ensure there is a

moisture and oil trap in the main air line.

Brush & roll Spray application is recommended as the best method to obtain a closed film within the

film thickness limits. Rolling may leave visible patterns in the film. A short nap, solvent

resistant roller is required.

Use a high quality natural bristle brush. Ensure brush is well loaded to avoid air entrain-

ment. Brush application is limited to small touch up areas of a few square inches.

Thinner Amercoat 65

Cleaning solvent Amercoat 12 Cleaner or Amercoat 65 thinner

Safety precautions For paint and recommended thinners see safety sheet 1430, 1431 and relevant material

safety data sheets

This is a solvent borne paint and care should be taken to avoid inhalation of spray mist

or vapor as well as contact between the wet paint and exposed skin or eyes.

DRY/CURE TIMES*

* Product is not designed for heavy mechanical abuse. Care should be taken during shipping and handling.

Make any necessary repairs prior to service. Coating film will become more durable after exposure to high

temperatures.

AVAILABILITY

Packaging Available in 1-gallon and 5-gallon units

Product codes SPEC3279 Amercoat 3279

Worldwide statement While it is always the aim of PPG Protective & Marine Coatings to supply the same product

on a worldwide basis, slight modification of the product is sometimes necessary to comply

with local or national rules/circumstances. Under these circumstances an alternative product

data sheet is used.

WARRANTY STATEMENT

PPG warrants (i) its title to the products, (ii) that the quality of the product(s) conform to PPGs specifications for such products

in effect at the time of manufacture and (iii) that the products shall be delivered free of the rightful claim of any third person for

infringement of any U.S. patent covering the products. THESE ARE THE ONLY WARRANTIES PPG MAKES AND ALL

OTHER EXPRESS OR IMPLIED WARRANTIES, UNDER STATUTE OR ARISING OTHERWISE IN LAW, FROM A COURSE

OF DEALING OR USAGE OF TRADE, INCLUDING WITHOUT LIMITATION, ANY OTHER WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE OR USE, ARE DISCLAIMED BY PPG.

AMERCOAT 3279

page 2/3

Temperature F/C 50/10 70/21 90/32

Dry to handle (hrs) 8 6 5

Dry to recoat (hrs) 3 2 1.5

Cure to high temperature

service (hrs)

7 10 13

Cure to mild abrasion resistance 48 24 16

Maximum recoat (days) Unlimited until heated above ambient conditions

page 3/3

AMERCOAT 3279

The information in this data sheet is based upon laboratory tests PPG believes to be accurate and is intended for guidance

only. PPG may modify the information contained herein at any time as a result of practical experience and continuous product

development. All recommendations or suggestions relating to the use of PPG products, whether in technical documentation, or

in response to a specific inquiry, or otherwise, are based on data, which to the best of PPGs knowledge, are reliable. The

products and information are designed for users having the requisite knowledge and industrial skills and it is the end-users

responsibility to determine the suitability of the product for its intended use.

PPG has no control over either the quality or condition of the substrate, or the many factors affecting the use and application of

the product. Therefore, PPG does not accept any liability arising from loss, injury or damage resulting from such use or the

contents of this data sheet (unless there are written agreements stating otherwise).

This data sheet supersedes all previous versions and it is the users responsibility to ensure that this data sheet is current prior

to using the product. The English text of this document shall prevail over any translation thereof.

LIMITATION OF LIABILITY

The information in this data sheet is based upon laboratory tests we believe to be accurate and is intended for guidance only. All

recommendations or suggestions relating to the use of the products made by PPG Protective & Marine Coatings, whether in

technical documentation, or in response to a specific enquiry, or otherwise, are based on data which to the best of our knowledge

are reliable. The products and information are designed for users having the requisite knowledge and industrial skills and it is the

end-users responsibility to determine the suitability of the product for its intended use.

PPG Protective & Marine Coatings has no control over either the quality or condition of the substrate, or the many factors affecting

the use and application of the product. PPG Protective & Marine Coatings does therefore not accept any liability arising from loss,

injury or damage resulting from such use or the contents of this data sheet (unless there are written stating otherwise).

The data contained herein are liable to modification as a result of practical experience and continuous product development.

This data sheet replaces and annuls all previous issues and it is therefore the users responsibility to ensure that this sheet is current

prior to using the product. The current data sheets are maintained at www.ppgpmc.com

The English text of this document shall prevail over any translation thereof.

You might also like

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Amercoat ABC 3Document0 pagesAmercoat ABC 3Stefano CostaNo ratings yet

- Dimetcote 9 PDS AIDocument3 pagesDimetcote 9 PDS AIAmer Y KNo ratings yet

- Product Data Sheet: DescriptionDocument4 pagesProduct Data Sheet: DescriptionJose Manuel Guizado SolisNo ratings yet

- Sigmafast 278Document4 pagesSigmafast 278MekhmanNo ratings yet

- Pds Sigmadcover 410Document4 pagesPds Sigmadcover 410sibi_s_rajNo ratings yet

- Sigmacover 410Document4 pagesSigmacover 410gstketutNo ratings yet

- Intertherm 838Document4 pagesIntertherm 838Ashta VakrNo ratings yet

- Interbond 600Document4 pagesInterbond 600Trịnh Minh KhoaNo ratings yet

- All DatasheetsDocument485 pagesAll Datasheetssflynn79No ratings yet

- Sigmazinc 109 HSDocument5 pagesSigmazinc 109 HSKrishna VachaNo ratings yet

- Formula 150 Primer (MILDTL-24441)Document4 pagesFormula 150 Primer (MILDTL-24441)Trịnh Minh KhoaNo ratings yet

- 00 6825 PDFDocument5 pages00 6825 PDFibrahim_mohamed3361100% (1)

- 7564 Sigmatherm 540Document2 pages7564 Sigmatherm 540Ibrahim MahranNo ratings yet

- 7102 - Sigma Vikote 63Document0 pages7102 - Sigma Vikote 63eraswastaNo ratings yet

- Sigmacover 522Document4 pagesSigmacover 522Asela BollegalaNo ratings yet

- Sigmacover 456: Description Principal CharacteristicsDocument5 pagesSigmacover 456: Description Principal Characteristicsmayukhguhanita2010No ratings yet

- Sigmaguard 720Document4 pagesSigmaguard 720Danny DurhamNo ratings yet

- Protective Coating-3Document0 pagesProtective Coating-3Sivaratnam NavatharanNo ratings yet

- Sigmarine 24: Description Principal CharacteristicsDocument3 pagesSigmarine 24: Description Principal CharacteristicsJose Antonio GomezNo ratings yet

- Intergard 986Document4 pagesIntergard 986Ashta VakrNo ratings yet

- Sigma PrimeDocument7 pagesSigma Primegstketut0% (1)

- Steelmaster 1200WF TDSDocument4 pagesSteelmaster 1200WF TDSSatish VishnubhotlaNo ratings yet

- Sigmacover 246Document5 pagesSigmacover 246Carlos Monsalve VejarNo ratings yet

- TDS 678 Resist+78 Euk GB PDFDocument5 pagesTDS 678 Resist+78 Euk GB PDFRyukiNo ratings yet

- FT - Amercoat 3279Document5 pagesFT - Amercoat 3279Rodrigo Sánchez BautistaNo ratings yet

- Intergard 475HS: Primed SurfacesDocument3 pagesIntergard 475HS: Primed SurfaceskareemNo ratings yet

- 7465 - Sigmacover 435Document0 pages7465 - Sigmacover 435eraswastaNo ratings yet

- 7-LINE® - 7-374 SERIES: Product Data SheetDocument5 pages7-LINE® - 7-374 SERIES: Product Data SheetJose Manuel Guizado SolisNo ratings yet

- Sigmadur 550Document4 pagesSigmadur 550gstketutNo ratings yet

- Amercoat® 878: Product Data SheetDocument5 pagesAmercoat® 878: Product Data Sheetabdelkader benabdallahNo ratings yet

- 7190 - Sigmarine 81Document0 pages7190 - Sigmarine 81eraswastaNo ratings yet

- Sigmacap PriCoat 155 V2Document3 pagesSigmacap PriCoat 155 V2ajuhaseenNo ratings yet

- Interprime 198 PDFDocument4 pagesInterprime 198 PDFandreaju2013No ratings yet

- Interbond 2340UPC Application Guidelines Rev 03 180321Document6 pagesInterbond 2340UPC Application Guidelines Rev 03 180321Kingsman 86No ratings yet

- Ultraconductive Coating: Conductive Coating For LSPDocument3 pagesUltraconductive Coating: Conductive Coating For LSPfaradaiNo ratings yet

- B22 7537 11-2006 Sigmadur 550Document4 pagesB22 7537 11-2006 Sigmadur 550Muhamad HassanNo ratings yet

- 7117 - Sigmarine 28Document0 pages7117 - Sigmarine 28eraswastaNo ratings yet

- Amercoat 471 Application May 08Document2 pagesAmercoat 471 Application May 08Biju_PottayilNo ratings yet

- Steel Master 1200 WFDocument4 pagesSteel Master 1200 WFshameelNo ratings yet

- Sigmacover 630 March 13Document6 pagesSigmacover 630 March 13leonciomavarezNo ratings yet

- PDS 7435 09-2005 Sigma Phenguard 935 (English)Document4 pagesPDS 7435 09-2005 Sigma Phenguard 935 (English)KyNo ratings yet

- 9 PDSDocument2 pages9 PDS전상문No ratings yet

- en-US 7000Document4 pagesen-US 7000Jose Manuel Guizado SolisNo ratings yet

- Sylgard 160Document3 pagesSylgard 160diogocNo ratings yet

- 7479 - Sigmacover 510Document0 pages7479 - Sigmacover 510eraswastaNo ratings yet

- Sigmatherm Thermovit 600 (HR)Document2 pagesSigmatherm Thermovit 600 (HR)shibushineNo ratings yet

- TDS 2280 Penguard+FC Euk GB PDFDocument5 pagesTDS 2280 Penguard+FC Euk GB PDFRyukiNo ratings yet

- Technical Data Sheet: Description MINIMUM SPREAD RATES (Mil Thickness)Document1 pageTechnical Data Sheet: Description MINIMUM SPREAD RATES (Mil Thickness)Karthik AnandanNo ratings yet

- HYSOL® FP4323 (ES4323) : Technical Data SheetDocument2 pagesHYSOL® FP4323 (ES4323) : Technical Data SheetAsad NaeemNo ratings yet

- Date Sheet For PaintingDocument5 pagesDate Sheet For PaintingAws MohamedNo ratings yet

- PDS 7618 11-2005 Sigmaline 445Document4 pagesPDS 7618 11-2005 Sigmaline 445Anonymous 613HTXNo ratings yet

- Interprime 160Document0 pagesInterprime 160Mehman NasibovNo ratings yet

- Theory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlFrom EverandTheory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlNo ratings yet

- Bottles, Preforms and Closures: A Design Guide for PET PackagingFrom EverandBottles, Preforms and Closures: A Design Guide for PET PackagingRating: 4.5 out of 5 stars4.5/5 (3)

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsFrom EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsRating: 3.5 out of 5 stars3.5/5 (14)

- Eddy Current Testing For Ferritic Weld InspectionDocument4 pagesEddy Current Testing For Ferritic Weld Inspectionmekag94No ratings yet

- Inspecting Inaccessible PipingDocument4 pagesInspecting Inaccessible Pipingmekag94No ratings yet

- AGA Cutting Aluminum Facts About UKDocument16 pagesAGA Cutting Aluminum Facts About UKmekag94No ratings yet

- DesuperheaterDocument5 pagesDesuperheaterKrishna KumarNo ratings yet

- Sapa Pipe and TubeTechnical Inserts June 2011Document10 pagesSapa Pipe and TubeTechnical Inserts June 2011mekag94No ratings yet

- AGA Cutting Aluminum Facts About UKDocument16 pagesAGA Cutting Aluminum Facts About UKmekag94No ratings yet

- Future Pipe InfoDocument29 pagesFuture Pipe Infomekag94No ratings yet

- Future Pipe InfoDocument29 pagesFuture Pipe Infomekag94No ratings yet

- Pickling HandbookDocument20 pagesPickling HandbookRhona100% (1)

- Avesta Pickling Gel PDFDocument2 pagesAvesta Pickling Gel PDFmekag94No ratings yet

- Ameron Dimetcote 9 PDS AIDocument3 pagesAmeron Dimetcote 9 PDS AImekag94No ratings yet

- The Death of Welding InspectorDocument1 pageThe Death of Welding Inspectormekag94100% (1)

- Cpar Characteristics and Functions Week 3Document128 pagesCpar Characteristics and Functions Week 3christianwood0117No ratings yet

- The First Voyage Round The World by MageDocument405 pagesThe First Voyage Round The World by MageGift Marieneth LopezNo ratings yet

- Income Tax and VATDocument498 pagesIncome Tax and VATshankar k.c.100% (2)

- RSC Article Template-Mss - DaltonDocument15 pagesRSC Article Template-Mss - DaltonIon BadeaNo ratings yet

- Prognostic Factors and Management of Patients With Choanal AtresiaDocument7 pagesPrognostic Factors and Management of Patients With Choanal Atresiafarah maulida martaNo ratings yet

- CRISTIAN COLCERIU - PERSONALITATI CLUJENE Prof - Dr.ing - POMPILIU MANEADocument21 pagesCRISTIAN COLCERIU - PERSONALITATI CLUJENE Prof - Dr.ing - POMPILIU MANEAcristian colceriu100% (2)

- Honda IzyDocument16 pagesHonda IzyTerry FordNo ratings yet

- The Comma Rules Conversion 15 SlidesDocument15 pagesThe Comma Rules Conversion 15 SlidesToh Choon HongNo ratings yet

- Oceanarium: Welcome To The Museum Press ReleaseDocument2 pagesOceanarium: Welcome To The Museum Press ReleaseCandlewick PressNo ratings yet

- Reflection On The PoorDocument5 pagesReflection On The Poorapi-347831792No ratings yet

- Introduction To HDLDocument28 pagesIntroduction To HDLBack UpNo ratings yet

- Akilas Mebrahtom ResumeDocument1 pageAkilas Mebrahtom ResumeAnonymous lLpBfQNo ratings yet

- ETNOBotanica NombresDocument188 pagesETNOBotanica Nombresjalepa_esNo ratings yet

- Case 3 SectionC Group 1 (Repaired)Document3 pagesCase 3 SectionC Group 1 (Repaired)SANDEEP AGRAWALNo ratings yet

- Measurement and Scaling Techniques1Document42 pagesMeasurement and Scaling Techniques1Ankush ChaudharyNo ratings yet

- Ancient Sumer Flip BookDocument9 pagesAncient Sumer Flip Bookapi-198624210No ratings yet

- Erosional VelocityDocument15 pagesErosional VelocityGary JonesNo ratings yet

- A2Document4 pagesA2Akshay KumarNo ratings yet

- Bubble Test Direct Pressure InserviceDocument3 pagesBubble Test Direct Pressure InserviceEdAlmNo ratings yet

- Camless EnginesDocument4 pagesCamless EnginesKavya M BhatNo ratings yet

- June 2017 (IAL) MS - Unit 1 Edexcel Physics A-LevelDocument16 pagesJune 2017 (IAL) MS - Unit 1 Edexcel Physics A-LevelNyraStardollNo ratings yet

- Ismb ItpDocument3 pagesIsmb ItpKumar AbhishekNo ratings yet

- Mathematics - Mathematics of Magic - A Study in Probability, Statistics, Strategy and Game Theory XDocument32 pagesMathematics - Mathematics of Magic - A Study in Probability, Statistics, Strategy and Game Theory XHarish HandNo ratings yet

- PGCRSM-01-BLOCK-03 Research Design ExperimentalDocument29 pagesPGCRSM-01-BLOCK-03 Research Design ExperimentalVijilan Parayil VijayanNo ratings yet

- Gujarat Urja Vikas Nigam LTD., Vadodara: Request For ProposalDocument18 pagesGujarat Urja Vikas Nigam LTD., Vadodara: Request For ProposalABCDNo ratings yet

- What You Need To Know About Your Drive TestDocument12 pagesWhat You Need To Know About Your Drive TestMorley MuseNo ratings yet

- Paul Wade - The Ultimate Isometrics Manual - Building Maximum Strength and Conditioning With Static Training-Dragon Door Publications (2020) - 120-146Document27 pagesPaul Wade - The Ultimate Isometrics Manual - Building Maximum Strength and Conditioning With Static Training-Dragon Door Publications (2020) - 120-146usman azharNo ratings yet

- Jpedal ManualDocument20 pagesJpedal ManualDamián DávilaNo ratings yet

- 1 PBDocument7 pages1 PBIndah Purnama TaraNo ratings yet

- Notice: Premerger Notification Waiting Periods Early TerminationsDocument5 pagesNotice: Premerger Notification Waiting Periods Early TerminationsJustia.comNo ratings yet