Professional Documents

Culture Documents

Data Sheet-DG Set - Rev 0

Uploaded by

jhakg_169712275Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Sheet-DG Set - Rev 0

Uploaded by

jhakg_169712275Copyright:

Available Formats

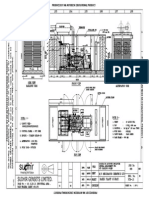

KJWW Engineering (I) Pvt. Ltd. Meghmani Organics Ltd.

Technical Data Sheet

1000KVA DG Set Chemical Plant at Dahej

SR. NO. 1 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 GENERAL Tag Nos. Rating Quantity Ambient Temperature Altitude Humidity Make of Alternator Make of Engine Make of AVR

DESCRIPTION

SPECIFIED

VENDOR DATA

DG-1 KVA No. Deg.C 1000 KVA ONE 45oC 90% * * * *

1.10 Make of Governor 2 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 Engine & Auxiliaries: Make, type and Model No. Continuous duty (yes/no) Nos. of stages Power Generated in BHP / KW Nos. & Arrangement of Cylinders Bore dia.(MM) Stroke length (MM) Swept Volume (CuM) (Displacement) Normal Clearance (MM)

* Yes at Variable load * * * * * * * * 1500 * * * * * Water cooled Radiator / Heat Exchanger Yes *

2.10 Nos. of Valves (suction / exhaust) 2.11 Rated RPM 2.12 Compression Ratio 2.13 Compression Pressure (PSI) 2.14 Maximum Cylinder Pressure (PSI) 2.15 Mechanical Efficiency 2.16 Thermal Efficiency 2.17 Type of Cylinder cooling System 2.18 Type of Fuel (HSD Yes/No) 2.19 Fuel consumption curve. 2.20 Specific Fuel Oil consumption under NTP (in Gms/BHP/Hr.) within 5% Tolerance (Vendor to guarantee above figures) a) b) c) 2.21 At full rated output ( ltr/hr) At 3/4th rated output (ltr/hr) At rated output

* * * * * * Required. As per BS 5514 with Class A1 Governing. * * * * Closed loop +ve pr. Inbuilt pump in engine. * * * * * 24V DC, Battery Start

1

d) At full rated out put but under site condition Fuel Injection Pressure a) b) Full rated Output (PSI) No Load (PSI)

2.22 Speed load characteristics. 2.23 Governor response time. 2.24 Flywheel a) b) c) d) Diameter (mm) Width of Rim (mm) Thickness of Rim (mm) Weight (approx.)

2.25 Lubrication system. 2.26 Specification of Lub Oil 2.27 Auxiliary Pump type / capacity 2.28 Main Pump type / capacity 2.29 Cyclic variation (cyl.Sec.) 2.30 Crankshaft ultimate tensile strength (PSI) 2.31 Method of Starting system

KJWW Engineering (I) Pvt. Ltd. Meghmani Organics Ltd.

Technical Data Sheet

1000KVA DG Set Chemical Plant at Dahej

SR.

DESCRIPTION

SPECIFIED * Less than 20 sec. * Yes As per BS 5514 with Class A1 Governing

VENDOR DATA

NO. 2.32 Nos. of Batteries with capacity 2.33 Time required for starting from cold (sec.) 2.34 Type of Governor & Model No. 2.35 Suitable for Parallel operation (yes / no) 2.36 Guranteed list of Governing Parmanent variation ---Full Load thrown on

---Full load thrown off 2.37 Total speed variation, which can be effected by hand speed regulating * gear 2.38 Safety controls, alarms and trips to be provided. 2.38 List of engine driven auxiliaries. 2.39 List of motor driven auxiliaries with motor ratings if any. 2.40 Engine Cooling system / Cooling Media 2.41 Cooling Water Circulation (CuM / hr.) 2.42 Cooling Water Inlet / Outlet Temp. (Deg. C) 2.43 Specification of Fuel recommended 2.44 Capacity of fuel day tank 2.45 Rated output at normal temp. & pressure as per BSS 649: 1958 2.46 Over Load for 1hr. at standard operation condition 2.47 Guranteed Lub oil consumption at full rated output (Lt/Hr) 2.48 Details of Standard Accy. Offered with the engine. 2.49 Time reqd. to pick up full speed & then synchronising with the system. See Note 6 and 7. * Fuel x Lube oil pump, pre lube oil pump. Cooling water pump & CT fan motor. * * * 990 1000 KVA 10% overload for 1hr, in every 12 hr. continuous running. * Fuel tank, bearing couple with seal. 2 min. approx.

3 3.1 3.2 3.3 3.4 3.5 3.6 3.7 3.8

Information about Alternator: Make Type Type of enclosure Frame size. Continuous rated output (KVA) and synchronous speed as per IS4722:2631 1000 KVA at site condition at NTP condition Rated KW at 0.8 PF Power Factor. Insulation Class. 1. 2. 3. Main Rotor Main Stator Exciter Stator Rotor Cores. * * * * 415 50 3 * * * * * H 800 0.8 (lagging) * * SPDP with IP-23

3.9

Temperature rise above design ambient temperature of 45C 1. 2. 3.

3.10 3.11

Nos. of RTDs in Winding and Bearings Rated voltage (Volts)

3.12 Rated Frequency(Hz) 3.13 No. of phases. 3.14 Full load current at 0.8 P.F. a) 10% overload capacity for hours. b) 50% overload capacity for seconds 3.16 Resistance in Ohms a) b) Main Stator Main Rotor 3.15 Current carrying capacity of AC winding in amps.

KJWW Engineering (I) Pvt. Ltd. Meghmani Organics Ltd.

Technical Data Sheet

1000KVA DG Set Chemical Plant at Dahej

SR. NO. c) d) Excitor Stator Excitor Rotor

DESCRIPTION *

SPECIFIED

VENDOR DATA

3.17 Type of AVR 3.18 Inherent voltage Regulation

* Solid state, electronic. As per IS 4722

3.19 Voltage regulation from no load to full load at Power Factor from 0.8 lag. 5% to unity with 4% speed regulation of engine. 3.20 Damper winding fitted on poles ( yes/no ). 3.21 Radial clearance between stator and rotor. 3.22 Critical speed of rotor. 3.23 Direction of rotation. 3.24 Bearing Type (DE and NDE) 3.25 Method of lubrication in Bearing 3.26 GD2 of rotating mass in diesel engine, A C generator. 3.27 Types and make of excitation unit. 3.28 Permanent Magnet Generator (PMG) Excitation (Yes / No) 3.29 Excitation at rated load and power factor 1. 2. 3.30 Field voltage Field amps. * * * * * * Yes * * Clockwise looked from engine Ball / roller Grease * * Yes

Efficiency curve and performance data 1. 2. 3. 4. 100% full load 75% full load 50% full load 25% full load

3.31 Efficiency at rated Voltage and 0.8 PF

* 3.32 Continuous maximum unbalanced current withstand shall be (BSS 2613) as Yes per Relevant Indian Standards. 3.33 Withstand time current value considering 3 phases and 1 phase short 3 sec. circuit at alternator terminals. 3.34 Maximum continuous Negative phase sequence Current 3.35 Short circuit ratio. 3.36 Winding connection. 3.37 Method of neutral grounding. 3.38 Method of cooling. 3.39 Weight of Generator (over all) (kgs) 3.40 Overall dimension (L x H X W) mm 3.41 Mounting 3.42 Terminal box arrangement 3.43 Shaft extension 3.44 Rotor weight 3.45 Stator Weight 3.46 GD square of Rotor 3.47 Transient performance * * Double layer lap Solidly grounded * * * Horizontal foot mounted On top NA * * *

* 3.48 Waveform Distortion at No Load * 3.49 Max. KW rating of the motor that can be started when AC generator is on * load, load and full load. 3.50 Telephonic harmonic 3.51 Voltage regulation 1. 3. Type Dead Band (if any ) 2. Burden of VR on CTs < 2% 5% * *

None 3.52 Maximum voltage dip /rise when full load is imposed or removed and * Recovery time to obtain rated voltage. 3.53 Starting Time from initiation to Alternator to ready to accept load 3.54 Time to restore voltage to within 3% of nominal for above condition 3.55 Calculated percentage reactances

3

* * *

KJWW Engineering (I) Pvt. Ltd. Meghmani Organics Ltd.

Technical Data Sheet

1000KVA DG Set Chemical Plant at Dahej

SR. NO. a) b) a) b) c) 3.56 synchronous reactance transient reactance

DESCRIPTION Xd Xd' Xd" Xo X2 * * * * *

SPECIFIED

VENDOR DATA

sub-transient reactance zero sequence reactance Negative sequence

Space heater rating. * 3.57 Capacity based on voltage regulation & based on over current along with * supporting calculations shall also be furnished. 4 PLC / Microprocessor based Control System (bidder to specify the availability of the following in their system & also to specify additional features if any).

4.1 Metering (shall display minimum following parameters): 4.1.1 Generator set 3 phase line to line voltage. 4.1.2 Generator set 3 phase line to neutral voltage. 4.1.3 Parallel bus voltage(3 phase / line to line). 4.1.4 Current (3 phase) 4.1.5 Power factor 4.1.6 KW 4.1.7 KWH 4.1.8 Alternator Frequency(Hz) 4.1.9 Parallel bus frequency 4.1.10 Winding and bearing temperature. 4.1.11 Engine running hour display 4.1.12 Engine RPM Display 4.1.13 System DC Voltage Display 4.1.14 % Rated Power 4.2 Engine Control: 4.2.1 Low Oil Pressure Alarm / Trip / Display 4.2.2 High Coolant Temp. Alarm / Trip / Display 4.2.3 Over speed Alarm / Trip 4.2.4 Over Crank Interlock 4.2.5 Cool Down Timer Alarm / Trip 4.2.6 Engine Cycle Cranking Operation 4.2.7 Engine Pre-glow indication 4.2.8 Engine Fuel Solenoid Control 4.2.9 Engine Starter Control 4.2.10 Engine Water Temp. Monitor 4.2.11 Day Tank Alarm 4.3 Protection of Alternator: 4.3.1 Overload Protection 4.3.2 IDMT Over Current & E/F Protection 4.3.3 Short Circuit Protection 4.3.4 Under Voltage & Over Voltage protection with time delay 4.3.5 Reverse Power Protection (Active & Reactive) 4.3.6 Loss of Excitation Protection 4.3.7 Under / Over Frequency Protection 4.3.8 Trip Circuit Supervision relay 4.3.9 Winging Temp. Protection & Indication 4.3.10 Bearing Temp. Protection & Indication 4.3.11 Phase Rotation Protection 4.4 AMF, Synchronising & Load Sharing: (this system shall be inclusive of all governor control, voltage regulation, AMF, synchronysing & load sharing control as requires for isolated bus & parallel application. Vendor to specify inclusion of the following). Any other components & accy. Etc. as required to complete the work. Required. Required. Required.

KJWW Engineering (I) Pvt. Ltd. Meghmani Organics Ltd.

Technical Data Sheet

1000KVA DG Set Chemical Plant at Dahej

SR. NO. 4.4.1 AMF facility 4.4.2 Dead Bus Logic 4.4.3 Auto synchronising 4.4.4 Active Load sharing 4.4.5 Reactive load sharing 4.4.6 Fail to synchronise 4.4.7 Failure to closure 4.4.8 Battery Monitoring system 4.4.9 Digital Alarm & status display 4.4.10 Starting Control system 4.4.11 Advance serviceability

DESCRIPTION

SPECIFIED

VENDOR DATA

At Present only AMF Feature Required

4.4.12 Voltage Regulation Performance 4.4.13 Run / Auto / Off switch 4.4.14 Emergency Stop Switch 4.4.15 History & Duty cycle Data 4.4.16 Communication Facility 5 5.1 5.2 5.3 Battery : Type & make of battery Nos. of batteries See Note 1 *

Amp. hour rating of battery (10 hr. rate) and charge and discharge * characteristic of battery. Engine Cum Alternator Control Panel Engine starting switch with key Gauge (150mm dia.) Or Electronic Display (LCD) Meters Alarms Trips Annunciator Panel and others Control Wiring SYNCHRONISING PANEL /BRACKET Erection & Commissioning First fill of oil + lubricants E & C - Spares + Consumables. REQUIRED SEE NOTE - 4 SEE NOTE - 5 SEE NOTE - 6 SEE NOTE - 7 SEE NOTE - 8 SEE NOTE - 9 Required Required * *

6 6.1 6.2 6.3 6.4 6.5 6.6 6.7 7 8

9 10 11 12 13

Spare Parts Make of Components OPERATIONS PHILOSOPHY VIBRATION ISOLATION PADS SILENCER

Required Required as per approved list As per Specification Required Residential Type / High rise including 30 mtr. Common chimney as per regulations of Local Pollution Control Board.

* * * * *

14 15 16 17 18 19 20 21 22

DUCTING WITH COMPENSATORS RADIATOR ROOM VENTILATION SYSTEM EARTHING CONDUCTOR ACCOUSTIC INSULATION OF D.G. SET SAMPLING OF OIL (PARA 4.4/4.5) COOLING TOWER FAN COOLING WATER CIRCULATION PUMP COOLING WATER PIPING ALL COOLING WATER PIPING FITTING

5

Required Not Required Not Required 2 Nos. 75 x 12 mm G.I. Required Not Required Required Required ERW-IS-1239 hearing. ANSI-B-16.5

* * * * * * * * *

KJWW Engineering (I) Pvt. Ltd. Meghmani Organics Ltd.

Technical Data Sheet

1000KVA DG Set Chemical Plant at Dahej

SR. NO.

DESCRIPTION VALVES, END CONNECTION ETC.

SPECIFIED AS PER ASTM

VENDOR DATA

NOTES : 1) 2) 3) 4) 5) BATTERY SHALL BE HEAVY DUTY LEAD ACID, SEALED MAINTENANCE FREE TYPE. COOLING SHALL BE CARRIED OUT THROUGH RADIATOR / HEAT EXCHANGER. BRUSHLESS, SELF EXCITED, SELF REGULATED WITH AUTOMATIC VOLTAGE REGULATOR GAUGES SHALL BE PROVIDED FOR PRESSURE GAUGE AND WATER TEMP. GAUGE FOR COOLING WATER INLET & OUTLET AT HEAT EXCHANGER. METERS SHALL BE PROVIDED FOR a) BATTERYCHARGER D.C.VOLTMETER WITH SELECTOR SWITCH d) BATTERY CHARGING D.C.AMMETER . 6) ALARMS SHALL BE PROVIDED FOR a) HIGH WATER TEMPERATURE ALARM b) ENGINE FAILS TO START ALARM. c) EMERGENCY STOP ALARM. d) OVERSPEED ALARM / TRIP. 7) TRIPPING CIRCUIT SHALL BE PROVIDED FOR a) LOW LUBE OIL PRESSURE c) ENGINE OVERSPEED 8) 9) 10) 11) 12) b) HIGH WATER TEMPERATURE d) HIGH OR LOW VOLTAGE. b) RUNNING HOUR INDICATOR c) RPM INDICATOR

12 WINDOWS ANNUNCIATOR SHALL BE PROVIDED TO SUIT SYSTEM REQUIREMENT FOR EACH SET. 2.5 sq.mm 650V GRADE PVC INSULATED COPPER WIRES SHALL BE USED FOR WIRING. ALL DATA OF APPROVED MAKE SHALL BE FURNISHED DURING OFFER STAGE ONLY. CONTROL PANEL SHALL BE SUITABLE FOR TERMINATION OF TPN, ALUMINIUM BUSDUCT OF 5000A RATING * - VENDOR TO SPECIFY.

You might also like

- Dynamometer: Theory and Application to Engine TestingFrom EverandDynamometer: Theory and Application to Engine TestingNo ratings yet

- Data Sheet-DG Set - Rev 0Document6 pagesData Sheet-DG Set - Rev 0jhakg_169712275No ratings yet

- Electric Motors Inspection ManualDocument40 pagesElectric Motors Inspection ManualEngr AbdurRahmanNo ratings yet

- Hydro TurbinesDocument17 pagesHydro TurbinesSavesh Tripathi100% (1)

- Hybrid Systems Based on Solid Oxide Fuel Cells: Modelling and DesignFrom EverandHybrid Systems Based on Solid Oxide Fuel Cells: Modelling and DesignNo ratings yet

- GT Operation (Nanjin)Document146 pagesGT Operation (Nanjin)Ady FardyNo ratings yet

- Rated Value by 10% As Per: "A Task Force Report" For Zero' HV Motor Failure in Tata Steel"Document5 pagesRated Value by 10% As Per: "A Task Force Report" For Zero' HV Motor Failure in Tata Steel"jagadish pradhanNo ratings yet

- Offshore Electrical EngineeringFrom EverandOffshore Electrical EngineeringRating: 3.5 out of 5 stars3.5/5 (5)

- 2 - 1!01!02 - Basic Operation Concept For Turbine and Auxiliary Plant - r00Document59 pages2 - 1!01!02 - Basic Operation Concept For Turbine and Auxiliary Plant - r00Tiara Noir100% (2)

- Worked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsFrom EverandWorked Examples in Electrical Machines and Drives: Applied Electricity and ElectronicsRating: 3 out of 5 stars3/5 (5)

- Technical Data Sheets - TurbineDocument19 pagesTechnical Data Sheets - Turbinepavankumar001No ratings yet

- Reozjc: Standard Features Ratings RangeDocument4 pagesReozjc: Standard Features Ratings RangePapi CruzNo ratings yet

- Model Predictive Control of High Power Converters and Industrial DrivesFrom EverandModel Predictive Control of High Power Converters and Industrial DrivesNo ratings yet

- 10P01 1a e 604 R00 - HCSD - Pump - MotorDocument17 pages10P01 1a e 604 R00 - HCSD - Pump - Motorsuleman247No ratings yet

- Power Systems-On-Chip: Practical Aspects of DesignFrom EverandPower Systems-On-Chip: Practical Aspects of DesignBruno AllardNo ratings yet

- 150RZGDocument4 pages150RZGJorge Andre Olivera Aranibar100% (1)

- Gerador A Gas PDFDocument4 pagesGerador A Gas PDFpaulo102030No ratings yet

- Kipor KDE2200,3500,5000,6500,6700E, X, T, TA Service ManualDocument44 pagesKipor KDE2200,3500,5000,6500,6700E, X, T, TA Service Manualmenderman100% (4)

- Kipor Diesel Gen Service ManualDocument44 pagesKipor Diesel Gen Service ManualSteven J Baynes86% (28)

- Case Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferFrom EverandCase Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferRating: 5 out of 5 stars5/5 (2)

- Saturn - Russia 12MW Gas TurbineDocument22 pagesSaturn - Russia 12MW Gas Turbinedndudc100% (1)

- Is 4722-2001Document23 pagesIs 4722-2001Saranya Sumi100% (3)

- Leega 350kvaDocument6 pagesLeega 350kvaBrown builderNo ratings yet

- RS 385SHDocument3 pagesRS 385SHshahpinkalNo ratings yet

- Da-6000ss (60H 110V)Document15 pagesDa-6000ss (60H 110V)Geiler Benitez PiñaNo ratings yet

- 491QEengine Service ManualDocument222 pages491QEengine Service ManualFabian Carrasco NaulaNo ratings yet

- Specifications: ModelDocument9 pagesSpecifications: ModelGeiler Benitez PiñaNo ratings yet

- Guidelines For Selection of Generator For SHPDocument44 pagesGuidelines For Selection of Generator For SHPrajfabNo ratings yet

- DG4LEDG6LEDocument38 pagesDG4LEDG6LEkinosiNo ratings yet

- Owner'S Manual: Air-Cooled Diesel Engine Generator Set Dg4Le / Dg6LeDocument40 pagesOwner'S Manual: Air-Cooled Diesel Engine Generator Set Dg4Le / Dg6LePedja BekicNo ratings yet

- C22 27ekw 60Hz Spec Sheet HEX OpenDocument4 pagesC22 27ekw 60Hz Spec Sheet HEX OpenEnrique Villamizar LaguadoNo ratings yet

- Taylor Power SystemsDocument4 pagesTaylor Power SystemsTeresa CarterNo ratings yet

- Olympiangep18 4Document4 pagesOlympiangep18 4macolorlopezNo ratings yet

- Safe Work Method of Statement For Testing and Commissioning of Diesel GeneratorsDocument9 pagesSafe Work Method of Statement For Testing and Commissioning of Diesel GeneratorsHumaid ShaikhNo ratings yet

- C4.4 58ekw 60Hz Spec Sheet KCDocument4 pagesC4.4 58ekw 60Hz Spec Sheet KCAnnabelle AnnaNo ratings yet

- Generator and Excitation SystemDocument43 pagesGenerator and Excitation Systemsandeep11789No ratings yet

- 1000 Kva 400v c32 Low BSFC PrimeDocument6 pages1000 Kva 400v c32 Low BSFC PrimeelipholebNo ratings yet

- IS 5422-Turbine Type Generator-Gen Spec PDFDocument15 pagesIS 5422-Turbine Type Generator-Gen Spec PDFmailbkraoNo ratings yet

- C4.4 86ekw 50Hz Spec Sheet HEXDocument4 pagesC4.4 86ekw 50Hz Spec Sheet HEXCésar PérezNo ratings yet

- CC Pump Manual Full OriginalDocument109 pagesCC Pump Manual Full OriginalKanphong.smNo ratings yet

- Kohler10RY g4064Document4 pagesKohler10RY g4064Bianka HernandezNo ratings yet

- 3612Document6 pages3612Chandrashekar PatigeNo ratings yet

- Datasheet TachogeneratorDocument4 pagesDatasheet TachogeneratorNurulHidayatNo ratings yet

- Presentation DG SetsDocument52 pagesPresentation DG SetsNageswar Makala100% (5)

- P60PBDocument4 pagesP60PBNiswatun Hida0% (1)

- GB T7064Document27 pagesGB T7064Julio B. HildebrandNo ratings yet

- Owner's Manual Model DG6LE Air-Cooled Diesel Engine Generator SetDocument34 pagesOwner's Manual Model DG6LE Air-Cooled Diesel Engine Generator SetmaocaleirlNo ratings yet

- Design Calculation: Larsen & Toubro Limited ECC Division - EDRCDocument16 pagesDesign Calculation: Larsen & Toubro Limited ECC Division - EDRCamit100% (1)

- Caterpillar C4.4DIT Generator SetDocument4 pagesCaterpillar C4.4DIT Generator SetAnom HarimurtiNo ratings yet

- CAT C7.1 Generator Set.: Image May Not Reflect Actual Generator Set OfferedDocument4 pagesCAT C7.1 Generator Set.: Image May Not Reflect Actual Generator Set OfferedMbah BroNo ratings yet

- Gearbox SelectionDocument4 pagesGearbox SelectionsanjushaNo ratings yet

- CAT C7.1 Generator Set.: Image May Not Reflect Actual Generator Set OfferedDocument4 pagesCAT C7.1 Generator Set.: Image May Not Reflect Actual Generator Set OfferedKo ZayNo ratings yet

- 500 KVA PrimeC15 Lean I6 - EUDocument6 pages500 KVA PrimeC15 Lean I6 - EUanon_46672526No ratings yet

- What Is VK and Imag IDocument4 pagesWhat Is VK and Imag Ijhakg_169712275No ratings yet

- Battery Sizing SheetDocument6 pagesBattery Sizing Sheetjhakg_1697122750% (1)

- CR4 - Thread - Knee Point Voltage and Current TransformersDocument3 pagesCR4 - Thread - Knee Point Voltage and Current Transformersjhakg_169712275No ratings yet

- 02 Earthing SystemsDocument113 pages02 Earthing SystemsRameez ZafarNo ratings yet

- Knee Point Voltage of Current Transformer PS Class - Electrical EngineeringDocument3 pagesKnee Point Voltage of Current Transformer PS Class - Electrical Engineeringjhakg_169712275No ratings yet

- SP 7 (2005) - National Building Code of India 2005 (Group 1 To 5)Document1,157 pagesSP 7 (2005) - National Building Code of India 2005 (Group 1 To 5)VIKRAM singhNo ratings yet

- DG Set Layout As Per MolDocument1 pageDG Set Layout As Per Moljhakg_169712275No ratings yet

- GETCO TendersDocument5 pagesGETCO Tendersjhakg_169712275No ratings yet

- Transformer DimensionsDocument1 pageTransformer Dimensionsjhakg_169712275No ratings yet

- FND (1010 Kva Rad Type SDG) Fcc-ModelDocument1 pageFND (1010 Kva Rad Type SDG) Fcc-Modeljhakg_169712275No ratings yet

- Item Wise Details of Vendor Registration With Registration No. and DateDocument20 pagesItem Wise Details of Vendor Registration With Registration No. and DatesunilgvoraNo ratings yet

- Current Carrying Capacity of BusbarsDocument8 pagesCurrent Carrying Capacity of Busbarsrasheed313No ratings yet

- Grid Standards RegDocument19 pagesGrid Standards RegEzhil Vendhan PalanisamyNo ratings yet

- Ga 1010 Kva Rad Std-ModelDocument1 pageGa 1010 Kva Rad Std-Modeljhakg_169712275No ratings yet

- Ugvcl HT Power Connection NormsDocument15 pagesUgvcl HT Power Connection Normsjhakg_169712275No ratings yet

- 30m.high Tower Steel Structure Detail-ModelDocument1 page30m.high Tower Steel Structure Detail-Modeljhakg_169712275No ratings yet

- 30m.high Tower Steel Structure Detail-ModelDocument1 page30m.high Tower Steel Structure Detail-Modeljhakg_169712275No ratings yet

- C-2.4.2 Electrical Design PhilosophyDocument29 pagesC-2.4.2 Electrical Design Philosophyjhakg_169712275No ratings yet

- 15 M Main Road LightingDocument8 pages15 M Main Road Lightingjhakg_169712275No ratings yet

- Philips Lamp Lumens DataDocument26 pagesPhilips Lamp Lumens Datajhakg_169712275No ratings yet

- INDIAN Steel TableDocument6 pagesINDIAN Steel TableKingshuk SarkarNo ratings yet

- Ugvcl HT Power Connection NormsDocument15 pagesUgvcl HT Power Connection Normsjhakg_169712275No ratings yet

- DG Set - Rev 0Document30 pagesDG Set - Rev 0jhakg_169712275No ratings yet

- Cable Schedule For GSPC REV P1Document8 pagesCable Schedule For GSPC REV P1jhakg_169712275No ratings yet

- Single-Ended Reflected Beam Smoke Detector: Applications GuideDocument9 pagesSingle-Ended Reflected Beam Smoke Detector: Applications GuideLuis Walter LeoneNo ratings yet

- Current Carrying Capacity of BusbarsDocument8 pagesCurrent Carrying Capacity of Busbarsrasheed313No ratings yet

- CR4 - Thread - Power Generator SizingDocument6 pagesCR4 - Thread - Power Generator Sizingjhakg_169712275No ratings yet

- Chapter 5 - CheerdanceDocument10 pagesChapter 5 - CheerdanceJoana CampoNo ratings yet

- Marion Nicoll: Life & Work by Catharine MastinDocument147 pagesMarion Nicoll: Life & Work by Catharine MastinArt Canada InstituteNo ratings yet

- GCP Vol 2 PDF (2022 Edition)Document548 pagesGCP Vol 2 PDF (2022 Edition)Sergio AlvaradoNo ratings yet

- RPH Week 31Document8 pagesRPH Week 31bbwowoNo ratings yet

- Liquitex Soft Body BookletDocument12 pagesLiquitex Soft Body Booklethello belloNo ratings yet

- Ancient Sumer Flip BookDocument9 pagesAncient Sumer Flip Bookapi-198624210No ratings yet

- EngHub How To Break HabitsDocument13 pagesEngHub How To Break HabitsViktoria NovikovaNo ratings yet

- Days Papers 2001Document341 pagesDays Papers 2001jorgefeitoza_hotmailNo ratings yet

- Existentialism in LiteratureDocument2 pagesExistentialism in LiteratureGirlhappy Romy100% (1)

- Xtype Power Train DTC SummariesDocument53 pagesXtype Power Train DTC Summariescardude45750No ratings yet

- Omnitron CatalogDocument180 pagesOmnitron Catalogjamal AlawsuNo ratings yet

- Rotating Equipment & ServiceDocument12 pagesRotating Equipment & Servicenurkasih119No ratings yet

- Green Dot ExtractDocument25 pagesGreen Dot ExtractAllen & UnwinNo ratings yet

- Dynalift Sed0804679lDocument1 pageDynalift Sed0804679lzaryab khanNo ratings yet

- Cultural Sensitivity BPIDocument25 pagesCultural Sensitivity BPIEmmel Solaiman AkmadNo ratings yet

- B. Inggris X - 7Document8 pagesB. Inggris X - 7KabardiantoNo ratings yet

- Exponential Smoothing - The State of The ArtDocument28 pagesExponential Smoothing - The State of The ArtproluvieslacusNo ratings yet

- Lesser Known Homoeopathic Medicines of Alopecia Areata.20200718115446Document9 pagesLesser Known Homoeopathic Medicines of Alopecia Areata.20200718115446BruntNo ratings yet

- Bossypants Autobiography and Womens SelvesDocument26 pagesBossypants Autobiography and Womens SelvesCamila Paz GutiérrezNo ratings yet

- At The Origins of Music AnalysisDocument228 pagesAt The Origins of Music Analysismmmahod100% (1)

- How To Add Attachment Using JAVA MappingDocument4 pagesHow To Add Attachment Using JAVA MappingmvrooyenNo ratings yet

- Boarding House Preferences by Middle Up Class Students in SurabayaDocument8 pagesBoarding House Preferences by Middle Up Class Students in Surabayaeditor ijeratNo ratings yet

- Measurement and Scaling Techniques1Document42 pagesMeasurement and Scaling Techniques1Ankush ChaudharyNo ratings yet

- Akilas Mebrahtom ResumeDocument1 pageAkilas Mebrahtom ResumeAnonymous lLpBfQNo ratings yet

- Embedded Systems Online TestingDocument6 pagesEmbedded Systems Online TestingPuspala ManojkumarNo ratings yet

- Enrile v. SalazarDocument26 pagesEnrile v. SalazarMaria Aerial AbawagNo ratings yet

- All India Civil Services Coaching Centre, Chennai - 28Document4 pagesAll India Civil Services Coaching Centre, Chennai - 28prakashNo ratings yet

- Muscles of The Dog 2: 2012 Martin Cake, Murdoch UniversityDocument11 pagesMuscles of The Dog 2: 2012 Martin Cake, Murdoch UniversityPiereNo ratings yet

- Lalit Resume-2023-LatestDocument2 pagesLalit Resume-2023-LatestDrew LadlowNo ratings yet

- Possessive Determiners: A. 1. A) B) C) 2. A) B) C) 3. A) B) C) 4. A) B) C) 5. A) B) C) 6. A) B) C) 7. A) B) C)Document1 pagePossessive Determiners: A. 1. A) B) C) 2. A) B) C) 3. A) B) C) 4. A) B) C) 5. A) B) C) 6. A) B) C) 7. A) B) C)Manuela Marques100% (1)