Professional Documents

Culture Documents

Art:10 1023/A:1014927129259

Uploaded by

Mihaela VladOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Art:10 1023/A:1014927129259

Uploaded by

Mihaela VladCopyright:

Available Formats

World Journal of Microbiology & Biotechnology 18: 271275, 2002. 2002 Kluwer Academic Publishers. Printed in the Netherlands.

271

Acetic acid production by Dekkera/Brettanomyces yeasts

S.N. Freer Fermentation Biochemistry Research Unit, National Center for Agricultural Utilization Research, USDA*, Agricultural Research Service, 1815 N. University Street, Peoria, IL 61604, USA Tel.: +1-309-6816472, Fax: +1-309-6816427, E-mail: freersn@ncaur.usda.gov

Received 4 September 2001; accepted 7 January 2002

Keywords: Acetic acid, Brettanomyces, Dekkera, ethanol

Summary Yeast belonging to the genera Brettanomyces and Dekkera are noted for spoiling cellar and bottled wine through the production of haze, turbidity and acetic acid. However, I was unable to nd information on the use of these yeasts for the expressed purpose of acetic acid production. Sixty yeast strains belonging to these, and several other genera, from the ARS Culture Collection, Peoria, IL, were screened for their ability to produce both ethanol and/or acetic acid. For ethanol production, the strains were grown anaerobically at 24 and 30 C in batch culture using glucose (100 g/l) as the carbon/energy source. For acetic acid production, the strains were grown aerobically in batch culture using either glucose (100 g/l) or ethanol (35 g/l) as the carbon/energy source. In the initial ethanol production screen, 19 strains produced at least 45 g ethanol/l. In the initial acetic acid screen, 28 of the yeast strains produced at least 5 g acetic acid/l from 100 g glucose/l, while 23 strains produced at least 5 g acetic acid/l from 35 g ethanol/l.

Introduction Acetic acid is an important industrial chemical with an annual domestic production of about 2.12 106 metric tons in 1995. Currently, the commercial production of glacial acetic acid is exclusively by petrochemical routes. A potential industrial use of acetic acid is the production of environmentally friendly de-icers, including calcium magnesium acetate (CMA), as a non-corrosive road deicer, and potassium acetate and sodium acetate, as airport runway de-icers. More than 9.07 106 metric tons of rock salt are poured onto North American highways each year to provide safer driving conditions during the winter months. This heavy use of de-icing chemical destroys roadside vegetation, damages aquatic ecosystems, pollutes groundwater and domestic potable water supplies, and damages the highway infrastructure (Fritzsche 1992). Recognizing the negative impact that using salt as a de-icer has upon the environment, in the mid-1970s, the US Department of Transportations Federal Highway Administration funded research to develop substitutes for the chloride salts currently used as de-icers. Calcium magnesium acetate was identied as a poten* Names are necessary to report factually on available data; however, the USDA neither guarantees nor warrants the standard of the product, and the use of the name by USDA implies no approval of the product to the exclusion of others that may be suitable.

tially acceptable, non-corrosive, environmentally benign alternative to road salt (Dunn & Schenk 1980). CMA is a mixture of calcium acetate and magnesium acetate. It is currently manufactured by reacting glacial acetic acid with dolomitic lime (CaOMgO) or limestone (Ca/MgCO3). In addition to its potential use as a de-icer, there are reports that CMA, when used as an additive in coal-red combustion units, reduces sulphur dioxide emissions, thus, partially mitigating the problem of acid rain pollution (Sharma 1991; Levendis 1991). Two microbiological approaches have been previously proposed for the fermentative production of acetic acid/ CMA from corn (Yang et al. 1997). In one approach, glucose is fermented by yeast and the resultant ethanol euent is aerobically converted to acetic acid by Acetobacter. In the other approach, Clostridium thermoaceticum is used to convert glucose to acetic acid. High concentrations of acetic acid are produced in the yeast-Acetobacter process, however, the oxygen requirement for Acetobacter conversion makes the process energy intensive. The thermophilic process (5560 C) requires only a single bioreactor, but it is also energy intensive and results in low nal acetic acid levels. The genus Dekkera and its anamorph, the genus Brettanomyces, are characterized by multipolar budding (van der Walt 1984a,b; Smith et al. 1990), the presence of a Custers eect (also called a negative Pasteur eect) (Custers 1940; Scheers 1961, 1966, 1967; Scheers &

272 Wiken 1969; Wijsman et al. 1984), a coenzyme Q that contains nine isoprene units (Yamada et al. 1980), and the formation of acetic acid (Custers 1940). Yeasts belonging to these genera are often noted for spoiling cellar and bottled wine through the production of haze, turbidity and acetic acid (Sponholz 1993), as well as being used in the secondary fermentation of lambic beer. However, I was unable to nd any information on the use of these yeasts for the express purpose of acetic acid production. Sixty yeast strains belonging to these and several other genera were screened for their ability to produce ethanol and/or acetic acid from either glucose or ethanol in batch culture.

S.N. Freer Growth, ethanol, carbohydrate and acetic acid analysis Growth was measured by the increase in optical density at 600 nm. Glucose, ethanol and acetic acid were quantied by high-pressure liquid chromatography (HPLC) on a Spectra-Physics chromatograph (Thermo Ferinizara, Woodstoch, GA) tted with a BioRad HP87H column (Bio-Red Laboratories, Hercules, CA). The mobile phase was 5 mM sulphuric acid. The compounds of interest were detected with a Waters 410 differential refractometer (Millipore, Watas Chromatography Division, Marborough, MA). Results

Materials and methods Organisms, media and growth conditions The following yeasts were tested in this study: Brettanomyces bruxellensis Y-1412, Y-1411, Y-1441; B. lambicus Y-1413, Y-1330; B. claussenii Y-2290, Y-1414, YB-4087; B. anomalus Y-1415, Y-12670; B. custersianus Y-6653, B. intermedius Y-2394, Y-2395, YB-3363; B. naadenensis Y7706; Brettanomyces spp. YB-5226, YB-5225, YB-5234, YB-5231, YB-5240, YB-5233, YB-5227, YB-5260, Y5740, YB-5243, YB-5235, YB-5241, YB-3695, YB-3696, YB-954, YB-3694, Y-7447, YB-5230, YB-3998, YB5212, Y-5242; Dekkera intermedia YB-5164, YB-4553, Y-1092, YB-4241; D. bruxellensis Y-17523, Y-17535, Y17525, Y-17524, Y-17534, Y-12961; D. naadenensis Y17526; D. anomala Y-17521, Y-17520, Y-17522; Eeniella nana Y-17527, Y-17533; Zygosaccharomyces bailii Y2227; Z. bisporus Y-7558; Pichia membranaefaciens Y2026, Y-2089; P. fermentans Y-1619; P. anomala Y-366; Candida krusei Y-7179; Issatchenkia orientalis Y-5396. All of the organisms were obtained from the ARS Culture Collection, Peoria, IL, and are designated by their NRRL enumerations. The basal medium (YP) consisted of 20 g peptone/l and 10 g yeast extract /l. Inocula were prepared by transferring a loop of cells from a fresh slant to 20 ml of YP medium containing 20 g glucose/l. The cultures were incubated aerobically on a rotary shaker at 200 rev/min and 28 C for 48 h, and 0.2 ml was used to inoculate 20 ml of fresh medium. After 24 h, the cells were harvested by centrifugation at 7000 g for 10 min, washed once in sterile distilled water, and suspended in 20 ml of sterile distilled water. The experimental asks were inoculated using 0.9 ml of cell suspension. For acetic acid production, initial screening was performed in 125 ml baed asks containing 30 ml of basal medium prepared with either 100 g glucose/l or 35 g ethanol/l. For ethanol production, 30 ml of basal medium containing 100 g glucose/l in 50 ml asks were inoculated and capped with serum stoppers and vented with No. 26 gauge sterile needles. The experimental cultures were incubated at either 24 or 30 C on a rotary (New Brunswich Scientic Co., Inc., Edison, NJ) shaker at 250 rev/min.

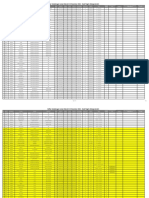

Production of acetic acid and ethanol from either glucose or ethanol The capacity of 60 yeast strains to produce ethanol and acetic acid, when grown anaerobically, from 100 g glucose/l is presented in Table 1. In general, the yeasts tested were reasonably ecient at fermenting glucose. Only three yeasts (Brettanomyces spp. NRRL YB-5241, YB-3695 and YB-3694) produced no ethanol from glucose. Of the 60 yeasts tested, 19 produced at least 45 g ethanol/l, while only 10 yeasts produced less than

Table 1. Growth, acetate and ethanol production from glucose (anaerobic fermentation). Culturea (NRRL) Growth (A600) Acetate (g/l) Ethanol (g/l) Residual glucose (g/l)

B. bruxellensis Y-1412 25.84 Y-1411 24.78 B. lambicus Y-1330 16.05 B. claussenii Y-2290 33.89 Y-1414 30.44 B. anomalus Y-1415 30.40 Y-12670 31.17 Brettanomyces sp. YB-5260 13.67 D. intermedia YB-4553 41.37 Y-1092 38.11 YB-4241 32.01 D. bruxellensis Y-17534 37.65 Y-12961 21.74 D. anomala Y-17521 29.79 Y-17520 29.60 Y-17522 29.30 Z. bailii Y-2227 8.09 Z. bisporus Y-7558 21.31 P. fermentans Y-1619 14.19

a

1.1 0.0 0.0 3.0 0.0 0.4 0.0 3.4 0.0 1.0 1.3 1.0 1.0 0.0 0.0 0.0 1.0 0.0 2.0

45.6 48.5 51.9 49.0 49.4 47.1 50.4 48.9 48.9 48.5 49.4 45.0 50.6 48.9 48.7 50.1 49.6 46.1 45.6

0.0 0.0 0.0 0.0 0.0 2.8 0.0 0.3 0.0 0.0 0.0 0.0 0.0 0.0 0.0 0.0 3.4 3.0 0.0

Only cultures that produced at least 45 g ethanol/l are listed.

Acetate from yeasts 10 g ethanol/l. The six strains that produced the most ethanol were B. lambicus NRRL Y-1330, D. bruxellensis NRRL Y-12961, B. anomalus NRRL Y-12670, D. anomala NRRL Y-17533, B. claussenii NRRL Y-1414 and D. intermedia NRRL YB-4241. As expected, none of the yeasts produced large amounts of acetic acid when grown fermentatively. The capacity of the yeasts to produce acetic acid when grown aerobically in medium initially containing 35 g ethanol/l is presented in Table 2. All of the yeasts tested, except Brettanomyces sp. NRRL YB-5235, utilized, to varying degrees, ethanol as a carbon/energy source. However, 24 of the 60 yeast strains tested produced no detectable acetic acid when grown on ethanol. Twentythree of the yeasts produced greater than 5 g acetic acid/ l while 11 of the strains tested produced greater than 20 g acetic acid/l. The ve strains that produced the most acetic acid from ethanol were D. bruxellensis NRRL Y-17525, B. intermedius NRRL Y-2394, B. custersianus NRRL Y-6653, D. intermedius NRRL Y-5164 and D. anomala NRRL Y-17520. All of these yeasts produced over 25 g acetic acid/l, however, none completely utilized the initial 35 g ethanol/l. The capacity of the yeasts to produce acetic acid and ethanol when grown aerobically in medium initially containing 100 g glucose/l is also presented in Table 2. Forty-seven of the yeast strains tested produced detectable levels of ethanol under these growth conditions.

273 Twenty-six of the yeasts produced no detectable acetic acid when grown aerobically on glucose. Sixteen of these strains produced no detectable ethanol either, even though many of them completely utilized the initial 100 g glucose/l. No other fermentation products, including glycerol, were detected by HPLC in the culture beers of these yeasts. Twenty-eight of the strains tested produced at least 5 g acetic acid/l. Of these, 16 produced over 20 g acetic acid/l. The ve strains that produced the most acetic acid from glucose were D. intermedia NRRL Y-5164 and NRRL YB-4553, B. intermedius NRRL Y2394 and NRRL Y-2395, and D. bruxellensis NRRL Y17525. All of these cultures produced over 29 g acetic acid/l, however, none of these cultures completely utilized the 100 g glucose/l initially present in the medium. Eect of temperature All of the cultures were tested for ethanol and/or acetic acid production at 30 C using glucose (100 g/l) or ethanol (35 g/l) as the carbon/energy source (data not shown). In general, the cultures made about the same amount of product, regardless of the growth temperature. However, the cultures grown at 30 C tended to produce the product more rapidly. When grown at 30 C, the fermentations were completed in 35 days, while the cultures grown at 24 C required 57 days for

Table 2. Growth, acetate and/or ethanol production from either glucose or ethanol (aerobic metabolism). Culturea (NRRL) B. bruxellensis Y-1412 B. claussenii Y-2290 B. anomalus Y-1415 B. custersianus Y-6653 B. intermedius Y-2394 Y-2395 YB-3363 D. intermedia YB-5164 YB-4553 Y-1092 YB-4241 D. bruxellensis Y-17523 Y-17535 Y-17525 Y-17524 Y-17534 D. anomala Y-17521 Y-17520 Y-17522

a

Growth (A600) 48.93 12.19 23.05 24.81 29.08 61.16 31.58 35.49 39.98 17.92 20.75 24.70 29.52 31.95 31.50 30.21 10.50 24.20 12.39

Acetate (g/l)

Residual EtOH (g/l)

Growth (A600) 35.37 34.61 39.51 82.63 19.45 32.25 32.33 33.99 33.72 32.09 33.15 27.13 28.56 34.96 29.70 31.26 29.00 26.66 29.19

Acetate (g/l)

Ethanol (g/l)

Residual glucose (g/l)

2.4 10.0 17.6 28.0 29.2 0.0 24.0 27.7 24.3 18.3 18.3 23.4 22.2 33.0 24.6 22.0 17.8 25.3 14.8

2.2 26.5 16.7 10.1 9.5 0.8 13.8 6.5 10.7 18.0 17.4 8.5 15.6 10.4 14.4 15.2 26.4 18.5 22.3

22.9 24.6 22.4 0.0 29.6 29.1 23.7 31.7 30.0 21.2 21.6 24.0 18.7 31.6 26.9 19.0 23.0 24.4 20.4

21.8 15.4 23.8 0.0 10.5 13.5 11.0 6.1 24.3 16.7 21.6 6.2 10.5 15.7 7.0 8.5 18.6 10.2 7.7

14.4 41.2 17.1 53.4 40.2 31.2 43.6 48.1 57.4 33.4 20 67.9 49.1 26.1 52.3 52 29.8 24.4 58.8

Only cultures that produced at least 20 g acetic acid from either ethanol (left) or glucose (right) are listed.

274 completion, as measured by the presence of a constant residual carbon source and no further increase in acetic acid production. The only exception to this was B. bruxellensis NRRL Y-1411. This strain produced 0.9 and 19.9 g acetic acid/l when grown on ethanol at 24 C and 30 C, respectively (data not shown). When glucose was the carbon/energy source, NRRL Y-1411 produced 18.4 and 18.8 g acetic acid/l when grown at the two temperatures (data not shown).

S.N. Freer greatly, depending upon the amount of acetic acid produced. When grown aerobically, the pH values of the culture beer after 7 days incubation ranged from 4.2 to 6.8, while the anaerobic cultures ranged from 5.1 to 6.3 (data not shown). Finally, not all of the strains produced acetic acid from both glucose and ethanol. Three strains, NRRL Y2395, NRRL Y-1411 and NRRL Y-12961, produced acetic acid from glucose. Little, if any, acetic acid was produced when ethanol was used as the carbon/energy source, although the yeasts grew well (Table 2 and data not shown). Conversely, three strains, NRRL Y-6653, NRRL Y-5240 and NRRL Y-5235, produced acetic acid when ethanol was the carbon/energy source, but produced no detectable acetic acid from glucose (Table 2 and data not shown). Further studies on the functioning of the enzymes involved in acetaldehyde oxidation are needed to fully explain these ndings.

Discussion Acetic acid is believed to be produced in yeast by the oxidation of acetaldehyde, which can be formed either by the pyruvate dehydrogenase bypass or by the oxidation of ethanol. In both pathways, acetaldehyde is a free intermediate that is converted to acetate by aldehyde dehydrogenase and subsequently activated to acetyl-CoA by acetyl-CoA synthetase. Two aldehyde dehydrogenases (one constitutive and one regulated) have been described in yeasts (Seegmiller 1955; Steinman & Jakoby 1967; Carrascosa et al. 1981). It has been suggested that the constitutive aldehyde dehydrogenase functions in the pyruvate dehydrogenase bypass and that the regulated aldehyde dehydrogenase functions in the oxidation of ethanol. Apparently, acetate is excreted into the medium if it is not completely activated to acetyl-CoA. In D. anomala (Geros et al. 2000), acetyl-CoA synthetase is repressed by glucose. Thus, when grown aerobically in medium containing high concentrations of glucose, conditions that favor the excretion of acetic acid are invoked. Similarly, acetate is produced in Saccharomyces cerevisiae if there is insucient acetyl-CoA synthetase activity present for the complete oxidation of acetate to acetylCoA (Postma et al. 1989). However, in D. bruxellensis (syn. B. abstinens; Smith 1998) acetyl-CoA synthetase activity does not appear to be repressed by glucose; thus, even under culture conditions where high amounts of acetic acid are produced, the pathway does not appear to be blocked (Carrascosa et al. 1981). The results of the screen for acetic acid production indicated that the majority of the Dekkera/Brettanomyces spp. deposited in the ARS Culture Collection were capable of producing acetic acid when either glucose or ethanol was used as a carbon/energy source. Overall, the ve strains that produced the most acetic acid were D. intermedia NRRL YB-4553 and YB-5164, B. intermedius NRRL Y-2394, D. bruxellensis NRRL Y-17525, and D. anomala NRRL Y-17520. All of these strains fermented glucose eciently (Table 1), and produced over 24 g acetic acid/l from both glucose and ethanol (Table 2). In general, the eciency of acetic acid production was reasonably low. This was probably due, in part, to the inhibitory eects that acetic acid had upon the yeasts, as the pH values of the batch cultures were not controlled. The nal pH values of the various cultures varied

References

Carrascosa, J.M., Viguera, M.D., Nunez de Castro, I. & Scheers, W.A. 1981 Metabolism of acetaldehyde and Custers eect in the yeast Brettanomyces abstinens. Antonie van Leeuwenhoek 47, 209 215. Custers, M.T.J. 1940 Onderzoekingen over het gistgeslacht Brettanomyces. PhD thesis, Technische Hoogeschool te Delft, Delft, The Netherlands. Dunn, S.A. & Schenk, R.U. 1980 Alternate highway deicing chemicals. Federal Highway Administration Report FHWA-RD-79-106. Fritzsche, C.J. 1992 Nonpoint source pollution, calcium magnesium acetate deicer, an eective alternative for salt-sensitive areas. Water Environment and Technology 4, 4451. Geros, H., Azevedo, M.-M. & Cassio, F. 2000 Biochemical studies on the production of acetic acid by the yeast Dekkera anomala. Food Technology and Biotechnology 38, 5962. Levendis, Y.A. 1991 Catalysis of the combustion of carbonaceous particles (synthetic chars and coal) by addition of calcium acetate. In Calcium Magnesium Acetate, An Emerging Bulk Chemical for Environmental Applications. eds. Wise, D., Levendis, Y. & Metghalchi, M. pp. 221246. Amsterdam: Elsevier. ISBN 0444885110. Postma, E., Verduyn, C., Scheers, W.A. & van Dijken, J.P. 1989 Enzymatic analysis of the Crabtree eect in glucose-limited chemostat cultures of Saccharomyces cerevisiae. Applied and Environmental Microbiology 55, 468477. Scheers, W.A. 1961 On the inhibition of alcoholic fermentation in Brettanomyces yeasts under anaerobic conditions. Experientia 17, 4046. Scheers, W.A. 1966 Stimulation of fermentation in yeasts by acetoin and oxygen. Nature (London) 210, 533534. Scheers, W.A. 1967 Eects of oxygen and acetoin on fermentation and growth in Brettanomyces and some other yeast genera. In Atti XIV Congresso della Societa Italiana di Microbiologia MessinaTaormina, Italy. 1416 October 1967. pp. 91107. Napoli, Italy: Societa Italiana di Microbiologia. Tipograria di Blasica. Scheers, W.A. & Wiken, T.O. 1969 The Custers eect (negative Pasteur eect) as a diagnostic criterion for the genus Brettanomyces. Antonie van Leeuwenhoek 35, A31A32. Seegmiller, J.E. 1955 TPN-linked aldehyde dehydrogenase from yeast. Methods in Enzymology, 1, 511514. Sharma, P.K. 1991 Calcium impregnation of coals as a means for sulfur emissions control in combustion. In Calcium Magnesium Acetate, An Emerging Bulk Chemical for Environmental Applica-

Acetate from yeasts

tions. eds. Wise, D., Levendis, Y. & Metghalchi, M. pp. 273296. Amsterdam: Elsevier. ISBN 0444885110. Smith, M.Th. 1998 Dekkera van der Walt. In The Yeasts, A Taxonomic Study, 4th edn. eds. Kurtzman, C.P. & Fell, J.W. pp. 174177. Amsterdam: Elsevier. ISBN 0444813128. Smith, M.T., Yamazake, M. & Poot, G.A. 1990 Dekkera, Brettanomyces and Eeniella: electrophoretic comparison of enzymes and DNADNA homology. Yeast 6, 299310. Sponholz, W.-R. 1993 Wine spoilage by microorganisms. In Wine Microbiology and Biotechnology. ed. Fleet, G.H. pp. 395420. Switzerland: Harwood Academic Publishers. ISBN 3718651327. Steinman, C.R. & Jakoby, W.B. 1967 Yeast aldehyde dehydrogenase. Journal of Biological Chemistry 242, 50195023. van der Walt, J.P. 1984a Brettanomyces Kuerath et van Lair. In The Yeast, A Taxonomic Study, 3rd edn. ed. Kreger-van Rij, N.J.W. pp. 562567. Amsterdam: Elsevier Science Publishers. ISBN 0444804218.

275

van der Walt JP. 1984b Dekkera van der Walt. In The Yeast, A Taxonomic Study, 3rd edn, ed. Kreger-van Rij, N.J.W. pp. 146 150. Amsterdam: Elsevier Science Publishers. ISBN 0444804218. Wijsman, M.R., van Dijken, J.P., van Klee, B.H.A. & Scheers, W.A. 1984 Inhibition of fermentation and growth in batch cultures of the yeast Brettanomyces intermedius upon a shift from aerobic to anaerobic conditions (Custers eect). Antonie van Leeuwenhock 50, 183192. Yamada, Y., Takinami-Nakamura, H., Tahara, Y. & Smith, M.T. 1980 The coenzyme Q system in the classication of the ascosporogenous genus Dekkera and the asporogenous yeast genus Brettanomyces. Antonie van Leeuwenhoek 46, 595599. Yang, S.-T., Jin, Z. & Chollar, B.H. 1997 Production of low-cost acetate deicers from biomass and industrial wastes. In Snow Removal and Ice Control Technology. pp. 6069. Washington, DC: Transportation Research Board, National Research Council. ISBN 0309062160.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Apprentice ActDocument2 pagesApprentice ActFazal AhmadNo ratings yet

- Open Tender 14Document42 pagesOpen Tender 14یاسر محمود ملکNo ratings yet

- Nidhi STR NewDocument72 pagesNidhi STR NewSamuel DavisNo ratings yet

- The New India Biosimilar GuidelinesDocument23 pagesThe New India Biosimilar GuidelinesBrand SynapseNo ratings yet

- Cloning vector pUC19 sequence from GenBankDocument4 pagesCloning vector pUC19 sequence from GenBankTITANREDNo ratings yet

- Biomedical Engineer or Product Engineer or Design Engineer or QuDocument2 pagesBiomedical Engineer or Product Engineer or Design Engineer or Quapi-77627251No ratings yet

- Top 50 pharma companies ranked by global sales in 2001Document11 pagesTop 50 pharma companies ranked by global sales in 2001Juraj KubáňNo ratings yet

- Daftar Kedatangan Isolasi Mandiri 25 Desember 2021Document3 pagesDaftar Kedatangan Isolasi Mandiri 25 Desember 2021Tirta BudiawanNo ratings yet

- World Cotton Research Conference-5Document594 pagesWorld Cotton Research Conference-5Barkat2012100% (3)

- Biochemistry I: From Chemistry To Biology: Using Energy To Create Order and ComplexityDocument20 pagesBiochemistry I: From Chemistry To Biology: Using Energy To Create Order and ComplexityCiara CaldwellNo ratings yet

- Types of Biotechnology BrochureDocument2 pagesTypes of Biotechnology Brochure여자마비100% (1)

- Global Pharmaceutical Sales ForceDocument27 pagesGlobal Pharmaceutical Sales ForceMarija JukicNo ratings yet

- Bacillus Enzyme Industrial ProductionDocument17 pagesBacillus Enzyme Industrial ProductionBagas Zaki MNo ratings yet

- HBS Millennium Case AnalysisDocument4 pagesHBS Millennium Case AnalysisDeepak Arthur JacobNo ratings yet

- International Congress 1263Document12 pagesInternational Congress 1263AksMastNo ratings yet

- Media Preparation ProtocolDocument5 pagesMedia Preparation ProtocolmohdkhairNo ratings yet

- tmpC7F TMPDocument14 pagestmpC7F TMPFrontiersNo ratings yet

- Chapters 1 and 2 (Harpers Biochemistry)Document16 pagesChapters 1 and 2 (Harpers Biochemistry)Joy Karen DamasigNo ratings yet

- Bamboo Tissue CultureDocument12 pagesBamboo Tissue Culturemobyelectra100% (1)

- Ajay Kumar-SELDocument4 pagesAjay Kumar-SELrat001No ratings yet

- Cap 1 Parasitic NematodeDocument24 pagesCap 1 Parasitic NematodeJorge Chavez FloresNo ratings yet

- FullDocument4 pagesFullLeonardo HerreraNo ratings yet

- Gene Transfer MethodDocument29 pagesGene Transfer Methodmurali manohar pNo ratings yet

- Early-Stage Valuation in The Biotechnology IndustryDocument54 pagesEarly-Stage Valuation in The Biotechnology Industrytransbunko100% (1)

- Plasmid Curing of Escherichia Coli Cells With Ethidium BromideDocument4 pagesPlasmid Curing of Escherichia Coli Cells With Ethidium BromideLucasJ.LenziNo ratings yet

- Human Genome BasicsDocument12 pagesHuman Genome BasicsPradeep Kumar. NagisettyNo ratings yet

- Recombinant TherapeuticsDocument18 pagesRecombinant Therapeuticssachin kumarNo ratings yet

- SadhanaDocument134 pagesSadhanasuraj.atmos458No ratings yet

- Nanofabrication With BiomoleculesDocument10 pagesNanofabrication With BiomoleculesAnonymous NFsIMHyfLtNo ratings yet

- 1279706285sugar PubDocument60 pages1279706285sugar Pubsanman05No ratings yet