Professional Documents

Culture Documents

Bourbon Peridot - Yard 270 - 271005 PDF

Uploaded by

porpeta_jescOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bourbon Peridot - Yard 270 - 271005 PDF

Uploaded by

porpeta_jescCopyright:

Available Formats

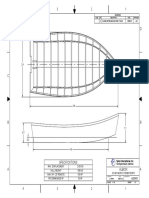

M/V BOURBON PERIDOT

Multifunctional Platform Supply Vessel

ULSTEIN P105

Hull no. 270 Designed by Ulstein Design AS Delivered 2005 by Ulstein Verft AS Built for Bourbon Offshore Norway AS

Diesel electric power and propulsion plant. Large pipe carrying capacity (4 pipe lengths). Large capacities of liquid and dry bulk cargos. Dedicated tanks for all types of liquid cargos. Four tanks (316L stainless steel) for methanol and special products. Segregated tanks for oil-based mud and water-based mud. Cargo discharge stations for cargos midship both sides and aft one side. Cargo discharge stations for methanol and special products midship stbd. and aft stbd. Extensive integrated alarm and monitoring system, including cargo control. Shelter guard on main deck with gangway on top, providing dry weather deck. Stern gate for truck loading of cargo. Truck axle load 23 tonnes on deck Good manoeuverability and station keeping capabilities, with dynamic positioning. Outstanding motion characteristics which ensure high operability. Extremely good course keeping ability. Low noise and vibration levels in accommodation and on work deck. Power economic solutions and low fuel oil consumption due to efficient hull form. Low NOx emission levels from main engines. Prepared for later installation of exhaust gas catalyzers. Interior walls and ceilings are separated from the steel structures by elastic mounting. The wheelhouse has excellent visibility in all directions. Direct view of cargo deck area from day room. M/V Bourbon Peridot is built and painted (tanks and exterior) in drydock inside covered dockhall, thus ensuring controllable atmosphere and the best quality of work.

Shipbuilding by Ulstein Verft AS: Ulstein builds sophisticated vessels with a strong focus on innovative technological solutions and methods

ULSTEIN P105 is a Platform Supply Vessel designed by Ulstein Design AS. Hull no. 270 is lengthened by 4,9 metres and furnished with an additional accommodation deck. MAIN DIMENSIONS Length over all Length between p.p. Breadth moulded Depth to main deck Draught max Design draught C A PA C I T I E S Fuel oil (MDO) 1065 m3 Fresh water 986 m3 Drill water 763 m3 Ballast water 1400 m3 Brine 426 m3 Liquid mud, 8 tanks, 2,5 t/m3 1065 m3 Slop 60 m3 Methanol/Special products 424 m3 Base oil 386 m3 Dry bulk tanks (8 off) 400 m3 Urea 30 m3 Oil Recovery dedicated tanks 1068 m3 Cargo deck area (61,6 m x 16,3 m) 1004 m2 Cargo deck dimensioning 10 t/m2 Deck load (VCG 1,0 m above main deck) ca. 2900 ton Deadweight at max draught 6,5 m 4861 ton Gross tonnage, international 4163 GRT Net tonnage, international 1423 NRT Max speed: approx.15,2 knots C L A S S I F I C AT I O N / F L AG DnV 1A1, SF, E0, DynPos AUTR, LFL*, CLEAN, COMF-V(3), OILREC, Fire Fighter I, DK(10), HL(2,8), NAUT-OSV (LOC). Flag: NOR. A C C O M M O D AT I O N Hotel compliment of high standards and with capacity for 50 persons. Two one-bed state cabins with day-room and bedroom Seven one-bed state cabins Five one-bed cabins Eight two-bed cabins Misc. cabins for twenty persons Hospital Day room, smoke lounge, client office, conference room on C-deck Galley and mess/cafeteria on A-deck Deck pantry, laundry, wardrobe, gymnasium, office on main deck etc. Dry provision room, refrigerated room, and freezer room T E C H N I C A L D ATA approx. 91,1 80,3 19,0 8,0 6,5 6,0 m m m m m m

TECHNICAL DATA Deck Cranes One knuckle boom crane, 10 t, 10 m. Dyn. factor 1,15 One knuckle boom crane, 3 t, 10 m. Dyn. factor 1,15 Dry bulk plant Eight tanks, each of 50 m3 Duplex BHS compressor, 2 x 30 m3/min, 5,6 bar Two segregated loading/discharge systems Two dust cyclones with collectors for vent lines Liquid Cargo Discharge Systems Two fresh water pumps, 250 m3/h 9 bar, centrifugal Two brine pumps, 100 24, twin screw One Ballast / DW pump, 250 9, twin screw One Ballast / DW pump, 250 9, centrifugal Two Fuel oil pumps, 250 9, twin screw One base oil pump, 150 9, centrifugal Two Methanol pumps, hydraulic driven, 100 7, centrifugal One Special product pump, hydraulic driven, 100 7, centrifugal One special product pump, hydraulic driven, 100 - 7, twin screw Four Mud pumps, 100 24, eccentric screw Two washing/stripping/slop pumps, 12,9/16 - 10/3, eccentric screw All pumps (except methanol pumps) are electric driven with frequency converter control High pressure hydraulic aggregate Ten Agitators el. driven for mud and slop tanks Tank cleaning system for mud, brine, and slop tanks Nitrogen generator plant for methanol and special products tanks Flowmeter for FO Side Thrusters Two tunnel thruster fwd., 883 kW, CPP, frequency controlled Swing-up compass thruster fwd., 883 kW, CPP, frequency controlled Roll Damping System Two Roll Reduction Tanks Manoeuvering/Positioning Joystick Dynamic Positioning System DnV AUTR with: Position Reference Systems: DPS 700, HIPAP 500, Fan beam Navigation / Communication S-band ARPA radar and X-band ARPA radar Digital chart system ECDIS (duplo) Conning station Radio installation according to GMDSS area A3 Satcom F, Satcom C. Automatic Identification System (AIS) Voyage Data Recorder (VDR) Internal Communication ULSTEIN COM common distribution of advanced digital automatic telephone, data network, and satellite TV antenna signal to all offices and cabins Batteryless telephone system, separate PA system, DECT TV Satellite antenna Deck Machinery One combined Windlass / Mooring winch Two Tugger Winches, pull 15 t and 20 t Two Capstans aft, pull 10 t Machinery / Propulsion System Diesel electric power and propulsion plant Four main generator engines, each of MCR 1901 kW at 1800 rpm Two Main Azipull Propellers, CPP, with frequency converters each 2500 kW / dia. 3000 mm / speed 0-207 rpm Oil Purification Plant Two FO Separators, self cleaning, automatic Fire Detection System Addressable fire detection central Video and monitoring system A colour video camera system (5 cameras) for surveillance of engines, switchboard and propulsion room. Fire Fighting System Water mist protection system for engine room, casing, switchboard room, and incinerator room. Local water mist protection system for main generator sets, FO separators, hot water boiler Separate system for deep fat fryer External Fire Fighting System One Fi-Fi pump and stepup gear, driven by main engine Two Fi-Fi monitors Four fire water spray monitors and self-protection spray system Electric Power Plant (450 Volt AC 60 Hz) Four main generators, each of 2028 kVA, cosw 0,9 Emergency generator, 215 ekW Electric Equipment Main Switchboard 450 V, 230 V in switchboard / trafo room Emergency Switchboard Separate engine control room on main deck Motor Control Centres Integrated Alarm and monitoring System (IAS) Outlet 400 A for deck equipment NOFO Cabinet on deck 16 off deck outlets for cooling containers

N-6067 ULSTEINVIK, Norway. Tel. +47 7000 8000 Telefax +47 7000 8000. www.ulsteingroup.com

You might also like

- Platform Supply Vessel ULSTEIN PX121Document6 pagesPlatform Supply Vessel ULSTEIN PX121maria_bustelo_2No ratings yet

- Ferries PDFDocument25 pagesFerries PDFletathienNo ratings yet

- Maersk DeveloperDocument12 pagesMaersk DeveloperNoor HadiNo ratings yet

- Maersk IntrepidDocument8 pagesMaersk Intrepidrickyngs100% (1)

- Pro & Contra Hydropower: AdvantagesDocument16 pagesPro & Contra Hydropower: AdvantagesbarukomkssNo ratings yet

- Dart Fisher OffshoreSupportVesselDocument8 pagesDart Fisher OffshoreSupportVesselbeddows_sNo ratings yet

- Tanker IDocument44 pagesTanker IDanijelNo ratings yet

- Jack-Up Derrick Barge Ju-251: 1. Name OF Vessel 2. Owners 3. Year Built 4. BuildersDocument8 pagesJack-Up Derrick Barge Ju-251: 1. Name OF Vessel 2. Owners 3. Year Built 4. BuildersNguyễn Việt ÁnhNo ratings yet

- Maersk DelivererDocument12 pagesMaersk DelivererNoor HadiNo ratings yet

- Marine Products and Systems Catalogue PDFDocument202 pagesMarine Products and Systems Catalogue PDFJojoHanNo ratings yet

- GSPDocument27 pagesGSPVirgil Titimeaua100% (1)

- Maersk Discoverer PDFDocument12 pagesMaersk Discoverer PDFNoor HadiNo ratings yet

- Dessus Sunreef 60 SailingDocument53 pagesDessus Sunreef 60 Sailingt.loncaric12No ratings yet

- Stena IceMax BrochureDocument8 pagesStena IceMax BrochureFabio FernandesNo ratings yet

- TankersDocument13 pagesTankersFungsam LimNo ratings yet

- RigDocument12 pagesRigDavid SeowNo ratings yet

- TankersDocument13 pagesTankerscptmehmetkaptan100% (1)

- Chemical Tanker Clipper SiraDocument1 pageChemical Tanker Clipper SiraLePrince2010No ratings yet

- Brochures AkerWayfarer II PremiliminaryDocument4 pagesBrochures AkerWayfarer II PremiliminarymivanoNo ratings yet

- 200 Pax BargeDocument22 pages200 Pax BargeKalyana Kumar100% (1)

- 09-7220 UT 728 S R1 - Design PresentationDocument22 pages09-7220 UT 728 S R1 - Design PresentationCinthia Lidia Hidrogo PaulinoNo ratings yet

- Brief Presentation of Ut-Design UT 739 L: Multifunctional, Deep Water Anchor Handling, Tug, Supply and Service VesselDocument32 pagesBrief Presentation of Ut-Design UT 739 L: Multifunctional, Deep Water Anchor Handling, Tug, Supply and Service VesselCinthia Lidia Hidrogo PaulinoNo ratings yet

- IMT990 Data SheetDocument1 pageIMT990 Data SheetBarun DixitNo ratings yet

- Offshore Barge LeafletDocument6 pagesOffshore Barge LeafletAri Rizki RivaldoNo ratings yet

- FPSO PresentationDocument30 pagesFPSO Presentationmechmonkey007100% (1)

- Incinerator Brochure 2012 PDFDocument11 pagesIncinerator Brochure 2012 PDFStancu PetricăNo ratings yet

- Ahts 0610Document12 pagesAhts 0610seckin80100% (1)

- Mobile Drilling and Workover Rig WF 125 SaDocument8 pagesMobile Drilling and Workover Rig WF 125 Saluciana_gaby100% (1)

- Direct Driven Fire Water Pump With Angle Gear: Keep Going. Keep SafeDocument8 pagesDirect Driven Fire Water Pump With Angle Gear: Keep Going. Keep Safeandy131078No ratings yet

- DeepOcean AtlanticChallenger 12 PDFDocument4 pagesDeepOcean AtlanticChallenger 12 PDFkenja1No ratings yet

- Marine Products and Systems Catalogue - RR PDFDocument202 pagesMarine Products and Systems Catalogue - RR PDFLiladhar Ganesh Dhoble100% (3)

- Boltec LCDocument2 pagesBoltec LCCristian CarrascoNo ratings yet

- TTS Cargo CranesDocument4 pagesTTS Cargo Cranes123habib123fikriNo ratings yet

- LNG Fuelling SystemsDocument13 pagesLNG Fuelling SystemsBlue Corridor Natural Gas Vehicle Rally 2014No ratings yet

- IncineratorDocument11 pagesIncineratorRavi Chetan100% (1)

- Product Sheet Damen Tanker 8000-02-2016Document2 pagesProduct Sheet Damen Tanker 8000-02-2016ibnuNo ratings yet

- D9-mg AUXDocument3 pagesD9-mg AUXLuis JesusNo ratings yet

- Fluid Handling ColfaxDocument12 pagesFluid Handling ColfaxLeon SanchezNo ratings yet

- FTFTI6569 Manifoldssleds Brochure 2Document8 pagesFTFTI6569 Manifoldssleds Brochure 2Deepa VelNo ratings yet

- Rem Etive A4Document6 pagesRem Etive A4Pramod KumarNo ratings yet

- Atlas Copco Utilitary Vehicles - FamilyBrochure - ENGDocument12 pagesAtlas Copco Utilitary Vehicles - FamilyBrochure - ENGmasterandreis100% (2)

- Tugboat - ULUCAYDocument6 pagesTugboat - ULUCAYudelmarkNo ratings yet

- 0106 BPUM BR Direct Driven 07-15-150dpi WebDocument8 pages0106 BPUM BR Direct Driven 07-15-150dpi WebIzallmachineNo ratings yet

- 22 25 SW04Document4 pages22 25 SW04rafaNo ratings yet

- Brian LadeDocument36 pagesBrian LadeMatteo CafieroNo ratings yet

- Submersible Propeller Pump Type ABS VUPXDocument8 pagesSubmersible Propeller Pump Type ABS VUPXAgus SalmanNo ratings yet

- Oshkosh PLS Specifications (2000) BrochureDocument6 pagesOshkosh PLS Specifications (2000) BrochureNickiedeposieNo ratings yet

- SubmersiblePropellerPump VUPX E10359Document8 pagesSubmersiblePropellerPump VUPX E10359hafezasadNo ratings yet

- Offshore Projects - 0Document22 pagesOffshore Projects - 0Dana GuerreroNo ratings yet

- UT-Design: Fact SheetDocument2 pagesUT-Design: Fact SheetAbdullah AhmadNo ratings yet

- COSL Innovator Brochure 12 09Document4 pagesCOSL Innovator Brochure 12 09melody04223No ratings yet

- ENSCO 120 Series: Ultra-Premium Harsh Environment JackupsDocument4 pagesENSCO 120 Series: Ultra-Premium Harsh Environment JackupsDayanand Wasate100% (1)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Pounder's Marine Diesel Engines and Gas TurbinesFrom EverandPounder's Marine Diesel Engines and Gas TurbinesRating: 4 out of 5 stars4/5 (15)

- Machines, Tools and Methods of Automobile ManufactureFrom EverandMachines, Tools and Methods of Automobile ManufactureRating: 4 out of 5 stars4/5 (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Nave DNMRDocument3 pagesNave DNMRAmalia CatalinaNo ratings yet

- Types of RuddersDocument33 pagesTypes of Ruddersmario enriquezNo ratings yet

- Cause and Effect of Negative StabilityDocument11 pagesCause and Effect of Negative StabilityAnthony Parong IIINo ratings yet

- List CalculationDocument7 pagesList CalculationTavy TavyNo ratings yet

- WP 2 Report 2 Regression Analysis For Tankers and Bulk Carriers PDFDocument36 pagesWP 2 Report 2 Regression Analysis For Tankers and Bulk Carriers PDFdikiNo ratings yet

- Jacket Installation FlowchartDocument1 pageJacket Installation FlowchartNath YauNo ratings yet

- Cold War Submarines PDFDocument432 pagesCold War Submarines PDFSteven Hamilton89% (9)

- Maxsurf Stability Quick StartDocument5 pagesMaxsurf Stability Quick StartMALIK TALHA ALI SAJIDNo ratings yet

- ROR Questions1Document27 pagesROR Questions1tejmayer100% (2)

- Notice: Spira International, IncDocument2 pagesNotice: Spira International, Incidix bloodjackersNo ratings yet

- Introduction To Ship Load LinesDocument7 pagesIntroduction To Ship Load Linesนัทเดช เรืองสวนNo ratings yet

- 07 NAC Inclining Test (160213)Document9 pages07 NAC Inclining Test (160213)Gilles MathieuNo ratings yet

- Star Wars - FFG - Ad - Set 7Document3 pagesStar Wars - FFG - Ad - Set 7Max KlostermannNo ratings yet

- ABS River-Rules-July21Document414 pagesABS River-Rules-July21MARCONo ratings yet

- S-072002-05FIG Determination of Critical Wind Velocity For Dragging AnchorDocument1 pageS-072002-05FIG Determination of Critical Wind Velocity For Dragging AnchorGilbert CondadaNo ratings yet

- Our Vessel Fleet: S/N Vessel Name Dimensions (L.O.A. X Breadth X Depth) GT / NT Class Flag Year BuiltDocument2 pagesOur Vessel Fleet: S/N Vessel Name Dimensions (L.O.A. X Breadth X Depth) GT / NT Class Flag Year BuiltramyaNo ratings yet

- Bonjean Curve (Abanid, Bacus, Parba, Timbal)Document1 pageBonjean Curve (Abanid, Bacus, Parba, Timbal)Prince AbanidNo ratings yet

- TEST-Use of SMCP For Routine Communication (13.01.2021) PDFDocument1 pageTEST-Use of SMCP For Routine Communication (13.01.2021) PDFMitea Gabriel-Cristian100% (2)

- Pms Monthly ReportDocument2 pagesPms Monthly ReportKunal SinghNo ratings yet

- Mca Section 1 - Icing Allowances Cover Sheet AlsoDocument8 pagesMca Section 1 - Icing Allowances Cover Sheet AlsoAmit ChahandeNo ratings yet

- 3b Midterm LMS SEAM 6Document90 pages3b Midterm LMS SEAM 6Patrick CastroNo ratings yet

- Accident Report Form (ARF) : Initial NotificationDocument4 pagesAccident Report Form (ARF) : Initial NotificationVisveswaran InbasekaranNo ratings yet

- The Naalu CollectiveDocument3 pagesThe Naalu CollectiveivanhoeiiiNo ratings yet

- Bouyage VesselDocument3 pagesBouyage VesselDavid TeodorNo ratings yet

- Sponsoring Scholarship Organisations Officer CadetsDocument10 pagesSponsoring Scholarship Organisations Officer CadetsAlekseiNo ratings yet

- Anchoring PracticeDocument99 pagesAnchoring PracticeNaveenYadav100% (9)

- Unit 2. Duties of The Officer On Cargo Watch and Log Entries-SENT ONDocument5 pagesUnit 2. Duties of The Officer On Cargo Watch and Log Entries-SENT ONDank100% (1)

- MBC Operations - B6A (JSW Jaigarh Port)Document6 pagesMBC Operations - B6A (JSW Jaigarh Port)niraj noharaNo ratings yet

- Principal Vessel Documentations Requirement PDFDocument3 pagesPrincipal Vessel Documentations Requirement PDFMilandro Lou AcuzarNo ratings yet

- 2017-03 Clipper Quito Eng PDFDocument21 pages2017-03 Clipper Quito Eng PDFabdeNo ratings yet