Professional Documents

Culture Documents

SOP Outline 2013-14

Uploaded by

Mohit KhandelwalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SOP Outline 2013-14

Uploaded by

Mohit KhandelwalCopyright:

Available Formats

Indian Institute of Management Bangalore Elective Course: Sales and Operations Planning Course Outline 2013-14 PGP: V Term

Instructor: LS Murty D Block I Floor Ph: 3044; e-mail: lsmurty@iimb.ernet.in

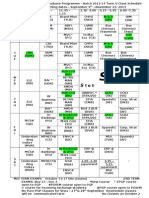

Course Objective: Ever since the beginning, the objectives of organisations evolved from availability to low cost to quality and shorter lead-time. Accordingly, the manufacturing systems evolved through job shops, mass production lines and just-in-time systems. Under the present conditions of intense global competition, the objectives are expanded to include variety and flexibility as well. There has also been an increasing awareness about the need for intraorganizational and interorganizational integration for firms to effectively compete within and across supply chains. With a view to address this context, this course, though anchored in Operations Planning, is positioned at the interface of marketing and operations functions and addresses the integration of sales planning and operations planning. Course Schedule: S.No 1 Date Sep 9 Topic Introduction Production planning parameters, information flow view of planning, hierarchical approach to planning Master Data for Planning Systems Material master, bill of materials, work centers, routes Forecasting Forecasting methods: time series (moving averages, exponential smoothing, time trends multiplicative model), causal models: regression, judgment models, evaluating forecasts. Read: chapter 2 Case: National Manufacturing Company Using Forecasts Pyramid forecasting Read: chapter 2

Credits: 3

Sep 10

Sep 16

S.No 4

Date Sep 17

Topic Capacity Planning Capacity planning in manufacturing and service systems; queuing concepts Read: Chapter 10 Aggregate Planning Read: chapter 12 and Heuristic Approaches to Aggregate Planning (handout), and Disaggregation (Handout) Case: NMC develop an optimal and heuristic approach to planning at NMC. Aggregate Planning Read: chapter 12 Case: Ranchi Refractories Chemicals Limited Material Requirements Planning (MRP) Read: Material Requirements Planning (handout) Material Requirements Planning (MRP) contd Read: Material Requirements Planning (handout) Master Production Scheduling Read: Chapter 6 Material Requirements Planning (MRP) contd. Read: Material Requirements Planning (handout) Capacity Requirements Planning (CRP) Case: Nichols Company Manufacturing Resources Planning (MRP II) Read: A Note on MRP II (Handout) Read: Chapter 3 Distribution Requirements Planning Read: Chapter 8

Sep 23

Sep 24

Sep 30

Oct 1

Oct 7

10

Oct 8

11

Oct 21

12

Oct 22

13

Oct 28

Sales and Operations Planning Case: Fabtek Guest Lecture Enterprise Resources Planning (ERP) Read: Enterprise Resource Planning (handout) Case: Avasarala Automation Limited

14 15

Oct 29 Nov 5

S.No 16

Date Nov 11

Topic Operations Scheduling: DBR Method Read: Constraints Management An Indian Case of Throughput Improvement (handout) Chapter 11 (pp 379 389) Production Control: LoB, Schedule Performance Curve Read: Line of Balance (Handout) Synchronizing the Operation (Handout) Theory of Constraints (ToC): Thinking Processes Read: Elements of ToC Management System (Handout) Case: A hotel that does not fit in Presentations Presentations Course Conclusion

17

Nov 12

18

Nov 18

19 20

Nov 19 Nov 25

Textbook: Vollmann T E, W L Berry, D C Whybark and F R Jacobs, Manufacturing Planning and Control for Supply Chain Management, New Delhi: TMH. Course Prerequisites: Students are expected to have knowledge of quantitative methods [Linear Programming, in particular] for some sessions. Teaching Method: The teaching method consists of a mix of lectures, discussions, and cases. Case analyses / presentations and Term Paper are group work. Attendance Policy: For PGP students, attendance is not compulsory. However, students are responsible for their learning as some questions in the exam could be based on class discussions. Evaluation: Cases Term Paper End-Term Exam 30% 30% 40%

You might also like

- Logistics and Supply Chain Management 0Document5 pagesLogistics and Supply Chain Management 0srinivasNo ratings yet

- CO - Operations Research - 2020Document7 pagesCO - Operations Research - 2020Riya PandeyNo ratings yet

- IILM Institute For Higher EducationDocument8 pagesIILM Institute For Higher EducationPuneet MarwahNo ratings yet

- BITS PILANI Operation Management SyllabusDocument12 pagesBITS PILANI Operation Management Syllabussap6370No ratings yet

- Lesson Plan NaacDocument6 pagesLesson Plan Naacgarima0% (1)

- Project Management - PGDM FT 2011-13 NewDocument9 pagesProject Management - PGDM FT 2011-13 NewHitesh Kothari0% (1)

- Or SyllabusDocument1 pageOr SyllabusNavdeep ChohanNo ratings yet

- Manac Outline 2023-24Document4 pagesManac Outline 2023-24priyankaNo ratings yet

- New Course Outline Format For PGP-SCMADocument6 pagesNew Course Outline Format For PGP-SCMASuman SaurabhNo ratings yet

- BAR, Term - VDocument3 pagesBAR, Term - VRupesh JainNo ratings yet

- Article Review #6Document4 pagesArticle Review #6Ranjit SawantNo ratings yet

- XIM University: Xavier Institute of ManagementDocument5 pagesXIM University: Xavier Institute of ManagementAyushi GautamNo ratings yet

- Human Resoure ManagementDocument5 pagesHuman Resoure ManagementKulmeet SinghNo ratings yet

- Operation CoursesDocument13 pagesOperation CoursesFarhan SarwarNo ratings yet

- Updated - Cma - PGP 25 t2 Course OutlineDocument4 pagesUpdated - Cma - PGP 25 t2 Course OutlineSwati PorwalNo ratings yet

- Analysis & Design of Logistics Systems - Winter '09Document4 pagesAnalysis & Design of Logistics Systems - Winter '09barath1986No ratings yet

- Mba ZG526Document11 pagesMba ZG526Puneet JoshiNo ratings yet

- SCHEME - G Sixth Semester (CO)Document44 pagesSCHEME - G Sixth Semester (CO)samrajpal123No ratings yet

- MBCQ 722 Operations & Materials Management L T P C 2 1 0 3 Pre-requisites/Exposure Graduate in Engineering/Science Discipline Co-RequisitesDocument8 pagesMBCQ 722 Operations & Materials Management L T P C 2 1 0 3 Pre-requisites/Exposure Graduate in Engineering/Science Discipline Co-RequisitesSenthil Kumar GanesanNo ratings yet

- PPIC Outline Fall 2016Document8 pagesPPIC Outline Fall 2016mianwaseemNo ratings yet

- 48 AssinmentDocument325 pages48 AssinmentManish Kumar50% (2)

- Effective Project Management: Traditional, Agile, ExtremeFrom EverandEffective Project Management: Traditional, Agile, ExtremeNo ratings yet

- Syllabus: Faculty of Management Studies, University of DelhiDocument7 pagesSyllabus: Faculty of Management Studies, University of DelhiAtul MittalNo ratings yet

- Pom Diary c02Document6 pagesPom Diary c02naveenNo ratings yet

- Course Outline - Mba5271scmDocument6 pagesCourse Outline - Mba5271scmPrashant RajNo ratings yet

- Enterprise Resource Computing: M P Sebastian Professor IIM KozhikodeDocument25 pagesEnterprise Resource Computing: M P Sebastian Professor IIM KozhikodeNarender MandanNo ratings yet

- IE301 Operations ManagementDocument3 pagesIE301 Operations ManagementloshidhNo ratings yet

- MSM Course Outline - Sec. A, B, C, D and EDocument4 pagesMSM Course Outline - Sec. A, B, C, D and EjayaNo ratings yet

- BPR DissertationDocument8 pagesBPR DissertationWritingPaperHelpUK100% (1)

- Course Outline Operations ManagementDocument4 pagesCourse Outline Operations ManagementUmair GurmaniNo ratings yet

- Strategic PlanningDocument5 pagesStrategic PlanningArun TanwarNo ratings yet

- Dissertation BPMDocument5 pagesDissertation BPMCollegePapersHelpManchester100% (1)

- Quantatative Methods SylDocument7 pagesQuantatative Methods SylThảo Bùi PhươngNo ratings yet

- Baagpankaj@iimk Ac inDocument5 pagesBaagpankaj@iimk Ac inPressesIndiaNo ratings yet

- Course SyllabiDocument21 pagesCourse SyllabiSana BhittaniNo ratings yet

- QM ZG526 COURSE HANDOUT Operations ManagementDocument10 pagesQM ZG526 COURSE HANDOUT Operations ManagementDeviNo ratings yet

- Jaipuria Institute of Management PGDM-RM Trimester Iii Academic Year 2018-19Document9 pagesJaipuria Institute of Management PGDM-RM Trimester Iii Academic Year 2018-19AryanSinghNo ratings yet

- Datascience and Machine LearningDocument8 pagesDatascience and Machine LearningsumanNo ratings yet

- Process Analysis and Design - Outline - RevisedDocument3 pagesProcess Analysis and Design - Outline - RevisedRajas G GanjaveNo ratings yet

- Indian Institute of Management, Shillong: Rajiv GandhiDocument5 pagesIndian Institute of Management, Shillong: Rajiv GandhiHarshit PandeyNo ratings yet

- (OR) - EPGP Kochi - AMBA Course OutlineDocument3 pages(OR) - EPGP Kochi - AMBA Course Outlineadarsh dNo ratings yet

- T. A. Pai Management Institute (Tapmi), Manipal: Forecasting ModelsDocument5 pagesT. A. Pai Management Institute (Tapmi), Manipal: Forecasting ModelsRhytham KothariNo ratings yet

- 1) Operations and Quality Management) STDDocument8 pages1) Operations and Quality Management) STDgondhapurNo ratings yet

- Syllabus OF VII & VIII Semesters B.E. Industrial Engineering & Management 2017-18Document40 pagesSyllabus OF VII & VIII Semesters B.E. Industrial Engineering & Management 2017-18Joven CastilloNo ratings yet

- Mba PM Slides AllDocument676 pagesMba PM Slides AllSrabon Shahriar RafinNo ratings yet

- IBS Hyderabad: Academic Year: 2022-23 Course HandoutDocument9 pagesIBS Hyderabad: Academic Year: 2022-23 Course HandoutShrayan SarkarNo ratings yet

- Strategic-Oriented Implementation of ProjectsFrom EverandStrategic-Oriented Implementation of ProjectsRating: 4 out of 5 stars4/5 (1)

- Sad MipDocument5 pagesSad MipTamil SreeNo ratings yet

- Master Thesis Lean ManufacturingDocument8 pagesMaster Thesis Lean Manufacturingfjnsf5yf100% (2)

- POM 102 SyllabusDocument8 pagesPOM 102 SyllabusmarkangeloarceoNo ratings yet

- EPGP-13 OM Course Outline - Sec CDocument4 pagesEPGP-13 OM Course Outline - Sec CKabeer KarnaniNo ratings yet

- OmDocument8 pagesOmRishabh ShekharNo ratings yet

- Course Outline Project MGT BBA7th Fall 2023Document5 pagesCourse Outline Project MGT BBA7th Fall 2023Liam NoahNo ratings yet

- 09 ICED09 Wynn Simulation and SelectionDocument12 pages09 ICED09 Wynn Simulation and SelectionMame WoldaNo ratings yet

- Foundations of Operations Management - WK5 - Preparation For CLA2Document4 pagesFoundations of Operations Management - WK5 - Preparation For CLA2SushobhanNo ratings yet

- Syllabus MM5004 Operation ManagementDocument23 pagesSyllabus MM5004 Operation ManagementSerly SanoniNo ratings yet

- Post Graduate Program in Management (PGPM) : My Email IDDocument11 pagesPost Graduate Program in Management (PGPM) : My Email IDAnubhav KhatriNo ratings yet

- Procurement Candidate Manual SS OnlineDocument427 pagesProcurement Candidate Manual SS Onlinehaill100% (1)

- FCH21484Document4 pagesFCH21484PavanNo ratings yet

- Land Holding Report Agriculture Census 2011Document97 pagesLand Holding Report Agriculture Census 2011Mohit KhandelwalNo ratings yet

- IBM MobileFirst Fact Sheet - Feb 2014Document4 pagesIBM MobileFirst Fact Sheet - Feb 2014Mohit KhandelwalNo ratings yet

- Forbes India Magazine - Ready To GerminateDocument3 pagesForbes India Magazine - Ready To GerminateMohit KhandelwalNo ratings yet

- FMCG Econometrics Whitepaper Microsoft Advertising Intl PDFDocument14 pagesFMCG Econometrics Whitepaper Microsoft Advertising Intl PDFMohit Khandelwal100% (1)

- Save BrandDocument4 pagesSave Brandmindfreaker1987No ratings yet

- World Crop AcreageDocument27 pagesWorld Crop AcreageMohit KhandelwalNo ratings yet

- PR Contact ListDocument10 pagesPR Contact ListMohit KhandelwalNo ratings yet

- CSP 2013Document6 pagesCSP 2013Mohit KhandelwalNo ratings yet

- ITC Target PriceDocument3 pagesITC Target PriceMohit KhandelwalNo ratings yet

- Enterprise Resilience ReportDocument0 pagesEnterprise Resilience ReportMohit KhandelwalNo ratings yet

- Manvi Motors-Graphical RepresentationDocument1 pageManvi Motors-Graphical RepresentationMohit KhandelwalNo ratings yet

- Club Selection Form For Jcs (2013-14) : 1. Why Do You Want To Join HMC?Document4 pagesClub Selection Form For Jcs (2013-14) : 1. Why Do You Want To Join HMC?Mohit KhandelwalNo ratings yet

- Session 18 TimeDocument14 pagesSession 18 TimeMohit KhandelwalNo ratings yet

- 15448Document9 pages15448Mohit KhandelwalNo ratings yet

- Please Find Below The Link To Apply For FIIDocument1 pagePlease Find Below The Link To Apply For FIIMohit KhandelwalNo ratings yet

- Template 1Document8 pagesTemplate 1Mohit KhandelwalNo ratings yet

- Vista Schedule v49Document6 pagesVista Schedule v49Mohit KhandelwalNo ratings yet

- Abbrv PDFDocument2 pagesAbbrv PDFMohit KhandelwalNo ratings yet

- Fabtek b2b PDFDocument8 pagesFabtek b2b PDFMohit KhandelwalNo ratings yet

- Segmented Servicing Model: BY Gandharv Madan Vishrut Shukla Mohit KhandelwalDocument7 pagesSegmented Servicing Model: BY Gandharv Madan Vishrut Shukla Mohit KhandelwalMohit KhandelwalNo ratings yet

- Leveraged Recapitalization and Exchange Offers: Prof. Ian GiddyDocument28 pagesLeveraged Recapitalization and Exchange Offers: Prof. Ian GiddyMohit KhandelwalNo ratings yet

- Nabisco - Sol v0.1 PDFDocument13 pagesNabisco - Sol v0.1 PDFMohit Khandelwal100% (1)

- ImpDocument1 pageImpMohit KhandelwalNo ratings yet

- MRP SIM AssignmentDocument5 pagesMRP SIM AssignmentMohit KhandelwalNo ratings yet

- CSP Notice New LetterheadDocument1 pageCSP Notice New LetterheadMohit KhandelwalNo ratings yet

- Term 5 TTDocument2 pagesTerm 5 TTMohit KhandelwalNo ratings yet

- Report On Oil DeregulationDocument79 pagesReport On Oil Deregulationnishtha15No ratings yet

- MRP SimDocument35 pagesMRP SimMohit KhandelwalNo ratings yet

- MRP SIM AssignmentDocument5 pagesMRP SIM AssignmentMohit KhandelwalNo ratings yet

- Chapter 18 ControllingDocument24 pagesChapter 18 ControllingAsad Uz Jaman100% (2)

- Adwords Fundamental Exam Questions Answers 2016Document21 pagesAdwords Fundamental Exam Questions Answers 2016Avinash VermaNo ratings yet

- Merger Between IndusindDocument26 pagesMerger Between IndusindAnand Narayan Singh0% (2)

- EIU Research Proposal Approval Form - Updated 2Document20 pagesEIU Research Proposal Approval Form - Updated 2RozhanNo ratings yet

- Survey Questionnaire - Marketing Strategy of Fast Food Chains and Consumer Behavior PatternsDocument4 pagesSurvey Questionnaire - Marketing Strategy of Fast Food Chains and Consumer Behavior PatternsJaspher Lanzo100% (1)

- Group 1 Team 03 RohitDocument3 pagesGroup 1 Team 03 RohitAntara RabhaNo ratings yet

- How Integrated Marketing Communications (IMC) Works? A Theoretical Review and An Analysis of Its Main Drivers and EffectsDocument37 pagesHow Integrated Marketing Communications (IMC) Works? A Theoretical Review and An Analysis of Its Main Drivers and EffectsDevy Mulia SariNo ratings yet

- Self-Instructional Manual (SIM) For Self-Directed Learning (SDL)Document34 pagesSelf-Instructional Manual (SIM) For Self-Directed Learning (SDL)sunny amarillo100% (1)

- Compiled By: Tanveer M Malik (17122) Atif Abbas Faizan Puri - 13368 MaheshDocument38 pagesCompiled By: Tanveer M Malik (17122) Atif Abbas Faizan Puri - 13368 MaheshM.TalhaNo ratings yet

- Lesson 1Document33 pagesLesson 1Cher NaNo ratings yet

- TESCO - Forum Assignment Marketing ManagementDocument7 pagesTESCO - Forum Assignment Marketing ManagementAnanthi Balu100% (1)

- Feedback: Business Management Practical ExamDocument18 pagesFeedback: Business Management Practical Examakiyama madoka100% (1)

- 2221 - Acct6328039 - Lkfa - TP1-W2-S3-R2 - 2602285150 - Amama Ira Amalia PriyonoDocument11 pages2221 - Acct6328039 - Lkfa - TP1-W2-S3-R2 - 2602285150 - Amama Ira Amalia PriyonoAmama AI APNo ratings yet

- Statement IbblDocument1 pageStatement Ibblmamunkhan1216jNo ratings yet

- Chapter ThreeDocument20 pagesChapter Threehenokt129No ratings yet

- Transaction Event Keys pdf-1Document4 pagesTransaction Event Keys pdf-1vedant maheshwariNo ratings yet

- SAP IS Blue Print DocumentDocument4 pagesSAP IS Blue Print DocumentSupriyo DuttaNo ratings yet

- 523755152-503469149-GO2Bank-Template-2-2 NOVDocument3 pages523755152-503469149-GO2Bank-Template-2-2 NOVAlex NeziNo ratings yet

- Nike Marketing MixDocument9 pagesNike Marketing MixHarshit MaheshwariNo ratings yet

- Kami Export - EIA1UsOfIr9QbQFYxXTypQDocument2 pagesKami Export - EIA1UsOfIr9QbQFYxXTypQMary BonBon ChangNo ratings yet

- From Beds, To Burgers, To Booze - Grand Metropolitan and The Creation of A Drinks GiantDocument13 pagesFrom Beds, To Burgers, To Booze - Grand Metropolitan and The Creation of A Drinks GiantHomme zyNo ratings yet

- The Cost of Capital: Sources of Capital Component Costs Wacc Adjusting For Flotation Costs Adjusting For RiskDocument37 pagesThe Cost of Capital: Sources of Capital Component Costs Wacc Adjusting For Flotation Costs Adjusting For RiskMohammed MiftahNo ratings yet

- Project Management Growth: Concepts and DefinitionsDocument60 pagesProject Management Growth: Concepts and DefinitionsbezaNo ratings yet

- CAF 3 CMA Autumn 2023Document6 pagesCAF 3 CMA Autumn 2023Hammad ShahidNo ratings yet

- SBIR Program OverviewDocument13 pagesSBIR Program OverviewFernie1No ratings yet

- Human Resource PlanningDocument16 pagesHuman Resource PlanningSiddharth Jain100% (1)

- Expro Builders Pte. LTD (Sandar Raj Sundara Pandian)Document17 pagesExpro Builders Pte. LTD (Sandar Raj Sundara Pandian)testingNo ratings yet

- Agility Vs FlexibilityDocument13 pagesAgility Vs FlexibilityDeepakNo ratings yet

- CH 07Document99 pagesCH 07baldoewszxc80% (5)

- Lesson 5 EBBADocument152 pagesLesson 5 EBBAHuyền LinhNo ratings yet