Professional Documents

Culture Documents

Annual, Docking, Intermediate Survey

Uploaded by

Ajay SinghOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Annual, Docking, Intermediate Survey

Uploaded by

Ajay SinghCopyright:

Available Formats

----------------------- Page 1----------------------Report no: Page 1 of 13 Annual surveys/Intermediate surveys/Docking Surveys Survey Checklist In accordance with the classifications

survey requirements for all ships inclu ding oil tankers and bulk carriers. [ See additional check lists for chemical tankers and gas carriers ] Name of Ship IMO Number Mark Yes or No in appropriate box for each item If an item is not applicable mark A in appropriate box. All required dates should be recorded at these surveys as dd/mm/yy For docking survey complete sections GA to HH as applicable. Annual survey: - to be held within 3 months before or after the anniversary da te Load Line Survey- to be held within 3 months before or after the anniversary date Intermediate survey: - together with the 2nd or 3rd annual survey (including f ull requirements of the Annual Survey) Docking survey: - to be held as required by regs. pt.1 ch. 2, sec. 3.5 In-water survey, in lieu of the drydocking between special surveys AA 050 d? Yes/No AB General Are all Statutory Certificates and the Certificate of Class vali N

National Administration Requirements

050 Have the country files been checked to ascertain any flag admini stration requirements? Yes/No/NA 100 Have all flag administration technical and reporting requirement s been complied with? Yes/No/NA AC Manning

050 Does the ship s complement comply with the Minimum Safe Manning Do cument? (If not the Flag is to be advised) Y es/No/NA 100 Are the master, officers and ratings certificated as required by the STCW Convention? Yes/No/NA AD General (Annual and Intermediate Surveys) Confirm no modifications have been made to the ship or equipment

which would affect the class or the Certificates (any 050 Yes/No modifications are to be reported) 100 Confirm that all periodical surveys required for boilers and oth er pressure vessels are up to date. Yes/No 150 Confirm the CSM and CSH cycles are up to date in accordance with the current survey status. Yes/No/NA Confirm that the Periodical Survey of the automation and/or remot e controls for the main propulsion plant are not overdue. (see also 200 Yes/No/NA section CA ) 300 Yes/No/NA 350 urvey Yes/No/NA Confirm the Certificate of Class now endorsed for Intermediate S Confirm the Certificate of Class now endorsed for Annual Survey

Safety Management System Failures 400 The organisation responsible for the issue of the SMC have been notified when deficiencies relating to a possible Safety Management Yes/No/NA System failure have been identified Does the Certificate of Class require to be re issued, is a clas s notation being removed / suspended as a result of this survey (If yes the 450 Yes/No/NA Report needs to be marked for vetting) Lloyd's Register, its affiliates and subsidiaries and their respective officers, employees or agents are, individually and collectively, referred to in this cla use as the 'Lloyd's Register Group'. The Lloyd's Register Group assumes no responsibility and shall not be liable to any person for any loss, damage or expense caused by reliance o n the information or advice in this document or howsoever provided, unless that person has signed a contract with the relevant Lloyd's Register Group entity for the p rovision of this information or advice and in that case any responsibility or liability i s exclusively on the terms and conditions set out in that contract. LR2100A (2007.02) ----------------------- Page 2----------------------Report no:

Page 2 of 13 AE Documentation (Annual and Intermediate Surveys) AS APPLICABLE A.S. or I.S. 050 ate issued by endorsement date 050a 050b 050c 050d 050e 050f 050g 050h 050i e Carriage of Dangerous Chemicals in Bulk 050j ied 050k Gases in Bulk * International Pollution Prevention Certificate for the Carria ge of 050l Noxious Liquid Substances in Bulk 300 The approved stability/loading information is on board Yes/No/NA 100 The log entries record that the following have been checked or tested and found satisfactory within twelve (12) hours before departure from any port. Steering gear (The tests included, where applicable, the operati on of the main steering gear, the auxiliary steering gear, remote 100a Yes/No control systems, bridge steering position, emergency power suppl y, rudder angle indicators, steering gear system power unit) * International Ship & Port Facility Security Code Certificate *International Certificate of Fitness for the Carriage of Liquef The Document of Compliance [DOC] * International Certificate of Fitness for the Carriage of Dangerous Chemicals in Bulk or The Certificate of Fitness for th *Cargo Ship Safety Construction Certificate *Cargo Ship Safety Equipment Certificate *Cargo Ship Safety Radio Certificate * International Load Line or Exemption Certificate * International Oil Pollution Prevention Certificate * Certificate of Class * Cargo Ship Safety Certificate (where applicable) * International Safety Management Certificate) SMC & copy of Certificate Expiry date Certific

100b

Communications system bridge to steering gear compartment Yes/No

100c

Full movement of the rudder Yes/No

100d

Visual inspection of steering linkage Yes/No

150 The log entries record that emergency steering drills have been carried out every three (3) months. Yes/No 200 The change-over procedure diagrams of steering gear are posted. Yes/No 250 All officers are reportedly familiar with steering gear change-o ver procedures. Yes/No 300 The approved stability/loading information is on board. Yes/No 350 For ships assigned timber loadlines the approved timber deck ca rgo loading and lashing plan is on board. Yes/No/NA 400 A complete file of the enhanced survey reports and the conditi on evaluation report is on board [ ESP ships ] Yes/No/NA 450 For bulk carriers the loading / unloading booklet is on board Yes/No/NA For bulk carriers with restrictions with the respect to the carr iage of cargoes with a density of 1,780 kg/cub.m above that a triangle is 500 Yes/No/NA permanently marked at mid ship ] For bulk carriers of 150m in length and upwards of single skin c onstruction designed to carry solid bulk cargoes having a density of 550 1,780 kg/cu.m above constructed before 1 July 1999 have after th e implementation date given in SOLAS 94/97 reg. XII/3 sufficient Yes/No/NA stability and strength to withstand flooding of the foremos t cargo hold 600 An approved Cargo Securing Manual for ships carrying cargo unit s including containers is on board Yes/No/NA [ SOLAS 74/97 reg. XII/8.3

650

A loading booklet for carriage of cargoes in bulk is on board Yes/No

700 Confirm that Asbestos was not used on board at this survey (SOL AS 74/00 REG. II-1/3-5) Yes/No A set of as-built construction drawings and other plans showing a ny subsequent structural alterations are kept 750 st Yes/No/NA On board (for ships constructed on or after 1 January 2007) * See notes section KA LR2100AClass (2007.02) ----------------------- Page 3----------------------Report no: Page 3 of 13 BA Hull Survey (Annual and Intermediate Surveys)

The condition of the hull and its closing appliances is satisfact ory as far as could be seen, The following items should be included as 050 Yes/No applicable (see also Appendix 1 for shell doors): Hatchways; weather decks, ship side plating above the waterline, casings, skylights, flush deck scuttles, deckhouses and companionways; superstructures; windows; side scuttles; and deadl ights; chutes and other openings; scuppers; sanitary discharges and 100 Yes/No valves; guard rails and bulwarks; freeing ports; gangways and lif elines; and permanent fittings for timber deck cargoes. Closing appliances were not tied or temporarily secured open Vents and air pipes condition should be verified , including weld connection between air pipes and deck plating (Annual and 150 Yes/No Intermediate Surveys) 200 The condition of the anchoring and mooring equipment is satisfac tory, as far as could be seen. Yes/No 250 The watertight and weather tight doors have been examined, o perationally tested (remotely and locally) and found satisfactory. Yes/No 300 The condition of the watertight bulkhead penetrations is satisfa

ctory, as far as could be seen. Yes/No 350* The structural fire protection arrangements remain unchanged (Al terations are to be reported). Yes/No/NA 450* The manual and/or automatic fire doors have been operationally t ested and found satisfactory. Yes/No/NA 500 Yes/No/NA 550 Yes/No 600 Special requirements for ships permitted to sail with reduced fr eeboards found satisfactory [ when applicable ] Yes/No/NA 670 Yes/No/NA 700 Hull Planned Maintainance Audit has been completed as applicable , see check list 2100 HPMS Yes/No/NA Hatch covers, coamings and gaskets have been checked and mechanic ally operated hatch covers operationally tested and sealing 750 Yes/No/NA arrangements found weathertight. Confirm that no unapproved changes have been made to the hatch co vers, hatch coamings and their securing and sealing devices 770 Yes/No/NA Since the previous survey 800 The collision and other watertight bulkheads have been examined a s far as could be seen and found satisfactory Yes/No 850 actory Yes/No The drainage from enclosed spaces on the freeboard deck is satisf Environmental Protection Notation EP. (when applicable) The freeboard marks have been verified. The operation of the loading instrument has been verified.

900 The functionality of bilge well alarms to cargo holds and conveyo r tunnels found satisfactory [ when applicable ] Yes/No 950 Any expansion joints in the sea water systems have been visually examined and found satisfactory Yes/No

Salt water ballast tanks 1000 The tanks where protective coating was not applied at constructio n or has been reported in POOR condition and not repaired have Yes/No/NA been examined and found satisfactory. (report tanks) 1050 Examination and thickness measurement of structure identified as having substantial corrosion [ details to be to be reported ] Yes/No/NA Note: Those tanks which may require to be internally examined at annual survey are indicated in the Survey Status. Yes/No BB 050 tiffeners. Yes/No/NA Dry bulk cargo ships (bulk carriers) Close-up survey of cargo hold steel hatch covers, coamings and s

Close-up survey and thickness measurement of areas of substantial corrosion identified in the Survey Status or the Executive Summary 050a Yes/No/NA carried out satisfactorily (report area(s) and thicknesses) 100 Yes/No/NA 150 Yes/No/NA 150a An overall survey of the forward cargo hold and an aft cargo hol d, on single skin ships (annual only) Yes/No/NA 200 Yes/No/NA 200a Overall survey of all cargo holds, on single skin ships, two sel ected on double skin ships (annual and intermediate) Yes/No/NA Close-up survey of at least 25% of the cargo hold side shell fram es, their lower end attachments and adjacent shell plating in a 200b Yes/No/NA forward cargo hold, on single skin ships (annual only) 250 Yes/No/NA 250a Overall survey of all cargo holds (annual only) For ships greater than 15 years old For ships between 10 and 15 years old For ships less than 10 years old Dewatering of forward spaces

Yes/No/NA Close-up survey of at least 25% of the cargo hold side shell fram es, their lower end attachments and adjacent shell plating in a 250b Yes/No/NA forward cargo hold and one other selected cargo hold, on single s kin ships (annual only) The close-up survey has been extended to include all other cargo holds because of the need for remedial action 250c Yes/No/NA (details to be reported). Any necessary thickness measurement is to be reported. LR2100AClass (2007.02) ----------------------- Page 4----------------------Report no: Page 4 of 13 BC Oil tankers (including combination carriers) and chemical tankers

Close-up survey and thickness measurement of areas of substantial corrosion identified in the Survey Status or the Executive Summary 050 Yes/No/NA carried out satisfactorily (report area(s) and thicknesses) Salt water ballast tanks to be examined: Tanks where a hard protective coating was not applied at construc tion or 050a Yes/No/NA the hard protective coating has been reported to be in less than GOOD condition and not repaired. (report tanks) Single hull oil tankers (including combination emical tankers Ballast tanks adjacent to [ i.e. with a common plane boundary ] a cargo tank with any means of heating have been examined and found satisfactory. Thickness measurement is to be carried out w here considered necessary by the Surveyor 100 Yes/No/NA Special consideration may be given by the Surveyor to those tanks or spaces where the coatings are found in GOOD condition at the previous Intermediate or Special Survey BD All ships assigned the special features notation certified contain carriers) and ch a soft coating has been applied or

er securing arrangements . 050 The condition of the securing arrangements is satisfactory as fa r as could be seen. Yes/No/NA BE iffeners. Yes/No/NA 100 Yes/No/NA 100a Overall survey of one forward and one after cargo hold and their associated tween deck spaces (annual only) Yes/No/NA 150 Yes/No/NA 150a only). Yes/No/NA Overall survey of all cargo holds and tween deck spaces (annual For ships greater that 15 years old For ships between 10 and 15 years old General dry cargo ships (see note 400 section KA ) Close-up survey of cargo hold steel hatch covers, coaming and st

Close-up survey of at least 25% of all shell frames, including th eir end attachments and adjacent shell plating in a forward lower cargo 150b Yes/No/NA hold and one other selected lower cargo hold (annual only). The close up survey has been extended to include all other cargo holds because of the need for remedial action (details to be 150c Yes/No/NA reported). Any necessary thickness measurement is to be reported. *See notes Section KA For Intermediate Surveys see section IA CA Machinery and Electrical Installation Survey (Annual and Intermed iate Surveys) 050 The machinery and boiler spaces and essential machinery have bee n generally examined and found satisfactory. Yes/No/NA 100 The emergency escape routes from the machinery and boiler spaces are free of obstruction. Yes/No/NA 150 The machinery and boiler spaces are free of all visible fire and explosion hazards. Yes/No/NA

Piping systems containing fuel oil, lubricating oil or other flam mable oils where fitted have been examined and operated as far as 200 practicable, special attention being paid to tightness, fire prec aution arrangements, flexible hoses and sounding arrangements and Yes/No/NA found satisfactory. The main and auxiliary steering arrangements, including their ass ociated equipment, alarms and control system, have been examined, 250 Yes/No/NA operated and found satisfactory. All the means of communication between navigating bridge, machine ry control and alternative steering positions have been tested 300 Yes/No/NA and found satisfactory. The bilge pumping systems for each watertight compartment, includ ing bilge wells, extended spindles, pumps and level alarms where 350 Yes/No/NA fitted, have been examined and operated as far as practicable and all found satisfactory. Non-metallic expansion joints in piping systems which penetrate t he hull and are fitted below the deepest loaded 400 Yes/No/NA waterline have been examined and found satisfactory. An external examination of boilers, pressure vessels, including s afety devices , foundations, controls, relieving gear, insulation, gauges 450 Yes/No/NA and piping has been carried out as far as practicable, and found satisfactory. The electrical equipment and cabling forming the main and emergen cy electrical installations have been generally examined under 500 operating conditions as far as practicable. Bonding straps for th e control of static electricity and earthing arrangements as fitted have Yes/No/NA also been examined. The satisfactory operation of the main and emergency sources of p ower, including lighting systems and electrical services essential for 550 safety in an emergency mode have been verified. (Where the sourc es of power are automatically controlled they have been tested in Yes/No/NA the automatic mode.) 600 A general examination of the following, where applicable, has be en carried out and operation considered satisfactory: Yes/No/NA 600a Automation equipment, including random testing of alarm, automat ic and shutdown functions Yes/No/NA

600b IP Yes/No/NA

UMS

CCS ICC system (indicate those appropriate with X)

or

600c DP and PCR (enter detail of notation and indicate with X if PCR is appropriate) Yes/No/NA 600d The DP System has been tested under operating conditions to an ap proved test schedule Yes/No/NA 600e licable) Yes/No/NA Navigational Arrangements examined for NAV1, IBS (when app

An examination of the electrical installation in areas which may contain flammable gas or vapour and/or combustible dust, it has 650 Yes/No/NA verified that it is in good condition and has been properly maint ained LR2100AClass (2007.02) ----------------------- Page 5----------------------Report no: Page 5 of 13 The machinery, boilers and other pressure vessels, associated pipi ng systems and fittings are installed and protected as to reduce to a 700 Yes /No/NA minimum any danger to persons on board, due regard being given to moving parts, hot surfaces and other hazards Confirm that the normal operation of the propulsion machinery can be sustained or restored even though one of the essential 750 Yes /No/NA auxiliaries becomes inoperative Confirm that the engine room telegraph, the second means of commun ication between the navigation bridge and the machinery 800 Yes /No/NA space and the means of communication with any other positions from which the engines are controlled are operating satisfactorily 850 Examining, in general that the precautions provided against shock, fire and other hazards of electrical origin are being maintained Yes /No/NA 900 Oil mist detection system on Main and Auxiliary engines verified

Yes /No/NA 950 Confirm that the Machinery Planned Maintenance audit has been comp leted as applicable , see check list 2100MPMS Yes /No/NA 1000 Confirm that the Screwshaft Condition Monitoring and Turbine Condi tion Monitoring audits have been completed as applicable Yes /No/NA DA Statutory Survey Related Items (Annual and Intermediate Services)

050* The fire control plan and duplicate have been examined and are pr operly posted. Yes /No/NA 100* All fire and/or smoke detection and alarm systems have been exami ned and tested, as far as practicable, and found satisfactory. Yes /No/NA An operative test of the fire main system and each fire pump, incl uding the emergency fire pump, has been carried out separately, to 150* Yes /No/NA demonstrate that the two required jets of water could be provided simultaneously from different hydrants. 200* All fire hoses, nozzles, applicators and spanners are situated at their respective stations and in satisfactory condition. Yes /No/NA The fixed fire fighting system controls, piping, instructions and markings are properly maintained and serviced. Yes /No/NA 250* Date of last reported system test Yes /No/NA 300* All semi-portable and portable extinguishers are fully charged, i n their stowed position and with valid service dates. Yes /No/NA The remote controls for stopping fans and machinery and shutting o ff fuel supplies in machinery spaces and where fitted, the remote 350 Yes /No/NA controls for stopping fans in accommodation spaces and means of cu tting off power to the galley are in working order. 400 The closing arrangements of ventilators, annular spaces, skylight s, doorways and tunnel where applicable are satisfactory. Yes /No/NA Confirming as far as practical, that no changes have been made in the structural fire protection, examining any manual and automatic 450* fire doors and proving their operation, testing the means of closi

ng the main inlets and outlets of all ventilation systems and testing Yes /No/NA the means of stopping power ventilation systems from outside the s pace served 500* o/NA Where Lloyd s Register is authorised to carry out the Periodic Load Line Inspection, Load Line Annual Survey and/or SAFCON Annual or Intermediate1 Survey on behalf of the National Authority provided the AS/ITSS is satisfactorily completed as appropriate in accordance 550 with the checklist requirements then the Load Line, SAFCON survey dates may be recommended and the certificates endorsed accordingly provided in the case of the SAFCON the following is al so dealt with: 550a /No/NA 550b /No/NA 600 Confirmation that the following is satisfactory: damage control plans for ships built 1/2/92 and after Yes manoeuvring booklet with information displayed on bridge Yes The fireman s outfits are complete and in satisfactory condition. Yes/N

600a structural fire protection and fire doors including remote stoppi ng of ventilation systems Yes /No/NA 600b /No/NA 600c /No/NA 600d NA 600e /No/NA 600f /No/NA 600g /No/NA 1 Intermediate SAFCON surveys are mandatory for all ships operating on the Harmo nised System of Survey and Certification. arrangements for escape from working spaces Yes first start arrangements Yes domestic gaseous fuel arrangements Yes engineer s alarm is audible in the engineer s accommodation area Yes/No/ noise protection in machinery spaces Yes ventilation of machinery spaces Yes

* See notes Section KA LR2100AClass (2007.02) ----------------------- Page 6----------------------Report no: Page 6 of 13 EA Oil Tankers, including Combination Carriers (Annual and Intermedia te Surveys)EB /No/NA 050 Cargo tank openings including gaskets, covers, coamings, P/V valv es and flame screens are all satisfactory as far as could be seen. Yes /No/NA 100 A portable instrument for measuring flammable vapour concentratio ns with sufficient spares and means of calibration is satisfactory. Yes /No/NA 150 Flame screens on vents at all bunker, oily ballast and oily slop tanks and void spaces are satisfactory as far as could be seen. Yes /No/NA An examination of cargo, crude oil washing, bunker, ballast, strip ping and vent piping systems including vent masts and headers has 200 Yes /No/NA been carried out and all found in satisfactory condition. An examination of cargo tank venting arrangements and secondary me ans of venting or over/ under pressure alarms, if fitted, has 250 Yes /No/NA been found operational and satisfactory. 300 The condition of electrical equipment in dangerous zones is satis factory as far as could be ascertained. Yes /No/NA 350 /No/NA EC Fire Extinguishing Arrangements Access to bow arrangements found satisfactory Yes Weather deck Yes

Examination of the fixed fire-fighting system for the cargo pump room, confirming that the installation tests have been satisfactorily 050* completed with its means of operation clearly marked and when app ropriate , checking the operation of the remote means for Yes /No/NA closing the various openings, all found satisfactory

100* The deck foam and deck sprinkler systems were found to be operabl e and in satisfactory condition Yes /No/NA ED 050 /No/NA EE Cargo pump room Emergency Towing Arrangements Condition of emergency towing arrangements found satisfactory Yes

Confirm that no potential sources of ignition (in or near the carg o pump room) such as loose gear, excessive product in bilges, 050 Yes /No/NA excessive vapours, combustible materials, etc. have been observed and if found then eliminated. 100 /No/NA 150 All electrical equipment is in satisfactory condition as far as c ould be ascertained. Yes /No/NA The emergency lighting in all cargo pump rooms of tankers construc ted after 1 July 2002 have been examined 200 Yes /No/NA and found satisfactory 250 ures. /No/NA 300 y. /No/NA The pump room bulkheads are free of signs of oil leakage or fract Yes The sealing arrangements of bulkhead penetrations are satisfactor Yes The access ladders are in satisfactory condition. Yes

350 An external examination of piping systems has been carried out an d all found in a satisfactory condition. Yes /No/NA 400 The cargo, bilge, ballast and stripping pumps examined as far as practicable and found satisfactory for: Yes /No/NA 400a /No/NA 400b own devices. /No/NA 400c Operation of electrical and mechanical remote operating and shutd Yes Integrity of pump room bilge system and pump foundations. Excessive gland seal leakage. Yes

Yes /No/NA 450 The ventilation system is operational the ducting intact, the dam pers are operable and the screens are clean. Yes /No/NA 500 As far as could be seen, the installed pressure gauges on cargo d ischarge lines and level indicator systems are operational. Yes /No/NA EF Inert gas systems (where fitted)

050 From external examination, all components and piping found free o f signs of corrosion or gas/effluent leakage. Yes /No/NA 100 /No/NA 150 /No/NA 200 The deck water seal filling and draining system is operational an d without evidence of water carry-over. Yes /No/NA 250 /No/NA 300 The operation of all remotely operated or automatically controlle d valves, in particular the flue gas isolating valve(s) found satisfactory. Yes /No/NA 350 tisfactory. /No/NA The interlocking feature of the soot blowers checked and found sa Yes The non-return valve is operational. Yes The scrubber room ventilation system is operational. Yes Both inert gas blowers are operational. Yes

LR2100AClass (2007.02) ----------------------- Page 7----------------------Report no: Page 7 of 13 400 The gas pressure regulating valve automatically closes when the inert gas blowers are secured Yes/No/NA The following safety devices of the inert gas system have been ch ecked, as far as practicable, using simulated conditions where 450 Yes/No/NA necessary and found satisfactory:

450a Yes/No/NA 450b Yes/No/NA 450c Yes/No/NA 450d Yes/No/NA 450e Yes/No/NA

high oxygen content of gas in the inert gas main

Low gas pressure in the inert gas main.

low pressure in the supply to the deck water seal

high temperature of gas in the inert gas main

low water pressure to the scrubber

450f accuracy of portable and fixed oxygen measuring equipment by mea ns of calibration gas Yes/No/NA 450g Yes/No/NA 450h Yes/No/NA 450i failure of the power supply to the automatic control system for the gas regulating valve and to the instrumentation Yes/No/NA 450j continuous indication and permanent recording of pressure and ox ygen content in the inert gas main Yes/No/NA 450k Yes/No/NA 450l Inert Gas System operated on completion of the checks listed abo ve and found satisfactory Yes/No/NA GA Docking Surveys Hull , Rudder and Anchors high gas pressure in the inert gas main failure of the inert gas blowers high water level in the scrubber

Note: - Particular attention should be paid to any application or renewal of high resistance paint Systems to the underwater portion of the hull. Surveyors should submit particulars of the Maker and c oating material to ensure that a suitable record is entered in the Yes/No/NA Memorandum A satisfactory examination of the shell including bottom, side an d bow plating, sea inlet boxes, keel, stern, sternframe and rudder(s) 050

Yes/No/NA was carried out. The clearances of rudder bearings are satisfactory. Report cleara nces: Yes/No/NA 100 The sea suctions, overboard discharge valves, sea chests, straine rs and their connections to the hull were generally examined and all 150 Yes/No/NA found Satisfactory. 200 The propeller and fastenings, sternbush fastenings, and the grat ings at the sea inlets were examined and found satisfactory. Yes/No/NA The propeller shaft seal(s) were found satisfactory and tight and the propeller shaft(s) clearance(s) were satisfactory. Yes/No/NA 250 Yes/No/NA The anchoring and mooring equipment was examined as far as practi cable, the anchors and cables partially raised and. Lowered using 300 Yes/No/NA the windlass and found satisfactory Note: The examination of anchors, chain cables, chain lockers and the requirements for thickness measurement are to be dealt with at Yes/No/NA docking surveys held in connection with the special survey. GB Docking Surveys rs) 5 years old and over Oil tankers (including combination carrie Report clearance/poker gauge readings:

A satisfactory general examination of the electrical equipment an d cables in dangerous zones such as cargo pump room and spaces 050 adjacent to and zones above cargo tanks for defective and non-cer tified safe-type electrical Yes/No/NA equipment, improperly installed The insulation resistance of the circuits was satisfactorily test ed or there is a recent record of insulation resistance testing, that is 100 Yes/No/NA considered acceptable. (see Intermediate Survey). Where the Administration has implemented the Harmonised System of Survey and Certification and where LR is authorised to issue the 400 Cargo Ship Safety Construction or Cargo Ship Safety Certificate c

onfirm certificate endorsed in respect to the date of inspection of the Yes/No/NA ships bottom. Enter date:LR2100AClass (2007.02) ----------------------- Page 8----------------------Report no: Page 8 of 13 HA Docking Surveys - Paint systems

050 The condition of the paint system applied to the underwater port ion of the hull is satisfactory Yes/No/NA 100 Yes/No/NA 100a Yes/No/NA 100b tive Yes/No/NA 100c Yes/No/NA 100d Yes/No/NA 150 ll Yes/No/NA 150a Yes/No/NA 150b Yes/No/NA 200 Yes/No/NA 200a es/No/NA 200b Any application including touch up details reported in the narra Memorandum Exists Y Tin Free Anti-Fouling (TBT Free) [ If applied ] Dry Film Thickness: microns High Resistant Paint applied to the underwater portion of the hu Memorandum now added:Any application including touch up details reported in the narra Memorandum Exists High Resistant Paint (H.R.P.) [ If applicable ]

Memorandum - Missing but applicable

Manufacturer:

tive Yes/No/NA 200c Yes/No/NA 200d Yes/No/NA 250 aler coat ] Yes/No/NA 250a Yes/No/NA 250b Yes/No/NA 250c Yes/No/NA * See notes Section KA IA IB II Additional Survey Requirements (Intermediate Surveys) All ships Certificate type : [ i.e. Record/EU/IMO ] Date : DD/MM/YY Anti-fouling system : [ i.e. TBT / non-TBT / TBT covered with se Memorandum now added:Memorandum - Missing but applicable

Certificate No :

050 The electrical generating sets have been examined under working conditions and found satisfactory. Yes/No/NA 100 Yes/No/NA Representative salt-water ballast tanks, including any protective coating, have been generally examined internally and found 100A Yes/No/NA satisfactory. (Report tanks) 150 Yes/No/NA 150a All salt-water ballast tanks, including any protective coating, generally examined internally and found satisfactory. (Report tanks) Yes/No/NA 150b The anchors have been partially raised and lowered satisfactoril y using the windlass Yes/No/NA Ships of 10 years old and over Ships of 5 years to 10 years old

200 Dry cargo ships 15 years old and over (not general dry cargo ship s, see section IE) Yes/No/NA 200a An overall survey of a forward and an after cargo hold has been carried out and found satisfactory. (Report holds) Yes/No/NA LR2100AClass (2007.02) ----------------------- Page 9----------------------Report no: Page 9 of 13 IC 050 Yes/No/NA Cargo, crude oil washing, bunker, ballast, steam and vent piping on weather decks, also vent masts and headers examined and found 050a Yes/No/NA satisfactory. The insulation resistance of the circuits was satisfactorily test ed or there is a recent record of insulation resistance testing that is 050b Yes/No/NA considered acceptable. (see Docking Survey) Single hull oil tankers [ including ore/oil and ore/bulk/oil ship s ] of 5 years to 10 years old Examination of all salt- water ballast tanks. Where considered ne cessary by the surveyor, thickness measurement and testing are 050c Yes/No/NA To be carried out to ensure the structural integrity remains effe ctive Double hull oil tankers and chemical tankers of 5 years to 10 yea rs old Overall survey of representative salt-water ballast tanks as sele cted by the surveyor . If the survey reveals no visible defects , the 050d Yes/No/NA Examination may be limited to a verification that the hard protec tive coating remains in GOOD condition Oil tankers [ including ore/oil and ore/bulk/oil ships ] over 10 Oil Tankers (including Combination Carriers) and Chemical Tankers All tankers

years old Survey requirements are to be completed to the extent of the perv ious Special Survey (applicable to ESP surveys) with testing of cargo 050e Yes/No/NA holds and ballast tanks as deemed necessary by the attending surv eyor. 050f Requirements for longitudinal strength evaluation to be carried out as deemed necessary by the attending Surveyor Yes/No/NA ID 050 Yes/No/NA 050a Yes/No/NA Close-up survey to establish the condition of at least 25% of the cargo hold side shell frames including their upper and lower end 050b attachments, adjacent shell plating and the transverse bulkheads in the forward cargo hold and one other selected cargo hold, on Yes/No/NA single skin ships The close-up survey has been extended because of the need for rem edial action (details to be reported). Any necessary thickness 050c Yes/No/NA measurements are to be reported. Thickness measurement of areas subject to close up survey (may be specially considered if no structural diminution and protective 050d Yes/No/NA coating in good conditions) Overall survey of representative salt-water ballast tanks, as sel ected by the surveyor. The selected tanks are to include the fore peak 050e Yes/No/NA Tank, aft peak tank and a number of other tanks, taking into acco unt the total number and type of ballast tanks 100 Yes/No/NA Survey requirements are to be completed to the extent of the prev ious Special Survey (applicable to ESP surveys) with testing of cargo 100a Yes/No/NA holds and ballast tanks and internal examination of fuel oil tank For ships over 10 years Overall survey of all cargo holds. Dry bulk cargo ships (bulk carriers) 5 years old and over For ships between 5 and 10 years old

s as deemed necessary by the attending surveyor. IE General dry cargo ships (see notes KA 400 ) 50 Yes/No/NA 50a Overall survey of one forward and one aft cargo hold and their as sociated tween deck spaces. Yes/No/NA The close-up survey has been extended because of the need for rem edial action (details to be reported). Any necessary thickness 50b Yes/No/NA measurements are to be reported. 50b Overall survey of representative salt-water ballast tanks, as se lected by the surveyor Yes/No/NA 100 Yes/No/NA 100a Yes/No/NA The close-up survey has been extended because of the need for rem edial action (details to be reported). Any necessary thickness 100b Yes/No/NA measurements are to be reported. 150 Yes/No/NA Survey requirements are to be completed to the extent of the prev ious Special Survey (applicable only to surveys of hull structure and 150a piping systems in way of cargo holds, cofferdams, pipe tunnels an d void spaces within cargo length area and all salt water ballast Yes/No/NA tanks) Tank testing, survey of automatic air pipe heads and internal exa mination of fuel oil, lubricating oil and fresh water tanks are to be 150b Yes/No/NA carried out as deemed necessary by the attending Surveyor IF Dry Cargo Ships (other than bulk carriers and general dry cargo s hips) (see notes KA 450 ) 050 Yes/No/NA For ships over 15 years For ships over 15 years Overall survey of all cargo holds and tween deck spaces. For ships between 10 and 15 years For ships between 5 and 10 years

050a Overall Survey of selected cargo holds to be carried out[ detail s to be reported ] Yes/No/NA LR2100AClass (2007.02) ----------------------- Page 10----------------------Report no: Page 10 of 13 JA List Tanks Examined and Reported (Annual and Intermediate Surveys) Good/Fair/Poor/NA Structural conditi Protective coating condition Forward and aft peak tanks Topside tanks Deep tank/side tanks/centre tanks Water ballast tanks LR2100AClass (2007.02) ----------------------- Page 11----------------------Report no: Page 11 of 13 Double bottom tanks Other tanks KA Notes/Comments

on

050 Sections AA - LA of the checklist are to be completed at classifi cation surveys (i.e. AS, ITSS or DS) as applicable. DA items 050 e 100 ips applies. At annual or intermediate survey where the periodical surveys refe rred to in AD 100, 150, 200 and 250 (see page 1) are due or overdue these are to be 150 satisfactorily completed in order that the Certificate of Class ca n be endorsed. However where overdue periodical surveys cannot be completed at t he time of annual/intermediate surveys as a result of extenuating circumst Items marked thus* (i.e. Section BA items 350 and 450, Section 300 and 500 and Section EC items 50 and 100) are only required to b dealt with on ships to which Part 6, Chapter 4 of the Rules for Sh

ances then the following procedure may be adopted: During attendance for all classification surveys the surveyor shou ld review the classification status and establish that all other due or overdue Periodical Surveys have been dealt with or have been postponed by agreement. Circumstances may exist when it is not practical for the owners to present items for 200 survey (e.g. port authorities do not always allow immobilisation) and, under these or similar circumstances, surveyors should undertake a general examination and testing/review as required, after obtaining confir mation from the Master or Chief Engineer that the item remains efficient, and ag ree to a postponement of survey for a period not exceeding three months fro m the due date of survey. 250 The items which may be postponed in these circumstances without r eference to the committee are: CSM and CSH items (other than cargo holds and SW ballast tanks) CSM and CSH items should not be postponed beyond the completion da te of the cycle without reference to London Classification Section or the Devolv ed Classification Executive. When a postponement has been agreed the items should be included on the Interim Certificate under the heading Postponemen t of Survey and listed with the report narrative. The period of postp onement is to be stated. Owners request for postponement of surveys other than the above ar e to be referred to London Classification Services or Regional Devolved Classifi cation 300 Executive. The Regulations Part 1, Chapter 2, Section 1.1.9 require that t he International Convention Certificates, listed in Section AE , 050 are issued by Lloyd s 350 Register, a National Administration or an IACS Member when so auth orised. London Classification Services should be advised when this Regulation is not complied with. For the application of the requirements outlined in the Regulation s Part 1, Chapter 3, sections 2, 3, 4 and 5, a general dry cargo ship is defined as a self propelled ship of 500 gross tonnes or above, constructed generally with a tween deck and intended to carry solid cargos. This excludes bulk carrie rs, 400 refrigerated cargo ships, roll on-roll off ships and ships dedicat ed for the carriage of containers, forest products (but not log or timber carrie rs), wood chips , cement, livestock carriers and docking / deck ships 450 Dry Cargo Ship is defined as :- Ship intended to carry solid carg oes [ includes container ships, reefers, forest product carriers, ro ro and ceme nt carriers ]

LR2100AClass (2007.02) ----------------------- Page 12----------------------Report no: Page 12 of 13 LA St Approved Operating and Maintenance Manual confirmed on board and satisfactory 050 (a) Yes/No/NA Yes/No/NA maintenance maintained (passenger ro-ro ships only . Operations and maintenance schedule confirmed on board (ro-ro shi ps only for side 050 (b) Yes/No/NA Yes/No/NA shell and stern doors Note: approval not required) Operation of doors and power units witnessed and found satisfacto ry. Doors operated 100 Yes/No/NA Yes/No/NA Yes/No/NA Yes/No/NA from closed to fully open state, with freedom of movement est ablished 150 Door structure and surrounding ship structure examined and found satisfactory. Yes/No/NA Yes/No/NA Yes/No/NA Yes/No/NA The door sealing arrangements including gaskets and retaining bar s found to be 200 Yes/No/NA Yes/No/NA satisfactory. The door cleating, locking and securing arrangements are complete , with no evidence 250 Yes/No/NA Yes/No/NA Yes/No/NA Yes/No/NA of alteration, have been examined and operate satisfactorily. 300 The door hinging arrangements have been examined and found to be satisfactory. Yes/No/NA Yes/No/NA Yes/No/NA Yes/No/NA 350 The local and/or remote operation of securing devices/cleats fou nd to be satisfactory. Yes/No/NA Yes/No/NA Yes/No/NA Yes/No/NA Yes/No/NA Yes/No/NA for bow doors) LL Appendix 1 B Bow, Inner Bow, Side and Stern Doors I S

All equipment associated with the opening, closing and securing o f the doors, that is 400 wire ropes, chains, sheaves, rollers, guides, shackles etc. exami ned and found to be Yes/No/NA Yes/No/NA Yes/No/NA Yes/No/NA satisfactory. 500 The tightness of the doors has been confirmed. Yes/No/NA Yes/No/NA Yes/No/NA Yes/No/NA

The remote control panels and associated indicator lights, closed circuit television 550* system, water leakage indicator lights and alarm systems have bee n examined and Yes/No/NA Yes/No/NA Yes/No/NA Yes/No/NA found to operate satisfactorily. 600* The required notice boards are in place and the ships log entrie s confirmed. Yes/No/NA Yes/No/NA Yes/No/NA Yes/No/NA 650 Power units Yes/No/NA Yes/No/NA The power units used for the opening, closing and securing of the doors have been 650a Yes/No/NA Yes/No/NA Yes/No/NA Yes/No/NA found to operate satisfactorily. 650b The hydraulic system including pipelines and fittings has been c onfirmed free of leaks. Yes/No/NA Yes/No/NA Yes/No/NA Yes/No/NA The hydraulic system (or other power systems) has been tested to confirm that in the. 650c Yes/No/NA Yes/No/NA Yes/No/NA Yes/No/NA event of system failure the hydraulically operated securing devic es remain locked. 650d ory. All associated electrical equipment examined and found satisfact Yes/No/NA Yes/No/NA Yes/No/NA Yes/No/NA sufficient securing de Yes/No/NA water leaka Yes/No/NA Yes/No/NA

It is confirmed that the Report C11 on board provides information regarding the door arrangements as fitted, including details of vices, remote control 700 Yes/No/NA Yes/No/NA Yes/No/NA devices and associated indicator lights, CCTV system, ge indicators and bilge system.

Confirm the bilge system for the space between the inner and oute r bow doors tested 750 Yes/No/NA satisfactorily. 800 Confirm that the bilge system for vehicle deck(s) has been teste d satisfactorily. Yes/No/NA Has this ship a special feature class notation "LA" with respect to bow doors, stern 850 doors or side doors used as cargo ramps for vehicle loading and d ischarging Yes/No/NA operations? Has this ship an optional descriptive notation (CR) in column 6 o f the Register of ships 900 with respect to bow doors, stern doors or side doors used as carg o ramps for vehicle Yes/No/NA loading and discharging operations? 950 If yes for 850 or 900, are the surveys required by the Cargo Gea r Register up to date? Yes/No/NA *For all inward opening doors (without size restriction) and outw ard opening doors with a clear opening of 12m or more, this is a Rule requirement . B = Bow door S = Side doors I = Inner bow door St = Stern door

Note: The above are intended to apply to doors on roll on-roll off ships but m ay be applied as necessary to other shell doors in 050 LR2100AClass (2007.02) ----------------------- Page 13----------------------Report no: Page 13 of 13 The following survey has been carried out Initial/Annual/Intermediate/Docking* The Certificates have been endorsed The following checklist parts have been completed Place of Survey Date of Survey

Surveyor to A member of the Lloyd s Register Group Remarks: LR2100AClass (2007.02)

You might also like

- Shipowners Club Reactivation of Vessels After A Period of Layup 2017 - 08 PDFDocument4 pagesShipowners Club Reactivation of Vessels After A Period of Layup 2017 - 08 PDFToheid AsadiNo ratings yet

- How to Abandon Ship: The World War II Classic That Can Save Your LifeFrom EverandHow to Abandon Ship: The World War II Classic That Can Save Your LifeNo ratings yet

- Ship Lay Up Guidelines Mar10Document24 pagesShip Lay Up Guidelines Mar10Hamada GadNo ratings yet

- Condition Assessment Programme (CAP)Document9 pagesCondition Assessment Programme (CAP)Giorgi KandelakiNo ratings yet

- Industrial Thermoprocessing Equipment - Safety For Generation and Use Atmosphere Gases PDFDocument34 pagesIndustrial Thermoprocessing Equipment - Safety For Generation and Use Atmosphere Gases PDFEmanuelValenciaHenaoNo ratings yet

- Ship Inspection FormDocument67 pagesShip Inspection Formitavsa100% (3)

- Preparation For Dry Docking: (As A Chief Engineer) : 27 February 2012 at 11:40Document6 pagesPreparation For Dry Docking: (As A Chief Engineer) : 27 February 2012 at 11:40Swopon ShahjahanNo ratings yet

- Lloyd - Maintenance Guide Checklist Rev3Document22 pagesLloyd - Maintenance Guide Checklist Rev3Amit Kumar Sen100% (1)

- Survey Report East of EnglandDocument55 pagesSurvey Report East of EnglandThan Htet100% (1)

- Commercial Ship Surveying: On/Off Hire Condition Surveys and Bunker SurveysFrom EverandCommercial Ship Surveying: On/Off Hire Condition Surveys and Bunker SurveysRating: 4.5 out of 5 stars4.5/5 (6)

- Good Maintenance On Board Ships E2017Document94 pagesGood Maintenance On Board Ships E2017criNo ratings yet

- Ericson SampleDocument77 pagesEricson SampleChet Stephens50% (2)

- Standard P&i Condition SurveyDocument31 pagesStandard P&i Condition Surveyluchiappi100% (9)

- Short Condition Survey Report-2012-1Document7 pagesShort Condition Survey Report-2012-1alive2flirtNo ratings yet

- From T-2 to Supertanker: Development of the Oil Tanker, 1940 - 2000, RevisedFrom EverandFrom T-2 to Supertanker: Development of the Oil Tanker, 1940 - 2000, RevisedNo ratings yet

- Technical Specification DP SystemDocument48 pagesTechnical Specification DP SystemAjay SinghNo ratings yet

- Survey Report Gold OceanDocument61 pagesSurvey Report Gold OceanLuu Quang HoaNo ratings yet

- PSSR BookletDocument51 pagesPSSR BookletMariappan Na100% (2)

- Survey Checklist ANCODocument23 pagesSurvey Checklist ANCOkonstadine100% (1)

- Docking Survey Checklist: Name of The Ship: IR. Number: Port of Registry: Report No.Document3 pagesDocking Survey Checklist: Name of The Ship: IR. Number: Port of Registry: Report No.capone55No ratings yet

- Checklist For The Intermediate Cargo Ship Safety Equipment CertificateDocument12 pagesChecklist For The Intermediate Cargo Ship Safety Equipment CertificateRASMIRANJAN PANDA100% (2)

- Equipment No Na08 Echo SounderDocument2 pagesEquipment No Na08 Echo SounderAjay SinghNo ratings yet

- Marine Survey Practice - Intermediate and Periodical SurveyDocument3 pagesMarine Survey Practice - Intermediate and Periodical SurveyJym GensonNo ratings yet

- Class NK Good Maintenance Onboard ShipsDocument74 pagesClass NK Good Maintenance Onboard Shipsiacovosf836100% (2)

- Sample Bulk Carrier: Inspected at Coquimbo, Chile 26 September 2018Document54 pagesSample Bulk Carrier: Inspected at Coquimbo, Chile 26 September 2018nizartounsi100% (1)

- Flag State Control InspectionDocument15 pagesFlag State Control Inspectionrider_382150% (2)

- Ship ConstructionDocument23 pagesShip ConstructionRiyan Prayoga100% (1)

- ESP Guidance For All Ships V13.6 Jan 2019Document53 pagesESP Guidance For All Ships V13.6 Jan 2019Sreenivasan VaralilNo ratings yet

- Indian Holiday ResortsDocument4 pagesIndian Holiday ResortsAjay SinghNo ratings yet

- Detainable and ISM Related Deficiencies PSC Inspection Report of Class NK & NK-SMC Ships in June 2015Document9 pagesDetainable and ISM Related Deficiencies PSC Inspection Report of Class NK & NK-SMC Ships in June 2015Btwins123100% (1)

- OPS 01 - Fleet Superintendent's Onboard Meeting ChecklistDocument3 pagesOPS 01 - Fleet Superintendent's Onboard Meeting ChecklistEmre AlgülNo ratings yet

- ESP - Booklet For Bulk Carriers (Including Ore Carriers) - tcm155-206340Document71 pagesESP - Booklet For Bulk Carriers (Including Ore Carriers) - tcm155-206340Jusak Sonang SiahaanNo ratings yet

- On Hire Survey and Off Hire SurveyDocument4 pagesOn Hire Survey and Off Hire SurveyOhh Min75% (4)

- Marine SurveyorsDocument1 pageMarine SurveyorsNick SmithNo ratings yet

- 2020 ISM CodeDocument11 pages2020 ISM CodeAndriyNo ratings yet

- Fluid MechanicsDocument37 pagesFluid MechanicsI Anonymous67% (3)

- Tanker Disasters: IMO's Places of Refuge and the Special Compensation Clause; Erika, Prestige, Castor and 65 CasualtiesFrom EverandTanker Disasters: IMO's Places of Refuge and the Special Compensation Clause; Erika, Prestige, Castor and 65 CasualtiesNo ratings yet

- Hull Survey MethodsDocument10 pagesHull Survey MethodsGuit GuitNo ratings yet

- Modeling of Buried Natural Gas Pipeline Decompression: X. L. Zhou G. G. KingDocument8 pagesModeling of Buried Natural Gas Pipeline Decompression: X. L. Zhou G. G. Kingmatrix69No ratings yet

- In Water SurveyDocument33 pagesIn Water SurveyZin Maung Tun100% (1)

- Vetting Introduction For SuprintendentsDocument17 pagesVetting Introduction For SuprintendentsknellerNo ratings yet

- M.V. Spar Virgo at Tuticorin Off Hire Bunker ConditionDocument15 pagesM.V. Spar Virgo at Tuticorin Off Hire Bunker ConditionVikkiVikiNo ratings yet

- Dry Docking PDFDocument3 pagesDry Docking PDFDeepakNo ratings yet

- Marine Surveying - Drafting BasicDocument43 pagesMarine Surveying - Drafting BasicReynold KevinNo ratings yet

- B SC (Nautical)Document161 pagesB SC (Nautical)Ajay SinghNo ratings yet

- Emergency Towing Procedures Required For All ShipsDocument2 pagesEmergency Towing Procedures Required For All ShipsAjay Singh100% (1)

- Valuation of Marine VesselsDocument41 pagesValuation of Marine VesselsReza Babakhani100% (1)

- ASM June 2019 ISM ManualDocument10 pagesASM June 2019 ISM ManualAjay Singh100% (1)

- Ship Initial Inspection Checklist: Port State ControlDocument34 pagesShip Initial Inspection Checklist: Port State ControlBHASKAR HALDAR100% (1)

- Checklist For The Renewal Survey of Iopp CertificateDocument8 pagesChecklist For The Renewal Survey of Iopp CertificateMohd ShajiNo ratings yet

- West of England P&i GuidelinesDocument48 pagesWest of England P&i GuidelinesParthiban Nagarajan100% (1)

- Ship SurveyDocument12 pagesShip SurveyNur Luqman DzulkifliNo ratings yet

- Table of Shipboard Working ArrangementsDocument2 pagesTable of Shipboard Working ArrangementsKunal SinghNo ratings yet

- Checklist For TakeoverDocument3 pagesChecklist For TakeoverMariyath Muraleedharan KiranNo ratings yet

- Equipment No Na19 Magnetic CompasDocument2 pagesEquipment No Na19 Magnetic CompasAjay SinghNo ratings yet

- Checklist For Company Safety Management SystemDocument10 pagesChecklist For Company Safety Management SystemphamhahhNo ratings yet

- Cryogenic GuidelinesDocument31 pagesCryogenic Guidelineszvola100No ratings yet

- Port State Control Inspections: Management System CertificationDocument21 pagesPort State Control Inspections: Management System Certificationjose orozcoNo ratings yet

- Guidelines To Surveyor General: Hull & Machinery DetailsDocument3 pagesGuidelines To Surveyor General: Hull & Machinery DetailsRaman SaravananNo ratings yet

- CASALI Application Manual EngDocument102 pagesCASALI Application Manual Eng蔡豐任No ratings yet

- FLP2332 Diploma in Ship Superintendency Course FacultyDocument4 pagesFLP2332 Diploma in Ship Superintendency Course Facultyacacio8630No ratings yet

- Arras Mexei Mas 4000Document5 pagesArras Mexei Mas 4000mohammed Khaled100% (1)

- On-Off Hire SurveyDocument1 pageOn-Off Hire SurveyAditya PrasadNo ratings yet

- Docking Report of Orion wb2Document7 pagesDocking Report of Orion wb2joel jeffery SarkarNo ratings yet

- SireDocument3 pagesSireAmit MishraNo ratings yet

- Best Shipping Company in IndiaDocument10 pagesBest Shipping Company in IndiaDoehleDanautic100% (1)

- Marine Survey Practice - Notes Relative To Shell and Deck Plate RepairsDocument3 pagesMarine Survey Practice - Notes Relative To Shell and Deck Plate RepairsJym GensonNo ratings yet

- Ms Tse BrochureDocument24 pagesMs Tse Brochureshikha singhNo ratings yet

- The Apparent Solar TimeDocument3 pagesThe Apparent Solar TimeAjay SinghNo ratings yet

- Anchoring and What Precautions To TakeDocument2 pagesAnchoring and What Precautions To Takevikrami100% (2)

- What Is Difference Between Maritime Survey N InspectionDocument1 pageWhat Is Difference Between Maritime Survey N InspectionAjay SinghNo ratings yet

- EQUIPMENT No NA12 Speed Log RepeaterDocument2 pagesEQUIPMENT No NA12 Speed Log RepeaterAjay SinghNo ratings yet

- Equipment No 25 & 26Document2 pagesEquipment No 25 & 26Ajay SinghNo ratings yet

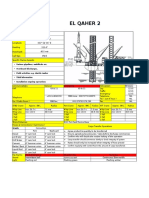

- ElQaher 2 Data CardDocument1 pageElQaher 2 Data CardAjay SinghNo ratings yet

- First Aid KitDocument1 pageFirst Aid KitAjay SinghNo ratings yet

- Procedure For Transmiting Designated VHF DSC Distress Alert From FurunoDocument1 pageProcedure For Transmiting Designated VHF DSC Distress Alert From FurunoAjay SinghNo ratings yet

- Equipment No Na01 RadarDocument2 pagesEquipment No Na01 RadarAjay SinghNo ratings yet

- Equipment No - Na13: Routine Checks Date Last Done Due Date RemarksDocument2 pagesEquipment No - Na13: Routine Checks Date Last Done Due Date RemarksAjay SinghNo ratings yet

- Equipment No Na16&Na17 AnemometerDocument2 pagesEquipment No Na16&Na17 AnemometerAjay SinghNo ratings yet

- Equipment No Na18 AisDocument2 pagesEquipment No Na18 AisAjay SinghNo ratings yet

- Equipment No Gm03 & Gm04 VHFDocument2 pagesEquipment No Gm03 & Gm04 VHFAjay SinghNo ratings yet

- Equipment No - Gm09: Routine Checks Date Last Done Due Date RemarksDocument2 pagesEquipment No - Gm09: Routine Checks Date Last Done Due Date RemarksAjay SinghNo ratings yet

- Equipment No Gm11 Fleet f77Document2 pagesEquipment No Gm11 Fleet f77Ajay SinghNo ratings yet

- Equipment No - Gm10: Routine Checks Date Last Done Due Date RemarksDocument2 pagesEquipment No - Gm10: Routine Checks Date Last Done Due Date RemarksAjay SinghNo ratings yet

- Equipment No - Gm02: Routine Checks Date Last Done Due Date RemarksDocument2 pagesEquipment No - Gm02: Routine Checks Date Last Done Due Date RemarksAjay SinghNo ratings yet

- EQUIPMENT No Fascimile Receiver GM08Document2 pagesEQUIPMENT No Fascimile Receiver GM08Ajay SinghNo ratings yet

- Equipment No GM 06 08vhf IcomDocument2 pagesEquipment No GM 06 08vhf IcomAjay SinghNo ratings yet

- Equipment No Sg01 Aldis LampDocument2 pagesEquipment No Sg01 Aldis LampAjay SinghNo ratings yet

- Equipment No Gm07 Inmarsat CDocument2 pagesEquipment No Gm07 Inmarsat CAjay SinghNo ratings yet

- TesDocument6 pagesTesDanika PutriNo ratings yet

- ANSYS Mechanical APDL Fluids Analysis GuideDocument44 pagesANSYS Mechanical APDL Fluids Analysis GuideGiLang MaulanaNo ratings yet

- Echilibru Chimic-1Document8 pagesEchilibru Chimic-1MirunaNo ratings yet

- Alat CSRDocument11 pagesAlat CSROperation TewehNo ratings yet

- Fire Safety Science News #37Document36 pagesFire Safety Science News #37IAFSSNo ratings yet

- Gas DiffusionDocument15 pagesGas DiffusionOh DausNo ratings yet

- Collins John Patrick 1994Document209 pagesCollins John Patrick 1994salvatore raffaNo ratings yet

- Detailed Lesson PlanDocument5 pagesDetailed Lesson PlanGspr BoJoyNo ratings yet

- General Chemistry Letbu 1Document8 pagesGeneral Chemistry Letbu 1Nur-hissam GandamraNo ratings yet

- Experiment 23 (Permeability)Document18 pagesExperiment 23 (Permeability)Anusha Anu100% (1)

- Lab ReportDocument9 pagesLab ReportAyaz BhattiNo ratings yet

- r050212302 Bio Chemical ThermodynamicsDocument4 pagesr050212302 Bio Chemical ThermodynamicsSrinivasa Rao GNo ratings yet

- 12pressure 1Document12 pages12pressure 1Imran ZafarNo ratings yet

- Analizer H2S Manual PDFDocument82 pagesAnalizer H2S Manual PDFJose LuisNo ratings yet

- 6317 - 1stedition APG1k ESM Manual PDFDocument211 pages6317 - 1stedition APG1k ESM Manual PDFshahzadNo ratings yet

- Topic List and Sample Items - B. TechDocument14 pagesTopic List and Sample Items - B. TechAryan ThakurNo ratings yet

- Mini MP 5200 Gas Analyzer Operator ManualDocument104 pagesMini MP 5200 Gas Analyzer Operator Manuallightjp1100% (3)

- FTPDocument6 pagesFTPGabi BarzăNo ratings yet

- Gatekeeper Inert Gas Purifier EsiteDocument4 pagesGatekeeper Inert Gas Purifier EsiteMarcos MedranoNo ratings yet

- 1 4940903211650252947 PDFDocument464 pages1 4940903211650252947 PDFyashsharmaNo ratings yet

- Matter in Our SurroundingDocument28 pagesMatter in Our SurroundingPrabodh GuptNo ratings yet

- Pressure Regulator ARGOS SeriesDocument24 pagesPressure Regulator ARGOS Seriescassio_tecdrawNo ratings yet

- 6732 Unit Test PHY2GDocument11 pages6732 Unit Test PHY2GSha ShareefNo ratings yet