Professional Documents

Culture Documents

Refining and Processing Sugar

Uploaded by

Thaddeus LewisCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Refining and Processing Sugar

Uploaded by

Thaddeus LewisCopyright:

Available Formats

reaching for sucrose.

And, whether you know it or not, youre opting for one of the purest foods found on the kitchen pantry shelf and in prepared food products. For thousands of years sugar has been an important food ingredient that provides a balanced sweet taste, safety as a preservative and provides functional properties essential in a multitude of foods. Sugar (sucrose) is a natural carbohydrate, found in fruits and vegetables. All green plants manufacture sugar through photosynthesis, the process by which plants generate energy and food reserves from sunlight.

When you reach for the sugar bowl, you are

Consumer Fact Sheet

Refining and Processing Sugar

Just as sugar plays a vital role in the growth and life cycle of plants, it is an important ingredient in our food supply. While all fruits and vegetables produce sugar, the sugar cane and sugar beet plants contain the most accessible stores of sucrose. Sugar is purified For many people, the term refined has lost its original meaning to purify and now carries a negative connotation. With sugar the refining process simply removes all impurities and the surrounding plant matter leaving only the pure sucrose. To further your understanding of sugar (sucrose) and its path from the field to the table, we provide the following plant to pantry tour. Raising CANE Sugar cane is a tropical grass that grows 10-20 feet high. Four U.S. states produce sugar cane: Florida, Hawaii, Louisiana and Texas. A stalk of the sugar cane plant contains 12-14% sucrose. The process of separating sugar from the sugar cane plant is accomplished in two steps: at sugar mills and at sugar refineries.

Make an informed choice. Choose pure natural sugar 15 calories per teaspoon.

The Sugar Association, Inc. 1300 L Street NW, Suite 1001, Washington, DC 20005 202/785-1122

The Sugar Mills are located near the sugar cane fields. It is here that the raw sugar is separated from the plant and shipped to a refinery. First, the sugar cane stalks are washed and cut into shreds by rotating knives. Next, huge rollers press the juice out of the shredded pulp. This juice is then:

www.sugar.org

Clarified-by adding milk of lime and carbon dioxide. The carbon dioxide bubbles through the mixture forming calcium carbonate, a chalk like crystal which attracts the non-sugar plant materials like wax, fats, and gums from the juice. In a clarifier, the calcium carbonate and the other materials fall out of the sucrose solution and settle to the bottom. Concentrated-by removing water from the clarified juice in multiple stages under vacuum. This allows the juice to boil at lower temperatures to protect the sugar from caramelization. The juice becomes a clear, rich brown syrup during this step.

Bulk raw sugar arrives at the refinery on ships or in railroad boxcars. It is mixed with warm affination syrup (a solution of water and sugar) to loosen the molasses surrounding the raw sugar crystals. This produces a batter-like mixture called magma. Large centrifuges spin the magma and separate the molasses film from the crystals. The crystals are washed, dissolved, clarified or filtered to remove the molasses and insoluble impurities. At this point, the product is a clear, golden-colored liquid.

other consumer and food industry products.

Crystallized-by evaporating the last portion of water under very tight controls in a vacuum pan. Seed grain (pulverized sugar) is fed into the pan as the water evaporates and crystals begin to form. The mixture leaves the vacuum pan as a thick crystal mass and is sent to a centrifuge, a large perforated basket spinning very rapidly much like a washing machine in the spin cycle, where it is spun and dried, yielding golden raw sugar.

Raw sugar is approximately 96-98% sucrose. The nearly pure sugar crystal is covered by a thin film of molasses, the thick raw syrup from the mill. The molasses coating contains sugar, water, plant material, minerals, and other nonsugars. The Cane Sugar Refinery transforms raw sugar into granulated sugar, brown sugar, and

This concentrated syrup is fed into a vacuum pan where it is seeded with fine sugar crystals. Through the skillful evaporation of the remaining water, these fine crystals are grown in the rich solution of sugar to produce perfect sugar crystals of the proper size. The sugar is spun in a centrifuge where the remaining syrup is spun off and the sugar crystals are washed with fresh, hot water. From the centrifuge the damp crystals are conveyed to large dryers where the moisture content of the sugar crystals is reduced from approximately 1% to .03%.

Carbon filters remove the remaining color, producing a water-white sugar syrup. The syrup is concentrated by evaporating some of the water.

The cossettes are gently lifted from the bottom to the top of the diffuser as hot water washes over them absorbing the sugar. After the sugar laden raw juice is drawn off, the beet pulp is left behind. This pulp is processed separately into pellets for livestock feed and other products. The juice is then filtered leaving a golden light brown clarified thin juice. This juice is boiled under vacuum where much of the water is evaporated, forming a thicker juice similar to pancake syrup.

The Sugar Beet Factory Sugar beet processing takes place in one location. At the factory, sugar beets are washed and sliced into thin strips called cossettes. The cossettes go through a large tank called a diffuser where raw juice is extracted. Heres how:

Sugar beets contain 16-18% sucrose and are processed at factories near the farms. Since sugars beets are grown and harvested seasonally, factories generally operate for a campaign (a period of time) of four to seven months. During these campaigns, facilities operate around-the-clock, seven days a week.

Its in the BEET Sugar beets flourish in temperate climates where the soil is rich and the growing season is about five months long. Farms can be found in California, Colorado, Idaho, Michigan, Minnesota, Montana, Nebraska, North Dakota, Oregon, and Wyoming.

The dried granulated sugar passes over screens to separate the various sizes of sugar crystals. Large and small crystals are packaged for standard consumer use and according to the specifications of industrial customers.

The massecuite is then sent to centrifuges for separation. By spinning rapidly in a perforated cylindrical basket, the syrup is thrown off through the screen holes. Clean hot water is used to wash the sugar, producing pure white sugar crystals. The damp crystals are dried with filtered air in a rotating drum granulator and the dried sugar passes over screens which separate the various sizes of sugar crystals. The products are then packaged and shipped to grocery stores and food manufacturers.

form. The resulting sugar crystal and syrup mix is called massecuite.

Sugar Sweet by Nature The sugar that results from sugar cane and sugar beet processing is the same sucrose that is found naturally in the original plants and in fruits and vegetables. The raw sugar color is removed by physical separation of plant materials and by carbon filters which absorb colored impurities. Since the pure sugar crystals are naturally colorless, no bleaching or whitening is necessary. A byproduct of the cane and beet sugar refining process is molasses which has a multitude of uses. Molasses is an important feed stock in the production of antibiotics, bakers yeast, rum and fuel alcohol, as well as an animal feed supplement. The Sweet Story Sugar is an important source of carbohydrate, contains no fat or cholesterol, and at 15 calories a teaspoon is kind to the waistline especially when combined with low-fat foods. Sugar is listed by the Food and Drug Administration (FDA) as GRAS (Generally Recognized As Safe).

After a second filtration to ensure that all non-sugar materials are removed, the juice goes to the boiling pans. Once again the juice is boiled under vacuum and crystals begin to

Sugar plays an important part in making good foods taste even better and has many functional attributes in food preparation. In addition to its role as a flavor enhancer, sugar can act as a preservative, a bulking agent, a balancing agent, and a fermentation aid. It is sugar that helps bread to rise, heightens flavor and preserves fruit in jams and jellies, provides smooth texture to candies and sauces, and balances the tart flavors of other ingredients in many main dish recipes.

Questions Most Frequently Asked About Sugar

2. Are some sugar products more or less refined than others? All sugar products on the market are refined. In addition to traditional light and dark brown sugar and pure white granulated sugar, some manufacturers produce lightly colored sugars (golden or tan) for specialty uses. Consumer sugar products range from about 96% sucrose (brown sugar) to 99.9% sucrose (white granulated sugar). Turbinado sugar is a light tan washed raw sugar product available in some areas. Demerara sugar is a golden colored specialty sugar product. These products undergo refining to separate sucrose from the plant material.

1. What nutritional impact does white sugar have on my diet? White sugar is pure sucrose, a carbohydrate. Carbohydrates provide energy, contain no fat, and like protein contribute 4 calories per gram in your diet (as opposed to the 9 calories per gram contributed by fat).Your body treats sucrose like any other carbohydrate it is converted into glucose and used by the cells for energy.

arrive at the refineries or processing plants. The initial tests are for purity and sucrose content. Then a battery of tests are continually run to ensure proper pH balance, temperature, color, and consistency as the sugar solution makes its way through the facility. Equipment and filtering materials are also monitored around the clock to ensure that they are working efficiently. Because its 99.9% pure sucrose, refined sugar is one of the highest quality products found in your grocery store. 6. What happens to the materials left over from sugar processing ? Many of the materials are recycled and reused. The plant matter from which the sugar is extracted is reused. The sugar cane stalk residue, called bagasse, often is used as a fuel to run the cane factory. Most sugar cane mills and refineries produce their own electricity and some even supply power to nearby towns. The beet residue, or pulp, is generally used for animal feed or further processed for use as fiber or other products. Molasses, used by distillers, bakers, pharmaceutical companies and others, is recycled through the beet sugar and cane sugar refining process an average of four times to extract the maximum amount of sucrose. Carbon chips, used in filtration, are recharged (revivified) and reused, too. In addition, much of the water removed along the way still contains sucrose (called sweetwater) so it is pumped back into the stations to be used again. Little is wasted in sugar refining.

3.What is brown sugar? Brown sugar is sugar crystals in a specially prepared molasses syrup with controlled natural flavor and color components. A number of sugar refiners make brown sugar by preparing and boiling a special syrup containing these components until brown sugar crystals form. Others produce brown sugar by blending a special molasses syrup with white sugar crystals. 4. Does sugar contain preservatives or other additives? No. Sugar is pure sucrose. It contains no preservatives or additives of any kind.

5. What quality controls are in place at the sugar cane refinery or sugar beet processing plant? Plenty. Samples of the sugar are examined from start to finish. Rigid standards are maintained by testing at each stage of the manufacturing process. Testing begins when the raw sugar (from sugar cane) or the sugar beets

For more information on the natural goodness of sugar contact the Sugar Association. www.sugar.org

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Judgement 1Document1 pageJudgement 1Thaddeus LewisNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Roadmap MGMT WasteDocument54 pagesRoadmap MGMT WasteMedha MalviyaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Waste ArticlesDocument3 pagesWaste ArticlesThaddeus LewisNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- IUPAC Provisional Recommendations: Chapter P-1 Nomenclature of Organic CompoundsDocument94 pagesIUPAC Provisional Recommendations: Chapter P-1 Nomenclature of Organic CompoundsJuan Carlos SihotangNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Linear and Binary SearchDocument1 pageLinear and Binary SearchThaddeus LewisNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Physics Notes VectorsDocument10 pagesPhysics Notes VectorsThaddeus LewisNo ratings yet

- ColorsDocument2 pagesColorsThaddeus LewisNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Mangroves 2Document9 pagesMangroves 2Thaddeus LewisNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Ntse Class Viii SatDocument12 pagesNtse Class Viii SatThaddeus LewisNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Community ServiceDocument9 pagesCommunity ServiceThaddeus LewisNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Mangroves 3Document12 pagesMangroves 3Thaddeus LewisNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Mangroves 3Document12 pagesMangroves 3Thaddeus LewisNo ratings yet

- Injso 2014 Sol FinalDocument7 pagesInjso 2014 Sol FinalThaddeus LewisNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Mangroves 1Document6 pagesMangroves 1Thaddeus LewisNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Name Designation Office Phones Email FaxDocument1 pageName Designation Office Phones Email FaxThaddeus LewisNo ratings yet

- Ntse MP 2013Document36 pagesNtse MP 2013Thaddeus LewisNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Source of ThingsDocument2 pagesSource of ThingsThaddeus LewisNo ratings yet

- Oscillation Paper 1Document3 pagesOscillation Paper 1Thaddeus LewisNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- 97 BiolDocument85 pages97 BiolacscchuNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- National - Things of IndiaDocument3 pagesNational - Things of IndiaThaddeus LewisNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- NTSE SyllDocument4 pagesNTSE SyllThaddeus LewisNo ratings yet

- Junior Science: Selection For Stage II (INJSO) : Sl. No State Name State Code No. of StudentsDocument8 pagesJunior Science: Selection For Stage II (INJSO) : Sl. No State Name State Code No. of StudentsgnkstarNo ratings yet

- JSO CentersDocument1 pageJSO CentersThaddeus LewisNo ratings yet

- NSEJS 2013 Paper SolutionsDocument6 pagesNSEJS 2013 Paper SolutionsDr Mohan SavadeNo ratings yet

- Archaic NameDocument4 pagesArchaic NameThaddeus LewisNo ratings yet

- LOK Sabha Seats IndiaDocument1 pageLOK Sabha Seats IndiaThaddeus LewisNo ratings yet

- Best Aviation Photography Ever DoneDocument39 pagesBest Aviation Photography Ever DoneThaddeus LewisNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- BiologyDocument10 pagesBiologyThaddeus LewisNo ratings yet

- Biology - PathogensDocument5 pagesBiology - PathogensThaddeus LewisNo ratings yet

- Abstracts CopenhagenDocument127 pagesAbstracts CopenhagenPisica ZmeuNo ratings yet

- Gcse Marking Scheme: Science - Biology JANUARY 2011Document16 pagesGcse Marking Scheme: Science - Biology JANUARY 2011sureshthevanNo ratings yet

- Literature Review On Eating HabitsDocument8 pagesLiterature Review On Eating Habitsea4hasyw100% (1)

- DLL 10 W9Document5 pagesDLL 10 W9Kristela Mae ColomaNo ratings yet

- Informe Expo Ingles 4 M FinalDocument6 pagesInforme Expo Ingles 4 M Finaltomas rNo ratings yet

- US Pet Food StudyDocument192 pagesUS Pet Food StudyRana OstaNo ratings yet

- GNLD's G1 Laundry Powder - Fast FactsDocument2 pagesGNLD's G1 Laundry Powder - Fast FactsNishit KotakNo ratings yet

- Pepsico India CSR ActivityDocument8 pagesPepsico India CSR ActivityRuhanNo ratings yet

- Red Bull Building Brand Equity in New WaysDocument5 pagesRed Bull Building Brand Equity in New WaysGyanendra SharmaNo ratings yet

- Handbookofvitaminc PDFDocument436 pagesHandbookofvitaminc PDFQUOC HANo ratings yet

- Irradiation Applications in Dairy Products: A ReviewDocument17 pagesIrradiation Applications in Dairy Products: A ReviewPravin Zine PatilNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Feasibility of Pulverized Eggshell As Cementing MaterialDocument12 pagesFeasibility of Pulverized Eggshell As Cementing MaterialAllen Grace MendezNo ratings yet

- Lipofer BrochureDocument2 pagesLipofer BrochurenbpravinNo ratings yet

- Progam and Rundown of IFS 2017 (New)Document47 pagesProgam and Rundown of IFS 2017 (New)Ardiyanto MaksimilianusNo ratings yet

- Internship Report Pure Foods CompanyDocument46 pagesInternship Report Pure Foods CompanyMuhammad WaqarNo ratings yet

- Family Health Health Education LPDocument6 pagesFamily Health Health Education LPDan Angelo MatiasNo ratings yet

- Theoretical Foundation of NursingDocument103 pagesTheoretical Foundation of NursingSamantha Loi Therese MedrosoNo ratings yet

- 0438 s12 QP 13Document16 pages0438 s12 QP 13Syamala NatarajanNo ratings yet

- Activity Intolerance NCPDocument7 pagesActivity Intolerance NCPamitNo ratings yet

- School Form 8 (SF 8)Document2 pagesSchool Form 8 (SF 8)Jes RamosNo ratings yet

- The Role of LOLA in HEDocument27 pagesThe Role of LOLA in HEHendraDarmawanNo ratings yet

- 80 Day Obession Runnig Schedule 3Document3 pages80 Day Obession Runnig Schedule 3Gissel0094No ratings yet

- 63c18da748714 Basic Geriatric Nursing 7th Edition Williams Test Bank px8nzf PDFDocument108 pages63c18da748714 Basic Geriatric Nursing 7th Edition Williams Test Bank px8nzf PDFerickomusiq7No ratings yet

- Analysis: Dietary and Nutritional Approaches For Prevention and Management of Type 2 DiabetesDocument9 pagesAnalysis: Dietary and Nutritional Approaches For Prevention and Management of Type 2 DiabetesMr. LNo ratings yet

- Continuum of Reliability Practice ExerciseDocument2 pagesContinuum of Reliability Practice Exercisenocturnos yohNo ratings yet

- Impact of Fast Food Consumption On Health: IjrtbtDocument5 pagesImpact of Fast Food Consumption On Health: IjrtbtAnisha AmmuNo ratings yet

- Multivitamin ChartDocument1 pageMultivitamin ChartReshan ChowdhuryNo ratings yet

- Ep 201 Industrial Chemistry Laboratory ReportDocument9 pagesEp 201 Industrial Chemistry Laboratory ReportThobashinni ManimaranNo ratings yet

- Soal Hots SBMPTN Ruang Guru For SantriDocument5 pagesSoal Hots SBMPTN Ruang Guru For SantriIbnu Hadi Muhammad IslahuddinNo ratings yet

- Exam: 1 Date: Nov 7 Duration: 45 Mins Name: Grade: (5)Document2 pagesExam: 1 Date: Nov 7 Duration: 45 Mins Name: Grade: (5)AlaNo ratings yet

- Love Yourself, Heal Your Life Workbook (Insight Guide)From EverandLove Yourself, Heal Your Life Workbook (Insight Guide)Rating: 5 out of 5 stars5/5 (40)

- Gut: The Inside Story of Our Body's Most Underrated Organ (Revised Edition)From EverandGut: The Inside Story of Our Body's Most Underrated Organ (Revised Edition)Rating: 4 out of 5 stars4/5 (378)

- The Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldFrom EverandThe Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldRating: 3.5 out of 5 stars3.5/5 (5)

- The Obesity Code: Unlocking the Secrets of Weight LossFrom EverandThe Obesity Code: Unlocking the Secrets of Weight LossRating: 4 out of 5 stars4/5 (5)

- Forever Strong: A New, Science-Based Strategy for Aging WellFrom EverandForever Strong: A New, Science-Based Strategy for Aging WellNo ratings yet

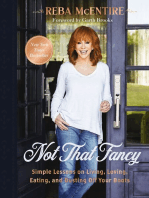

- Not That Fancy: Simple Lessons on Living, Loving, Eating, and Dusting Off Your BootsFrom EverandNot That Fancy: Simple Lessons on Living, Loving, Eating, and Dusting Off Your BootsNo ratings yet