Professional Documents

Culture Documents

File 246 Eng PDF

Uploaded by

RevaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

File 246 Eng PDF

Uploaded by

RevaCopyright:

Available Formats

m and region m , m and m industry

_________________________________________________

Basalt Fiber-Based Thermal Insulating Materials Market Research in Russia

Sample PDF

Moscow May 2007

Internet: www.infomine.ru e-mail: info@infomine.ru

Basalt Fiber-Based Thermal Insulating Materials Market Research in Russia

CONTENTS

Introduction ............................................................................................................. 8 1. Technology of production and characteristics of basalt fiber and basalt fiberbased products.................................................................................................... 9 1.1. Technology of production and kinds of basalt fiber-baseed products........... 9 1.2. Comparative characteristics of glass, mineral and basalt fibers and materials n their basis ...................................................................................................... 15 2. Production of thermal insulating materials and products on the basis of basalt fiber in Russia in 2000-2006............................................................................ 18 2.1. Production of thermal insulating materials and products on the basis of basalt fiber in Russia in 2000-2006 ........................................................................ 18 2.2. The main manufacturers of thermal insulating materials on the basis of basalt fiber............................................................................................................... 24 Plants of Group Rockwool....................................................................................... 24 Company TechnoNikol....................................................................................... 28 PJSC Isoroc .......................................................................................................... 31 JSC Ivotsteklo ....................................................................................................... 37 LLC Nazarovsky plant of thermal insulating fabrications and constructions 40 JSC Termosteps .................................................................................................... 44 JSC Termosteps-MTL .......................................................................................... 48 LLC IZOMIN ........................................................................................................ 48 JSC Tizol ............................................................................................................... 51 PJSC Plant Minplita ............................................................................................ 56 LLC Machine building plant Bask ................................................................... 59 LLC FibroBask .................................................................................................... 63 JSC Novgorod plant of glass fiber...................................................................... 65 PJSC Basalt fiber ................................................................................................. 68 LLC Scientific-production firm Izomat ............................................................ 69 Group of companies Ural Basalt........................................................................ 70 PJSC Dmitrov thermal insulation....................................................................... 72 LLC NPTO Korda.............................................................................................. 77 JSC Khabarovsk plant Bazalit DV ................................................................... 81 Small enterprises on production of fabrications on the basis of basalt fiber...... 84 3. Russian foreign trade in thermal insulating materials and fabrications on the basis of basalt fiber in 2000-2006 ................................................................... 87 3.1. Export of thermal insulating materials......................................................... 87 3.2. Import of thermal insulating materials......................................................... 91 Rockwool ................................................................................................................... 93 Paroc Group ............................................................................................................. 94 Izomat95 Isoroc 96

INFOMINE Research Group www.infomine.ru; e-mail: info@infomine.ru; phone/fax: (495) 237-8033

Basalt Fiber-Based Thermal Insulating Materials Market Research in Russia

4. Review of prices on thermal insulating materials and fabrications on the basis of basalt fiber.................................................................................................. 102 5. Consumption of thermal insulating materials and products on the basis of basalt fiber in Russia ..................................................................................... 106 6. Forecast of development of Russian market of thermal insulating materials and products on the basis of basalt fiber in 2007-2010 .............................. 111 6.1. Forecast of production and consumption of thermal insulating materials of Rosstroi ....................................................................................................... 111 6.2. Forecast of production of thermal insulating materials on the basis of basalt fiber from experts of LLC InfoMine ...................................................... 115 Appendix 1. Price lists on insulating fabrications on the basis of basalt fiber .......................................................................................................................... 117 JSC AKSI (as of 12.12.2006) ........................................................................ 118 JSC Ivotsteklo (as of 01.01.07) ..................................................................... 120 LLC Nazarovsky plant of thermal insulating fabrications and constructions (as of 12.02.2007)............................................................................................. 122 JSC Tizol ....................................................................................................... 126 PJSC Plant Minplita (as of 01.04.07)........................................................... 127 LLC Machine building plant BASK (as of February 2007)...................... 128 LLC FibroBask (as of February 2007) ........................................................ 129 LLC NPF Izomat (as of 01.02.07)............................................................... 130 LLC Basalt-Most (Klimovsk, Moscow region) ............................................. 131 LLC NPTO Korda (as of 29.01.07)............................................................. 132 JSC Khabarovsk plant Bazalit DV.............................................................. 133 Appendix 2. Contact information on companies ........................................ 134

INFOMINE Research Group www.infomine.ru; e-mail: info@infomine.ru; phone/fax: (495) 237-8033

Basalt Fiber-Based Thermal Insulating Materials Market Research in Russia

List of Tables

Table 1. Compararive characteristics of fibers .............................................................15 Table 2. Summarized table of manufacturers of products on the basis of basalt fiber with expert estimation of productive capacities ............................................20 Table 3. Range of products and performance data of fabrications, manufactured under brand name Rockwool.........................................................................26 Table 4. Performance data of fabrications PJSC AKSI (trademarks Technoblock and Technolight)............................................................................................29 Table 5. Performance data of fabrications PJSC AKSI (trademarks Technoroof, Technovent) ...................................................................................................30 Table 6. Range of products and fields of application of thermal insulating fabrications Isoroc (building insulation) .......................................................32 Table 7. Range of products and fields of application of thermal insulating fabrications Isoroc (technical insulation) ......................................................34 Table 8. Performance data of fabrications, manufactured by PJSC Isoroc (plates) .35 Table 9. Performance data of fabrications, manufactured by PJSC Isoroc (mats and cylinders) .......................................................................................................36 Table 10. Range of products from basalt fiber, produced by JSC Ivotsteklo...........37 Table 11. Range of products and performance data of fabrications, manufactured by JSC Ivotsteklo............................................................................................38 Table 12. Acoustic parameters of fabrications IZIS-B .................................................39 Table 13. Performance data of basalt fiber, manufactured by LLC Nazarovsky plant of thermal insulating fabrications and constructions...................................40 Table 14. Performance data of energetical thermal insulating plates energetical (PTE), manufactured by LLC Nazarovsky plant of thermal insulating fabrications and constructions .....................................................................41 Table 15. Performance data of energetical thermal insulating cylinders (TSTE), manufactured by LLC Nazarovsky plant of thermal insulating fabrications and constructions .........................................................................................42 Table 16. Performance data of energetical basalt cords (SHBE), manufactured by LLC Nazarovsky plant of thermal insulating fabrications and constructions................................................................................................42 Table 17. Performance data of energetical basalt quilts (MBPE), manufactured by LLC Nazarovsky plant of thermal insulating fabrications and constructions................................................................................................43 Table 18. Range of products on the basis of basalt fiber, manufactured by JSC Termosteps, and fields of their application ...............................................45 Table 19. Performance data of fabrications, manufactured by JSC Termosteps......47 Table 20. Range of products of fabrications, manufactured by LLC Izomin...........49 Table 21. Performance data of fabrications, manufactured by LLC Izomin............50 Table 22. Products, manufactured by JSC Tizol ......................................................52 Table 23. Range of products and performance data of engineering insulation, manufactured by PJSC Plant Minplita ......................................................56

INFOMINE Research Group www.infomine.ru; e-mail: info@infomine.ru; phone/fax: (495) 237-8033

Basalt Fiber-Based Thermal Insulating Materials Market Research in Russia

Table 24. Range of products and performance data of insulation for external walls and flat roofs, manufactured by PJSC Plant Minplita...............................57 Table 25. Range of products and performance data of insulation for production of sandwich-panels, manufactured by PJSC Plant Minplita .........................59 Table 26. Acoustic characteristics of fabrications, manufactured by PJSC Plant Minplita .......................................................................................................59 Table 27. Performance data of fabrications, manufactured by LLC Machine building plant Bask ..................................................................................................61 Table 28. Characteristics of basalt fiber and products on its basis, manufactured by LLC FibroBask .........................................................................................63 Table 29. Performance data of fabrications, manufactured by JSC Novgorod plant of glass fiber ................................................................................................66 Table 30. Physico-performance data of basalt fire retarding web material, manufactured by Group Ural Basalt..........................................................70 Table 31. Physico-performance data of basalt fabric, manufactured by Group of companies Ural Basalt...............................................................................71 Table 32. The main performance data of fabrications, manufactured by PJSC Dmitrov thermal insulation (quilts thermal insulating with filler)............72 Table 33. The main performance data of plates, manufactured by PJSC Dmitrov thermal insulation ........................................................................................73 Table 34. Characteristics of basalt fiber, manufactured by LLC Basalt-Most .........73 Table 35. Characteristics of production line on manufacturing of basalt cloth of LLC Basalt-Most................................................................................................74 Table 36. Characteristics of basalt cloth, manufactured by LLC Basalt-Most ........75 Table 37. Characteristics of line on production of thermal insulation plates at LLC Basalt-Most................................................................................................75 Table 38. Characteristics of thermal insulation plates, manufactured by LLC BasaltMost .............................................................................................................76 Table 39. Performance data of basalt mats, manufactured by LLC NPTO Korda.77 Table 40. Performance data of basalt plates, manufactured by LLC NPTO Korda78 Table 41. Performance data of basalt fabric and cardboard, manufactured by LLC NPTO Korda............................................................................................79 Table 42. Performance data of basalt fabrications, manufactured by LLC NPTO Korda .........................................................................................................79 Table 43. Performance data of basalt thermal insulation of type Lagging, manufactured by LLC NPTO Korda .......................................................80 Table 44. Products, manufactured by JSC Khabarovsk plant Bazalit DV .............82 Table 45. Dynamics of Russian exports of products on the basis of basalt fiber in 2000-2006, t, % .............................................................................................89 Table 46. The main Russian exporters, t, % .................................................................90 Table 47. The main suppliers of products on the basis of basalt fiber to Russia in 2005-2006......................................................................................................92 Table 48. Performance data of the main Izomat fabrications, supplied to Russian market ............................................................................................................96

INFOMINE Research Group www.infomine.ru; e-mail: info@infomine.ru; phone/fax: (495) 237-8033

Basalt Fiber-Based Thermal Insulating Materials Market Research in Russia

Table 49. Breakage of import of products on the basis of basalt fiber in 2006 by regions, t, % ...................................................................................................97 Table 50. Dynamics of import of products on the basis of basalt fiber in 2000-2006 by country-suppliers, t ...................................................................................99 Table 51. The main importers of products on the basis of basalt fiber in 2006, t, %.100 Table 52. Dynamics of prices of the main brand names by plants-producers in 20042006, $ /t ......................................................................................................103 Table 53. Supply-demand balance of products on the basis of basalt fiber in Russia in 2000-2006, thousand t .................................................................................108 Table 54. The main consumers of thermal insulation on the basis of basalt fiber in Russia in 2006, t ..........................................................................................109 Table 55. Forecast of relationship between multistory and individual residential houses by Federal Districts in 2010, % .......................................................112 Table 56. Summary data on expected volumes of production of the main kinds of thermal insulating and roofing materials in 2010........................................113 Table 57. Forecast of demand for thermal insulating fiber materials on the basis of mineral resources, % ...................................................................................114

INFOMINE Research Group www.infomine.ru; e-mail: info@infomine.ru; phone/fax: (495) 237-8033

Basalt Fiber-Based Thermal Insulating Materials Market Research in Russia

List of Figures

Figure 1. Dynamics of production of thermal insulating materials from basalt fiber in Russia in 2000-2005, t, thousand cub m .......................................................18 Figure 2. Dynamics of manufacturing fabrications on the basis of basalt fiber in 2000-2006, t (expert estimation) ...................................................................19 Figure 3. Regional pattern of positioning productive capacities of enterprises in Russia (by Federal Districts) .........................................................................23 Figure 4. Dynamics of manufacturing fabrications on the basis of basalt fiber by JSC Tizol in 2000-2006, t .................................................................................51 Figure 5. Dynamics of production of basalt plates by LLC Machine building plant Bask , t .......................................................................................................60 Figure 6. Dynamics of production of basalt mats by LLC Machine building plant Bask , thousand m3 ....................................................................................61 Figure 7. Dynamics of manufacturing fabrications on the basis of basalt fiber by JSC Novgorod plant of glass fiber in 2000-2006, t ..........................................65 Figure 8. Dynamics of manufacturing fabrications on the basis of basalt fiber by PJSC Basalt fiber in 2000-2006, t, cub m, %............................................68 Figure 9. Dynamics of production of thermal insulating materials on the basis of basalt fiber by JSC Khabarovsk plant Bazalit DV, t, %..........................81 Figure 10. Dynamics of exports of products on the basis of basalt fiber from Russia in 2000-2006, thousand t, %..........................................................................87 Figure 11. Dynamics of Russian import of products on the basis of basalt fiber in 2000-2006, t...................................................................................................91 Figure 12. Pattern of Rusian import of products on the basis of basalt fiber in 2006 by brand names, t, % ..........................................................................................93 Figure 13. Dynamics of import prices by brand names in 2004-2006, $/t .................102 Figure 14. Dynamics of export prices of the main Russian manufacturers in 20042006, $/t .......................................................................................................104 Figure 15. Averaged structure of prime costs of production of insulation on the basis of basalt fiber, %..........................................................................................104 Figure 16. Dependence of average price on thermal insulating materials of their density..........................................................................................................105 Figure 17. Dynamics of consumption of products on the basis of basalt fiber in Russia in 2000-2006 ....................................................................................108 Figure 18. Forecast of production of insulating materials on the basis of basalt fiber up to 2010, thousand t .................................................................................115

INFOMINE Research Group www.infomine.ru; e-mail: info@infomine.ru; phone/fax: (495) 237-8033

Basalt Fiber-Based Thermal Insulating Materials Market Research in Russia

Introduction

The report is devoted to analysis of Russian market of thermal insulating items, based on basalt fiber. The report consists of 6 Sections, contains 142 pages, including 18 Figures, 57 Tables and 2 Appendices. This work was implemented in two stage. At the first stage - a desk study we carefully considered and analysed all available sources of information. As information sources, we used data of Rosstat, Federal Customs Service of Russia, official domestic railage statistic of JSC RZhD (former Ministry of Railway Transport of Russia), sectoral (industrial) and regional press, annual and quarterly reports of companies, as well as data from web-sites of company-manufacturers. Then, to verify and correct the analysed and summarized data, at the second stage, we conducted telephone interview with specialists of a number company-manufacturers and consumers of the products interest. The presented information can be useful in activity of production and trade companies, as well as enterprises of building sector (both for manufacturers and consumers of thermal insulating materials). The first Section of the report presents brief characteristics of production technologies and performance specifications of initial basalt fiber, as well as comparative characteristics of various fiber materials. The second core - Section of the report (production) presents comprehensive analysis of production of items, based on basalt fiber in Russia. Notice that data of Rosstat (Federal Statistics Agency of Russia) are not complete and, in addition, are not consistent with data of Federal Customs Service of Russia that forced InfoMine to collect all available direct and indirect data concerning basalt fiber-based items production in the country. Finally, expert evaluation of standing of production of thermal insulating materials, based on basalt fiber in Russia was elaborated on the basis of comprehensive analysis of all obtained data, and error of the estimated figures is below 15-20%. Notice that we made the greatest stress on analysis of range and performance specifications of the products in the course of the analysis to provide maximal benefit of potential consumers of the study. The third Section presents analysis of foreign trade in thermal insulating materials, based on basalt fiber in Russia. The fourth (final) Section of the report presents estimation of the product market capacity and forecast of the market development for the nearest 5 years. Taking into account paucity of the official statistical data, we presented, for comparison, estimations of the market behavior, elaborated by a number of authoritative organiations, including International Academy of Energo-Information Sciences and Economic Problems, companies URSA, Rockwool, LLC Saint-Goben Isover, Federal Agency on Construction and communal Utilities of Russia (Rosstroi). The estimation of LLC InfoMine differs slightly from the other forecasts; nevertheless, qualitative (overall) forecasts of all experts are consistent on the whole. The difference concerns quantitative parameters of the production growth. The data, presented by InfoMine, are based on calculations, taking into account operating and scheduled for launching productive capacities.

INFOMINE Research Group www.infomine.ru; e-mail: info@infomine.ru; phone/fax: (495) 237-8033

Basalt Fiber-Based Thermal Insulating Materials Market Research in Russia

1. Technology of production and characteristics of basalt fiber and basalt fiber-based products

1.1. Technology of production and kinds of basalt fiber-baseed products Technical progress of the 20th century to a large degree was connected with creation and widest application of composite materials on the basis of glass, carbon, ceramic, silicate and chemical fibers. At the same time, production of the materials produces negative effect on natural environment and human health. For instance, for this reason, many countries prohibited production and use of asbestos fabrications and building materials ion the basis of metallurgical slags. In this connection, specialists pay much attention to elaboration and introduction of new rather cheap environmentally and health-friendly materials and products to replace more expensive or harmful/dangerous previous ones in their applications. The most applicable resource for obtaining a new class of fibers with unique properties proved natural rocks - basalts. Basalt is a common gray to black volcanic rock. It is usually fine-grained due to rapid crystallization as lava on the Earth's surface. It may be porphyritic containing larger crystals in a fine matrix. Basalt in the tops of subaerial lava flows and cinder cones will often be highly vesiculated, imparting a lightweight "frothy" texture to the rock. The term basalt is at times applied to shallow intrusive rocks with a composition typical of basalt, but rocks of this composition with a phaneritic (coarse) groundmass should generally be referred to as diabase or gabbro. The crustal portions of oceanic tectonic plates are predominantly made of basalt. Unweathered basalt is frequently black to greenishblack in color, characterized by a preponderance of calcic plagioclase feldspars and pyroxene together with minor amounts of accessory minerals such as olivine. In Russia, gabbro-basaltcomposition rocks are widespread, first of all, in mountain territories Ural, Kola Peninsula, Caucasus, Eastern Siberia, etc. Basalt fibers are produced from basalt rock using single component raw material by drawing and winding fibers from the melt. Once the basalt fibers have been produced, they are converted into a suitable form for particular application. Basalt fibers show higher tensile strength and modulus, better chemical resistance, extended operating temperature range, better environmental friendliness than regular E glass - all in one material - getting close to and sometime outperforming carbon fiber and high strength glass and other specialty fibers but beating them price wise. Basalt fibers are ideally suited for demanding applications requiring high temperatures, chemical resistance, durability, mechanical strength and low water absorption. General basalt fiber's technical features as below: 1. Permanent flame retardant resistance: Limiting oxygen index (Loi) >70 2. Extraordinary high softening temperature (point): >1200 Celsius degree 3. Operating temperature range: from -260 to 760 Celsius degree 4. High tensile strength (breaking strength): 3200 MPa

INFOMINE Research Group www.infomine.ru; e-mail: info@infomine.ru; phone/fax: (495) 237-8033

Basalt Fiber-Based Thermal Insulating Materials Market Research in Russia

5. Low elongation at break: 3.1 % 6. High elastic modulus: 89 GPa 7. Density: 2.7 gram/cubic centimeter 8. Low thermal conductivity: 0.035 W/mK 9. High sound absorption coefficient: 0.95 10. Low moisture absorption: 0.1 % 11. High specific volume resistance: 1x1012 ohmm 12. Radiation proof lead equivalent: 0.0073 mm Pb Notice that mineralogical and chemical composition varies to some extent that owes some range of fluctuations of its initial composition. Besides, basalt fiber can be manufactured of a raw of natural geological magmatic rocks of gabbro-basalt type: basalt, diabase, gabbro, amphibolite, andesite that also owes differences in initial composition of resources. Grade and quality of basalt fiber is determined by precise composition of multi-component charge for melting, being commercial secret of each manufacturer. Basalt fiber is a modern XXI-century material, combining ecological safety, natural longevity, and fire safety (incombustibility). Water-absorbing capacity of basalt fiber is much less than 1%, of fiberglass - up to 10-20%. For comparison, industrially manufactured fiberglass, especially of neutral composition, absorbs substantial amount of moisture in humid air, which weakens its physical-technical and longevity properties and eventually leads to fiber damage. On contrary, low nonvolatile water absorbency of basalt fiber ensures stability of thermal and physical characteristics in case of continuous service. Basalt fiber has high chemical stability and pertains to the first dimming class and greatly exceed fiberglass in acid, alkali and steam resistance characteristics. The disadvantages of fiberglass compared to basalt fiber are spinosity of threads, and discharge of the finest dust at disintegration of thermal insulation at thermal-cycle loads. Due to high elastic modulus, basalt fiber strength is 35-40% higher than that of fiberglass - the fiber is more elastic, non-spinous. Materials of basalt fiber have a greater operating life as compared to materials of fiberglass. Super-thin basalt fiber is firmly knitted by natural cohesive attraction. Basalt fibers are chemically stable to exposures of aggressive means and steam and do not accumulate radiation. Costs of basalt fiber production are markedly lower (by 15-20%) compared with other mentioned fibers manufacture owing to one-stage basalt fiber production scheme. Yield of basalt fiber from basalt is 100%. Notice also that fbasalt fiberproducing facilities are compact, environmentally safe and waste-free (only products of cumbistion of natural gas, cooled and cleaned in filters, are emitted to atmosphere). The sole factor, hindering wide application of basalt fiber in Russia is very low volume of their commercial production. In the ex-USSR, only Russia and Ukraine posses key basalt technologies, own commercial-grade productions, domestic and

INFOMINE Research Group www.infomine.ru; e-mail: info@infomine.ru; phone/fax: (495) 237-8033

10

Basalt Fiber-Based Thermal Insulating Materials Market Research in Russia

export markets. For the latest years, large volume of R&D works in basalt-fiber and adjacent spheres was implemented. Basalt fibers are subdivided into two groups: continuous fibers and discrete fibers (named also basalt super-thin fibers, BSTF or BSTV in Russian abbreviation), fields of application of which differ from each other. Continuous fibers: thickness of a fiber ranges 7 to 24 microns. Designation: At thickness 7-15 microns, it is used as reinforcing filler in production of of composite materials (basalt-plastic) and products on their basis with polymer and inorganic matrix. At thickness 15-24 microns, it is used as reinforcing filler of composite materials with organic and mineral binder (concrete, asphalt, gypsum, etc.). As initial material, it is used in production of fabrics of various purpose (for filters, fire-proof clothes, anti-fire felting etc.), covering bags (pipe reinforcing, cable protection, etc.). Technological process of continuous fiber manufacture consists of melt preparation, fiber drawing, forming, fiber surface sizing, fiber winding. Crushed rock is charged into the melting furnace by the dozing charger. Crushed rock is charged automatically by electromagnet drives. The melting furnace is bath-type. Furnace heating is carried-out by air-gas mixture. Air-gas mixture comes from common mixer through burner. Air-gas water supply consists of pipes, air output set, stop and control valves, burners Crushed rock comes into melt under temperature 1460 1500C in furnace bath. Furnace combustion gases are took off to vertical stand pipe and then through smoke bonnet to atmosphere. Stand pipe is equipped with flowthrough radiant slot recuperator. Feeder has channel and widows inside. Molten basalt flows from furnace through feeder channel. One of feeder window communicates with recuperator. From below feeder has a window with a flange connected with slot-type bushing. Feeder is heated by furnace waste gases. The melt flows through the platinum-rhodium bushing with 200 to 400 holes. The bushing is heated electrically. Bushing is cooled by means recycled technical water. Recycled water is feed through collector with stop valve and ex-ported through flexible pipes to waste funnel. The fibers are drawn from the melt under hydrostatic pressure. Melt is cooled by cooler and get harden to fibers. A sizing is applied to the surface of the fibers by sizing applicator. The components of the sizing impart strand integrity, lubricity, and resin compatibility. After the sizing is applied, the roving (complex threads, composed of 200-400 elementary fibers, binded with each other by oiling agent) are gathered into a bundle called a "strand" by means of a gathering shoe before approaching the take-up device. The attenuation rate, and therefore the final diameter, is controlled by the take-up device (forming winder). The strand passes from the gathering shoe to a winder where it is wound onto a forming tube (forming package is often referred to as "forming cake"). The dried cakes are ready for further processing.

INFOMINE Research Group www.infomine.ru; e-mail: info@infomine.ru; phone/fax: (495) 237-8033

11

Basalt Fiber-Based Thermal Insulating Materials Market Research in Russia

Capacities of currently operating productive facilities are 100, 260 and 500 tpy fiber. If required, in re-winding bay, from the threads produced, twisted threads are obtained with the use of standard equipment, used in processing glass fiber (winding, weaving, pultrusion etc.). Taking into account that basalt fiber is well-compatible with carbon one, highefficient hybrid materials can be manufactured by adding small (pre-determined) amount of carbon fibers to basalt fibers. The obtained thread, differing insignificantly in cost (owing to small content of expensive carbon fiber) will demonstrate considerably better elastic properties compared with basalt fiber (notice that elastic modulus of basalt fiber is around 11000 kgF/mm2, whereas that of carbon fiber is 22000-56000 kgF/mm2). Roving is initial material for: Winding rotation bodies (pipes 5 to 2000 mm I diameter at internal pressure of 0 to 400 atm for oil/gas transport, hot and cold water supply, chemically-aggressive liquids, friable materials, cable channeling, low- and high-pressure balloons; Production of reinforcing bar, sections (angle, beam, etc.) by pultrusion method for building roads, houses, port contructions, especially in seismic zones; Roving long-life prepreg for manufacturing details of machines, complexshape frames by methods of moulding, extrusion, etc.); Chopped strand for 3-D reinforcing concrete; Asphalt pavement, in building roads, aerodrome pavement, in manufacturing 3-D-reinforced basalt-plastics of various purpose; Production of mesh for 2-D reinforcing road pavement,aerodrome pavement, fastening slide rocks and other building technologies; Production of wide range of twisted basalt threads as initial material for weaving; Production of fabrics of various purpose: structural, filtering, fire-proof, electrical, roofing, etc. Production of thermochemical and radiation fabric prepregs for obtaining basalt-composites and wide range of products on their basis for: machine building, aircraft-building, ship-building, building, etc., repair of building cinstruction (walls, bridges, tunnels, pipelines, columns, etc.). Basalt discrete fiber (basalt super-thin staple fiber, BSTF or BSTV in Russian abbreviation) thickness of elementary fiber 3-9 microns, length 40-60 mm. It is used for: - production of energy-efficient heat-sound-insulating materials and articles; - cryogenic equipment; - hydroponics; - as filler of 3-D reinforced basalt composite materials and articles with various binders;

INFOMINE Research Group www.infomine.ru; e-mail: info@infomine.ru; phone/fax: (495) 237-8033

12

Basalt Fiber-Based Thermal Insulating Materials Market Research in Russia

- in ship-, aircraft-, motor building, engineering, acoustic technique, and for increasing fire-resistance and fire prevention of various objects. BSTF demonstrate the same unique useful properties as continuous basalt fiber (high-temperature performance ability, chemical resistance, low water absorption, vibration-resistance, fire retarding properties, etc.), and articles from the product surpass, in complex of the properties, similar materials of mineral wool, slag wool, natural organic materials (moss, etc.). Its service-life exceeds 100 years with keeping exploitation properties; BSTF is friendly for natural environment and human health, chemically-resistant, demonstrate good sound-proof, heat-insulating and raditionabsorption properties. BSTF is produced by so-called duplex-method of natural geological magmatic rocks of gabbro-basalt type by melting these materials at the temperature of 1,400 to 1,500 degree centigrade and hyperthermal blowing up to 1,600 degree centigrade by a high-speed gas flow (300 to 400 m/s) to discreet ultimate spun fiber. Technological process for basalt super thin fiber production consists of the following stages:

basaltic crushed rock preparing charging of basaltic crushed rock into the furnace melting of basaltic crushed rock melt preparing in the feeder (temperature and level) forming of the continuous primary fibers in the bushing, primary fiber blowing reeiving staple fiber BSTF by means of flow burner fiber linen forming (width, length, thickness and density) on the receivingforming conveyor.

Raw material - basaltic crushed rock with fraction from 5 to 12 mm. Basaltic crushed rock is charged into the dosing charger by electric hoist. Crushed rock is dosed and charged in the bath furnace automatically. Basaltic crushed rock is melted in the bath furnace. Furnace is heated by air-gas mixture. From bath furnace melted basalt is going into feeder, which is intended for melt preparation and receiving. From feeder melt is going into the bushing, where continuous primary fibers are formed. Then primary fibers go into the drawing device. Then fibers go into the blow burner, attached to the blow chamber. Primary fiber blowing is made by blow chamber. Blow chamber consists of metal frame with double walls, between which water circulates. Blow chamber runs on natural gas and compressed air mixture, mixed previously in the mixer. Thin staple basaltic fibers are formed in the blow chamber by high-speed high-temperature gas flow. There is more modern process of fiber obtaining is super-high-speed multi-roll centrifugal method, in which spraying is conducted at roll high-speed (up to 6500 rpm) centrifuges. In the course of fiber forming, the melt goes through electromagnetic field (so-called Eifel process) that finally yields very high-grade

INFOMINE Research Group www.infomine.ru; e-mail: info@infomine.ru; phone/fax: (495) 237-8033

13

Basalt Fiber-Based Thermal Insulating Materials Market Research in Russia

fiber 3-4.5 microns in diameter and 35-50 mm long with low content of non-fiber inclusions (2% maximum). Flow of combustion materials together with fiber is transported into the diffuser to the receiving-forming conveyor with wire strip. Fiber deposits at the zone, where conveyor's strip borders to the blow chamber, which is connected to fans and filters by pipeline. Then fiber in the form of basalt wool felt is tightened by roll and spooled on receiving drum. When required thickness is achieved felt roll is cut off, reeled and transported to the finished-products storage area or to the next department where fiber be processed to slabs, mats, cardboards, cords. Felt, moving on the conveyor, is again reeled on receiving drum. BSTF (basalt) wool felt is a fiber material which consists of chaotic stable fibers fastened together by natural cohesion forces; at thickness of 50-100 mm, BSTF wool felt doesnt need binder to keep its shape and compactness. Basalt super thin fiber BSTF is the layer of mixed up staple fibers, fastened together by natural bond forces. BSTF has high heat and sound insulation properties, low hygroscopic property (8 times lower then glass fiber has), high chemical stability to neutralizing and acid conditions, high application temperature. BSTF is the raw product for production of the following materials: heat and sound insulation blankets for turbines in aviation, marine, atomic nuclear power-plant, heat-electric generating plant, for pipe, heat insulation cardboard/plate with thickness from 5 to 25 mm (for household oven, tooling, boilers, for metallurgy in second layer of furnace lining as substitute of asbestos materials); sealing and heat-insulation cords; heat-insulation slabs on inorganic binding (for ship, metallurgy in second layer of furnace lining, where phenol can not be applied); materials for hydroponics; materials for filter production. For instance, in engineering, heat-sound-insulating mats of BSTF felt, covered by envelope of basalt fiber fabric, are actively used. Impregnation of BSTF felt with organic or inorganic binder with following drying at temperature 90-150 allows to obtain a new family of materials: soft and rigid cardboard (5-8 mm thick), soft and rigid plates (thickness of 10 to 25 mm). These products of low density (100 to 400 g/cm3) find the widest application and ready demand both at domestic and export markets. The cardboard/plate, manufactured with the use of bentonite clay as binder, operates at high temperatures up to 1000 and are widely used in hot production (metallurgy, etc.). Basalt heat-insulating cord is made of basalt super-thin fiber or thin fiber twisted into plaits and braided with glass or basalt roving. It is widely used for heatsound-insulating purposes in civil and industrial engineering, ship-building, machine building, aircraft building and other sectors of industry.

INFOMINE Research Group www.infomine.ru; e-mail: info@infomine.ru; phone/fax: (495) 237-8033

14

Basalt Fiber-Based Thermal Insulating Materials Market Research in Russia

1.2. Comparative characteristics of glass, mineral and basalt fibers and materials n their basis At present time, around 60% of heat- and sound-insulating materials belongs to fiber materials: glass, mineral and basalt wool. Resources and production All the considered fibers are inorganic, but manufactured by different processes. Glass fibers are produced from melted charge (composed of quartz sand, soda, limestone, fluxing agents, etc.) to obtain glass, from which fibers are obtaind by blow with steam, air or at centrifuge. From glass fiber, glass fiber mats and fabrics are obtained as commodity products. Mineral fibers are manufactured by smelting blast furnace slags with additives (slag wool) or some mineral resources (gabbro-basalts with additives of clays, dolomite, etc.), with following blow similarly to glass fiber prpduction; mineral wool mats and plates are obtained from mineral fiber. Basalt fiber is obtained from melted rocks of gabbro-basalt composition without any additives; among commercial products of basalt fiber are basalt mats, nonwowen web (cloth), fabrics, plates, cardboard. To lower density of heat insulator, the better its heat-insulating properties. From this viewpoint, basalt wool surpasses markedly glass and mineral wools, as it has thinner fibers and lower density (Table 1). Coefficient of thickening when exploiting describes degree of thickening (with increasing density) of insulation with operating time. In this parameter, basalt wool is also the best. Residual tensile strength figures show that up to 200 all the materials keep practically their properties, but at higher temperatures basalt fiber emonstrates obviously much better performance. Table 1. Compararive characteristics of fibers Parameter Glass fiber Mineral fiber Basalt (BSTF) (characteristics) Mechanical characteristics

Apparent density, kg/m3 1 2 3 4 5 Diameter of elementary fiber, microns Length of fibers, mm Elastic modulus, KgF/mm2 Coefficient of thickening when exploiting 12-25 4-12 15-50 Up to 7200 1.6 25-40 4-10 16 54008000 1.8 15-23 1-3 40-70 910011000 1.2

INFOMINE Research Group www.infomine.ru; e-mail: info@infomine.ru; phone/fax: (495) 237-8033

15

Basalt Fiber-Based Thermal Insulating Materials Market Research in Russia

Parameter (characteristics)

Residual tensile strength (after heat treatment), %, at temperature 20 200 400 600 Working temperature, Thermal conductivity, W/m Caking temperature,

Glass fiber

Mineral fiber

Basalt (BSTF)

100 92 52 caking -60+250 0.038..0.042 600

100 95 60 20 -180+450 0.040.047 850

100 98 85 76 -250+700 0.031..0.034 1100

Temperature characteristics

7 8 9

10

at temperature 200 450 900

Vibro-resistance (loss of weight at vibration), %, (v=50 Hz, =1mm, t=3 hours)

12 41 100 40 75 100 0.01 0.35 0.950.99 1.6 2.75 2.2 0.02

Acoustic characteristics

0.80.92 0.750.95 11 Sound-absorption coefficient Chemical resistance (loss of weight ), % In water 12 In alkali In acid Water absorption 13 for 24 hours, % Source: InfoMine 6.2 6 38.9 1.7 4.5 6.1 24 0.95

Temperature range of performance ability of basalt fiber is much wider, and high-temperature limit of the ability is also much higher,compared with glass and mineral fibers; besides, high-temperature strength of basalt fiber is also much greater. Vibration-resistance of basalt fiber is also much higher than that of mineral and glass fiber. That is why bsalt fiber finds widest application in wide range of constructions, subjected to heavy vibration and acoustic loads: transport vehicles (notice that initially basalt fibers were applied in aerospace industry and shipbuilding), engineering, technologica facilities, etc. Besides, basalt fibr articles serve as effective sond-insulator, which is not broken itself under effect of acoustic vibrations that owes, for instane, their exclusiver application as insulation in aircrafts. Basalt fibers surpass glass and mineral fibers in chemical resistance in 2.5-3 times in neutral and alkaline media and 8-17 times in acid media. Moreover, water absorption of basalt fiber is 85(!) times lower than that of glass and mineral fibers. That is why glass and mineral fibers are disintegrated much faster than basalt ones. Environmental safety of production and application Production processes of various fibers as such practically do not differ from each other in environmental impact. However, if taking into account production of resources, for basalt fiber and mineral fiber it is low-energy-consuming mining nonINFOMINE Research Group www.infomine.ru; e-mail: info@infomine.ru; phone/fax: (495) 237-8033 16

Basalt Fiber-Based Thermal Insulating Materials Market Research in Russia

metallic resources, whereas for glass fiber this is a complex of complex and highenergy-consuming mechanical and chemical processes with the use of chemicals, produced at other chemical enterprises, finally, with much higher environmental impact. Besides, there is one more important point here. Basalt fibers in mats are fastened with each other by natural cohesion forces, not requiring applying binder (only piercing or covering with fabric are applied for simplifying transporting and use of the mats). On contrary, fabrications from glass wool and mineral fiber always require applying binders, commonly phenolic resins (1.5-10 mass % in a fabrication). As known, phenol is toxic and carcinogenous component, so phenol-containing fabrication can not be considered as environmentally clean that restricts considerably field of their application, especially in housing. Environmental impact of the whole complex of technological processes on obtaining and exploitation of basalt fibers is much lower than that of case of glass or mineral fiber materials. In 2002, in Europe, a program of green building was adopted, one of elements of which is use of materials on the basis of natural basalts for heat- and sound-insulation.

INFOMINE Research Group www.infomine.ru; e-mail: info@infomine.ru; phone/fax: (495) 237-8033

17

Basalt Fiber-Based Thermal Insulating Materials Market Research in Russia

2. Production of thermal insulating materials and products on the basis of basalt fiber in Russia in 2000-2006

2.1. Production of thermal insulating materials and products on the basis of basalt fiber in Russia in 2000-2006 Statisticalm account of thermal insulating fabrications and materials on the basis of basalt fiber in Russia is conducted in 2 items: thermal insulating fabrications on the basis of basalt composite materials and thermal insulating quilts on the basis of basalt thermal insulating materials. The former item commodities are accounted in tonnes, and the latter in thousand cub m. From data of Federal Service of State Statistics (FSSS), production of thermal insulating fabrications from basalt composite materials for the period from 2000 to 2005 increased 5.2 times, that of quilts in 4.1 times, and the bulk of the growth belonged to 2003 (Fig. 1). Figure 1. Dynamics of production of thermal insulating materials from basalt fiber in Russia in 2000-2005, t, thousand cub m

Source: InfoMine on the basis of data of Federal Service of State Statistics (FSSS) of Russia

At the same time, researches of experts of LLC InfoMine showed that the FSSS data are not complete and do not include production figures of most of manufacturers of thermal insulating products on the basis of basalt fiber, including the greatest ones. This is connected with difficulties in dividing production data reporting into materials on the basis of basalt fiber and materials on the basis of mineral fiber, as well as low reporting discipline of some producers (especially small ones and LLC) in submitting their data to FSSS.

INFOMINE Research Group www.infomine.ru; e-mail: info@infomine.ru; phone/fax: (495) 237-8033

18

Basalt Fiber-Based Thermal Insulating Materials Market Research in Russia

Figure 2. Dynamics of manufacturing fabrications on the basis of basalt fiber in 2000-2006, t (expert estimation)

Source: InfoMine

In Fig. 2, InfoMine presents expert estimation of production of thermal insulating products on the basis of basalt fiber, prepared on the basis of the following sources: - analysis of materials of official web-sites of enterprise-manufacturers; - telephone interviewing officers of enterprise-manufacturers; - monitoring of regional press; - analysis of capacities of used equipment for production of thermal insulating materials on the basis of basalt fiber, manufactured by key specialised firms; - analysis of information on investment projects. Summarized data on the production are given in Table 2. Expert estimation of the production is given in tonnes averaged parameter, suitable for following comparison of volumes of production with volumes of imports and exports, as well as for calculation of the market capacity in Russia. Conversion coefficient: 1t = 40 m3 (average parameter, taken in specialised literature).

INFOMINE Research Group www.infomine.ru; e-mail: info@infomine.ru; phone/fax: (495) 237-8033

19

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Annexure 3 Courtesy Car AgreementDocument3 pagesAnnexure 3 Courtesy Car AgreementManishNo ratings yet

- Design and Use of AutomationDocument94 pagesDesign and Use of AutomationxeexeNo ratings yet

- Meeting Request LetterDocument2 pagesMeeting Request LetterRagni Tayal100% (1)

- JR PaperDocument1 pageJR PaperRevaNo ratings yet

- Engineering For Self Reliance and Sustainable Goals: Literature ReviewDocument1 pageEngineering For Self Reliance and Sustainable Goals: Literature ReviewRevaNo ratings yet

- Skin Tubular FRP-concrete-steel of The Art Review: Structural Behavior of Hybrid Double Column: StateDocument1 pageSkin Tubular FRP-concrete-steel of The Art Review: Structural Behavior of Hybrid Double Column: StateRevaNo ratings yet

- Artificial Intelligence Techniques To Predict The Compressive Strength of Sustainable Eco-Friendly Strain-Hardening Concrete CompositesDocument1 pageArtificial Intelligence Techniques To Predict The Compressive Strength of Sustainable Eco-Friendly Strain-Hardening Concrete CompositesRevaNo ratings yet

- JR PaperDocument1 pageJR PaperRevaNo ratings yet

- JR PaperDocument1 pageJR PaperRevaNo ratings yet

- JR PaperDocument1 pageJR PaperRevaNo ratings yet

- Intro To StaadProDocument4 pagesIntro To StaadProRevaNo ratings yet

- Structural Performance of Concrete Filled FRP Thin Walled Tubular BeamsDocument1 pageStructural Performance of Concrete Filled FRP Thin Walled Tubular BeamsRevaNo ratings yet

- Paper 4Document1 pagePaper 4RevaNo ratings yet

- Prestressed ConcreteDocument5 pagesPrestressed ConcreteRevaNo ratings yet

- Paper 2Document1 pagePaper 2RevaNo ratings yet

- Nanobased Cementitious Mortar For Ferrocement Jacketed ColumnDocument1 pageNanobased Cementitious Mortar For Ferrocement Jacketed ColumnRevaNo ratings yet

- Slope Deflection MethodDocument2 pagesSlope Deflection MethodRevaNo ratings yet

- JR-Guidelines For Plan & Design - Aug 2018Document7 pagesJR-Guidelines For Plan & Design - Aug 2018RevaNo ratings yet

- Potential Application of Nano ParticlesDocument1 pagePotential Application of Nano ParticlesRevaNo ratings yet

- FlowableDocument1 pageFlowableRevaNo ratings yet

- Investigation On The Performance Characteristics of Concrete Incorporating NanoparticlesDocument1 pageInvestigation On The Performance Characteristics of Concrete Incorporating NanoparticlesRevaNo ratings yet

- Taghuchi MethodDocument1 pageTaghuchi MethodRevaNo ratings yet

- Double Skinned Plated Composite BeamsDocument1 pageDouble Skinned Plated Composite BeamsRevaNo ratings yet

- Cyclic Response of Prestressed Concrete Beams Retrofitted With Precured Fibre Reinforced Polymer CompositesDocument1 pageCyclic Response of Prestressed Concrete Beams Retrofitted With Precured Fibre Reinforced Polymer CompositesRevaNo ratings yet

- Potential Application of Nano ParticlesDocument1 pagePotential Application of Nano ParticlesRevaNo ratings yet

- Double Skinned Plated Composite Beams PDFDocument1 pageDouble Skinned Plated Composite Beams PDFRevaNo ratings yet

- PSC TutorialDocument2 pagesPSC TutorialRevaNo ratings yet

- 13 2717Document12 pages13 2717RevaNo ratings yet

- Plant LayoutDocument3 pagesPlant LayoutRevaNo ratings yet

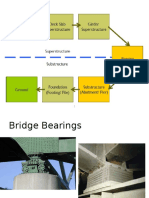

- BearingsDocument3 pagesBearingsRevaNo ratings yet

- Methods For Seismic Retrofitting of StructuresDocument10 pagesMethods For Seismic Retrofitting of StructuresSaikat KabirajNo ratings yet

- ICPaper 8Document11 pagesICPaper 8RevaNo ratings yet

- Global Needs For Knowledge Dissemination, Research, and Development in Materials Deterioration and Corrosion ControlDocument44 pagesGlobal Needs For Knowledge Dissemination, Research, and Development in Materials Deterioration and Corrosion ControlEugene OgosiNo ratings yet

- Qualifications and Disqualifications of CandidatesDocument3 pagesQualifications and Disqualifications of CandidatesCARLO JOSE BACTOLNo ratings yet

- Numerical Techniques For Global AtmosphericDocument577 pagesNumerical Techniques For Global AtmosphericTatiana N. LeónNo ratings yet

- 2023-04-28 NMSU Executive SummaryDocument2 pages2023-04-28 NMSU Executive SummaryDamienWillisNo ratings yet

- Losses in Valves and FittingsDocument17 pagesLosses in Valves and FittingsMintesnot AberaNo ratings yet

- ITEC 11 Lesson 1.1Document35 pagesITEC 11 Lesson 1.1ivyquintelaNo ratings yet

- Theory and Practice AssignmentDocument12 pagesTheory and Practice AssignmentMelikteNo ratings yet

- CHAPTER 2 Principles of MarketingDocument41 pagesCHAPTER 2 Principles of MarketingASHIMA THAPANo ratings yet

- Airbus Settles Fettling Dust With Clean Air SolutionDocument1 pageAirbus Settles Fettling Dust With Clean Air SolutionstephendixNo ratings yet

- XJ600SJ 1997Document65 pagesXJ600SJ 1997astracatNo ratings yet

- Techniques Tips For Polishing PDFDocument6 pagesTechniques Tips For Polishing PDFrobin parmarNo ratings yet

- " My Heart Will Go On ": Vocal: Celine DionDocument8 pages" My Heart Will Go On ": Vocal: Celine DionLail Nugraha PratamaNo ratings yet

- BDA Guide To Successful Brickwor1kDocument259 pagesBDA Guide To Successful Brickwor1kMudassar AhmadNo ratings yet

- IELTS Speaking Forecast Tháng 1-4Document21 pagesIELTS Speaking Forecast Tháng 1-4Toby ThomasNo ratings yet

- Surface Treatments & Coatings Ref: S. KalpakjianDocument22 pagesSurface Treatments & Coatings Ref: S. KalpakjianjojoNo ratings yet

- Ec8691 MPMC Question BankDocument41 pagesEc8691 MPMC Question BankManimegalaiNo ratings yet

- Report Managerial Finance@UniklDocument18 pagesReport Managerial Finance@UniklLee WongNo ratings yet

- Doctrine of Indoor ManagementDocument4 pagesDoctrine of Indoor ManagementRavi KtNo ratings yet

- GTA TaxonomyDocument12 pagesGTA Taxonomyalvaropiogomez1No ratings yet

- Circuito Eléctrico Bomba de Freno VochoDocument1 pageCircuito Eléctrico Bomba de Freno Vochosvelaib100% (1)

- Insular Bank of Asia vs. InciongDocument11 pagesInsular Bank of Asia vs. InciongChristiane Marie BajadaNo ratings yet

- Reinforcement Project Examples: Monopole - Self Supporter - Guyed TowerDocument76 pagesReinforcement Project Examples: Monopole - Self Supporter - Guyed TowerBoris KovačevićNo ratings yet

- SERVA 4-Axle Coiled Tubing Unit - Electric Over HydraulicDocument25 pagesSERVA 4-Axle Coiled Tubing Unit - Electric Over HydraulicWilliamNo ratings yet

- Types of IndexDocument4 pagesTypes of IndexKantha EnduriNo ratings yet

- QuaverEd Lesson Plan 6-7Document10 pagesQuaverEd Lesson Plan 6-7zgyleopardNo ratings yet

- Dove Case Study QNA: Presented - Rachna JoshiDocument7 pagesDove Case Study QNA: Presented - Rachna JoshiGo2 MummaNo ratings yet

- Moral IssuesDocument34 pagesMoral IssuesDaryll Jade PoscabloNo ratings yet

- Appendix 24 - QUARTERLY REPORT OF REVENUE AND OTHER RECEIPTSDocument1 pageAppendix 24 - QUARTERLY REPORT OF REVENUE AND OTHER RECEIPTSPau PerezNo ratings yet