Professional Documents

Culture Documents

Sezione 3 Pag. 25 PDF

Uploaded by

MAZZI1978Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sezione 3 Pag. 25 PDF

Uploaded by

MAZZI1978Copyright:

Available Formats

FUEL SYSTEM 3-25

5.

I~

2

SERVICING OF INJECTION NOZZLES ANO NOZZLE HOLDERS Q

-1

Clean the internai part of the nozzle kerosene by using a piece of wood. (1}

body

in

1. BODY

'2. 3. 4. 5. CYCRON BLADE ELEMENT DUST PAN . WING NUT

1.

8_-

JOINTSOL;-r OVERFLOW VALVE JOINT SOL T JOINT SO(,.T COVER ELEMENT

2. 3. 4. 5. 6.

9 10

.1.

11~

12-

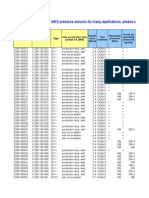

2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. FIG. 3-66

JOINTBOLT GASKET SCREW CAP NUT GASKET ADJUSTING SCREW NUT GASKET WASHER NOZZLE SPRING PUSH.ROD NOZZLE SPRING SCREW NOZZLE HOLDER NOZZLE NOZZLE NUT WASHER CONNECTOR EDGE FILTER

Visual inspection After washing, check the injection nozz(es against the fo(lowing : 1) Needfe valves. Check the valve seats. guide shafts and injection shaft for damage. ; 2) Nozzle body. Check the valve seats for carbon deposit and damage. Aiso check the injection orifices fbr uneven wear. Replace both of the parts by using an assembly even if either of the needfe valve or the nozzle body is found to be defective. Sliding test A sliding test shou(d be made on the entire injection nozzles often visual inspection. Hold the nozzle body vertically and pull the needle valve upward about 1/3 of its entire length and release it and see if it lowers onto its seat by its own weight. If lowering of the needle valve is unsmooth. check for presence of foreign matter and repeat the test. If the trouble persists. replace the entire nozzle assembly with a new one. Testing of injection nozzles on nozzle tester Make the following tests by using a nozzle tester . a. (njection starting pressure. b. Spray pattern and operating

(2)

(3}

5-1

Disassembly

Exercise extreme care when handling the injection nozzle assembly, partjcularly the nozzle body and needle valves as these parts are ultra-precisionfinished. Wash clean the injection nozzle assembly removed from the engine prior to disassembling. (1) Clamp the nozzle holder in a vise and remove the cap nut. (2) Remove the adjust screw lock nut and remove the adjust screw, then remove the spring. spring seat and push-rod. (3) Clamp the nozzle holder body with the nozzle side up in a vise. (4) With a wrench. remove the nozzle nut using care not to drop the nozzle. Remove the nozzle carefulJy not to drop the needle valve.

noise.

5-2

Inspection

of injection

nozzles

Wash clean the disassembled parts in clean kerosene and insert the needle valve into the nozzle body in new kerosene. If the needle valves are fouled with carbon deposit, clean them in kerosene by using a piece of wood and avoid the use of abrasive particles and other metal cleaners. Keep fingers away from the lapped portion of the needle valves. or rust formation will result. FIG. 3-67

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Bosch Injector Data SheetDocument124 pagesBosch Injector Data SheetThibaut Lrt56% (9)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Pelleting Handbook Gb04Document152 pagesPelleting Handbook Gb04eliesergs91% (11)

- Sebp4195 76 01 Allcd - 003 PDFDocument965 pagesSebp4195 76 01 Allcd - 003 PDFFacturas hidrodieselNo ratings yet

- We n5523521 v7 Hendrix Covered ConductorDocument55 pagesWe n5523521 v7 Hendrix Covered ConductorJ. Mauricio A. BejaranoNo ratings yet

- 3TNV70 ASA BroDocument1 page3TNV70 ASA BroSaMos AdRiianNo ratings yet

- EXPANDED INSPECTION CHECKLISTDocument2 pagesEXPANDED INSPECTION CHECKLISTfredy2212100% (1)

- Ch-5 Sheet Metal OperationDocument20 pagesCh-5 Sheet Metal OperationJAYANT KUMARNo ratings yet

- BA L M EPA Carb4 PDFDocument83 pagesBA L M EPA Carb4 PDFCristiTancuNo ratings yet

- Nonequilibrium Statistical MechanicsDocument299 pagesNonequilibrium Statistical MechanicsKshitij LauriaNo ratings yet

- 29B - Acid Gas Removal TechnologyDocument17 pages29B - Acid Gas Removal Technologyarlucky5459100% (1)

- Sezione 3 Pag. 15-27 PDFDocument13 pagesSezione 3 Pag. 15-27 PDFMAZZI1978100% (1)

- Sezione 3 Pag. 1-14 PDFDocument12 pagesSezione 3 Pag. 1-14 PDFMAZZI1978100% (1)

- Sezione 2 PDFDocument8 pagesSezione 2 PDFMAZZI1978100% (1)

- Sezione 1 Pag. 25-37 PDFDocument13 pagesSezione 1 Pag. 25-37 PDFMAZZI1978100% (1)

- Sezione 1 Pag. 11-24 PDFDocument14 pagesSezione 1 Pag. 11-24 PDFMAZZI1978100% (1)

- Sezione 1 Pag. 11-24 PDFDocument14 pagesSezione 1 Pag. 11-24 PDFMAZZI1978100% (1)

- Sezione 1 Pag. 1-10 PDFDocument10 pagesSezione 1 Pag. 1-10 PDFMAZZI1978100% (1)

- MODULE I - 10 Marks Basic Laboratory TechniquesDocument18 pagesMODULE I - 10 Marks Basic Laboratory TechniquesArun KumarNo ratings yet

- Mi 3210 Teraohmxa 10Kv: Professional Insulation Testing With Powerful Diagnostic ToolsDocument2 pagesMi 3210 Teraohmxa 10Kv: Professional Insulation Testing With Powerful Diagnostic ToolsTuan Anh Le CongNo ratings yet

- CH-2 IS MATTER AROUND US PUREDocument2 pagesCH-2 IS MATTER AROUND US PUREgurdeepsarora8738100% (1)

- ασκήσεις υδραυλικων λαδιουDocument160 pagesασκήσεις υδραυλικων λαδιουchristodoulos charalambousNo ratings yet

- Sabah TL 1Document1 pageSabah TL 1MT HazrieNo ratings yet

- Cooling Tower Research PaperDocument13 pagesCooling Tower Research PaperBhaskar KumarNo ratings yet

- Pump QuotationsDocument3 pagesPump Quotationsdibyendu65No ratings yet

- Siemens Overload RelayDocument6 pagesSiemens Overload Relaykhairalla mohamedNo ratings yet

- Alfa Laval Koltek MH Valve enDocument8 pagesAlfa Laval Koltek MH Valve enjpsingh75No ratings yet

- IEC Fuses 5x20 Low Breaking Capacity 5ST Time Lag: DimensionsDocument2 pagesIEC Fuses 5x20 Low Breaking Capacity 5ST Time Lag: DimensionsrNo ratings yet

- Earthing: To The 16th Edition IEE RegulationsDocument3 pagesEarthing: To The 16th Edition IEE RegulationsRakesh Kumar VermaNo ratings yet

- Huawei PI OverviewDocument15 pagesHuawei PI OverviewHdz EdilNo ratings yet

- Technical Specification TREO CF I48CA1Document1 pageTechnical Specification TREO CF I48CA1Razvan CorciuNo ratings yet

- 301 Basic Mechanics Course DescriptionDocument2 pages301 Basic Mechanics Course DescriptionAnonymous q9eCZHMuSNo ratings yet

- Is SP 72 2010Document25 pagesIs SP 72 2010mkannanofficialNo ratings yet

- BHELDocument38 pagesBHELSharath Chandra100% (1)

- Glowing TreesDocument2 pagesGlowing TreesJonathan SwiftNo ratings yet

- Rrsport 160 en INTDocument94 pagesRrsport 160 en INTstrateguo1No ratings yet

- How Cells Harvest Chemical Energy: Chapter ObjectivesDocument12 pagesHow Cells Harvest Chemical Energy: Chapter Objectivesirene9tan9ailianNo ratings yet

- Clase 05 - Chapter 9 - AAS-experimentalDocument44 pagesClase 05 - Chapter 9 - AAS-experimentalLuisa GallegoNo ratings yet