Professional Documents

Culture Documents

Ls-Dyna Faq CHN

Uploaded by

leawoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ls-Dyna Faq CHN

Uploaded by

leawoCopyright:

Available Formats

LSTC's Software Productions Introduction.

| AiFEA

Page 1 of 2

LSTCs Software Productions Introduction.

Published June 7th, 2007 in LS-DYNA. Tags: No Tags.

LSTCLivemore Software Technology Corp. LSTCHallquist1976HallquistLLNL(Lawrence Livemore National Laboratory )DYNA3D DYNA2D7682DYNA3D DYNA2DHallquist1986HallquistBenson VAX/VMS,IBM,UNIX,COS 1988HallquistLSTC DYNA3DLS-DYNA3D(LS-DYNA) DYNA3D 88DYNA3DLLNL RadiossPam-Crash LSTC LS-DYNA LS-DYNA http://www.lstc.com/pages/hardware.htm LS-DYNASMP()MPP()PC & 971 bugrelease notes LS-DYNALSTC CAE MSC.SoftwareLS-DYNAMSC.Dytran AnsysLS-DYNAAnsys/LS-Dyna ETALS-DYNADynaform LS-DYNA

http://www.aifea.com/blog/?p=9

2007-8-26

LSTC's Software Productions Introduction. | AiFEA

Page 2 of 2

LS-OPT LS-OPTLS-DYNA LinuxUNIX3.0LS-OPT Windows3.2 LS-OPTRSM(Response Surface Methodology)DOE(Design of Experiments)LS-OPTC Fortranhttp://www.lstc.com/pages/opt.htm LS-Prepost LS-PrepostLSTC 075 demohttp://www.lstc.com/lspp LS-Prepost Windows(kevin[dot] zsc[at]163.com)mail

0 Responses to LSTCs Software Productions Introduction.

No Comments

http://www.aifea.com/blog/?p=9

2007-8-26

LS-DYNA FAQ -1.Consistent system of units | AiFEA

Page 1 of 2

LS-DYNA FAQ -1.Consistent system of units

Published June 9th, 2007 in LS-DYNA. Tags: consistent units.

LS-DYNA FAQ LS-DYNA Copyright of original english version owned by relative author. Chinese version owned by Aifea.com/Kevin (Consistent Units) 0&1 LS-DYNA FAQ Definition of a consistent system of units (required for LS-DYNA): 1 force unit = 1 mass unit * 1 acceleration unit 1 1 1 1 acceleration unit = 1 length unit / (1 time unit)^2 1 = 1 /1

The following table provides examples of consistent systems of units. As points of reference, the mass density and Youngs Modulus of steel are provided in each system of units. GRAVITY is gravitational acceleration. MASS- LENGTH- TIME- FORCE- STRESS- ENERGY- DENSITY- YOUNGsVelocity(56.3KMPH) GRAVITY

kg m s N Pa Joule 7.83e+3 2.07e+11 kg cm s 1.e-02N kg cm ms 1.e+04N kg cm us 1.e+10N kg mm ms KN

15.65 9.806

7.83e-3 2.07e+09 1.56e+03 9.806e+02 7.83e-3 2.07e+03 1.56 9.806e-04

7.83e-3 2.07e-03 1.56e-03 9.806e-10 GPa KN-mm 7.83e-6 2.07e+02 15.65 9.806e-03

gm cm s dyne dy/cm2 erg 7.83e+0 2.07e+12 1.56e+03 9.806e+02 gm cm us 1.e+07N Mbar 1.e7Ncm 7.83e+0 2.07e+00 1.56e-03 9.806e-10 gm mm s 1.e-06N Pa 7.83e-3 2.07e+11 1.56e+04 9.806e+03 15.65 9.806e-03

gm mm ms N MPa N-mm 7.83e-3 2.07e+05

http://www.aifea.com/blog/?p=10

2007-8-26

LS-DYNA FAQ -1.Consistent system of units | AiFEA

Page 2 of 2

ton mm s N MPa N-mm 7.83e-9 2.07e+05 1.56e+04 9.806e+03 lbfs2/in in s lbf psi lbf-in 7.33e-4 3.00e+07 6.16e+02 386 slug ft s lbf psf lbf-ft 1.52e+1 4.32e+09 51.33 32.17

________________________________________________________________ kgfs2/mm mm 1.56e+04 kg mm s mN gm cm ms Kbui 3-11-97 JDay 1/9/01 s kgf kgf/mm2 kgf-mm 8.02e-10 2.07e+04 (Japan) 1e3 Pa 7.83e-6 2.07e+08 1e5 Pa 9.806e+02

7.83e+0 2.07e+06

0 Responses to LS-DYNA FAQ -1.Consistent system of units

No Comments

http://www.aifea.com/blog/?p=10

2007-8-26

Windows MPP LS-DYNA | AiFEA

Page 1 of 3

Windows MPP LS-DYNA

Published June 15th, 2007 in LS-DYNA. Tags: No Tags.

LS-DYNA SMP/MPPLSTC http://www.lstc.com/pages/hardware.htm LS-DYNALinux/Unix windowsMPP-DYNA windowsMPP DYNA 1. MPICH WindowsMPP DYNAMPICH MPIMPPLS-DYNA MPICHMPICH2.0Windows MPP-DYNAMPICH1.2.5or 1.2.6)http://www-unix.mcs.anl.gov/mpi/mpich1/mpichnt/ mpich.nt.1.2.5.exe (6 MB June 8, 2003)LSDYNAmanual 2. MPICH MPICH windows C:\Program Files\MPICH\mpd\bin MPIRegister.exeaccout mppuserDo you want this action to be presistent (y/n)yes windows domain\username 3. MPICH ->->MPICH->mpd->MPICH Configuration Tool

http://www.aifea.com/blog/?p=13

2007-8-26

Windows MPP LS-DYNA | AiFEA

Page 2 of 3

select mpich Apply 4. MPP DYNA ->->MPICH->mpd->mpirun

http://www.aifea.com/blog/?p=13

2007-8-26

Windows MPP LS-DYNA | AiFEA

Page 3 of 3

mpp-dynadyna k mpp-dynak Application: \\hostname\sharepath\mpp970.exe i=input.k memory=100m \\LENOVO-5081CA9D\test\mpp970_s_6763_intelsse_win32_mpich125.exe i=contact_projectile.k memory=10mCPUhosts Run2 windows2000windows XP mpi/ mpp mpichmpp dynainternet CMDGUImpirun

0 Responses to Windows MPP LS-DYNA

No Comments

http://www.aifea.com/blog/?p=13

2007-8-26

LS-DYNA FAQ -2.Mass Scaling | AiFEA

Page 1 of 4

LS-DYNA FAQ -2.Mass Scaling

Published June 19th, 2007 in LS-DYNA. Tags: , mass scaling.

F=ma *Control_timestepDT2MS DT2MSTSSFAC*|DT2MS| TSSFAC*|DT2MS|TSSFACDT2MS TSSFAC TSSFAC TSSFAC0.9 0.80.7 TSSFAC|DT2MS| GLSTATMATSUM *database_extent_binarySTSSZ3 ls-prepost Fcomp>Misc>time step size *control_timestepDT2MS TSSFAC*-DT2MS TSSFAC*|DT2MS| DT2MS *control_timestepMS1STMS1ST=1 DT2MSMS1ST=0) *control_terminationENDMAS *mat_spotweldDT*control_timestep (DT2MS=0)DT DTDT0 d3hspMATSUM GSLTAT DOESKE 1.DT2MS*mat_spotweldDT0d3hsp

http://www.aifea.com/blog/?p=16

2007-8-26

LS-DYNA FAQ -2.Mass Scaling | AiFEA

Page 2 of 4

d3hspadded spotweld mass; added mass & percentage increase; glstatmatsumadded mass 2. DT2MS*mat_spotweldDT0d3hsp glstatmatsumadded massd3hsp added spotweld mass DT2MS&DT=0 3. DT2MS0DT0 10%glstat & matsum added mass English Version Mass-scaling refers to a technique whereby nonphysical mass is added to a structure in order to achieve a larger explicit timestep. Anytime you add nonphysical mass to increase the timestep in a dynamic analysis, you affect the results (think of F = ma). Sometimes the effect is insignificant and in those cases adding nonphysical mass is justifiable. Examples of such cases may include the addition of mass to just a few small elements in a noncritical area or quasi-static simulations where the velocity is low and the kinetic energy is very small relative to the peak internal energy. In the end, its up to the judgement of the analyst to gage the affect of mass scaling. You may have to reduce or eliminate mass scaling in a second run to gage the sensitivity of the results to the amount of mass added. One can employ mass scaling in a selective manner by artificially increasing material density of the parts you want to mass-scale. This manual form of mass scaling is done independently of the automatic mass scaling invoked with DT2MS in *control_timestep. When DT2MS is input as a negative value, mass is added only to those elements whose timestep would otherwise be less than TSSFAC * |DT2MS|. By adding mass to these elements, their timestep becomes equal to TSSFAC * |DT2MS|. An infinite number of combinations of TSSF and DT2MS will give the same product and thus the same timestep but the added mass will be different for each of those combinations. The trend is that the smaller the TSSF, the greater the added mass. In return, stability may improve as TSSF is reduced (just as in non-mass-scaled solutions). If stability is a problem with the default TSSF of 0.9, try 0.8 or 0.7. If you reduce TSSF, you can increase |DT2MS| proportionally so that the product/timestep is unchanged. To determine where and when mass is automatically added, write GLSTAT and MATSUM files. These files will allow you to plot added mass vs. time for the complete model and for individual parts, respectively. To produce fringe plots of added mass in parts comprised of shell elements (DT2MS negative), set STSSZ=3 in *database_extent_binary. You can then fringe the added mass (per element) using LS-POST by choosing Fcomp > Misc > time step size. (Here, the label time step size is really the element added mass.) The difference between using a positive or negative number for DT2MS in *control_timestep is as follows: Negative: Initial time step will not be less than TSSF * -DT2MS.

http://www.aifea.com/blog/?p=16

2007-8-26

LS-DYNA FAQ -2.Mass Scaling | AiFEA

Page 3 of 4

Mass is added to only those elements whose timestep would otherwise be less than TSSF*abs(DT2MS). When mass scaling is appropriate, I recommend this method. The amount of mass that can be added using this method is limited. Excessive added mass will cause the job to terminate. Positive: Initial time step will not be less than DT2MS. Mass is added OR TAKEN AWAY from elements so that the timestep of every element is the same. This method is harder to rationalize although it is not subject to termination from excessive added mass. The parameter MS1ST in *control_timestep controls whether mass is added only once during initialization (MS1ST=1) or anytime as necessary to maintain the desired timestep specified via DT2MS (MS1ST=0). You can use ENDMAS in *control_termination to stop the calculation after a certain amount of mass has been added (active for automatic mass scaling only). ____________________________________________________________________________ Mass-scaling of deformable spotweld beams: The mass-scaling parameter in *mat_spotweld (DT) affects only the spotwelds. If no mass-scaling is invoked in *control_timestep (DT2MS=0.) AND the timestep is controlled by the deformable spotwelds, DT can be used to add inertia to the spotwelds during intialization in order to increase the timestep to a value of DT. When DT is nonzero, mass added to spotweld beams is reported to d3hsp. MATSUM momentum and KE does NOT factor in added mass to def. spotwelds. GLSTAT DOES factor in added mass to total KE (spotweld.beam.type9.mscale.initvel.k) Consider 3 cases of invoking mass-scaling in a model with deformable spotwelds: 1. Although percentage mass increase under Deformable Spotwelds: in d3hsp is bogus when DT2MS is neg. and DT in *mat_spotweld = 0, the following are correct: added spotweld mass in d3hsp added mass and percentage increase in d3hsp AFTER the first time step added mass in glstat and matsum 2. Added spotweld mass controlled by DT in *mat_spotweld is NOT INCLUDED in added mass given in d3hsp, glstat, or matsum when DT2MS is neg. and DT in *mat_spotweld is nonzero. This can be quite misleading. User must check for added spotweld mass in d3hsp. Recommended: Do not invoke both mass-scaling criteria. Neg. DT2MS with DT=0 (case 1 above) is preferred. 3. If DT is nonzero and DT2MS=0, the initial timestep will NOT consider added spotweld mass but the time step will increase by 10% each cycle until the correct timestep (considering added spotweld mass) is achieved. Glstat and matsum contain no added mass line item. The above can be illustrated using /j5000a_2/jday/test/weld/spotweld.beam.type9.mscale.k. __________________________________________________________________________________ Note that added mass may cause the energy ratio to rise. (See /j5000a_2/jday/test/erode/taylor.mat3.noerode.mscale.k)

http://www.aifea.com/blog/?p=16

2007-8-26

LS-DYNA FAQ -2.Mass Scaling | AiFEA

Page 4 of 4

1 Response to LS-DYNA FAQ -2.Mass Scaling

1 instability in lsdyna

Pingback on Jun 23rd, 2007 at 11:15 pm

http://www.aifea.com/blog/?p=16

2007-8-26

LS-DYNA FAQ -3.Long run times | AiFEA

Page 1 of 2

LS-DYNA FAQ -3.Long run times

Published June 20th, 2007 in LS-DYNA. Tags: long run time, time scaling.

(mass-scaling) (time-scaling)(time-scaling) d3hsp smallest100 remesh 50 LS-DYNA30% / cpuLSDYNA() FEA information newsletter/ (http://www.feapublications.com/pages/pdfnews/3feadec.pdf) See also: mass_scaling, quasistatic English Version When youre using explicit time integration, there is no magic cure for long run times associated with simulating very small geometries over relatively long periods of time. Mass-scaling carries a burden of having to confirm that the addition of nonphysical mass does not significantly affect the results (see attached file mass_scaling). A similar burden exists when time-scaling is employed. Time-scaling is a technique where the loading rate is increased and thus the simulation time is shortened in order to reduce the required number of timesteps. Make sure that your timestep is not being controlled by only a few small or stiff elements by searching in the d3hsp file for the string smallest. If there are only a few controlling elements, you can remesh in the vicinity of those elements or perhaps make them rigid. Though its rather obvious, run only as long as is necessary. This means in the case of a drop simulation, assigning an initial velocity to the dropped object and placing it a very small distance from the landing surface. After impact, run only long enough to get the results you need.

http://www.aifea.com/blog/?p=19

2007-8-26

LS-DYNA FAQ -3.Long run times | AiFEA

Page 2 of 2

Be aware that for lengthy simulations where the number of timesteps goes above half a million or so, youd be well advised to use a double precision executable of LS-DYNA to minimize error due to roundoff. Running double precision carries with it a cpu penalty of around 30%. Automatic explicit/implicit switching may be an option. Using this technique, the user can specify time windows in which implicit time integration is used as opposed to explicit time integration. An advantage of implicit time integration is that timesteps are not tied to element size and can thus be much larger. Of course, an implicit timestep is also much more expensive in terms of cpu. Further, not all LS-DYNA features and materials are implemented for implicit analysis at this time (though most are). Explicit/implicit switching is discussed in the following archived FEA Information newsletter http://www.feapublications.com/pages/pdfnews/3feadec.pdf See also: mass_scaling, quasistatic.

0 Responses to LS-DYNA FAQ -3.Long run times

No Comments

http://www.aifea.com/blog/?p=19

2007-8-26

LS-DYNA FAQ -4.Quasi-static | AiFEA

Page 1 of 3

LS-DYNA FAQ -4.Quasi-static

Published June 21st, 2007 in LS-DYNA. Tags: quasi static.

(Dynamic relaxation)(quasi-static) [1] / (time-scaling,mass-scaling) mass_scaling LS-DYNA *control_implicit_Appendix M See also: gravity.txt, readme.preload, mass_scaling, long_run_times, implicit.general, quick_initialization. Note[1] 1. d3plot0 LS-PrepostOutput->Nodal Displacements i8,3e16i8,3e15 drdisp.sifDR 2. *control_dynamic_relaxationIDRFLG=2 m=filename(filename)LS-DYNA 100filename English Version: Dynamic relaxation is not intended for general quasistatic analysis. Its ok for applying preload when the preload produces only small elastic strains or for initializing a system to a prescribed geometry[1] but its not good for much else. You can do a quasi-static analysis by running a regular explicit simulation, invoking time- and/or mass-scaling as necessary to crank out the results in a reasonable timeframe, but this approach can be tricky. You have to keep an eye on the kinetic energy in the system as you want to minimize the inertial effects. Basically, the kinetic energy should remain small relative to the internal energy. (By time-scaling, I mean applying the load more quickly than in the quasi-static experiment in order to reduce the simulation time.) See the file mass_scaling for more on mass-scaling.

http://www.aifea.com/blog/?p=20

2007-8-26

LS-DYNA FAQ -4.Quasi-static | AiFEA

Page 2 of 3

Or, you can try an implicit, static analysis using LS-DYNA. See the commands *control_implicit_ and Appendix M in the Users Manual. There are examples of implicit analysis on our user ftp site in the ls-dyna/example directory. See also: gravity.txt, readme.preload, mass_scaling, long_run_times, implicit.general, quick_initialization. Note [1] *** Initializing to a prescribed geometry *** 1. Write a file of nodal displacements from the final state of your first run. To get this data in the necessary format, use LS-TAURUS as follows: ls-taurus g=d3plot < execute s 1000 < goes to final state deform < write a file as described above t < termimate LS-TAURUS Note the d3plot does not contain nodal rotations and thus the rotations are written as zero. This could be a real problem for initialization of shells and beams. LS-PREPOST has an option to write the displacements using Output > Nodal Displacements but the output is i8,3e16 rather than the required i8,3e15 and hence the suggested use of LS-TAURUS. LS-TAURUS is not available for Windows PCs. Its free and available for Unix and Linux workstations. If you do a regular dynamic relaxation run to get to the initialized state, a file of prescribed displacements and rotations will automatically be written at the conclusion of the DR phase (drdisp.sif). Bug #2020 reported on 9/22/2004 that rigid body nodes do not get initialized according to data in m=pres_geom_file. Additional example in /home/jday/test/cantilever/solid/typ2sol_dr_nrb.k (creates drdisp.sif) and typ2sol_presgeom_nrb.k (m=drdisp.sif run). Nodes 11,22,33,44 are not initialized to whats in drdisp.sif 2. In your second run, quickly initialize to the prescribed geometry written in step 1. You need to set IDRFLG=2 in *control_dynamic_relaxation and include m=filename on the execution line where filename is the file created in step 1. Before the transient run begins, LS-DYNA will automatically run a precusor analysis of 100 timesteps wherein the nodse are displaced according to the data in filename. revised 7/21/03 jpd 7/2004

0 Responses to LS-DYNA FAQ -4.Quasi-static

http://www.aifea.com/blog/?p=20

2007-8-26

instability in lsdyna

Page 1 of 3

LS-DYNA FAQ -5.Instability

Published June 23rd, 2007 in LS-DYNA. Tags: instability, .

out-of-range velocities negative volume in brick element termination due to mass increase ()LS-DYNA ftp://user@ftp.lstc.com()LSTCuser BETAftp://ftp.lstc.com/outgoing/ls971( lstcftpIP) d3plot * LS-DYNA * (timestep)(mass-scaling) * /(hourglass) type 4 0.05 16type 8BWC=1 PROJ=1 (B-T) type=2 * bucket sorts0 bucket sort(5,21) *contact_automatic_surface_to_surface *contact_automatic_single_surfaceSOFT=1 1mm * * () * *damping

http://www.aifea.com/blog/?p=21

2007-8-26

instability in lsdyna

Page 2 of 3

See also: negative_volume_in_brick_element.tipsshooting-nodes English Version: Some messages that indicate an instability has occurred: out-of-range velocities negative volume in brick element termination due to mass increase Approaches to combating instability of an explicit solution: First and foremost, use the latest version/revision of LS-DYNA available. The latest production executables can be downloaded from ftp://user@ftp.lstc.com. Contact LSTC for the password to this user ftp account. More recent BETA executables are found in ftp://ftp.lstc.com/outgoing/ls971 (no password required). The next step is to write plot states frequently enough to see the evolution of the instability. This should offer clues into whats initiating the instability. Some other general tips toward resolving numerical instabilities: * Try running a double precision LS-DYNA executable. * Timestep. Try reducing the timestep scale factor (even if mass-scaling is invoked). * Element formulation and/or hourglass control. For underintegrated solids or shells that go unstable, try hourglass type 4 with a hourglass coefficient of 0.05. Or, try shell formulation 16 with hourglass type 8. If response of shells is primarily elastic, set BWC=1 and PROJ=1 (B-T shells only). Avoid type 2 solids. Use at least two solid elements thru the thickness of any solid part. * Contact. Set number of cycles between bucket sorts to zero so that the default sort interval will be used. If the relative velocity between two parts in contact is exceptionally high, it may be necessary to reduce the bucket sort interval (for instance to 5, 2, or even 1). If visible contact penetrations develop during the simulation, switch to *contact_automatic_surface_to_surface or *contact_automatic_single_surface with SOFT set to 1. Make sure geometry takes into account thickness of shells. If shells are VERY thin, e.g., less than 1 mm, scale up or set the contact thickness to a more reasonable value. Avoid redundant contact definitions, that is, dont treat contact between the same two parts using more than one contact definition. * Look for mistakes (typos, inconsistent units, etc.) in material input of parts

http://www.aifea.com/blog/?p=21

2007-8-26

instability in lsdyna

Page 3 of 3

that go unstable. * Turn off all *damping. These tips are of a general nature and may not be appropriate in all situations. See also: negative_volume_in_brick_element.tips, shooting-nodes

Asia Web Based SFA / MA Sales Force & Marketing Automation support ! Chinese, English

0 Responses to LS-DYNA FAQ -5.Instability

No Comments

http://www.aifea.com/blog/?p=21

2007-8-26

Negative volume in soft materials

Page 1 of 3

LS-DYNA FAQ -6.Negative Volume

Published June 24th, 2007 in LS-DYNA. Tags: Negative volume.

() (Lagrangian)(mesh smoothing)(remeshing) LS-DYNA(negative volume) *control_timestepERODE1*control_termination DTMIN ()ERODEDTMIN * * * (timestep scale factor)0.9 * (23) Jacobian Jacobian * ()45(hourglass)( )type 61.0; type 2 3 * (tetrahedral)10 * DAMP(foam model 57)0.5 * *contactBshooting node logic * *contact_interior part setcontact_interiorpartsset_part15DA4 contact_interior19701 type=2 * mat_126ELFORM=0 * EFG(*section_solid_EFG) See also: instability English Version:

http://www.aifea.com/blog/?p=22

2007-8-26

Negative volume in soft materials

Page 2 of 3

Negative Volumes in Foams (or other soft materials) In materials that undergo extremely large deformations, such as soft foams, an element may become so distorted that the volume of the element is calculated as negative. This may occur without the material reaching a failure criterion. There is an inherent limit to how much deformation a Lagrangian mesh can accommodate without some sort of mesh smoothing or remeshing taking place. A negative volume calculation in LS-DYNA will cause the calculation to terminate unless ERODE in *control_timestep is set to 1 and DTMIN in *control_termination is set to any nonzero value in which case the offending element is deleted and the calculation continues (in most cases). Even with ERODE and DTMIN set as described, a negative volume may cause an error termination (see erode/negvol.k). Some approaches that can help to overcome negative volumes include the following. - Simply stiffen up the material stress-strain curve at large strains. This approach can be quite effective. - Sometimes tailoring the initial mesh to accomodate a particular deformation field will prevent formation of negative volumes. Again, negative volumes are generally only an issue for very severe deformation problems and typically occur only in soft materials like foam. - Reduce the timestep scale factor. The default of 0.9 may not be sufficient to prevent numerical instabilities. - Avoid fully-integrated solids (formulations 2 and 3) which tend to be less stable in situations involving large deformation or distortion. (The fully integrated element is less robust than a 1-point element when deformation is large because a negative Jacobian can occur at one of the integration points while the element as a whole maintains a positive volume. The calculation with fully integrated element will therefore terminate with a negative Jacobian much sooner than will a 1-point element. (lpb)) - Use the default element formulation (1 point solid) with type 4 or 5 hourglass control (will stiffen response). Preferred hourglass formulations for foams are: type 6 with coef. = 1.0 if low velocity impact types 2 or 3 if high velcocity impact - Model the foam with tetrahedral elements using solid element formulation 10 (see ~pdf/dubois-foam-tets.pdf). - Increase the DAMP parameter (foam model 57) to the maximum recommended value of 0.5. - Use optional card B of *contact to turn shooting node logic off for contacts involving foam. - Use *contact_interior. A part set defines the parts to be treated by contact_interior. Attribute 4 (DA4 = 5th field of Card 1) of the part set defines the TYPE of contact_interior used. The default TYPE is 1 which is recommended for uniform compression. In version 970, solid formulation 1

http://www.aifea.com/blog/?p=22

2007-8-26

Negative volume in soft materials

Page 3 of 3

elements can be assigned TYPE=2 which treats combined modes of shear and compression. - If mat_126 is used, try ELFORM = 0. - Try EFG formulation (*section_solid_EFG). Use only where deformations are severe as this formulation is very expensive. Use only with hex elements. *********************************************************** See also: instablity.tips

FEA Software / Services Finite element software and FEA design/consultancy services Chemicals & Standards Single/Multi element & Custom made Worldwide Distribution Opportunity

0 Responses to LS-DYNA FAQ -6.Negative Volume

No Comments

http://www.aifea.com/blog/?p=22

2007-8-26

automatic implicit_explicit_switch

Page 1 of 1

LS-DYNA

Published June 25th, 2007 in LS-DYNA. Tags: implicit explicit switch.

LS-DYNA*Control_implicit_generalimflag( *define_curve ID) 0-0.01010.0 ID3 0-0.0120 input deckimplicit_explicit_switchk.txt 5434,5434a or 971k6763 (implicitbug )

0 Responses to LS-DYNA

No Comments

http://www.aifea.com/blog/?p=23

2007-8-26

sandwich in ls-dyna

Page 1 of 2

LS-DYNA(sandwich)

Published June 27th, 2007 in LS-DYNA. Tags: sandwich.

LS-DYNA(sandwich plate) 1. 2. shell Contact_tied (_offset) 3. *Mat_composite_damage *mat_enhanced_composite_damage(*control_shellLAMSHT 1) *intergration_shell

*INTEGRATION_SHELL 1,8,0 -.9722, .02778, 1 -.9167, .02778, 1 -.6667, .22222, 2 -.2222, .22222, 2 .2222, .22222, 2 .6667, .22222, 2 .9167, .02778, 3 .9722, .02778, 3 *PART material 1 1 11 *PART material 2 1 12 *PART material 3 1 11 *SECTION_SHELL 1 2 0.0000000 8.0000000 0.00000 -1.000000 18.000000 18.000000 18.000000 18.000000 0.0000000 *mat_composite_damage 11, 2.7e-6, 73.4, 73.4, 73.4, 0.32, 0.32, 0.32 27.8, 27.8, 27.8 1.e9, 1.e9, 1.e9, 1.e9 *mat_composite_damage 12, 6.3e-7, 0.286, 0.286, 0.286, .3, .3, .3 0.11, 0.11, 0.11 1.e9, 1.e9, 1.e9, 1.e9

http://www.aifea.com/blog/?p=26

2007-8-26

sandwich in ls-dyna

Page 2 of 2

*intergration_shellS-1 1 (ZZ)/(thickness/2) WF(Weighting factors)WF 1 part IDpart ID shell8lam22.rar

FEA Software / Services Finite element software and FEA design/consultancy services LVDT

1 Response to LS-DYNA(sandwich)

1 delubbi

Jun 29th, 2007 at 12:19 am

integration_shell

http://www.aifea.com/blog/?p=26

2007-8-26

Energy Balance in LS-DYNA

Page 1 of 7

LS-DYNA FAQ -7.Energy balance

Published June 28th, 2007 in LS-DYNA. Tags: Energy Balance, .

GLSTAT(*database_glstat) internal energy kinetic energy () contact(sliding) energy houglass energy system damping energy rigidwall energy GLSTATSpring and damper energy(discrete elements) (seatbelt elements)(*constrained_joint_stiffness) Internal EnergySpring and damper energy Spring and damper energyInternal energy SMP 5434aglstatjoint internal energy *constrained_joing_stiffness*constrained_joint_revolute(_spherical,etc) SMP 5434aMPP 5434a (Lagrange Multiplier) *constrained_joint_stiffnessjntforcglstat spring and damper energy MATSUMpartpart(*database_matsum) Hourglass energy*control_energyHGEN2 RWENRYLEN2 system damping energy(bulk viscosity)

http://www.aifea.com/blog/?p=29

2007-8-26

Energy Balance in LS-DYNA

Page 2 of 7

(energy dissipated)970.4748TYPE=-2

total energy external work

energy ratio(glstattotal energy/initial energy total energy/(initial energy + external work)) 1.0 LSprepostHistory>Global energies(eroded elements) GLSTATASCII>glstat Eroded Kinetic Energy & Eroded Internal Energy(Eroded energy) energy ratio w/o eroded energy1 1total energy/initial energy glstat glstateroded internal energy & eroded kinetic energy eroded internal energy matsum(noneroded) *control_contactENMASS2 eroded kinetic energy0 LSprepostHistory>Global

http://www.aifea.com/blog/?p=29

2007-8-26

Energy Balance in LS-DYNA

Page 3 of 7

(ISTUPD in *control_shell) (set TYPE=-2 *control_bulk_viscosity) matsumparts*damping_part_stiffness; 0.01 *control_energyRYLEN=2 ( ) 10% LS-DYNA23.8.3&23.8.4 parts glstat LS-prepost (Fcomp > Misc > Internal energy)/ sleout(*database_sleout) (initial penetration)(messagewarning) parts

http://www.aifea.com/blog/?p=29

2007-8-26

Energy Balance in LS-DYNA

Page 4 of 7

SOFT=1 & IGNORE=1(C) SOFT=2(segment-to-segment) 970 SBOPT(EDGE)4SOFT=2edge-toedge SOFT=2 DEPTH=5SOFT=2SBOPT DEPTH (SOFT=0SOFT=1) English version: Total energy reported in GLSTAT (see *database_glstat) is the sum of internal energy kinetic energy contact (sliding) energy hourglass energy system damping energy rigidwall energy Spring and damper energy reported in the glstat file is the sum of internal energy of discrete elements, seatbelt elements, and energy associated with joint stiffnesses (*constrained_joint_stiffness.). Internal Energy includes Spring and damper energy as well as internal energy of all other element types. Thus Spring and damper energy is a subset of Internal energy. The joint internal energy written to glstat by SMP 5434a is independent of the constrained_joint_stiffness. It would appear to be associated with the penalty stiffness of *constrained_joint_revolute (_spherical, etc). This was a missing energy term prior to SMP rev. 5434a. It is still a missing energy term in MPP rev. 5434a. It does NOT appear when a Lagrange Multiplier formulation is used. The energy associated with *constrained_joint_stiffness appears in the jntforc file and is included in glstat in spring and damper energy and internal energy. Recall that spring and damper energy, whether from joint stiffness or from discrete elements, is always included in internal energy. Energy values are written on a part-by-part basis in MATSUM (see *database_matsum). Hourglass energy is computed and written only if HGEN is set to 2 in *control_energy. Likewise, rigidwall energy and damping energy are computed and written only if RWEN and RYLEN, respectively, are set to 2.

http://www.aifea.com/blog/?p=29

2007-8-26

Energy Balance in LS-DYNA

Page 5 of 7

Stiffness damping energy is lumped into internal energy. Mass damping energy appears as a separate line item system damping energy. Energy dissipated due to shell bulk viscosity was not calculated prior to revision 4748 of v. 970. In subsequent revisions, set TYPE=-2 to iclude this energy in the energy balance. The energy balance is perfect if total energy = initial total energy + external work, or in other words if the energy ratio (referred to in glstat as total energy / initial energy although it actually is total energy / (initial energy + external work)) is equal to 1.0. Note that added mass may cause the energy ratio to rise. (See ~/test/erode/taylor.mat3.noerode.mscale.k) The History > Global energies do not include the contributions of eroded elements whereas the GLSTAT energies do include those contributions. Note that these eroded contributions can be plotted as Eroded Kinetic Energy and Eroded Internal Energy via ASCII > glstat. Eroded energy is the energy associated with deleted elements (internal energy) and deleted nodes (kinetic energy). Typically, the energy ratio w/o eroded energy would be equal to 1 if no elements have been deleted or less than one if elements have been deleted. The deleted elements should have no bearing on the total energy / initial energy ratio. Overall energy ratio growth would be attributable to some other event, e.g., added mass. Restated, when an element erodes, the internal energy and kinetic energy in glstat do not reflect the energy loss. Instead the energy losses are recorded as eroded internal energy and eroded kinetic energy in glstat. If you subtract eroded internal energy from internal energy, you have the internal energy of elements which remain in the simulation. Likewise for kinetic energy. The matsum files internal energy and kinetic energy include only contributions from the remaining (noneroded) elements. An example is attached. Note that if ENMASS in *control_contact is set to 2, the nodes associated with the deleted elements are not deleted and the eroded kinetic energy is zero. (See ~/test/m3ball2plate.15.k) The total energy via History > Global is simply the sum of KE and internal energies and thus doesnt include such contributions as contact energy or hourglass energy. Negative internal energy in shells: To combat this spurious effect, - turn off shell thinning (ISTUPD) - invoke bulk viscosity for shells (set TYPE = -2 in *control_bulk_viscosity) - use *damping_part_stiffness for parts exhibiting neg. IE in matsum

http://www.aifea.com/blog/?p=29

2007-8-26

Energy Balance in LS-DYNA

Page 6 of 7

Try a small value first, e.g., .01. If RYLEN=2 in *control_energy, then the energy due to stiffness damping is calculated and included in internal energy. (See negative_internal_energy_in_shells for a case study) Positive contact energy: When friction is included in a contact definition, positive contact is to be expected. Friction SHOULD result in positive contact energy. In the absence of contact damping and contact friction, one would hope to see zero (or very small) net contact energy (net = sum of slave side energy and master side energy). Small is a matter of judgement 10% of peak internal energy might be considered acceptable for contact energy in the absence of contact friction. (~/test/shl2sol/sphere_to_plate.examine_contact_damping_energy.k appears to illustrate that contact damping (VDC = 0, 30, 90) produces positive sliding (or contact) energy) Negative contact energy: Refer to p. 3.14, 3.15 of Crashworthiness Engineering Course Notes by Paul Du Bois. Contact jane@lstc.com to purchase these notes. Abrupt increases in negative contact energy may be caused by undetected initial penetrations. Care in defining the initial geometry so that shell offsets are properly taken into account is usually the most effective step to reducing negative contact energy. Refer to sections 23.8.3 and 23.8.4 in the LS-DYNA Theory Manual (May 1998) for more information on contact energy. Negative contact energy sometimes is generated when parts slide relative to each other. This has nothing to do with friction Im speaking of negative energy from normal contact forces and normal penetrations. When a penetrated node slides from its original master segment to an adjacent though unconnected master segment and a penetration is immediately detected, negative contact energy is the result. If internal energy mirrors negative contact energy, i.e., the slope of internal energy curve in glstat is equal and opposite that of the negative contact energy curve, it could be that the problem is very localized with low impact on the overall validity of the solution. You may be able to isolate the local problem area(s) by fringing internal energy of your shell parts (Fcomp > Misc > internal energy in LS-Prepost). Actually, internal energy density is displayed, i.e., internal energy/volume. Hot spots in internal energy density usually indicate where negative contact energy is focused. If you have more than one contact defined, the sleout file (*database_sleout) will report contact energies for each contact and so the focus of the negative contact energy investigation can be narrowed. Some general suggestions for combating negative contact energy are as follows: - Eliminate initial penetrations (look for Warning in messag file). - Check for and eliminate redundant contact conditions. You should NOT have

http://www.aifea.com/blog/?p=29

2007-8-26

Energy Balance in LS-DYNA

Page 7 of 7

more than one contact definition treating contact between the same two parts or surfaces. - Reduce the time step scale factor. - Set contact controls back to default except set SOFT=1 and IGNORE=1 (Optional Card C). - For contact of sharp-edged surfaces, set SOFT=2 (applicable for segment-to-segment contact only). Furthermore, in v. 970, setting SBOPT (formerly EDGE) to 4 is recommended for SOFT=2 contact where relative sliding between parts occurs. For improved edge-to-edge SOFT=2 contact behavior, set DEPTH to 5. Please note that SOFT=2 contact carries some additional expense, particularly using nondefault values of SBOPT or DEPTH, and so should be used only where other contact options (SOFT=0 or SOFT=1) are inadequate. The specifics of your model may dictate that some other approach be used.

Nuclear Energy Nuclear News: Revival of Nuclear Energy - Going Forward Together Coal Research, Consulting Coal, Petcoke & Electricity Advice Studies, Forecasts, Custom Analysis

0 Responses to LS-DYNA FAQ -7.Energy balance

No Comments

http://www.aifea.com/blog/?p=29

2007-8-26

LS-DYNA MPP | AiFEA

Page 1 of 2

LS-DYNA MPP

Published June 29th, 2007 in DYNA MPP. Tags: No Tags.

FE MPPLSDynaLSTCBensonDYNA history presentationMPPPC,SMPDyna LSTC(IBM,HP,SGI,SUN,etc)LS-DYNA Cluster LSTCMPP LS-DYNA Topcrunch.orgMPP DYNA Benchmark( )MPP LS-DYNA CPU DYNACPU MPP ( ) () MPP MPI domain decomposition DynaCPU domainCPUCPU mpitracer2890% 8K67%1K[Ref 1] (bandwidth & latency) IP bandwith & latencylatency CPU bandwidthlatency CPUCPU CPU bandwidthlatency myrinet,infibandGigE tuning LS-DYNA MPP LS-DYNA MPP 8K LS-DYNA MPPlinux cluster 7% MPIlinuxHPMPI/Intel-MPI/MPICH/LAMMPI Cluster

http://www.aifea.com/blog/?p=30

2007-8-26

LS-DYNA MPP | AiFEA

Page 2 of 2

40CPUs Linux ClusterGigE MPP DynaLAMMPI MPICHDYNA MPP topcrunch5434a3858 domain decomposition domainCPUCPU CPU CPUdomain decompositionCPU domaindomain CPUDomain decomposition domainDomain decomposition lsdyna keyword users manualMPP LS-Dyna MPP Reference: 1 . Message Passing and Advanced Computer Architectures.

Brian Wainscott and Jason Wang, LSTC.

2. A Correlation Study between MPP LS-DYNA Performance and Various Interconnection Networks a Quantitative Approach for Determining the Communication and Computation Costs. Yih-Yih Lin, Hewlett-Packard Company

OK - iSing99 9 9, 60

0 Responses to LS-DYNA MPP

No Comments

http://www.aifea.com/blog/?p=30

2007-8-26

hourglass control in ls-dyna

Page 1 of 5

LS-DYNA FAQ -8.Hourglass control

Published July 2nd, 2007 in LS-DYNA. Tags: hourglass control, .

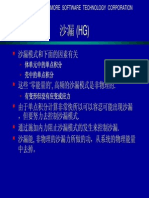

(hourglass) () LS-DYNA(type 1) (S/R) 2 ; ( );2 (shear-lock) *control_energyHGEN2*database_glstat *database_matsum part( <10%) *database_extent_binarySHGE=2LSPrepostFcomp>Misc>hourglass energy () (type 1) (type 4,5) 0.03~0.05 (type 1,2,3)

http://www.aifea.com/blog/?p=31

2007-8-26

hourglass control in ls-dyna

Page 2 of 5

81616 816(Twisted Beam) 12D(shell types 13 & 15)6 61.01 16(V970) (More on type 6 HG control from Lee Bindeman) 64,5 45LS-DYNA3.21 6 4 5 6 1.01.0 6 ( )6 6 4,56

http://www.aifea.com/blog/?p=31

2007-8-26

hourglass control in ls-dyna

Page 3 of 5

4 6LS-DYNA Users ManualBelytschkoBindeman English Version: Hourglass (HG) modes are nonphysical, zero-energy modes of deformation that produce zero strain and no stress. Hourglass modes occur only in under-intetgrated (single integration point) solid, shell, and thick shell elements. LS-DYNA has various algorithms for inhibiting hourglass modes. The default algorithm (type 1), while the cheapest, is generally not the most effective algorithm. A way to entirely eliminate hourglass concerns is to switch to element formulations with fully-integrated or selectively reduced (S/R) integration. There can be a downside to this approach. For example, Type 2 solids are much more expensive than the single point default solid. Secondly, they are much more unstable in large deformation applications (negative volumes much more likely). Third, type 2 solids have some tendency to shear-lock and thus behave too stiffly in applications where the element shape is poor. Triangular shells and tetrahedral solid elements do not have hourglassing modes but have drawbacks with regard to overly stiff behavior in many applications. A good way to reduce hourglassing is to refine your mesh but, of course, that isnt always practical. The method of loading can affect the degree of hourglassing. A pressure loading is preferred over loading individual nodes as the latter approach is more likely to excite hourglassing modes. To evaluate hourglass energy, set HGEN to 2 in *control_energy and use *database_glstat and *database_matsum to report the HG energy for the system and for each part, respectively. The point is to confirm that the nonphysical HG energy is small relative to peak internal energy for each part (<10% as a rule-of-thumb). For shells only, you can fringe hourglass energy density by first setting SHGE=2 in the LS-DYNA input deck (*database_extent_binary). Then, in LS-Prepost, choose Fcomp > Misc > hourglass energy. For fluid parts, the default HG coefficient is generally inappropriate (too high). Thus for fluids, the hourglass coefficient should generally be scaled back one or two orders of magnitude. Use only viscosity-based HG control for fluids. The default HG formulation (type 1) is generally ok for fluids. Stiffness-based HG control (types 4,5) is generally more effective than viscous HG control for structural parts. Usually, when stiffness-based HG control is invoked, I like to reduce the HG coefficient, usually in the range of .03 to .05, soas to minimize nonphysical stiffening of the response and at the same time effectively inhibiting hourglass modes. For high velocity impacts, viscosity-based HG control (types 1,2,3) is recommended even for solid/structural parts. Viscous HG control only stops the HG mode from developing further. Stiffness HG

http://www.aifea.com/blog/?p=31

2007-8-26

hourglass control in ls-dyna

Page 4 of 5

control will push the element back toward its undeformed configuration. CAUTION: Stiffness hourglass control tends to be overly stiff! (Paul Dubois) Type 8 HG control applies only to shell formulation 16. This HG type activates warping stiffness in type 16 shells so that warping of the element does not degrade the solution. Type 16 shells will solve the so-called Twisted Beam problem correctly if HG type 8 is invoked. Type 6 HG control invokes an assumed-strain co-rotational formulation for type 1 solid elements and under-integrated 2D solids (shell types 13 and 15). With the HG type set to 6 and the hourglass coefficient set to 1.0, an elastic part need only be modeled with a single type 1 solid through its thickness to achieve the exact bending stiffness. Type 6 HG control should always be used for type 1 solids in implicit simulations (in fact, this is done automatically in v. 970). ________________________________________________________________________ (More on type 6 HG control from Lee Bindeman) Type 6 hourglass control for solid elements differs from types 4 and 5 because is uses an assumed strain field and material properties to evaluate an assumed stress field. This stress is integrated in closed form over the element domain to obtain hourglass forces such that the element behaves like a fully integrated element with the same assumed strain field. The assumed strain field is designed to prevent spurious shears during pure bending and volumetric locking for nearly incompressible material. Types 4 and 5 hourglass control calculate an hourglass stiffness based on the element volume, wave speed and density as shown in equation 3.21 in the LS-DYNA Theoretical Manual. In my opinion, the main improvement of hourglass type 6 is that the stress field is integrated over the element domain. This makes the hourglass control quite robust when using solid elements with large aspect ratio or with skewed shapes. Type 4 and 5 hourglass control tend to not respond appropriately for large aspect ratio or skewed shapes so they tend to become much too stiff in some hourglass modes and too soft in others. Another more academic advantage to type 6 hourglass control is that it is possible to obtain accurate results in elastic bending problems with beams made of 1 element through the thickness. To do this, set the hourglass stiffness parameter to 1.0. Similarly, torsion of a rectangular bar of elastic material can be solved with very few elements when the hourglass stiffness parameter is set to 1.0. However, with non-linear materials, good coarse mesh results are impossible because the stress field does not vary linearly as is assumed with hourglass type 6. There is no way to capture the nonlinear nature of the stress field without more integration points through the beam thickness. To choose an hourglass control, you need to consider the problem. I would recommend type 6 hourglass control when elements have large aspect ratios (>2) or are significantly skewed, either initially or in a deformed configuration. Type 6 hourglass control is usually better with soft materials such as foam or honeycomb material that deform

http://www.aifea.com/blog/?p=31

2007-8-26

hourglass control in ls-dyna

Page 5 of 5

significantly during a calculation. In cases where the material is not particularly soft or elements are of reasonable shape and where the mesh is not too coarse, types 4, 5, and 6 hourglass control will likely all give about the same result, in which case type 4 hourglass control is recommended since it is faster than the others.

Finite element program SJ MEPLA - software for statics of glass structures

www.SJ-Software.de

FEA Software / Services Finite element software and FEA design/consultancy services

0 Responses to LS-DYNA FAQ -8.Hourglass control

No Comments

http://www.aifea.com/blog/?p=31

2007-8-26

damping in ls-dyna

Page 1 of 4

LS-DYNA FAQ -9.Damping

Published July 6th, 2007 in LS-DYNA. Tags: damping, .

LS-DYNA*DAMPING *DAMPING *CONTACT VDC VDC1020 *DAMPING LS-DYNA(Mass damping)*damping_global & *damping_part_mass ;*damping_relative *damping_relative/ 4*pi/TT( ()) (eigenvalue) 10%0.4*pi/T (*damping_global) (*damping_part_mass)( ) *damping_part_stiffness COEFCOEF0.1 COEF( ) 970 (*damping_frequency_range)Damping_frequency_rangeArupRichard Sturt LS-DYNA NVH

http://www.aifea.com/blog/?p=34

2007-8-26

damping in ls-dyna

Page 2 of 4

*damping_frequency_range 1%2% 30% Rayleigh C = alpah*M + beta*K LS-DYNARayleigh K Rayleigh 960(stiffness damping)960 COEF 950BETACOEFBETA*(w/2) 950960960 9703510()950 COEFV950BETA English Version: Damping is completely optional in LS-DYNA and is invoked using one the *DAMPING commands. Be aware that energy dissipation can occur through means other than *DAMPING, e.g., energy due to hourglass forces, energy due to rigidwall forces, energy due to contact friction forces, internal energy from discrete dampers, etc. Sometimes, contact forces can introduce noise into the response. In such cases, adding viscous damping via the VDC parameter on Card 2 of *contact may help reduce the noise. VDC is input as a percentage of critical damping a typical value is 10 to 20. ___________________________________________________________ Overview of *DAMPING commands: Mass damping in LS-DYNA, which includes *damping_global and *damping_part_mass, is intended to damp low-frequency structural modes but it has the added effect of damping rigid body modes. Thus parts that undergo significant rigid body motion should EITHER be excluded from mass damping

http://www.aifea.com/blog/?p=34

2007-8-26

damping in ls-dyna

Page 3 of 4

OR the mass damping should be turned off during the time the part undergoes rigid body motion OR *damping_relative should instead be used. By using *damping_relative, only motion/vibration that is relative to the motion of a particular rigid body is damped. The critical damping coefficient in the case of mass damping is 4*pi/T where T is the period of the mode targeted for damping (usually the lowest frequency (fundamental) mode). The period can be determined from an eigenvalue analysis or estimated from results of an undamped transient analysis. If the user elects to use mass damping, a damping value less than the critical damping coefficient is suggested. A value of 10% of critical damping, input as 0.4*pi/T, is fairly typical. You can choose to damp all parts using the same damping coefficient (*damping_global) or, to tailor the damping to the individual response characteristics of each part, you can assign a different damping coefficient to each part (*damping_part_mass). In either case, the damping coefficient can vary with time (useful to turn damping off or on in the middle of a simulation). *damping_part_stiffness is intended to damp high frequency, numerical oscillation and generally wont have much affect on structural vibration/oscillation. The damping coefficient COEF in this case appproximately represents a fraction of critical damping. A typical value of COEF is 0.1. If an instability results from using stiffness damping, eliminate the damping or reduce COEF (by perhaps an order of magnitude or more in some cases) so that stability is restored. Both mass and stiffness damping are implemented for implicit transient analysis. Another damping alternative in version 970 is a frequency-independent damping option which targets a range of frequencies and a set of parts (*damping_frequency_range). Damping_frequency_range was developed by Richard Sturt of Arup and its theoretical details are proprietary. It was developed with the intent of helping LS-DYNA to handle damping in vibration prediction problems properly - including vehicle NVH time-history analysis as well as certain classes of seismic problems and civil/structural vibration problems. The key points of *damping_frequency_range are: - Use for low amounts of damping only, e.g. up to 1% or 2% - The damping treatment slightly reduces the stiffness of the response thats because the applied damping force lags slightly behind the theoretically correct damping force, due to the need to evaluate frequency content. - The frequency range specified by the user should ideally be no more than a factor of 30 between highest and lowest. Damping is still achieved outside the frequency range but the amount of damping reduces. This damping is based on the nodal velocities; these might oscillate due to structure modes or due to rigid body rotation. __________________________________________________________________________ Additional commentary on damping In Rayleigh damping, the damping matrix is expressed as a linear combination of the mass and stiffness matricies:

http://www.aifea.com/blog/?p=34

2007-8-26

damping in ls-dyna

Page 4 of 4

C = alpha*M + beta*K The LS-DYNA implementation of Rayleigh damping for standard, nonlinear analysis is done at the element level, as you stated. This is done for numerical convenience, since in the explicit method we dont need to form the stiffness matrix K. Instead, we compute internal forces by simply integrating stresses over the element area. The Rayleigh damping terms are implemented as corrections to these stresses. The stiffness damping in version 960 is completely reformulated. Even though you may provide a 960 COEF value which is consistent with the 950 BETA value, , that is, COEF = BETA * (w/2) the 950 stiffness damping and the 960 stiffness damping will not be exactly equivalent. The 960 formulation of stiffness damping provides an APPROXIMATE fraction of critical damping in the high frequency domain. The details of the formulation are proprietary. The change in formulation was prompted by the frequent occurences of instability when using the old formulation. In rev. 3510 (or higher) of v. 970, the old 950-style stiffness damping formulation is available as an option and is invoked by setting the COEF parameter to a negative value. The parameter is then interpreted as a BETA value as documented in the v. 950 Users Manual.

Turbine testing Vibration measurement and modal analysis

www.optonor.com

Noise Vibration Analyzer 4 channels, handheld, FFT for modal ODS, balance, Data Collector, Meter

2 Responses to LS-DYNA FAQ -9.Damping

1 delubbi

Very good! Thanks!

Jul 17th, 2007 at 2:05 am

2 czj

Jul 22nd, 2007 at 10:30 am

thank your effort!!!

http://www.aifea.com/blog/?p=34

2007-8-26

ASCII output for MPP via binout

Page 1 of 3

LS-DYNA FAQ -10.ASCII output for MPP via binout

Published July 17th, 2007 in DYNA MPP and LS-DYNA. Tags: No Tags.

970ASCII output(matsum,rcforc,etc.) smpASCII output MPP-DYNA ASCII dbout(V.970Appendix LP.L3)binoutMPP binout*database_matsum,*database_rcforc,etc 1= old formatASCII(SMP) dbout(MPP) 2= new binout(MPP) 3= both formats LS-Prepostbinoutdboutdumpbdb ASCII LS-Prepost2(Group) CFDBinoutLoad binout lsda(lstc ftp site lsda)l2abinoutascii ioq/binout l2aMPP l2als-dyna(MPP or SMP)binoutbinout ASCIIl2abinout./l2a binout.0000 Binoutbinout binout MPP LS-DYNAbinoutbinout d3hsp binout >The following binary output file are being created, >and contain data equivalent to the indicated ascii output files > binout0000:(on processor 0) > nodout > matsum > rcforc > abstat > rbdout > sleout > jntforc (type 0) > binout0001:(on processor 1) > jntforc > binout0003:(on processor 3) > deforc

http://www.aifea.com/blog/?p=35

2007-8-26

ASCII output for MPP via binout

Page 2 of 3

MPP(from Jason) pfile pfile: gen {dboutonly} to execute: mpirun -np ## mpp970 i= p=pfile dbout.*(binout)dumpbdb ASCII English Version: Starting with version 970, a binary format for the so-called ASCII output files (matsum, rcforc, etc.) is available. MPP-DYNA runs do not write ASCII output files directly but instead write the data to binary database(s). There are two formats for this data: dbout (see Appendix L, p. L.3 in the v. 970 Users Manual) and binout. The default for MPP is to write the binout style of database. The second input parameter of *database_matsum, *database_rcforc, etc. controls what type of output will be written. 1 = old format, i.e., ASCII files (SMP) or dbout files (MPP) 2 = new binout format (this is the default for MPP) 3 = both formats written LS-PrePost can read the binout data directly with no conversion by dumpbdb being required. In LS-PrePost, select the square button labeled 2 (directly under the Group button. Next, select Binout and then, from the bottom of the window, select Load. From there, its pretty self-explanatory. There are two programs that are available as part of our lsda package (see the lsda directory under the user account of our ftp site). One is l2a which will extract the various ascii files from a binout file. The other is ioq which is a small utility that lets you read/explore the binout file directly. An l2a executable is generally included in the same tar file that contains the MPP executable for your platform but you can also use that l2a to operate on binout files produced by any LS-DYNA executable, MPP or SMP. To extract the ASCII files from a binout file, execute l2a and include the name of the binout file on the execution line, e.g., ./l2a binout.0000. Binout files are platform-independent, i.e., you can process binout data written by one platform on that same platform or on any other platform. When a binout database is written by an MPP LS-DYNA executable, there will be more than one file with the binout rootname. Each of these files must be opened individually to access all of the requested data. In the d3hsp file, youll see something like the following which tells

http://www.aifea.com/blog/?p=35

2007-8-26

ASCII output for MPP via binout

Page 3 of 3

you what data is contained in each binout file: > The following binary output files are being created, > and contain data equivalent to the indicated ascii output files > binout0000: (on processor 0) > nodout > glstat > matsum > rcforc > abstat > rbdout > sleout > jntforc (type 0) > binout0001: (on processor 1) > jntforc > binout0003: (on processor 3) > deforc Alternative control of output format for MPP (from Jason): if you put the following line in your pfile pfile: gen { dboutonly } to execute: mpirun -np ## mpp970 i= p=pfile The program will output dbout.* as before and you can use dumpbdb to extract all the ASCII files.

Microsoft Project Viewer View your Microsoft Project files with the complete .mpp file viewer.

0 Responses to LS-DYNA FAQ -10.ASCII output for MPP via binout

No Comments

http://www.aifea.com/blog/?p=35

2007-8-26

contact overview in ls-dyna

Page 1 of 3

LS-DYNA FAQ -11.Contact Overview

Published July 22nd, 2007 in LS-DYNA. Tags: contact overview.

LS-DYNA LS-DYNAwww.feapublicatoins.comFEA Information Newsletters 20018,9,10,12 Automatic vs. Non-automatic () Type 13(contact_automatic_single_surface)() 133 (contact_surface_to_surface)a3(contact_automatic_surface_to_surface) type13 RCFORC contact_force_transducer_penaltycontact.13vs26 contact_automatic_single_surface contact_automatic_general( ) Type 3(contact_surface_to_surface) *contact*control_contact(*contact) SOFT=2segment-based a3() type 13 SOFT SOFT*contactASOFT0SOFT=1 SOFT=0SOFT=2SOFT=0 SOFT=2 segment-based contactSOFT=1 & 2 contact.soft1 & contact.soft2() IGNORE ( )(IGNORE=0) (shooting node logic)shooting node logic (SNLOG=1)IGNORE

http://www.aifea.com/blog/?p=36

2007-8-26

contact overview in ls-dyna

Page 2 of 3

1shooting node logicSNLOG English Version: Provided herein are some very brief notes on LS-DYNA contact. Not all the contact types or contact options are discussed. [For a comprehensive review of contact in LS-DYNA, see the four-part series on contact modeling in the archived FEA information Newsletters available at www.feapublications.com The four parts of the series are in the August, September, October, and December 2001 newsletters.] Automatic vs. Non-automatic: Automatic contacts are recommended for most explicit simulations. Non-automatic contacts (in which contact orientation is important) are sometimes used for metal forming simulations where the geometries are very straightforward and contact surface orientation can be reliably established before the simulation is conducted. Non-automatic contacts are generally recommended for implicit simulations. TYPES: Type 13 contact (contact_automatic_single_surface) is a single surface contact (no master surface is defined) that always considers shell thickness and has no orientation. Thus its necessary that shell surfaces be modeled with at least a small gap between them. To avoid initial penetrations, the gap should be no less than the average thickness of the two shells potentially in contact. No gap is necessary between solid elements. The contact searching algorithm for type 13 contact is more complex than for type 3 (contact_surface_to_surface) or a3 (contact_automatic_surface_to_surface), i.e., type 13 can handle situations such as shell edge to surface, and to some extent, beam to shell surface. As with any single surface contact type, resultant forces are not directly retrievable in the RCFORC file; one must define a contact_force_transducer_penalty in order to retrieve the contact forces. The article contact.13vs26 provides additional information on contact_automatic_single_surface and contrasts it to contact_automatic_general. Type 3 contact (contact_surface_to_surface) contact is a surface-to-surface (two-way) contact where shell thickness consideration can either be turned on or off either in *contact or *control_contact (*contact has priority). The orientation of the contact segments is important with this contact type as the shell only looks in one direction for potential contact. In a two-way contact such surface_to_surface, nodes on the slave side are first checked for penetration thru the master surface and then master nodes are checked for penetration thru the slave surface. The exception is this approach is when segment-based contact is invoked by setting SOFT=2. Contact type a3 has no orientation (a shell looks for potential contact from either side of the shell

http://www.aifea.com/blog/?p=36

2007-8-26

contact overview in ls-dyna

Page 3 of 3

midplane) and always considers shell thickness, so in this regard, its quite similar to a type 13 contact. Table 6.1 in the 950 Keyword Users Manual lists the maximum penetration d that defines when a penetrating node is released from contact consideration. This distance d is different for a type 3 contact than for a type 13 contact. Some notes on contact parameters: SOFT SOFT is the first parameter on Optional Card A of *contact. The default value of SOFT is 0. SOFT=1 is more or less the same as SOFT=0 EXCEPT in the way the contact stiffness is determined. SOFT=2 is a radical departure from SOFT=0, both in the way contact stiffness is determined but also in the manner that the search for penetration is conducted. SOFT=2 invokes what is called segment-based contact. For notes regarding contact with SOFT= 1 and 2, see the articles contact.soft1 and contact.soft2, respectively. IGNORE At any point during the simulation, if a node is suddenly found to be below the surface (say, it was moving very fast and wasnt detected before penetration), the old style (IGNORE=0) algorithm just moves the node to the master surface without applying any forces (we term this shooting node logic). If the shooting node logic is turned off (SNLOG=1), then you get large forces suddenly appearing, and negative contact energy. If IGNORE is set to 1 then the shooting node logic flag SNLOG has no affect. Rather the amount of sudden penetration is noted and compensated for by adjusting the contact thickness locally. So at any time during the simulation, if a sudden penetration is detected, the program doesnt apply any large forces nor are any nodes moved. Contact forces, however, will resist FURTHER penetration. jpd 12/2002 revised 4/2003 revised 9/2003 auto vs. non-auto

cpu 40%

www.Intel.com/cn

Asia Web Based SFA / MA Sales Force & Marketing Automation support Chinese, English

0 Responses to LS-DYNA FAQ -11.Contact Overview

No Comments

http://www.aifea.com/blog/?p=36

2007-8-26

You might also like

- 尺八研究Document25 pages尺八研究leawoNo ratings yet

- 整车正面碰撞乘员约束系统评价体系报告Document11 pages整车正面碰撞乘员约束系统评价体系报告leawoNo ratings yet

- LS-DYNA 培训教程【姜正旭MSC.Software上海办事处】Document488 pagesLS-DYNA 培训教程【姜正旭MSC.Software上海办事处】leawoNo ratings yet

- ls dyna沙漏Document12 pagesls dyna沙漏leawoNo ratings yet

- LS-dyna 常见问题汇总2.0Document57 pagesLS-dyna 常见问题汇总2.0leawoNo ratings yet

- hypermesh主要面板英文翻译Document9 pageshypermesh主要面板英文翻译leawoNo ratings yet

- ETA China DynaDocument9 pagesETA China DynaleawoNo ratings yet

- AltairHyperWorks 美国汽车钢铁联盟对SUV车架的轻量化设计Document50 pagesAltairHyperWorks 美国汽车钢铁联盟对SUV车架的轻量化设计leawoNo ratings yet

- CH 6Document41 pagesCH 6林倩No ratings yet

- 树莓派开始玩转LinuxDocument196 pages树莓派开始玩转Linuxsxr1207No ratings yet

- CK610 SpecDocument208 pagesCK610 SpecPower PlantNo ratings yet

- 微處理指令Document24 pages微處理指令ss0421aaNo ratings yet

- 10 【大学计算机基础】绝密模拟题库(十)Document7 pages10 【大学计算机基础】绝密模拟题库(十)atan.j.34No ratings yet

- NI LabVIEW High-Performance FPGA User's GuideDocument94 pagesNI LabVIEW High-Performance FPGA User's GuidevnetawzNo ratings yet