Professional Documents

Culture Documents

Ba SV en Pnem PDF

Uploaded by

Sohaib KhalidOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ba SV en Pnem PDF

Uploaded by

Sohaib KhalidCopyright:

Available Formats

ARMATURENWERK

HTENSLEBEN GmbH

INSTRUCTION MANUAL

Butterfly Valve with

Pneumatic Actuator

AWH Armaturenwerk Htensleben GmbH

Schulstrae 5 / 6

D-39393 Htensleben

Germany

Phone: +49 - (0) 3 94 05 / 92 0

Fax: +49 - (0) 3 94 05 / 92 111

http:// www.awh.de

e.mail: awh-edelstahl@t-online.de

Issue 1/00

2

Issue 01 -00

PVT 900

Instruction Manual

Copyright

This document, or parts thereof, may not be reproduced or

divulged to any third party without express permission of AWH.

Violation will in cur prosecution.

All Rights Reserved.

3

3

Issue 01 -00

Instruction Manual

Butterfly valve with pneumatic actuator

1 Intended Use

AWH Butterfly valves have been designed and manufactured

for process pipework of hygienic standard with the aim of

shutting off liquid flow in trade and industrial applications (food

industry, chemical industry, pharmaceutical industry, and

minimum-germ processes).

The butterfly valve is remote-controlled and actuated through a

pneumatic drive which automatically guarantees the correcting

range.

A pneumatic drive with integral restoring spring is provided to

shut the valve in the event of (control air) pressure failure.

Minimum control air pressure: 5 6 bar

Maximum control air pressure: 9 - 10 bar

The rated pressure must not exceed 10 bar.

For the Technical Data Sheet please refer to the "Butterfly

valve product pages in the Web. Alternatively, it can be

obtained from AWH Armaturenwerk Htensleben GmbH. After

quoting the AWH reference.

The 'Intended Use' also meets the conditions and requirements

specified by the manufacturer for operation, maintenance and

repair.

This is a technical manual designed to neet the needs of

qualified process engineers.

Definition highly similar to that given in DIN EN-60204-1:

Specialist

A person who, in the light of his/her technical and functional

knowledge and experience as well as expertise with respect to

relevant standards, can judge assigned work and realise

potential risks and hazards that may exist.

4

4

Issue 01 -00

Instruction Manual

Butterfly valve with pneumatic actuator

1.1 Materials in Contact with the Product

Refer to Fig. 1-1

Flange (Item 9); 1.4301 / 1.4307 / 1.4404/ 1.4435

Disc (Item 8): 1.4301 / 1.4404

Packing (Item 11) Selected to suit operating conditions

Packing material:

EPDM Max. short-time sterilisation temperature: 130C

VMQ Max. short-time sterilisation temperature: 130C

FPM Max. short-time sterilisation temperature: 140C

The butterfly valve and packing, must be chosen, giving careful

consideration to the environment (i.e. product, temp. and flow)

requirements.

Surfaces

Outer surface: Bright metal / polished

Inner faces in contact with product: Ra < 1.6 m

5

5

Issue 01 -00

Instruction Manual

Butterfly valve with pneumatic actuator

1.2 Exploded View, Outline Drawings, and Dimensions

Fig. 1-1 Exploded view

1 Pneumatic actuator

2 Mounting bracket

3 Proximity switch

4 Mount for proximity switch

5 Hex screw

6 Indicator control arm

7 Position indicator

8 Disc

9 Flange

10 Bolts and nuts

11 Packing

12 Bushing

6

6

Issue 01 -00

Instruction Manual

Butterfly valve with pneumatic actuator

Typical connecting configurations for the butterfly valve are

shown below. Any mounting position can be chosen.

For dimensions refer to the Tables.

The operating range is 90 for the OPEN and the SHUT

positions.

For the Technical Data please refer to the "Butterfly valve

product pages in the Web. Alternatively, relevant data can be

obtained from AWH Armaturenwerk Htensleben GmbH.

Fig. 1-2 Connection configurations

7

7

Issue 01 -00

Instruction Manual

Butterfly valve with pneumatic actuator

Further connecting options are available inch-system

configuration, with clamp connection, flange-mounted

configuration, and with aseptic connection as per DIN 11864.

Dimensions DN 25 DN 32 DN 40 DN 50 DN 65

D

1

26.0 32.0 38.0 50.0 66.0

D

2

87.0 92.0 97.0 110.0 127.0

D

3

89.0 89.0 89.0 89.0 89.0

L

1

64.0 64.0 72.0 72.0 76.0

L

2

40.0 42.0 50.0 50.0 50.0

L

3

84.0 92.0 102.0 106.0 114.0

L

4

90.0 90.0 100.0 100.0 100.0

L

5

236.0 238.0 241.0 247.0 256.0

E Rd 52 x 1/6 Rd 58 x 1/6 Rd 65 x 1/6 Rd 78 x 1/6 Rd 95 x 1/6

Dimensions DN 80 DN 100 DN 125 DN 150 DN 200

D

1

81.0 100.0 125.0 150.0 200.0

D

2

142.0 162.0 200.0 230.0 306.0

D

3

89.0 89.0 129.0 129.0 129.0

L

1

100.0 104.0 112.0 124.0

L

2

60.0 64.0 112.0 124.0

L

3

134.0 152.0 180.0 198.0

L

4

136.0 136.0 168.0 178.0 112.0

L

5

263.0 273.0 305.0 320.0 320.0

E Rd 110 x 1/4 Rd 130 x 1/4 Rd 160 x 1/4 Rd 190 x 1/4

8

8

Issue 01 -00

Instruction Manual

Butterfly valve with pneumatic actuator

2 Contents

2.1 Contents

1 INTENDED USE 3

1.1 MATERIALS IN CONTACT WITH THE PRODUCT 4

1.2 Exploded View, Outline Drawings, and Dimensions 5

2 CONTENTS 8

2.1 Contents 8

2.2 List of Figures 8

3 SAFETY / HAZARDS 9

3.1 Informative Signs / Explanatory Notes 9

3.2 Identification of the Butterfly Valve 9

3.3 Safety Standards and Codes 10

3.4 Safety Inspections and Tests 10

4 WARNING NOTICES 11

5 TRANSPORT AND PACKAGING 12

6 INSTALLATION OF BUTTERFLY VALVE 13

6.1 Installing the Butterfly Valve with

- male/ male connection

- Female nut & liner connection 13

6.2 Installing the Butterfly Valve with

- welding ends

- between flanges 14

7 ASSEMBLY 15

7.1 Assembly of Butterfly Valve with Pneumatic Actuator 15

7.2 Assembly of Pneumatic Actuator with Position Feedback

Indication 17

8 MAINTENANCE / CLEANING 19

9 MALFUNCTION, CAUSE, RECTIFICATION 21

10 DISMANTLING / DISPOSAL 22

11 INDEX 23

2.2 List of Figures

Fig. 1-1 Exploded view 5

Fig. 1-2 Connection configurations 6

Fig. 7-1 Assembly of butterfly valve with pneumatic

drive 15

Fig. 7-2 Assembly of pneumatic drive with

position feedback indication 17

9

9

Issue 01 -00

Instruction Manual

Butterfly valve with pneumatic actuator

3 Safety / Hazards

3.1 Informative Signs / Explanatory Notes

Warnings

are shown in a frame and identified by a STOP sign.

Danger notices

are shown in a frame and identified by a DANGER warning

triangle.

Important reminders

are shown in a frame and identified by a "Hand".

3.2 Identification of the Butterfly Valve

Type No.

Information provided in this Instruction Manual only applies to

the butterfly valve type as indicated on the title page.

To enable us to respond to your questions properly it is

essential that details as below, are given correctly:

- Nominal diameter (DN);

- Packing material;

- Casing material;

- Connection type (DIN 11851; DIN 11864; welding, etc.)

- Handle;

- Accessories (position feedback indication, etc.).

Unless such information is provided your queries cannot be

properly and quickly handled.

10

10

Issue 01 -00

Instruction Manual

Butterfly valve with pneumatic actuator

3.3 Safety Standards and Codes

The butterfly valve is manufactured to conform with the German

versions of the following standards and codes:

1. VBG 5 (1/93);

2. DIN 3230;

3. DIN EN 10204;

4. Druckbehlterverordnung (Pressure Vessel Code);

5. EMV-Gesetz (EMC legislation);

6. Niederspannungs-Richtlinie (Low-voltage directive).

3.4 Safety Inspections and Tests

Conducted by the manufacturer in manufacturer's workshops

(Refer to Data Sheet).

11

11

Issue 01 -00

Instruction Manual

Butterfly valve with pneumatic actuator

4 Warning Notices

Butterfly valves, length and quality of piping must meet the

specific requirements. Installation and fitting work to be carried

out by qualified personnel.

Operation and maintenance at fluid temperatures greater than

80C may involve a burn or scalding hazard.

Care must be exercised to ensure that only fluids indicated on

the Data Sheet are used.

Compliance with the specifications in the Data Sheet is of

critical importance.

12

12

Issue 01 -00

Instruction Manual

Butterfly valve with pneumatic actuator

5 Transport and Packaging

Butterfly valves manufactured by AWH Armaturenwerk

Htensleben GmbH are thoroughly inspected and carefully

packaged prior to dispatch. Damage may still occur, due to

circumstances beyond our control.

Unpacking:

- Remove the caps from the pipe connections (if provided).

- Remove the remainders of packing materials.

Incoming inspection:

- Check against the delivery note to make sure the equipment

supplied is complete.

In case of damage

- Inspect the consignment for damage (visual inspection).

In case of defects

If the consignment has incurred damage in transit:

- Contact the final carrier immediately.

- Retain the packing material(s) (to enable the carrier to

inspect as necessary, and/or to permit the equipment to be

packed again for return to the consignor).

Packaging for return to consignor

Use the original packing materials if available.

Otherwise, call in a packaging contractor employing skilled

personnel.

In case of queries relating to packaging and precautions to be

taken for transport, please consult AWH Armaturenwerk

Htensleben GmbH.

Seaworthy packaging

For shipment to overseas destinations, the butterfly valves will

be sealed in plastic.

Outdoor storage

Outdoor storage is not acceptable.

In case of seaworthy packaging, the desiccant is designed for

storage periods of less than three months.

Storage in confined spaces

Storage conditions

- Temperature 20C to 30C

- Relative humidity < 60%

13

13

Issue 01 -00

Instruction Manual

Butterfly valve with pneumatic actuator

6 Installation of Butterfly Valve

Install the butterfly valve while taking into account the design

configuration of the pipework concerned and the coupling

requirements of the valve.

Face-to-face dimensions are clear from the outline drawings.

Care should be exercised to ensure that clearances and space

are as required for operation and maintenance.

Also, make sure that flanged joints and pipe joints are not

leaky.

Due care is essential during installation to rule out tensile and

compressive stresses on completion.

The construction of valve is such that a manually operated

butterfly valve can be easily converted to a remote-controlled

valve with pneumatic drive without any need for removing the

butterfly valve from the pipework.

6.1 Installing the Butterfly Valve with

- male/ male connection

- Female nut & liner connection

Care should be exercised when installing the butterfly valve to

make sure that the connecting adapters and the slotted nut

conform to an identical standard (e.g. DIN 11851 or

DIN 11864).

Prior to assembly, inspect the sealing ring on the threaded

nipple for damage and check to be sure it is properly fitted;

renew if necessary.

Also, care must be exercised not to damage the thread.

The butterfly valve is mounted by means of the slotted nut using

a C spanner.

14

14

Issue 01 -00

Instruction Manual

Butterfly valve with pneumatic actuator

6.2 Installing the Butterfly Valve with

- welding ends

- between flanges

Welding specifications

The valve is welded into piping to DIN 11850.

Welding process: TIG or orbital

Weld type: Square butt weld to DIN 8532

Pre-welding condition

Dismantle the valve prior to welding (Refer to Assembly /

Dismantling).

Weld preparation

- Square the pipe ends.

- Remove burrs from cut faces.

- Align the casing welding ends with the piping in both radial

and axial directions.

The welding ends must be in flat-to-flat contact, and be

welded without any gap.

Filler metals

Base metal Suitable filler metal

1.4301/ 1.4307 1.4302; 1.4316; 1.4551

1.4404 1.4430; 1.4455; 1.4576

1.4435 1.4430; 1.4440

Welding

- Connect forming gas prior to welding.

- Apply 3 or 4 tack welds prior to welding.

Postweld treatment

- No inside postweld treatment is required. The surface finish of

accessible zones can be improved by grinding.

- Outside postweld treatment can be performed by pickling,

brushing, grinding, and polishing.

Cleaning

Clean all welded components prior to assembly.

15

15

Issue 01 -00

Instruction Manual

Butterfly valve with pneumatic actuator

7 Assembly

7.1 Assembly of Butterfly Valve with Pneumatic Actuator

Fig. 7-1 Assembly of butterfly valve with pneumatic drive

1 Pneumatic actuator 6 Disc

2 Mounting bracket 7 Packing

3 Hex screw 8 Bolts and nuts

4 Position indicator 9 Bushing

5 Flange

16

16

Issue 01 -00

Instruction Manual

Butterfly valve with pneumatic actuator

Refer to Fig. 7-1

The pneumatic actuator (Item 1) and the butterfly valve

form a constructional unit.

To assemble the unit proceed as detailed below:

1. Bolt the pneumatic drive (Item 1) to the mounting bracket

(Item 2) using the hex screws (Item 3).

2. Bolt the pre-assembled butterfly valve (two flanges - one

mid-packing - 1 disc - two bushings) using the hex bolts and

hex nuts (Item 8).

Place the position indicator (Item 4) on the square end such

that it indicates the position of the disc.

When fitting the mounting bracket (Item 2) with the pneumatic

drive (Item 1) bolted in place, to the butterfly valve make sure

that:

- the square end of the disc engages the square socket of the

pneumatic drive;

- the milled recess provided in the mounting bracket (Item 2) is

fitted on the top pair of bolts and fastened.

When assembling, take into account the following:

- The pneumatic drive (Item 1) must be in accurate alignment

with the disc.

- Prior to installing the valve in the piping, check by control

trials to make sure that the desired OPEN or SHUT position

of the disc in the butterfly valve is as required. Otherwise,

install the disc offset 90 deg.

- Where a pneumatic drive (Item 1) is installed so that the

valve is opened under air pressure and shut under spring

action the disc is consistently rotated into home position

should compressed air fail.

17

17

Issue 01 -00

Instruction Manual

Butterfly valve with pneumatic actuator

7.2 Assembly of Pneumatic Actuator with Position Feedback Indication

Various configurations of position feedback indication are

available to suit customer's particular needs, e.g. using:

- 1 or 2 proximity switches;

two electric control units;

- one dual sensor.

Where provision for position feedback indication is made, the

relevant parts are fitted underneath the mounting bracket (Item

2) prior to assembly of the pneumatic drive (Item 1) with the

butterfly valve.

Fig. 7-2 Assembly of pneumatic drive with position feedback

indication

1 Pneumatic actuator 7 Position indicator

2 Mounting bracket 8 Disc

3 Proximity switch 9 Flange

4 Mount for proximity switch 10 Bolts and nuts

5 Hex screw 11 Packing

6 Indicator control arm 12 Bushing

18

18

Issue 01 -00

Instruction Manual

Butterfly valve with pneumatic actuator

Refer to Fig. 7-2

For assembly proceed as detailed below:

1. Use the hex screw (Item 5) to fasten the mount (Item 4)

jointly with the mounting bracket (Item 2) to the pneumatic

drive (Item 1).

2. Make the indicator control arm (Item 6) a clamp-fit on the

O.D. of the coupling on the square end, being sure that the

end of the indicator control arm (Item 6) is located below and

in accurate alignment with the proximity switch which, in turn,

has been fitted in the hole of the mount (Item 4) normal to

the cylinder of the pneumatic drive (Item 1).

When assembling, be sure to take the following into account:

- Prior to installing the valve in the piping, check to ensure

that, when the disc is in the OPEN or the SHUT position, the

end of the indicator control arm (Item 6) is physically located

below and aligned with one of the proximity switches

- When using different position feedback signalling systems

proceed as detailed in the description and as shown in the

exploded view.

To dismantle the constructional unit reverse the assembly

procedure.

19

19

Issue 01 -00

Instruction Manual

Butterfly valve with pneumatic actuator

8 Maintenance / Cleaning

Prior to starting cleaning, maintenance and repair work, check

to make sure that the following steps are taken to de-energise,

deselect and depressurise as applicable.

1. De-energise higher-level equipment / machine / unit .

2. Depressurise pneumatic system

Check to be sure

- that the butterfly valve is depressurised;

- that the valve is in home position.

3. Deselect the fluid

- Check to make sure the butterfly valve is depressurised.

- Remember that for fluid temperatures above 80C a

cooling-down period must be allowed before starting work.

Failure to comply with the above jeopardise personnel's life

and limb!

A servicing unit should be provided for control air to prolong the

useful life of O-rings.

Still, the pneumatic drive can operate on dry air.

Clean the valve in the as-installed condition by rinsing the faces

in contact with the fluid (CIP cleaning).

Cleaning fluids: 3% Nitric acid

3% Caustic-soda solution

Temperature: 80C max.

Care must be exercised to ensure that:

- clean and chlorine-free water is used as a diluent;

- caution: when measuring, avoid excessive concentration of

the cleaning agent;

- the valve is finally rinsed with ample water once cleaning is

completed.

20

20

Issue 01 -00

Instruction Manual

Butterfly valve with pneumatic actuator

Make sure that cleaning agents are stored in compliance with

relevant safety codes.

Care should be exercised when handling cleaning agents to

ensure that the safety instructions given on the Data Sheet

issued by the cleaning-agents manufacturer are followed.

Wearing rubber gloves and safety goggles is an essential

requirement to be met when performing cleaning work.

Caution must be used not to touch the butterfly valve or the

piping when hot fluids are being processed or while the

sterilisation process is in progress.

21

21

Issue 01 -00

Instruction Manual

Butterfly valve with pneumatic actuator

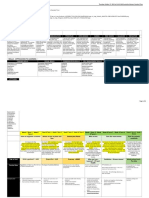

9 Malfunction, Cause, Rectification

If the proposed rectification fails to cure the trouble, please

contact a specialist contractor or AWH Armaturenwerk

Htensleben GmbH.

Problem Cause Rectification

Valve fails to operate Compressed air failure

Electric control at fault

Drive at fault

Start compressed air supply.

Check and ensure electric

signals.

Check and, if necessary,

renew.

Signals not received Loose cable on proximity switch

Broken cable

Loose indicator control arm

Proximity switch at fault

Electric power supply failure or

at fault

Fasten cable.

Renew cable.

Fasten indicator control arm.

Renew proximity switch.

Check and rectify as necessary.

Valve operates slowly Inadequate compressed air

supply

Drive exhaust port clogged

Boost compressed air supply.

Open up the port.

Valve operates non-uniformly Poor compressed air supply

High fluid pressure

Inconsistent electric signals

Boost compressed air supply.

Check fluid pressure and adjust

as necessary.

Eliminate signal flow trouble.

Valve generates excessive

mechanical noise

Valve or actuator drive at fault Renew the valve and or

actuator.

Leaky valve Faulty or worn packing Renew the packing.

22

22

Issue 01 -00

Instruction Manual

Butterfly valve with pneumatic actuator

10 Dismantling / Disposal

The butterfly valve mainly consists of stainless steel (except for

the electrical equipment). For disposal, relevant local

environmental regulations must be complied with.

Contaminated fluids as well as residue of cleaners must be

disposed of while complying with relevant local environmental

regulations.

Care must be exercised to avoid contact with harmful fluids.

23

23

Issue 01 -00

Instruction Manual

Butterfly valve with pneumatic actuator

11 Index

Assembly 15

Assembly of pneumatic drive with position feedback indication 17

Assembly of shutoff valve with pneumatic drive 15

Cleaning 19

Contents 8

Damage 12

De-energise system 19

Defects 12

Dismantling 22

Disposal 22

Explanatory notes 9

Exploded view, Dimensions 5

Filler metals 14

German standards and codes 10

Hazards 9

Incoming inspection 12

Informative signs 9

Installation of shutoff valve 13

Intended use 3

List of figures 8

Maintenance 19

Malfunction 21

Materials in contact with the product 4

Note 7

Outdoor storage 12

Packaging 12

Packaging for return to consignor 12

Pre-welding condition 14

Problem solving 21

Rectification 21

Safety 9

Safety standards 10

Safety testing 10

Seaworthy packaging 12

Specialist 3

Transport 12

Warning 19

Warning notices 11

Welding specifications 14

You might also like

- Heinbockel - Tensor Calculus - PartDocument5 pagesHeinbockel - Tensor Calculus - Partapi-3835172No ratings yet

- Iec60364 PDFDocument105 pagesIec60364 PDFMircea Murar60% (5)

- IELTS Listening TestDocument10 pagesIELTS Listening TestBasmanMarkus100% (1)

- Energy Efficient MotorsDocument8 pagesEnergy Efficient MotorsformechNo ratings yet

- 2088 DatasheetDocument14 pages2088 DatasheetSohaib KhalidNo ratings yet

- Boiler Energy Audit ManualDocument29 pagesBoiler Energy Audit ManualAnubhav100% (11)

- SteamDocument36 pagesSteamsalilm31100% (2)

- Resolução Levenspiel Impares Cap 7 PDFDocument7 pagesResolução Levenspiel Impares Cap 7 PDFChrislei RizzattiNo ratings yet

- 10266Document102 pages10266Sohaib KhalidNo ratings yet

- 3 PhmotorDocument4 pages3 PhmotorMissboy AjengkelinNo ratings yet

- Flow Switch HoneywellDocument1 pageFlow Switch HoneywellSohaib Khalid100% (1)

- VLT Micro FC 51 Parameter SettingDocument83 pagesVLT Micro FC 51 Parameter SettingSohaib Khalid0% (1)

- Bimetall Thermometer Typ21 enDocument2 pagesBimetall Thermometer Typ21 enSohaib KhalidNo ratings yet

- CE Conformity PDFDocument1 pageCE Conformity PDFSohaib KhalidNo ratings yet

- AB SMC Flex 150 ManualDocument162 pagesAB SMC Flex 150 Manualjpollard2No ratings yet

- FES0069C Div2Document2 pagesFES0069C Div2Sohaib KhalidNo ratings yet

- The Industrial Internet@Work: Marco Annunziata & Peter C. EvansDocument37 pagesThe Industrial Internet@Work: Marco Annunziata & Peter C. EvansSohaib KhalidNo ratings yet

- Butterfly Valve GS - SS - ZFA PDFDocument6 pagesButterfly Valve GS - SS - ZFA PDFSohaib KhalidNo ratings yet

- 5 Ways To Decrease CO EmissionsDocument1 page5 Ways To Decrease CO EmissionsSohaib KhalidNo ratings yet

- Bimetall Thermometer Typ21 enDocument2 pagesBimetall Thermometer Typ21 enSohaib KhalidNo ratings yet

- M12 Socket Sensor Connector with Gold-Plated ContactsDocument1 pageM12 Socket Sensor Connector with Gold-Plated ContactsSohaib KhalidNo ratings yet

- Instruction Manual: Butterfly Valve With HandleDocument0 pagesInstruction Manual: Butterfly Valve With HandleSohaib KhalidNo ratings yet

- Operating Instructions Type 6213: 2-Way Solenoid Valve, Internally Piloted, Normally Closed (Circuit Function A)Document2 pagesOperating Instructions Type 6213: 2-Way Solenoid Valve, Internally Piloted, Normally Closed (Circuit Function A)Sohaib KhalidNo ratings yet

- Machine Safety GuideDocument64 pagesMachine Safety GuideSohaib KhalidNo ratings yet

- Basic Soft Starter PrinciplesDocument9 pagesBasic Soft Starter PrinciplesmitelectricalNo ratings yet

- Earth CalcualtionDocument7 pagesEarth CalcualtionAndrew1221568No ratings yet

- Direttiva 99 92 CEDocument8 pagesDirettiva 99 92 CEslan79bisNo ratings yet

- Bimetall Thermometer Typ21 enDocument2 pagesBimetall Thermometer Typ21 enSohaib KhalidNo ratings yet

- DEPA-Druckluft-Membranpumpen, Serie L DEPA Air Operated Diaphragm Pumps, Series LDocument1 pageDEPA-Druckluft-Membranpumpen, Serie L DEPA Air Operated Diaphragm Pumps, Series LSohaib KhalidNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Line Differential Protection and Control RED615: Product GuideDocument32 pagesLine Differential Protection and Control RED615: Product GuidebrahimNo ratings yet

- Motor Protection Principles: Arijit Banerjee, Arvind Tiwari-GE Global Research Jakov Vico, Craig Wester - GE MultilinDocument35 pagesMotor Protection Principles: Arijit Banerjee, Arvind Tiwari-GE Global Research Jakov Vico, Craig Wester - GE Multilinvaradarajanrengasamy100% (1)

- Alley Alka-Seltzer Lab Report TemplateDocument3 pagesAlley Alka-Seltzer Lab Report TemplateAlley FitzgeraldNo ratings yet

- INDUCTORDocument18 pagesINDUCTORBhavaniPrasadNo ratings yet

- R Programming CheatsheetDocument6 pagesR Programming CheatsheetAnand PrasadNo ratings yet

- Bhopal Gas Tragedy Case StudyDocument10 pagesBhopal Gas Tragedy Case StudyAbhijith MadabhushiNo ratings yet

- EECS 373 Architecture, Assembly, and ABI LectureDocument29 pagesEECS 373 Architecture, Assembly, and ABI Lectureavinash_yuvarajNo ratings yet

- STAAD Structural Analysis Software DocumentDocument84 pagesSTAAD Structural Analysis Software DocumentSabu Abdul NoorNo ratings yet

- Telepo SDK Develop Guide (Linux For TPS300) - v1.0Document10 pagesTelepo SDK Develop Guide (Linux For TPS300) - v1.0VKM2013No ratings yet

- Marina Pier Repair Nasugbu BatangasDocument28 pagesMarina Pier Repair Nasugbu BatangasDennis SagaoNo ratings yet

- Section 3.3.4 Neutral Earthing Resistors R1Document7 pagesSection 3.3.4 Neutral Earthing Resistors R1waelabouelelaNo ratings yet

- Usb Modem 2Document4 pagesUsb Modem 2emadNo ratings yet

- 2019 Planning OverviewDocument7 pages2019 Planning Overviewapi-323922022No ratings yet

- FC102 Pid PDFDocument1 pageFC102 Pid PDFKwameOpareNo ratings yet

- CE 308 Lec 7 Mixing, Handling and Placing of ConcreteDocument29 pagesCE 308 Lec 7 Mixing, Handling and Placing of ConcretewasimkhaliqNo ratings yet

- MASTERSEAL 755 SPF v1 PDFDocument2 pagesMASTERSEAL 755 SPF v1 PDFJaga Nath100% (1)

- Oracle PLSQL Best Practices and Tuning PDFDocument270 pagesOracle PLSQL Best Practices and Tuning PDFKeyur Pandya100% (1)

- Electric Current and Ohm's Law - LecturesDocument21 pagesElectric Current and Ohm's Law - LecturesMuhammad AhmadNo ratings yet

- Wind MachinesDocument34 pagesWind Machinesjeswin johnsonNo ratings yet

- Electronically Controlled On-Demand 4WDDocument32 pagesElectronically Controlled On-Demand 4WDjulio797No ratings yet

- DesuperheatersDocument8 pagesDesuperheatersmuhdrijasmNo ratings yet

- Fiat 4061 PDFDocument6 pagesFiat 4061 PDFSamir YehyaNo ratings yet

- Barrera BANNER 2 PDFDocument10 pagesBarrera BANNER 2 PDFrollinga2013No ratings yet

- An Introduction To Marketing Research by SmithDocument448 pagesAn Introduction To Marketing Research by SmithKali Das100% (1)

- Class XII Computer Science: HOTS (High Order Thinking Skill)Document14 pagesClass XII Computer Science: HOTS (High Order Thinking Skill)JanakiNo ratings yet

- Effect of CSR on Corporate Reputation and PerformanceDocument13 pagesEffect of CSR on Corporate Reputation and PerformanceAnthon AqNo ratings yet

- Camden CM-30EE-LED Data SheetDocument2 pagesCamden CM-30EE-LED Data SheetJMAC SupplyNo ratings yet

- cGMP ChecklistDocument31 pagescGMP ChecklistWerner Schrammel100% (1)

- Project Report - FormatsDocument7 pagesProject Report - Formatsfazela shaukatNo ratings yet

- Fortigate Ipv6 54Document64 pagesFortigate Ipv6 54Fredy Gualdron VargasNo ratings yet