Professional Documents

Culture Documents

Circular Magnetic Structures For IPT PDF

Uploaded by

blooms116Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Circular Magnetic Structures For IPT PDF

Uploaded by

blooms116Copyright:

Available Formats

3096

IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 26, NO. 11, NOVEMBER 2011

Design and Optimization of Circular Magnetic Structures for Lumped Inductive Power Transfer Systems

Mickel Budhia, Student Member, IEEE, Grant A. Covic, Senior Member, IEEE, and John T. Boys

AbstractA solution that enables safe, efcient, and convenient overnight recharging of electric vehicles is needed. Inductive power transfer (IPT) is capable of meeting these needs, however, the main limiting factor is the performance of the magnetic structures (termed power pads) that help transfer power efciently. These should transfer 25 kW with a large air gap and have good tolerance to misalignment. Durability, low weight, and cost efciency are also critical. 3-D nite-element analysis modeling is used to optimize circular power pads. This technique is viable, since measured and simulated results differ by 10% at most. A sample of power pads was considered in this work, and key design parameters were investigated to determine their inuence on coupled power and operation. A nal 2 kW 700-mm-diameter pad was constructed and tested having a horizontal radial tolerance of 130 mm (equivalent to a circular charging zone of diameter 260 mm) with a 200 mm air gap. The leakage magnetic ux of a charging system was investigated via simulation and measurement. The proposed pads meet human exposure regulations with measurement techniques specic by the Australian Radiation Protection and Nuclear Safety Agency (ARPANSA) which uses the International Commission on Non-Ionizing Radiation Protection (ICNIRP) guidelines as a foundation. Index TermsElectromagnetic compatibility, electromagnetic coupling, inductive power transmission.

I. INTRODUCTION

NDUCTIVE power transfer (IPT) uses a varying magnetic eld to couple power across an air gap, to a load without physical contact. There are inherent advantages since the components are electrically isolated, operation in wet environments presents no safety risk, and systems are unaffected by such conditions. IPT produces no contaminants and is completely reliable and maintenance-free unlike conventional plug-in or brush and bar contact based methods. Today, it is used in numerous industrial and commercial applications and is continually nding new applications where safety and convenience are required [1][8]. Generally, IPT systems may be grouped into either distributed or lumped topologies. The former is suited to applications where continuous power is required, and the latter for cases where

Manuscript received October 7, 2010; revised January 14, 2011; accepted April 3, 2011. Date of current version November 18, 2011. Recommended for publication by Associate Editor C. R. Sullivan. The authors are with the University of Auckland, 38 Princess Street, Auckland 1142, New Zealand (e-mail: mbud009@aucklanduni.ac.nz; ga.covic@ auckland.ac.nz; j.boys@auckland.ac.nz). Color versions of one or more of the gures in this paper are available online at http://ieeexplore.ieee.org. Digital Object Identier 10.1109/TPEL.2011.2143730

power only needs to be transferred at a xed position. A distributed system consists of a primary coil laid out in a long loop forming a track and one or more secondary coils that couple to a small portion of the track and provide constant power to loads. A typical application example is a materials handling system with multiple bogeys where the primary track is in the order of tens of metres long [7]. A lumped system is based on discrete primary and secondary coils and power can only be transferred when the coils are closely aligned and have sufcient mutual coupling. Lumped systems may be further broken down in to either closely coupled or loosely coupled types. Closely coupled lumped systems operate with relatively small air gaps and the user typically has to plug in the primary, as was the case with charge paddles used in an early electric vehicle [9], [10]. Loosely coupled lumped systems operate with a large air gap and require no user intervention, and these are the subjects of investigation in this paper. The work done is in the context of recharging electric vehicles (EVs) and the loosely coupled lumped topology is considered more suitable than the distributed type given vehicles are typically parked in known xed locations, for example, parking lots, taxi ranks, and garages. Lumped systems vary in capacity from 0.5 W50 kW and can be used to recharge or power small electronic devices [1], [4], [8], Automatic guided vehicles (AGVs) [3], [7], recreational people movers [2] and electric vehicles (EVs) [5], [6]. The purpose of this research is to investigate the design of a circular pad structure suitable for battery charging, understand its operation, using appropriate simulation and experimental data, and optimize the pad design. A simulation approach using 3-D nite element analysis (FEA) is used in this work, therefore measurement versus simulation results are necessary to ensure computer models are valid. The inherent complexity of the problem is due to eld shaping caused by ferrite, and this means that analytic or precomputed solutions are impractical [11]. These solutions are generally more practical in situations where there are no magnetic materials in the vicinity of the coil as in lower power applications [12]. The work presented in this paper is in the context of recharging of EVs that require power levels of 25 kW, over an air gap of 200 mm. The horizontal tolerance should be sufciently large to enable a driver to park without aid from an electronic guidance system to receive a full power charge. This tolerance was specied to be within a circular charging zone having a radius between 100 150 mm, although pads with larger tolerance are clearly better. The ideas presented in this paper are applicable to any lumped IPT system using circular pads because these are scalable and

0885-8993/$26.00 2011 IEEE

BUDHIA et al.: DESIGN AND OPTIMIZATION OF CIRCULAR MAGNETIC STRUCTURES

3097

optimized designs result in considerable long-term cost and energy savings. The paper is structured as follows: The operation of an IPT system and the importance of efcient power pads are rst explained. The structure of a prototype power pad is then shown. Results of an optimization process are then presented together with performance characteristics of a built pad. This optimization process largely describes the design processes as it evolved. Initially, a small-scale concept prototype pad measuring 420 mm in diameter was constructed in the laboratory using known and available material. This pad was used to validate the output of the simulator after which optimization could begin. In the early validation stage, a number of key parameters are determined including the impact of horizontal and vertical offsets, coil width and position relative to the ferrite along with the amount of ferrite required. As this pad was clearly underpowered for the desired operation, a larger pad with a diameter of 600 mm was then considered by way of simulation that enables other design and optimization features to be considered in keeping with the design objectives. As shown, the pads are scalable and therefore any changes in pad size should include ratiometric changes to optimized variables to ensure optimal material usage and efciency for a given power output. Consequently, desirable characteristics of previous designs can be carried over to the next design. Based on these two optimization stages, a nal 700-mm-diameter prototype was built to meet the specications (again constructed based on available material). This is again validated by simulation. Throughout the optimization and development process, implementation issues that arise when making larger diameter power pads are discussed and resolved. Finally, leakage magnetic elds are measured and simulated in an EV context with the aim of meeting International Commission on Non-Ionising Radiation Protection (ICNIRP) guidelines. These have been used as a base for the Australian Radiation Protection and Nuclear Safety (ARPANSA) standard that recommends practical approaches for measuring leakage magnetic ux. II. IPT SYSTEMS A typical IPT system comprises three main components, the power supply, the magnetic coupling structure, and the pick-up (PU) controller, as shown in Fig. 1. The power supply produces a sinusoidal current in the VLF (1040 kHz) frequency range that excites an inductive transmitter pad. A parallel compensation capacitor (C1 ) is chosen so that its impedance is matched to that of the transmitter pad inductance L1 at the operational frequency. This allows transmitter pad current, I1 , to resonate and the large reactive current in L1 creates a greater ux density in the vicinity of the transmitter pad. This minimizes the VA rating of the power supply for a given load, as the switches within the supply only need to pass real power [13]. The transmitter and receiver pads act as a loosely coupled transformer that enables power transfer over relatively large air gaps. The IPT PU consists of receiver pad inductance L2 and a switched mode controller. The leakage inductance of L2 is compensated using C2 , which is also selected to have a matched impedance with the receiver pad at the operational frequency, forming a parallel resonant

Fig. 1.

Components of an IPT system.

tank. The voltage across C2 is then rectied and a switched mode controller enables the resonant tank to operate at a dened quality factor (Q) to boost power transfer and provide a usable dc output [14]. The power output of an IPT system (Pout ) is quantied by the open circuit voltage (Vo c ) and short circuit current (Isc ) of the receiver pad as well as the quality factor, as shown in (1) [13]. Pout = Psu Q = Vo c Isc Q = M I1

2 M I1 2M Q = I1 Q. (1) L2 L2

Here Psu is the uncompensated power and is equal to the product of Vo c and Isc , is the angular frequency of the transmitter pad current I1 , M is the mutual inductance between the pads and L2 is the inductance of the receiver pad with the transmitter pad open-circuited. As shown in (1), the output power is dependent on the power supply ( I1 2 ), magnetic coupling (M2 /L2 ) and PU controller (Q). The operational frequency and current of the power supply are limited by those switching devices presently available, and both have to be balanced against switching and copper losses. In practical applications, Q is constrained to 46 due to component VA ratings and tolerances [13], [15]. If and I1 are constant, Psu can be used for making comparisons between different pad designs. It is essential that the power pads have the highest M2 /L2 to ensure the overall feasibility, cost effectiveness, and efciency of the complete system. M is highly dependent on the separation between the pads and the distance between pad centers, whereas L2 is xed by the pad parameters such as size and number of turns in the coil. In practice while L2 s position relative to L1 does have some small effect on both inductances, such variation is minimized due to the inherently large air gaps required in EV charging. III. POWER PADS The circular magnetic structures considered in this work, which are used to couple ux between the primary transmitter and secondary receiver, are referred to as power pads and these are nominally identical. Each has six main components, as shown in the exploded view of Fig. 2. The aluminium ring and backing plate shield the chassis of the EV and surrounding area from stray magnetic elds, which is discussed later in Section V. The power pads can be made to be lower cost,

3098

IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 26, NO. 11, NOVEMBER 2011

Fig. 2.

Exploded view of a power pad.

more robust, and lighter than commonly used inductive couplers. Conventional techniques use pot cores [5], [16][18], U-shaped cores [1], [19], ferrite discs or plates [6], [12], [17], [20], [21], or E-cores [1]. These designs are comparatively fragile and expensive due to the geometry of the large pieces of ferrite required to achieve the desired ux path. In addition, designs using pot or E-cores are necessarily thick and, therefore, compromise the ground clearance of the EV or require extensive chassis modication. Coupling is highly dependent on the area through which mutual ux passes and, given the large horizontal tolerance (300 mm) required by an unguided EV, small coupler designs are infeasible. Also, small couplers usually operate with a small air gap to ensure the necessary coupling; however, this can also result in highly constrained and sensitive systems, as discussed in Section V. Arrays of coils with ferrite backing have been successfully used to allow power transfer over large areas in low power systems as discussed [4]; however, this technique is not cost effective for higher power EV charging systems. As shown in [22], each row or column of coils needs to be switched to prevent eld cancellation in the center of the multilayer array to increase power transfer. This is impractical with high-power systems given the large currents required. Coreless coils, as shown in [12], [23], [24], are generally not suitable for highpower applications where ferrous materials are in close proximity to the system due to eddy and hysteresis losses. Field shaping with ferrite constrains ux to desired paths improving coupling and consequently preventing excessive energy loss in surrounding materials due to leakage magnetic eld, which also needs to be considered for safety reasons [7]. As shown in (1), the mutual inductance between couplers and the primary current have the greatest inuence on power transferred, while the self-inductance of the coil is ideally constant independent of the position of the receiver to ensure that it can be easily tuned to resonance. In order to compensate for lower coupling and maintain good efciency, coreless systems are typically operated at higher frequencies in the range of hundreds of kHz to MHz [25], [26]. Efcient operation at such high frequencies is not possible with high-power systems due to performance limitations of available semiconductor devices. Note that systems with relatively large air gaps in relation to the pad size, as shown in [26], are generally only suited to small-scale systems where efciency is not a major issue.

The power pads, shown here, overcome several physical limitations of common couplers by using multiple smaller bars held in place by a shock absorbing coil former with further protection provided by the aluminium and plastic case. These power pads are relatively thin compared to standard core topologies, and they are lighter than conventional circular coupler designs that use solid ferrite discs. As the pads are intended for stationary charging systems for EVs parked in residential spaces, some assumptions have been made. The vehicle is assumed to be constrained in the forward direction by wheel chocks or some other barrier, therefore a horizontal tolerance of 100150 mm in each lateral direction is desired; this allows a 200300-mm-wide charging zone but larger tolerances are clearly better for ease of parking. Also, the EV is assumed to require a ground clearance of up to 200 mm. Note the pads are circular and, therefore, not directional. The power supply that is intended for use with the power pads (as indicated in Fig. 1), operates from single-phase and is ideally low cost and has near unity power-factor, as described in [27], [28]. This supply uses an inductor-capacitor-inductor (LCL) impedance-converting network that converts the voltagesourced inverter into a current source that is suitable for driving the primary pad inductance. It also lters the square wave output of the bridge minimizing RF interference. The power supply achieves cost efciency through the removal of the large dc bus capacitance and by using the leakage inductance of the output-isolating transformer to form the rst inductor of the LCL network. The second inductor is formed by the inductance of the transmitter pad and connecting wires; although in practice this is often larger than desired so that a series capacitance is added to achieve the desired value. The reduced component count makes the power supply extremely light and compact. Although the low bus capacitance increases the safety of the power supply, which is especially important in a domestic setting, this results in a 100 Hz modulation on the dc bus. This modulation combined with the 38.4 kHz modulated output of the inverter bridge results in peak currents that are twice as high as the RMS current, consequent care must be taken in the design to ensure the ferrite in the primary pad does not saturate. As the focus of this paper is the magnetic design and optimization, the operation of the power supply will not be discussed further, except that it is assumed to produce 23 Arm s sinusoidal currents in the transmitter at either 38.4 kHz or 50 kHz. An important objective in any pad design is to ensure that the native quality factor of both, the transmitter and receiver pad inductances (QL ), are high. This ensures low loss and high efciency because losses in the pad are equal to the VA across each its terminals divided by the QL . In the presented design that follows, QL (equal to the reactance of the pad divided by its native resistance) was found by measurement to be around 250. This high QL is a function of the design structure in Fig. 2, which produces a ux pattern directed toward the receiver. The ferrite strips guide the majority of the ux out of the front of the pads while the aluminum adds rigidity to the structure and helps remove any heat due to loss. For the transmitter pad, the driving VA is essentially constant given the power supply drives it with a constant controlled

BUDHIA et al.: DESIGN AND OPTIMIZATION OF CIRCULAR MAGNETIC STRUCTURES

3099

current (23 A) during operation. As shown in Section V, its selfinductance does not change signicantly even with displacement of the receiver pad due to the large air-gap. The largest pad built requires 36 kVA to deliver 2 kW. The worst-case loss in this pad is therefore only 140 W; this is spread over the surface of the pad and there is little or no measurable temperature rise during operation. The losses on the receiver side are much lower than the transmitter pad, given this native pad QL is much higher than the largest operational circuit Q (governed by the controller to be 6), as described in Section II. The charging zone of a parallel tuned receiver (as shown in Fig. 1) is determined by energizing the transmitter at rated maximum primary current and selecting the number of turns on the receiver to design Isc , so that at worst-case separation it equals the required load current and ensures power can be delivered. As discussed in many papers [2], [13], [14], the voltage on the load is naturally xed by either the battery or a voltage controller. As such, the operational Q is xed, based on the position of the receiver, as the output voltage across the load is proportional to Vo c Q. Thus a 2 kW pad has a VA at worst displacement of Q Pout = 12 kVA giving a pad loss of 48 W. A 5 kW system would have 120 W loss; however, this is spread over a larger surface area. With pads aligned at the center of the charge zone the pad Vo c and Isc are both higher than at the edge of the charging zone where full power can still be delivered, however, the electronic controller on the secondary (as discussed in [13]) simply operates so that the average power delivered to the load is controlled by lowering the operating Q and limiting the current. Consequently, pad losses are reduced in this operating region. Alternatively, the primary current can be reduced by the supply to lower Vo c and Isc within this region to achieve the same result. When the receiver pad is offset outside the specied charge zone, both Vo c and Isc drop, and if operation is continued, the secondary Q will rise to compensate for the drop in Vo c to achieve the required output voltage. However, Isc cannot be increased and, because it is below the required load current, full power cannot be delivered. Thus, the pad loss stays approximately constant in this region as its output VA is approximately constant, but if the power transfer becomes too low the secondary controller or primary power supply will shut OFF. A. Modelling the Power Pads The pads of Fig. 2 have been modeled with a 3-D FEA package called JMAG. The dimensions of the pad and, therefore, model are shown in Fig. 3, along with the excitation conditions. The measured and simulated proles are shown in Fig. 4. In these results, the horizontal offset describes the distance between the pad centers, while the vertical offset describes the separation between the plastic covers, each of which is 5-mm thick. The EV battery requires an input power of 2 kW, and this is the assumed maximum power rating of a typical household mains socket. As shown, there is a small error between the measured and simulated results. The simulation results are slightly conserva-

Fig. 3.

Pad layout and dimensions.

Fig. 4. Measured and simulated Psu against horizontal offset at specied vertical offsets. Operational Q of a 2 kW system with a 40 mm air gap is also shown based on measured results.

tive and the error may be due to simplications in the model. A compromise between the size of the surrounding air region and elements in the model has been made to achieve the highest accuracy to simulation time ratio. The manufacturing tolerances (+/3 mm) result in coil and ferrite positions that are not as precisely positioned as in the simulation. The peak ux density is less than 150 mT; therefore, nonlinearity in the ferrite has been ignored and it is considered to be an isotropic material with a relative permeability of 2300. Overall, the results are in excellent agreement and enable further pad designs to be explored with condence. A null occurs in the power prole at a horizontal offset of 160 mm regardless of separation, as shown in Fig. 4. This is consistent between measured and simulated results and arises at the point where mutual coupling between the coils reduces to zero. This is due to ux cancellation, as shown in Fig. 5, where magnetic ux density vectors in a cross-section through the centers of both pads are plotted. In this position, the directions of ux from opposite sides of the transmitter pad coil, as shown by idealised paths, oppose each other and, therefore, effectively cancel resulting in almost no induced voltage in the receiver pad coil. Although power transfer at the null is extremely small and practical operation in its vicinity is not possible, its existence is responsible for the fundamental horizontal tolerance limit of

3100

IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 26, NO. 11, NOVEMBER 2011

Fig. 5. Magnetic ux density vector plot for 420 mm diameter pads in the null position (a horizontal offset of 160 mm).

circular pads. As shown in Fig. 4, regardless of separation and hence the power output when the pads are centered, all proles must pass through this null; consequently, this also determines the gradient of the reduction in power as the pads are moved horizontally. The null occurs after an offset of approximately 38% of the pad diameter with the 420 mm pad simulated. As such, the diameter needs to be increased substantially in order to allow acceptable horizontal tolerance for EV applications. A 420 mm diameter pad at a separation of 40 mm will allow 2 kW of power to be transferred with a horizontal offset of 90 mm assuming a Q of 6. While the power transfer is sufcient, the relatively small air gap means practical implementation is infeasible. Although the system may be initially designed for a given operational separation, loading or aging of suspension components will cause the car to lower over time. If the operational air gap is less than 40 mm, small changes in vertical travel result in large variations of coupled power (as shown by the Psu at the origin on the proles in Fig. 4). The transmitter pad forms the last inductor of the LCL network and it is critical that its inductance remains within the range that can be driven safely from the power supply [27]. The inductance of the transmitter pad could rise signicantly due the presence of ferrite in the receiver pad if the separation between the power pads becomes much lower than that originally designed for. This will detune the primary network forcing the power supply inverter bridge to supply additional reactive currents, and this could ultimately damage the switches. Furthermore, on the receiver side, excessive mutual inductance will mean that the coupled voltages and currents are much larger than expected, so that the control switches may have to shunt much higher currents. In consequence, the secondary electronics need to be signicantly overrated to avoid damage [13]. These reasons provide a strong incentive to design and optimize the pads to enable operation at greater separations to allow practical implementation. IV. OPTIMIZATION The layout of the 420 mm pad has been determined by the availability of ferrite bars, current ratings of the wire, and experience (assuming both pads are identical). Increasing the number of turns increases the uncompensated power of the receiver linearly due to the increased magnetomotive force (MMF), however, doing so increases the pad inductance. The pads are driven by a current source (in this work) and larger inductances results

in higher terminal voltages. There are practical limits based on insulation, safety, and standards so that terminal voltages should be below 1 kV and ideally below 500 V. In addition, especially wide coils increase cost and cause high I2 R losses that lower system efciency. The chosen 12-turn coil is a good compromise between copper loss, coupled power, ux density in the ferrite, and pad inductance. The inductance of the transmitter pad is 60 H and at 23 A at 50 kHz this corresponds to a terminal voltage of 430 V, which is considered practical in this context. The amp-turns (NI) determine the ux density in the transmitter pad and, hence, coupled power to the receiver pad. The ux density must be constrained to avoid saturation of the ferrite (which occurs at 200 mT) and excessive hysteresis loss. The peak ux in the transmitter pad is around 100 mT (the RMS ux density is shown in Fig. 5 and due to double modulation, the peak is double the RMS). The current in the receiver pad is signicantly lower than that in the transmitter so that even under maximum resonance (Q = 6) the ferrite in the receiver will not saturate. If the required power cannot be transferred within these constraints then a larger pad is required. The optimization approach employed here is to use the original pad, as shown in Fig. 3, as a base and by simulating possible changes, make a recommendation on the preferable variable to maximise. Four possible changes (without adding extra ferrite) are to: spread the coil, change the coil center diameter (indicated by E in Fig. 3), or to maintain the same center diameter while moving the ferrites radially inward or outward. The coil is simulated with a rectangular cross-section that is divided into 12 sections rather than individual turns to reduce the number of elements, and hence simulation time. Increasing the spread of the coil involves widening the cross-section. This approach has been veried with measured and simulated results on bar PUs and is accurate if the gap between individual turns is less than a few coil diameters [29]. A. Investigating Coupling Effects Due to Pad Layout Fig. 6 shows the effect of changing the coil width on Psu noting the coil width is normalised to that of the original base pad. Simulations, where the normalised coil width is signicantly less than 1, have been undertaken for completeness. Practical implementation would require multilayer coils, and this may undesirably add to the thickness of the pad. As shown, the initial coil width in the base pad is close to optimal. Ideally, the coil coverage for pads with a separation distance of 40 mm is 0.9 of the base pad (43 mm), which translates to approximately 40% of the ferrite length. The remaining three possible changes that can be done to the pad without adding extra ferrite are shown in Fig. 7. Fig. 7(b) shows the range of radial ferrite movement, Fig. 7(c) shows the coil and ferrite positions, and Fig. 7(d) illustrates the simulated coil diameter range. The graphs of Fig. 7(e) and (f) show the effect of changing the three design parameters when the power pads have 40 and 80 mm separations, respectively. Fig. 7(e) and (f) shows that considering all parameter variation permutations is not necessary to determine optimal pad layout. Performance is determined by the relative positions of the coil

BUDHIA et al.: DESIGN AND OPTIMIZATION OF CIRCULAR MAGNETIC STRUCTURES

3101

Fig. 6. Varying spread of the coil on centered pads at 40 mm and 80 mm separations, I1 = 23 A at 50 kHz.

and ferrites. It may appear that more power can be transferred if the coil is moved outward by 4 mm and the ferrites moved in by 4 mm since the maxima of both curves are symmetric about the y-axis, however; moving the coil out by 4 mm means the ferrite is effectively moved in by 4 mm relative to the coil and moving both components to their local optimum positions will actually decrease power transfer. Best performance is achieved if the ferrites are slightly offset toward center, a ferrite central diameter of 230 mm should be used for a 420-mm-diameter pad. This approach is preferable to increasing the coil central diameter, as doing so would require extra copper and increase losses and cost. The coil central diameter, as shown in Fig. 3, should be approximately 57% of the pad diameter. The position of the power null, as shown in Fig. 4, is affected by the coil diameter but using a larger coil to shift the null is not possible since the coupled power drops signicantly as the coil is made larger. B. Improving Coupling by Adding Ferrite Coupling will improve if more ferrite is added, and this may be done by adding more bars, making the bars longer, wider or thicker, or by adding feet that extend the portion of ferrite uncovered by the coil. To determine which variable should be maximized, various simulations were undertaken while keeping the pads at a xed separation and vertically aligned (without any horizontal offset) for ideal power transfer. An efciency comparison in terms of ferrite utilization was then made using VA/m3 of ferrite as a metric. Adding ferrite that is not utilized efciently will make the pad unnecessarily heavy and expensive. The volumetric comparison focussed on changes to the original design of Fig. 3. The impact on coupling (via Psu ) was studied by investigating changes in each variable of interest. The length, width, thickness, the addition of feet. and number of ferrite bars were varied by simulation. The variables were swept from their minimum to maximum possible value given geometrical constraints. The notation in the legend shows the limits of the variable, while the increment used is preceded by a comma. Results are shown in Fig. 8 below.

Fig. 7. (a)(d) Various pad designs where: (a) Original, (b) varying ferrite, (c) varying coil and ferrite, and (d) varying coil position, (e)(f) Psu with I1 = 23 A at 50 kHz and pad separation at 40 mm and 80 mm, respectively.

As expected, four of the curves intersect at a point equal to the volume of the initial pad. The curve for the pad with feet has a small offset at this point because additional ferrite is present (compared to the original design) to make the feet. The gradient of the curve relating to increasing ferrite length is highest, indicating that this gives the best ferrite utilization. This is expected since longer blocks permit the highest ux paths in air above each bar. The performance of the pad is inuenced least by the thickness of the ferrite bars, consequently, if pad weight is a critical design parameter, thinner blocks may be used. However. doing so makes saturation more likely and increases

3102

IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 26, NO. 11, NOVEMBER 2011

Fig. 8. Volumetric comparison of changes in pad parameters at a separation of 80 mm. I1 = 23 AR M S at 50 kHz.

Fig. 9. (a) Vertical power prole for 300800 mm diameter pads with an excitation current of 23 AR M S at 38.4 kHz, (b) layout of a 600 mm pad.

hysteresis loss. The peak ux density in a 6-mm-thick bar was found under the conditions simulated here to be 176 mT, whereas it is 102 mT in a 10-mm-thick bar, it is possible to operate with thinner blocks. C. Relating Coupled Power to Pad Size The 420 mm pads do not achieve sufcient power transfer for practical EV charging even with bars that are made as long as possible. Larger pads are required for greater power transfer and improved horizontal tolerance. The position of a null in a power prole for a given pad occurs when the horizontal offset is 40% of the pad diameter and this null can only be shifted further from the origin by using larger pads. This also has the desirable effect of smoothing the prole for a given offset. As circular pads by their nature are scalable, the conclusions reached from the investigation in part B have been applied to a variable size pad model. The number of turns of 4-mm diameter wire is adjusted to cover 40% of the ferrite bar length, the eight 30-mm-wide ferrite bars are made as long as practically possible and were centered on the coil. The coils central diameter (D in Fig. 4) has been set to 57% of the pad diameter. Optimal ferrite coverage can be achieved by winding coils with a larger pitch or by increasing the number of turns. The former approach results in impractical designs as coils with excessive pitches allow ux leakage between turns reducing the ux path height, and hence coupled power. The ux path height is shown by the idealized ux lines in Fig. 5(a), and this height is the main reason why ferrite length has the greatest effect on Psu for a given volumetric increase. The graph in Fig. 9(a) shows vertical proles for various pad sizes, this prole is formed as the separation is increased between horizontally aligned pads. The simulation frequency has been changed to 38.4 kHz as this optimization work is being

done in parallel with power supply development and presently available switches are more suited a lower frequency. Performance at 50 kHz can be easily determined by linear scaling. The structure of a 600 mm pad is shown in Fig. 9(b) The coupled power increases substantially with vertical offsets that are relatively low for given pads as exemplied. A 500 mm pad has a Psu of 1 kVA at 100 mm and it is 3 kVA for a 600 mm pad, the power coupled triples while the pad diameter only increases by 20%. This large variation makes matching a particular pad for an application challenging, as the highest power pad is not necessarily suitable when tolerance is considered. As discussed in Section III-A, using a 420 mm pad to couple 2 kW resulted in designs that were extremely sensitive to changes in both the horizontal and vertical position, relative to normal operating position of 40 mm (similar behaviour is shown for a 400 mm pad in Fig. 9 above). Extreme sensitivity to changes in vertical offset is common to all pads and is clearly illustrated by the initial steepness of all the respective curves. The high initial Psu for pads with close relative vertical spacing combined with the xed position of the null results in designs that are necessarily intolerant of horizontal offset. For these reasons designs that operate in the shaded region of Fig. 9(a) are preferable and considered more practical in an EV context where insensitivity to positioning error is of major importance. The relationship between pad size and coupled power becomes more apparent, as the pads become larger; the useful operation zone appears to increase steadily and is roughly shown to be linear by the gradient of the shaded area. Clearly, larger pads are less sensitive to vertical separation, and this is indicated by the divergence of the shaded area toward the right. The fundamental Psu limit of the modeled circular pads with the layout shown in Fig. 9(b) is 2 kVA at 220 mm and an

BUDHIA et al.: DESIGN AND OPTIMIZATION OF CIRCULAR MAGNETIC STRUCTURES

3103

800-mm diameter pad is needed to achieve this. Larger pads of this type can be used; however, the space under an EV typically limits pads to less than 1 m2 in area. Large pads are also not cost effective and are heavy affecting overall vehicle efciency. As noted earlier, the operational Q of the receiver pad controller is typically limited to 6; therefore, 800 mm pads can be expected to couple 25 kW with as much horizontal tolerance as the topology allows. This fundamental power transfer limit means that large pads are required to reduce sensitivity to positioning error while still achieving output powers of 25 kW. Performance can be improved by adding ferrite, however, any improvement should be achieved with the absolute minimum amount of ferrite to ensure cost efciency, as is the subject of investigation in the next section. For this optimization process, a 600-mm diameter pad was chosen as there is sufcient space within the pad to add ferrite and, as indicated in Fig. 8, a signicant performance increase can be expected. Prior to shifting focus to the larger pad, the key points from the previous investigation are carried over to ensure the 600 mm pad is optimal with regard to ferrite utilization. As such, the coil is 57% of the diameter, the ferrites are centered on the coil, the number of ferrites is increased, and they are made as long as possible. D. Optimization of a 600 mm Pad With Added Ferrite Investigating Ferrite Width The increase in coupling for relatively small changes in the width of the bars appears to be reasonably linear, as indicated in the graph of Fig. 8. Simulations were undertaken using ferrite sectors to investigate this further, however, physical implementation of a sector type pad is challenging due to the small points at which the ferrites must meet in the center of the circle. Cutting to such ne tolerances at the point is impractical, since ferrite is brittle and pressure moulding dies used on green ferrite cannot be made to such small dimensions [10], [21]. As such, a modied design is investigated that removes the sector tips, enabling a practical ferrite structure. This, however, creates a hole in the center of the pad. This hole diameter (in the center of a 600-mm diameter pad model with 18 ferrite wedges) was then varied to determine the effect of using shorter ferrite wedges, the results are shown in Fig. 10. A hole diameter 12% of the pad diameter (72 mm in Fig. 10) is a good compromise, since there is extremely little gain in power transfer if the hole is made signicantly smaller, in addition the ferrite utilization is also at its maximum. To properly determine the effect of ferrite width on coupling, the angle of the ferrite sectors in a 600 mm pad with a 72-mm hole was varied from 2 to 20 . The simulation results are shown in Fig. 11. As with the original pad, the increase in coupling is relatively linear for angles ranging from 2 to 6 . The rate of increase in coupling decreases signicantly beyond 6 , this indicates ferrite is not being used efciently. An advantage of having more ferrite is that saturation is less likely, although with the 2 kW power rating of these pads saturation is unlikely. There appears to be little advantage in using pads with wedge-shaped ferrite bars and considering the difculty with forming sectors in practice, development was ceased.

Fig. 10. Power coupled and ferrite utilization against hole diameter on centered pads with 10 ferrite sectors at a separation of 150 mm. I1 = 23 AR M S at 38.4 kHz

Fig. 11. Power coupled and ferrite utilization against angle of ferrite sectors for cenetred pads (with 18 ferrite sectors in total) at separations of 150 mm and 200 mm. I1 = 23 AR M S at 38.4 kHz.

E. Optimization of a 5 kW 600 mm Pad With a 150 mm Air Gap In many applications, shorter charge times are desired; this can be achieved if custom wiring is installed in a household system allowing a higher current rating. It was decided that a pad with a diameter of 600 mm should provide sufcient coupling to allow a 5 kW charge with more tolerance to misalignment at 150 mm separation. A model of the larger pad was built assuming the ferrite bars could be cut to the desired size. The coil width was made up of 18 turns of 4-mm diameter Litz wire, the bars were made as long as possible and the coil was made 57% of the pad diameter. Since the layout is similar to the 420 mm circular pad, the overall thickness is still 25 mm. Although the pad layout was optimized, initial simulations showed that it was unable to meet the performance requirements of 2 kW transfer at a separation of 200 mm with a horizontal tolerance of 100 mm when operating with a transmitter pad

3104

IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 26, NO. 11, NOVEMBER 2011

Fig. 12.

Comparison of different ferrite arrangements.

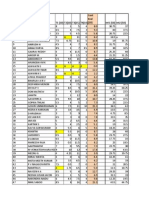

current of 23 ARM S at 38.4 kHz. The ferrite is already being utilized relatively efciently, but more needs to be added in order to improve coupling. There are numerous possibilities, however, designs that require simple ferrite cutting operations are preferred. The most optimal of the different pad designs are ranked in order of power and are shown Fig. 12. In all cases, it is assumed that the ferrite bars used in construction have the following dimensions: 118 mmL 30 mmW 10 mmT, as these are readily available as I parts of EI cores. Each pad is adequately described by Psu at different ideal separations, the number of ferrite bars required and the ferrite utilization efciency, which has been calculated at a separation of 100 mm. Proles of the various pad topologies have been compared, and it has been noted that regardless of the maximum Psu that results when the receiver pad is positioned such that it is centered on the transmitter, all receiver pads experience a null when offset horizontally by approximately 40% of the pad diameter. The slope of power prole is determined by the position of the null and the Psu with the pads centered. The Psu for pads with a 100 mm air gap of type (e) in Fig. 12 is 2.5 kVA and is 3.8 kVA for pad (a). Both pads have a null in their prole at approximately 240 mm, thus the slope for type (a) is greater. As shown in Section IV-A, it is not advisable to increase the diameter of the coil with the aim of shifting the null as Psu will drop substantially increasing sensitivity to misalignment. Designs with the best ferrite utilization have long or narrow ferrite blocks shown in Fig. 12(e) and (d), respectively. The former provides favourable magnetic paths that increase ux density above the pad, while the latter enables ux around the coil to be guided more effectively. The desirable features of both have been combined to create a model of an optimal pad, as shown in Fig. 13. This pad weighs 15.6 kg and is capable of a transferring 5 kW across an air gap of 150 mm with a horizontal tolerance of 90 mm and, therefore, a full power charging zone 180 mm in diameter (using a maximum operational Q of 6). Its Psu prole is shown in Fig. 14 along with the required Q at a separation of 150 mm. This pad requires 31.5 standard ferrite bars and has a ferrite utilization value of 3.80 VA/cm3 and is within a few percent of the most optimal utilization, as shown in Fig. 12(e), which is 3.89 VA/cm3 of ferrite. Assuming the EV is constrained in the forward direction, as would typically be case when parking in a garage, a 180-mm-wide charging zone is possible with an air gap of 150 mm, and this is considered

Fig. 13.

Optimal pad layout.

Fig. 14. Simulated prole of an optimized pad with 200 mm separation. Q curves shown for 5 kW output at 100 mm and 150 mm.

within the ability of a driver if appropriate markings are made on the ground. A 200 mm ground clearance requirement, as desired, may be satised if the transmitter is elevated by 50 mm, which is a completely practical solution. Furthermore, the installation cost within a garage of such a system is minimal for the user, since the oor needs little modication. An appropriately marked transmitter pad is unlikely to become a tripping hazard, especially if a low-gradient circular ramp is placed around it. The above optimization process was done assuming that the desired ferrite sizes are available or larger bars can be cut to

BUDHIA et al.: DESIGN AND OPTIMIZATION OF CIRCULAR MAGNETIC STRUCTURES

3105

Fig. 15.

700 mm pad layout.

size. In cases where ideal ferrite is not available, preferable compromises are to make the ferrite blocks as long as possible or as narrow as possible. The layout shown in Fig. 12(c) requires readily available ferrite bars, although ferrite utilization is low, good performance is achieved since a relatively large number of bars are used. Conversely, the pad in Fig. 12(e) also uses unmodied bars and has the highest ferrite utilization, although it has only 18 bars resulting in a lower Psu . V. IMPLEMENTATION OF AN IPT SYSTEM A 2 kW charging system operating off a standard single-phase power socket with an air gap of approximately 200 mm is more desirable than the previously optimized 150 mm 5 kW system. The length and number of the ferrite bars is the most important factor relating to power transfer at a given separation and a 700-mm diameter pad model was constructed, and is shown in Fig. 15. The dimensions of the pad were largely dictated by the availability of ferrite and machining capability. Each of the 12-ferrite spokes is made up of three standard ferrite I bars (93 mmL 28 mmW 16 mmT) from EPCOS. The extra one and a half bar pieces, as shown in Fig. 12(b), were not placed in the gaps in order to minimize weight and to avoid cutting ferrite. The coil comprises 26 turns of 4-mm diameter Litz wire. The operational frequency was reduced to 20 kHz as the switches used for the power control were best suited to a slightly lower frequency. The measured and simulated results are shown in Fig. 16. Notably, a power null occurs when the secondary is offset from the primary at approximately 40% of the pad diameter. Assuming an operational Q of 6 is allowed, this 700 mm pad allows a charging zone with a full power diameter of 260 mm with an air gap of 210 mm. This is better than our initial specication of a minimum charge radius of 200 mm. Although there are large sections of aluminium that do not appear to be shielded from the coil by ferrite, the loss in the aluminium backing pate is low and this is reected by the high QL value of the pad (as discussed in Section III), which is measured to be 250 with a precision LCR meter. This low loss is partly attributed to the low resistivity of aluminium (minimizing I2 R loss), the physical distance between it and the coil and because it only has to shield leakage ux. The ferrite strips guide a signicant proportion of the ux generated by the transmitter coil away from the backing plate and upward to the receiver. The pads were operated with 2 kW being transferred for several hours without thermal issues.

Fig. 16. Simulated and measured horizontal proles at 210 mm separation with a primary current of 23 AR M S at 20 kHz and operational Q for 2 kW output.

Since the pads operate with a relatively large air gap unlike those used in [6], [17], [20], transmitter and receiver pad inductance variations are minimal; therefore, there is little effect on tuning in both the power supply and PU during operation as a result of misalignment. If smaller air gaps are chosen, the coupling is improved, but the output power will be made sensitive to any misalignment. Consequently, such variations will need to be handled in the design of the system, as discussed in [27]. The graphs in Fig. 17(a) and (b) show the measured variation of the transmitter and mutual inductances against separation and horizontal offset, respectively. The 26 turn pads are identical and, therefore, have essentially the same self-inductance of 540 H. This large inductance means that 1.6 kV is required across the terminals of the transmitter to get a current of 23 A. This presents a potential safety hazard and requires careful terminal insulation. Compensation capacitors can, however, be placed in series with the pad winding and internal to the pad structure to effectively reduce the inductance, and hence the voltage at the external terminals. If required, the capacitors can be distributed throughout the winding in order to meet voltage limits. However, these approaches inherently reduce pad reliability due to additional internal connections and ideally should be avoided. Alternatively, the pad can be bilar wound to lower the inductance and, hence, driving voltage while keeping the NI product and, therefore, the generated ux constant. The second approach was chosen noting a bilar wound pad needs to be driven with 46 A. The inductance of each 13-turn coil was 130 H and 131 H for the inner and outer winding, respectively. The inductance of the outer winding with the inner shorted was 5.0 H, and it was 5.1 H for the opposite set of measurements. This corresponds to a total mutual inductance of 256 H. The inductance of the bilar pad is 130 H, which gives a terminal voltage of 780 V. This is below the general upper safety limit of 1 kV. By constraining the voltage with a bilar winding, suitable components can be selected with VA ratings that guarantee operation without fault.

3106

IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 26, NO. 11, NOVEMBER 2011

Fig. 18.

2 kW pads with an air gap of 200 mm.

Fig. 17. Transmitter pad and mutual inductances against (a) vertical offset and (b) horizontal offset (at 200 mm separation). Fig. 19. Measured and simulated ux density along a contour midway between aligned and offset pads beginning at the center.

A. Practical Issues Meeting Field Leakage Regulations To enable application on an EV, the pads should ideally comply with the International Commission on Non-Ionising Radiation Protection guidelines (ICNIRP). These regulations have been established to limit human exposure to time-varying EMF with the aim of preventing adverse health effects. ICNIRP stipulates that the general public should not be exposed to body average RMS ux densities greater than 6.25 T in the frequency range of 0.8 to 150 kHz. The limit is raised for occupational exposure and is frequency dependent, between 0.8 to 65 kHz the limit is 30.7 T and between 65 to 150 kHz the exposure level in T is dened by 2.0/f, where f is the frequency in MHz; this corresponds to 13.3 T at 150 kHz [30]. ICNIRP does not explicitly describe measurement techniques for determining whether systems meet the guidelines making design development difcult. Measurement techniques have been addressed by the Australian Radiation Protection and Nuclear Safety Agency (ARPANSA), based on ICNIRP guidelines formulating human exposure standards covering frequencies from 3 kHz to 300 GHz [31]. As such, the ARPANSA standard exposure levels are also frequency dependent, the body average reference level for general public exposure to magnetic elds is 6.1 T between 10 to 150 kHz. The occupational exposure level between 65 to 100 kHz is dened by 1.63/f Am1 , at 100 kHz it is 20.5 T. Between 100 and 150 kHz the level is dened by 9.16/f 0 . 25 Am1 (f in MHz), corresponding to 18.5 T at the upper limit.

The measurement techniques described in the standard also include spot limits, body average, and temporal averaging. Spot limits may be up to a factor of 20 greater than the exposure level at a given frequency; consequently, the maximum exposure level for the general public at a given spot is 27.3 T in the frequency range of 10 to 65 kHz. Temporal averaging allows exposure measurements to be taken over a time of 100 s, as such this may be 1 or 10 cycles. Spatial averaging is applicable to frequencies lower that 100 MHz and involves taking the average exposure level at four points on the human body, the head, chest, groin, and knees. As long as the average value is at or below the exposure level and no spots exceed the applicable spot maximum, the system is considered to be in compliance. For systems presented in this paper, this means the general public should not be exposed to an average ux density greater than 6.1 T and with no spots exceeding 27.3 T. Simulations and measurements have been undertaken to investigate leakage elds around a system transferring 2 kW across an air gap of 200 mm with the pads centered. Measurements were taken with a Narda ELT-400 three-axis exposure level tester that has a probe area of 100 cm2 . The leakage ux density is greatest along the line midway between the pads, as shown in Fig. 18. The measured and simulated results along this line are shown in Fig. 19, with appropriate exposure limits plotted.

BUDHIA et al.: DESIGN AND OPTIMIZATION OF CIRCULAR MAGNETIC STRUCTURES

3107

Fig. 20. Measured ux density applying spatial averaging across a female standing 170 mm from the edge of a power pad system transferring 2 kW.

The graphed contour illustrates the worst leakage ux from the pads; leakage directly above and below the pads is lower due to shielding provided by the aluminium case and ring. The spot ux density is 27.3 T at a distance of 500 mm from the center of the pad or 150 mm from the pad edge. Leakage is marginally worse with misaligned pads where the 27.3 T limit is reached 550 mm from center. Spatial averaging is applied for the worst-case scenario, where a 1.5-m-tall female is standing 170 mm from the pad edge; the results are shown in Fig. 20. The system will easily comply with ARPANSA regulations. VI. CONCLUSION In order to ensure that IPT systems are as efcient, cost effective, and light as possible, it is critical that the desired coupling between the power pads is achieved with a minimum amount of ferrite. The difference between nite-element models and measured results shown here is 10% at most, meaning that pads optimized using the simulator will perform as expected in practice. The fundamental horizontal tolerance limit for charging pads that are circular is shown to be approximately 40% of the pad diameter. Narrow, evenly spaced ferrite bars give the most effective performance to weight result. A 2 kW IPT system was also built and tested using a 700-mm diameter power pad. Existing ferrite bars were used for convenience and offer a better practical solution since a bar made up of individual ferrite pieces is less likely to fracture than a single long solid bar. Leakage elds have been investigated via simulation and measurement and show that the pads meet ICNIRP guidelines according to ARPANSA regulations. The quantitative results presented in this paper form a basis for the proper design of power pads for IPT systems. REFERENCES

[1] K. Chang-Gyun, S. Dong-Hyun, Y. Jung-Sik, P. Jong-Hu, and B. H. Cho, Design of a contactless battery charger for cellular phone, IEEE Trans. Ind. Electron., vol. 48, no. 6, pp. 12381247, Dec. 2001. [2] G. A. Covic, G. Elliott, O. H. Stielau, R. M. Green, and J. T. Boys, The design of a contact-less energy transfer system for a people mover system, in Proc. PowerCon 2000, vol. 1, pp. 7984. [3] T. Hata and T. Ohmae, Position detection method using induced voltage for battery charge on autonomous electric power supply system for vehicles, in Proc. The 8th IEEE Int. Workshop Adv. Motion Control, 2004, Kawasaki, Japan, pp. 187191. [4] S. Y. R. Hui and W. W. C. Ho, A new generation of universal contactless Battery Charging platform for portable Consumer Electronic equipment, IEEE Trans. Power Electron., vol. 20, no. 3, pp. 620627, May 2005.

[5] R. Laouamer, M. Brunello, J. P. Ferrieux, O. Normand, and N. Buchheit, A multi-resonant converter for non-contact charging with electromagnetic coupling, in Proc. 23rd Int. Conf. Ind. Electron. Control Instrum., 1997, vol. 2, pp. 792797. [6] F. Nakao, Y. Matsuo, M. Kitaoka, and H. Sakamoto, Ferrite core couplers for inductive chargers, in Proc. Power Convers. Conf., 2002, Osaka, Japan, vol. 2, pp. 850854. [7] P. Sergeant and A. Van Den Bossche, Inductive coupler for contactless power transmission, IET Electr. Power Appl., vol. 2, no. 1, pp. 17, 2008. [8] F. F. A. Van Der Pijl, J. A. Ferreira, P. Bauer, and H. Polinder, Design of an inductive contactless power system for multiple users, in Proc. 41st Annu. Ind. Appl. Conf., 2006. Tampa, FL, pp. 18761883. [9] K. W. Klontz, D. M. Divan, and D. W. Novotny, An actively cooled 120 kW coaxial winding transformer for fast charging electric vehicles, IEEE Trans. Ind. Appl., vol. 31, no. 6, pp. 12571263, Nov./Dec. 995. [10] R. Severns, E. Yeow, G. Woody, J. Hall, and J. Hayes, An ultra-compact transformer for a 100 W to 120 kW inductive coupler for electric vehicle battery charging, in Proc. 11th Annu. Appl. Power Electron. Conf. Exposition, 1996, vol. 1, pp. 3238. [11] H. F. Blanchette and K. Al-Haddad, Solving EMI-related problems for reliable high-power converters design with precomputed electromagnetic models, IEEE Trans. Power Electron., vol. 25, no. 1, pp. 219227, Jan. 2010. [12] L. Xun and S. Y. Hui, Optimal design of a hybrid winding structure for planar contactless battery charging platform, IEEE Trans. Power Electron., vol. 23, no. 1, pp. 455463, Jan. 2008. [13] J. T. Boys, G. A. Covic, and A. W. Green, Stability and control of inductively coupled power transfer systems, in Proc. IEE Electr. Power Appl., Jan., 2000, vol. 147, no. 1, pp. 3743. [14] W. Chwei-Sen, O. H. Stielau, and G. A. Covic, Design considerations for a contactless electric vehicle battery charger, IEEE Trans. Ind. Electron., vol. 52, no. 5, pp. 13081314, Oct. 2005. [15] O. H. Stielau and G. A. Covic, Design of loosely coupled inductive power transfer systems, in Proc. Power Syst. Technol. Int. Conf., 2000, vol. 1, pp. 8590. [16] S. Valtchev, B. Borges, K. Brandisky, and J. B. Klaassens, Resonant contactless energy transfer with improved efciency, IEEE Trans. Power Electron., vol. 24, no. 3, pp. 685699, Mar. 2009. [17] H. Sakamoto, K. Harada, S. Washimiya, K. Takehara, Y. Matsuo, and F. Nakao, Large air-gap coupler for inductive charger [for electric vehicles], IEEE Trans. Magn., vol. 35, no. 5, pp. 35263528, Sep. 1999. [18] J. Hirai, K. Tae-Woong, and A. Kawamura, Study on intelligent battery charging using inductive transmission of power and information, IEEE Trans. Power Electron., vol. 15, no. 2, pp. 335345, Mar. 2000. [19] D. A. G. Pedder, A. D. Brown, and J. A. Skinner, A contactless electrical energy transmission system, IEEE Trans. Ind. Electron., vol. 46, no. 1, pp. 2330, Feb. 1999. [20] M. Dockhorn, D. Kurschner, and R. Mecke, Contactless power transmission with new secondary converter topology, in Proc. 13th Power Electron. Motion Control Conf. 2008. Poznan, Poland, pp. 17341739. [21] Y. Matsuo, O. M. Kondoh, and F. Nakao, Controlling new die mechanisms for magnetic characteristics of super-large ferrite cores, IEEE Trans. Magn., vol. 36, no. 5, pp. 34113414, Sep. 2000. [22] L. Xun and S. Y. Hui, Simulation study and experimental verication of a universal contactless battery charging platform with localized charging features, IEEE Trans. Power Electron., vol. 22, no. 6, pp. 22022210, Nov. 2007. [23] J. L. Villa, J. Sall an, A. Llombart, and J. F. Sanz, Design of a high frequency inductively coupled power transfer system for electric vehicle battery charge, Appl. Energy, vol. 86, no. 3, pp. 355363, 2009. [24] S. Judek and K. Karwowski, Supply of electric vehicles via magnetically coupled air coils, in Proc. 13th Power Electron. Motion Control Conf. 2008. Poznan, Poland, pp. 14971504. [25] L. Xun, W. M. Ng, C. K. Lee, and S. Y. Hui, Optimal operation of contactless transformers with resonance in secondary circuits, in Proc. 23rd Annu. IEEE Appl. Power Electron. Conf. Exposition, 2008. Austin, TX, pp. 645650. [26] B. L. Cannon, J. F. Hoburg, D. D. Stancil, and S. C. Goldstein, Magnetic resonant coupling as a potential means for wireless power transfer to multiple small receivers, IEEE Trans. Power Electron., vol. 24, no. 7, pp. 18191825, Jul. 2009. [27] H. Chang-Yu, J. T. Boys, G. A. Covic, and M. Budhia, Practical considerations for designing IPT system for EV battery charging, in Proc. IEEE Vehicle Power Propulsion Conf., 2009. Dearborn, MI, pp. 402407.

3108

IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 26, NO. 11, NOVEMBER 2011

[28] J. T. Boys, C. Y. Huang, and G. A. Covic, Single-phase unity powerfactor inductive power transfer system, in Proc. IEEE Power Electron. Specialists Conf., 2008. Rhodes, Greece, pp. 37013706. [29] G. A. Covic, J. T. Boys, M. L. G. Kissin, and H. G. Lu, A three-phase inductive power transfer system for roadway-powered vehicles, IEEE Trans. Ind. Electron., vol. 54, no. 6, pp. 33703378, Dec. 2007. [30] Guidelines for limiting exposure to time-varying electric, magnetic, and electromagnetic elds (up to 300 GHz), Health Phys., vol. 74, no. 4, pp. 494522, 1998. [31] Maximum exposure levels to radiofrequency elds 3 kHz to 300 GHz, Australian Radiation Protection and Nuclear Safety Agency (ARPANSA), 2002.

John T. Boys received the B.E., M.E., and Ph.D. degrees in electrical and electronic engineering from the University of Auckland, Auckland, New Zealand, in 1963, 1965, and 1968, respectively. After completing his Ph.D. he was with SPS Technologies for ve years before returning to academia as a Lecturer at the University of Canterbury. He moved to Auckland in 1977, where he developed his work in power electronics. He is currently a Professor of electronics at the University of Auckland, New Zealand, in the Department of Electrical and Computer Engineering and co-founder of HaloIPT. He has published more than 100 papers in international journals and is the holder of more than 20 US patents from which licenses in specialized application areas have been granted around the world. His specialist research areas are power electronics and inductive power transfer where he and Prof. G. A. Covic jointly head power electronics research. He is a Fellow of the Royal Society of New Zealand and a Distinguished Fellow of the Institution of Professional Engineers, New Zealand.

Mickel Budhia (S05) received the B.E. degree in electrical and electronic engineering from the University of Auckland, Auckland, New Zealand, in 2008, where he is currently working toward the Ph.D. degree. His research interest includes analyzing and designing magnetic couplers used in inductive power transfer systems for electric vehicle charging.

Grant A. Covic (S88-M89-SM04) received the B.E. (Hons.) and Ph.D. degrees in electrical and electronic engineering from the University of Auckland (UoA), New Zealand, in 1986 and 1993, respectively. He was appointed as a full time Lecturer in 1992, a Senior Lecturer in 2000, and in 2007 as an Associate Professor in the Electrical and Computer Engineering Department at the UoA, New Zealand. Currently, he jointly heads power electronics research with Prof. John Boys at the UoA and is cofounder and Chief Research Engineer of a new global start-up company HaloIPT focusing on electric vehicle charging infrastructure. He holds a number of US patents with many more pending in the area of inductive (contactless) power transfer (IPT). His current research and consulting interests include power electronics, electric vehicle battery charging, and IPT from which he has published more than 100 refereed papers in international journals and conferences.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ABB AMS Synchronous GeneratorsDocument16 pagesABB AMS Synchronous GeneratorsPabloAlv67% (3)

- 8085 MicroprocessorDocument23 pages8085 Microprocessorauromaaroot196% (55)

- Marks S5Document8 pagesMarks S5blooms116No ratings yet

- Honor KillingDocument1 pageHonor Killingblooms116No ratings yet

- Covic IPT Powering Our Future PDFDocument126 pagesCovic IPT Powering Our Future PDFblooms116No ratings yet

- Design Methodology For IPT PDFDocument10 pagesDesign Methodology For IPT PDFblooms116No ratings yet

- Analog Communication AssignmentDocument2 pagesAnalog Communication Assignmentblooms116No ratings yet

- Possibilities in IPT PDFDocument50 pagesPossibilities in IPT PDFblooms116No ratings yet

- TI Wireless Power Reciever PDFDocument29 pagesTI Wireless Power Reciever PDFblooms116No ratings yet

- ECE 294: Embedded Systems Lab: (Fourth Semester) Labsheet 2Document3 pagesECE 294: Embedded Systems Lab: (Fourth Semester) Labsheet 2blooms116No ratings yet

- Microchip 18F877 DatasheetDocument218 pagesMicrochip 18F877 DatasheetberetyNo ratings yet

- Assignment-2 OCT3 2013 SubmitDocument1 pageAssignment-2 OCT3 2013 Submitblooms116No ratings yet

- Architecture of 8085Document10 pagesArchitecture of 8085blooms116No ratings yet

- Micro Intro Lecture 2Document83 pagesMicro Intro Lecture 2blooms116No ratings yet

- Micro Intro 1 Lecture 1Document61 pagesMicro Intro 1 Lecture 1blooms116No ratings yet

- Microprocessor - ECE312: Introduction ClassDocument17 pagesMicroprocessor - ECE312: Introduction Classblooms116No ratings yet

- Lect 3Document23 pagesLect 3blooms116No ratings yet

- Lect 2Document27 pagesLect 2blooms116No ratings yet

- Implementation of Perturb and Observe Based MPPT Algorithm For Photovoltaic SystemDocument6 pagesImplementation of Perturb and Observe Based MPPT Algorithm For Photovoltaic SystemAliXmetecNo ratings yet

- MST 9001d Diesel Engine Ecu Test Rig Phs Instruction 1Document13 pagesMST 9001d Diesel Engine Ecu Test Rig Phs Instruction 1sk034jy081No ratings yet

- Nri Institute of Technology: Q.No - Roll No'sDocument2 pagesNri Institute of Technology: Q.No - Roll No'sDr. P. Rama Koteswara RaoNo ratings yet

- Bird Meter 4391A-ManualDocument46 pagesBird Meter 4391A-Manualpy5rcbNo ratings yet

- Rim Seal Fire Protection SystemDocument21 pagesRim Seal Fire Protection SystemSuraj singhNo ratings yet

- IT1251 Information Coding TechniquesDocument23 pagesIT1251 Information Coding TechniquesstudentscornersNo ratings yet

- AirFiber X UGDocument80 pagesAirFiber X UGDadi SucahyonoNo ratings yet

- LPRD00Document3 pagesLPRD00blem_0075100% (1)

- DR 20 Pro Hoist Tech DataDocument40 pagesDR 20 Pro Hoist Tech DatagqttNo ratings yet

- General Specifications AI-517-02: GS48C17Z02-00E-NDocument8 pagesGeneral Specifications AI-517-02: GS48C17Z02-00E-N赵先生No ratings yet

- Daikin RXS-K - Technical DataDocument21 pagesDaikin RXS-K - Technical DataPrestoneKNo ratings yet

- 3-Phase Motor Drives W Oscilloscope 48W-73863-0Document31 pages3-Phase Motor Drives W Oscilloscope 48W-73863-0CarloNo ratings yet

- Transducers - SummaryDocument27 pagesTransducers - Summaryaelle00No ratings yet

- Simulation For Iot Based Smart Traffic Control System For Emergency VehiclesDocument44 pagesSimulation For Iot Based Smart Traffic Control System For Emergency VehiclesJeba JinilNo ratings yet

- User Manual For Wireless Controller HAMA SCORPAD 00051838 PS3Document3 pagesUser Manual For Wireless Controller HAMA SCORPAD 00051838 PS3Victor GheorgheNo ratings yet

- LM5118 Evaluation BoardDocument16 pagesLM5118 Evaluation BoardAnonymous oyUAtpKNo ratings yet

- Easily Correct Phase Shift On A Delta-To-Wye Transformer For ParallelingDocument11 pagesEasily Correct Phase Shift On A Delta-To-Wye Transformer For ParallelingMujahid Ahmed FadelNo ratings yet

- Front Load Washer Speed QueenDocument52 pagesFront Load Washer Speed QueenGoliat1971No ratings yet

- Corneta 855-BN-D30-BDocument3 pagesCorneta 855-BN-D30-BnelsonNo ratings yet

- PLEXIM Plecs ManualDocument602 pagesPLEXIM Plecs ManualziokkoizNo ratings yet

- I48E-EN-01 SigmaServoDrive DatasheetDocument18 pagesI48E-EN-01 SigmaServoDrive DatasheetjuujaaNo ratings yet

- BOSS Slow Gear SG-1 Attack DelayDocument1 pageBOSS Slow Gear SG-1 Attack Delay大石 真義No ratings yet

- ETC Raisoni Endsem PaperDocument14 pagesETC Raisoni Endsem PaperYogesh Jounjalkar100% (1)

- Site Test Report Date: Al-Osais Co. KHUDARIYAH S/S 115/13.8 KV S/S CT Supervision Relay - MVTPDocument4 pagesSite Test Report Date: Al-Osais Co. KHUDARIYAH S/S 115/13.8 KV S/S CT Supervision Relay - MVTPsikander843562No ratings yet

- 2 N 6394Document8 pages2 N 6394lgrome73No ratings yet

- Baby Talker 500 ManualDocument144 pagesBaby Talker 500 Manualmarcin_pawlak_550% (2)

- Computer OrganizationDocument67 pagesComputer OrganizationDani RaniNo ratings yet

- THS710,20,30 PDFDocument130 pagesTHS710,20,30 PDFTyrannyBRNo ratings yet