Professional Documents

Culture Documents

April 5, 1966 B. Weiser 3,243,910: Filed Feb. 2, 1965

Uploaded by

fgrt490Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

April 5, 1966 B. Weiser 3,243,910: Filed Feb. 2, 1965

Uploaded by

fgrt490Copyright:

Available Formats

April 5, 1966

B. WEISER

SHOTGUN CHOKE

3,243,910

Filed Feb. 2, 1965

F/G. 2

/6 2% 20

52 4 ,6 I770/6 fI 3 I

J ' /28

26

F/G. 4

Z40.

INVENTOR.

BERNARD WEISER

ATTORNEYS

United States Patent 0

1

SHOTGUN CHOKE

3,243,910

Patented Apr. 5, 1966 Z

3,243,910

Bernard Weiser, 51 Canal St., Weatogue, Conn. Filed Feb. 2, 1965, Ser. No. 429,720

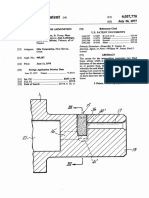

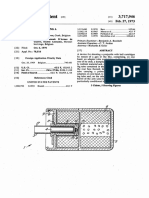

The central bore 14 extends coaxially through the shell 12 and includes a ?rst cylindrical bore portion 30 adapted to receive the shotgun muzzle 16 in press ?t relationship. The choke 10 may be permanently secured to the gun

muzzle by an appropriate metal fusion process, such as

14 Claims. (Cl. 42-79)

This invention relates to improvements in shotgun choke attachments and has for its general object the pro vision of an improved adjustable choke for elfectively

silver soldering. It should be noted that when the choke attachment is positioned upon the shotgun it extends for wardly from the gun muzzle in coaxial alignment with

10

controlling a shotgun shot pellet pattern.

Another object of the invention is to provide an adjust able shotgun choke which may be rapidly and accurately selectively conditioned to effect a desired shot pellet dis tribution. A further object of the invention is to provide a shotgun

the gun bore. Since it may be necessary to remove the forward sight from the shotgun in order to attach the choke to the gun, a sighting means is preferably provided on the choke. In one presently preferred embodiment of the invention the sighting means is a bead sight 32 threadably secured to

shotgun.

choke which reduces the recoil and muzzle blast of a

the collar 20; however, it should be apparent that the

type of sight used and its location upon the choke may be varied to suit the markmans preference. The central bore 14 also includes a second portion 34 adjacent the muzzle 16 and a cylindrical third or forward portion 36 adjacent the portion 34. The portion 34 is tapered to converge from the muzzle to the cylindrical portion 36. It should be further noted that the tapered second portion has a major diameter at least equal to the

A still further object of the invention is to provide an

adjustable shotgun choke of simple and yet durable design

and construction and which may be manufactured at low

cost.

The drawing shows preferred embodiments of the in

vention and such embodiments will be described, but it will be understood that various changes may be made from the constructions disclosed, and that the drawing

and description are not to be construed as de?ning or

diameter of the shotgun bore, whereas the cylindrical

third portion 36 has a diameter smaller than the diameter of the gun bore. The vent openings 18, 18 de?ned within the shell 12 are

limiting the scope of the invention, the claims forming a part of this speci?cation being relied upon for that pur

pose.

preferably longitudinally aligned transversely extending

slots which communicate with the cylindrical third or

30 forward portion 36.

In the drawing:

FIG. 1 is a plan view of a shotgun choke embodying the present invention. FIG. 2 is a longitudinal section, taken generally along the line 2-2 of FIG. 1, showing the device mounted on the muzzle end of a shotgun barrel. FIG. 3 is a transverse section taken generally along the line 33 in FIG. 2.

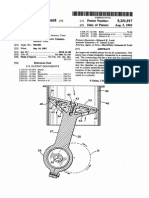

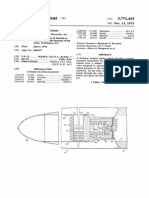

FIG. 4 is a partially sectional side elevation of a modi ?ed form of the choke shown in FIG. 1. Referring now to the drawing, and particularly to FIGS. 1 and 2, a choke embodying the present invention is indi

In the present preferred embodi ment of the invention, the openings 18, 18 are obliquely disposed to the central bore axis for forwardly exhaust

ing the gases of explosion, and are all located to one side of an axial plane of the bore for a purpose to be

further discussed hereinafter.

A pair of diametrically opposed transversely aligned

apertures 19, 19 de?ned by the shell 12 also communicate with the cylindrical third portion 36. Three slot-shaped vent openings 18, 18 are shown in the embodiment of the invention here described; however,

closing means is preferably a collar 20 surrounding a

it will be apparent from the description which follows that the number, shape and size of these openings may generally comprises a tubular shell 12 having a central vary without departure from the spirit of the invention. bore 14 adapted to receive a shotgun muzzle 16 and a col The collar 21) is preferably an annular ring surrounding lar 21). At least one vent opening 18, 18 communicates the smooth portion 24 in slidable engagement therewith 45 with the central bore 14 for venting the gases of explo adapted for axial movement therealong and selective sion when the gun is discharged. A closing means 20 positioning relative thereto. is provided for closing at least a portion of the vent A ball detent mechanism, indicated generally by the opening. In the presently preferred form of the inven numeral 22, provides means for retaining the collar 20 in tion three vent openings 18, 13 are employed. The vent 50 selected longitudinal position relative to the shell 12.

cated generally by the reference numeral 10. The choke

substantially smooth portion 24 of the shell 12, slidably mounted thereon for adjustable positioning therealong.

The collar 20 may be positioned to expose all of the vents

18, 18 or to cover or ciose one or two of them; however,

A ball 38 positioned within a radial aperture 40 in the

collar 29 is urged radially inwardly by an annular spring

42 positioned within an annular recess 44 in the collar 26.

The recess 44 is radially aligned with the aperture 40. A

55 longitudinal recess 46, de?ned in the outer surface of the

it should be noted that in the presently preferred em

bodiment of the invention at least one vent remains open

shell 12, is adapted to receive a portion of the ball 38

therein, limiting the overall longitudinal travel of the col

or uncovered at all times. A means for selectively posi lar 20 relative to the shell 12 and serving to prevent rota tioning the collar 20 relative to the shell 12 is provided tional movement of the collar relative to the shell. by a ball detent mechanism indicated generally by the 60 Sockets 48, 48 associated with the recess 46 are adapted to numeral 22. receive a portion of the ball 38 thereby providing means The shell 12 is preferably cylindrical having a smooth for retaining the collar 2%} in selected longitudinal posi

surface portion 24 and a forward or muzzle end portion tion relative to the shell 12. 26 of reduced diameter to aid in heat dissipation. The In the choke of FIGS. 1 through 3, the collar 20 may surface of the muzzle end portion is preferably knurled be selectively positioned in any one of three positions. 65 to facilitate handling the device and to improve its gen In the open choke or full line position of FIG. 2, the eral appearance. A plurality of radially contoured annu collar 20 resides in a maximum rearward position toward lar grooves 28, 28 are de?ned in the muzzle end portion the gun muzzle exposing all three of the vent openings 26. One of these grooves serves as a receptacle for a ball 18, 18 to allow for maximum venting of the gases. In detent mechanism associated with a dispersion adapter the full choke or broken line position of FIG. 2, the collar 70 to be described hereinafter. The remaining grooves 28, 20 achieves maximum forward position and covers two 28 merely enhance the appearance of the device. of the three vent openings 18, 18. It should be noted

3,243,910

3

that the forwardmost vent 18 remains uncovered at all times, thereby allowing some gas to be vented from the bore 14 when the collar is in the full choke position. An intermediate collar position shown in FIG. 1, is also pro vided wherein only one of the three vent openings 18, 18 is covered. The gases of explosion expand in all directions as they emerge from a shotgun muzzle. Since the shot column in a shotgun shell comprises a multiplicity of individual

pellets, it does not respond as a mass when it is pro

noted that a cylindrical shell 12a includes a central bore 14a. having a cylindrical bore portion 36a and other bore characteristics identical to those of the aforedescribed choke.

The cylinder 12a de?nes a plurality of vent openings 18a, 13a communicating with a central bore which open ings are in all respects similar to those of the choke of FIG. 1. An internally threaded collar 20a cooperates with an externally threaded portion 24a of the shell 12a,

10

thereby providing means for selectively positioning the

pelled by the expanding gas. The laterally expanding

gases tend to impart lateral velocity to the pellets in the outer layers of the shot column as they leave the muzzle

a vent impinge upon an associated surface to impart a In the choke of the present invention, the shot column forward thrust thereto. This arrangement renders the leaves the muzzle of the shotgun and enters the choke choke recoil responsive. It should also be noted that through a tapered bore section from which it passes into the cylindrical bore section 36 having a bore smaller 20 the lateral escape of gas from the vent opening 1811 not associated with a ?ange surface 15 also serves to ma than the shotgun bore. Thus, the shot column is some terially reduce recoil. what compressed and its density is increased under the A sighting means 32a is mounted on one of the annu maximum available pressure of the expanding gases. lar rings 13, 13 in the modi?ed choke shown in FIG. 4. The cylindrical bore section 36 tends to direct the com A further modi?cation of a shot pattern may be elfected pacted shot column on a substantially true flight to its 25 by the use of a dispersion adapter indicated generally by mark. Increasing the density of the shot column before

collar along the shell. Also included upon the shell 12a is at least one annular ?ange 13, 13 having a surface 15, 15 normal to the shell axis and forwardly adjacent at least one of the vent openings 18a, 18a. resulting in lateral dispersion of some of the pellets with The vent openings are so disposed relative to the asso a resulting loss of shot pattern density. This problem is 15 ciated ?ange surfaces 15, 15 that the gases escaping from well known to those skilled in the shotgun art.

the numeral 42 as shown in FIG. 4. The adapter 42 com prises a tubular section 44 having a cylindrical bore por tion 46 adapted to engage a muzzle end portion 26a of to vent some of the expanding gases of explosion from 30 the tubular shell 12a. Means for releasably retaining the section 44 in engage the choke bore after the shot column has entered the ment with the shell 12a is provided by a ball detent mech cylindrical portion or section 36 of the bore. The selec anism 22a generally similar to the aforedescribed ball tively positioned collar 20 provides means for controlling detent mechanism 22. One of the annular radially con the escape of gas through the vent openings communicat toured recesses 28a, 28a on the muzzle end portion 26a ing with the central bore of the choke thereby controlling provides a receptacle for the ball detent mechanism 22a. the amount of expanding gas which ultimately emerges at The adapter 42 includes a tapered bore section 50 ad the choke muzzle. Shotgun shells are available in a wide

it leaves the forward end or muzzle of the choke is be

lieved to reduce the in?uence of the laterally expanding gases upon it. It will also be noted that provision is made

variety of charge weights, shot sizes and shot counts. The adjustable feature of the choke of the present inven

jacent and coaxially aligned with the third or cylindrical portion 36a. The tapered bore portion 50 has a di tion enables the marksman to adapt his shotgun to employ 40 ameter adjacent the third portion at least equal to the di ameter of the third portion 36a. The tapered section the characteristics of a given shell most elfectively. 50 may either converge or diverge from the third portion As previously noted, all of the vent openings 18, 18 lie in accordance with the shot pattern modi?cation desired. on one side of an axial plane of the shell 12. The choke An adapter 42 having a diverging bore 50 is shown in of the present invention is normally mounted on the shot gun with the vent openings facing upwardly; therefore, 45 full lines in FIG. 4. A converging bore 50 shown in the same ?gure is indicated by broken lines. the gases of explosion escaping from these vents exert a The invention claimed is: downward thrust at the muzzle end of the gun. In the 1. A choke attachment for a shotgun comprising a normal shooting position, one of the marksmans hands is tubular shell having a central bore, said bore including placed upon the underside of the gun forestock, thereby a ?rst portion adapted to receive the muzzle of a shot supporting the forward portion of the gun and providing gun and extend forwardly therefrom in coaxial alignment a natural resistance to downward thrust. Thus, it should therewith, said bore including a second portion adjacent be apparent that the escaping gases exert a force in a said ?rst portion, said bore further including a generally direction opposite to the balancing force exerted by the cylindrical third portion adjacent said second portion, said marksman in holding the gun. Since the marksman is third portion having a diameter smaller than the shot prepared to compensate for this downward thrust and can

readily do so, he is able to retain more effective control

gun bore diameter, said shell de?ning at least one vent

of the gun at the instant of discharge, thereby reducing muzzle movement and the further shot pattern disturbance which otherwise might result therefrom.

In a large gauge shotgun, such as a twelve gauge, a

opening communicating laterally with said third portion,

and means for selectively closing at least a portion of said

vent opening.

2. A choke attachment for a shotgun comprising a tubu lar shell having a central bore, said bore including a ?rst portion adapted to receive the muzzle of a shotgun and

relatively heavy powder charge is used and it has been found that under some shooting conditions, better control

may be effected by discharging some of the gases of ex plosion transversely of the gun barrel. It is for this reason

extend forwardly therefrom in coaxial alignment there with, said bore including a second portion adjacent said that the diametrically opposed transverse apertures 19, 65 ?rst portion, said bore further including a generally cylin drical third portion adjacent said second portion, said 19 are provided. It should be noted that in the open third portion having a diameter smaller than the shot choke position, the collar 2%) assumes a maximum rear gun bore diameter, said shell de?ning a plurality of vent ward position exposing the apertures 19, 19 whereas, these openings communicating laterally with said third portion, apertures are partially covered by the collar in the in termediate collar position and fully covered in the full 70 and means for selectively closing at least one of said vent

choke or maximum forward position. Such transverse apertures are preferably not provided on chokes for smaller gauge shotguns. Referring now to FIG. 4, wherein a modi?ed form of

openings.

3. In a choke attachment for a shotgun the combination comprising a tubular shell having a central bore, said bore including a ?rst portion adapted to receive the muzzle of choke of FIG. 1 is indicated generally at 10a, it will be 75 a shotgun and extend forwardly therefrom in coaxial

3,243,910

5

alignment therewith, said central bore including a sec ond portion adjacent said ?rst portion, said central bore

a

cylindrical shell having a coaxial central bore, said bore

including a ?rst portion adapted to receive the muzzle of a shotgun and extend forwardly therefrom in coaxial alignment therewith, said bore including a tapered sec~ ond portion adjacent said ?rst portion, said bore further including a cylindrical third portion having a diameter smaller than the diameter of the shotgun bore, said

further including a generally cylindrical third portion ad jacent said second portion, said third portion having a diameter smaller than the shotgun bore diameter, said shell de?ning a plurality of vent openings communicating

with said third portion, a collar surrounding a peripheral

portion of said shell, and means for selectively positioning

said collar relative to said shell to cover at least one of

second portion converging to said cylindrical portion,

said second portion having a major diameter at least

10

said vent openings.

4. In a choke attachment for a shotgun muzzle, the combination comprising a tubular shell having a central

equal to the shotgun bore diameter, said shell de?ning

a plurality of longitudinally spaced apart transversely ex tending slots communicating with said third portion, said

slots being disposed on one side of an axial plane, and

bore, said shell being adapted to receive the muzzle of a shotgun and extend forwardly therefrom in coaxial align ment therewith, said central bore including a cylindrical

bore portion having a diameter smaller than the shot gun bore diameter, said central bore further including a

being obliquely disposed to said axis to forwardly ex haust the gases of explosion, an annular collar encircling a portion of said shell, and means for selectively posi

tioning said collar relative to said shell to cover at least one of the said slots. portion and the muzzle converging to said cylindrical bore 13. A choke attachment for a shotgun comprising a portion, said tapered bore portion having a major di 20 tubular shell having a central bore, said bore including a

tapered bore portion intermediate said cylindrical bore

ameter at least equal to the diameter of the shotgun bore, said shell de?ning a plurality of vent openings com

?rst portion adapted to receive the muzzle of a shotgun and extend forwardly therefrom in coaxial alignment

municating with said cylindrical bore portion, a collar adapted to surround a peripheral portion of said shell and means for selectively positioning said collar relative to

said shell to cover at least one of said vent openings.

therewith, said bore including a second portion adjacent said ?rst portion, said tbore further including a generally

cylindrical third portion adjacent said second portion,

said third portion having a diameter smaller than the shotgun bore diameter, said shell de?ning at least one

5. The combination as de?ned in claim 1 further char acterized .by the addition of sighting means. 6. The combination de?ned in claim 1 further char acterized by an additional tubular section adapted to en gage the forwardly extending end portion of said tubular shell, said section de?ning a tapered bore adjacent said third portion coaxial therewith, said tapered bore hav ing a diameter adjacent said third portion at least equal

to the diameter of said third portion and means for re

vent opening, communicating laterally with said third

portion, said vent opening being located in a half section of

said third portion adjacent said second portion, and means

for selectively closing at least a portion of said vent open

ing.

14. A choke attachment for a shotgun comprising a

tubular shell having a central bore, sa-id bore including

a ?rst portion adapted to receive the muzzle of a shot gun and extend forwardly therefrom in coaxial align ment therewith, said bore including a second portion ad jacent said ?rst portion, said bore further including a

leasably retaining said section in engagement with said shell. 7. The combination set forth in claim 6 wherein the

means for releasably retaining said section is a ball detent mechanism. 8. The combination as set forth in claim 2 wherein

said vent openings are disposed on one side of an axial

generally cylindrical third portion adjacent said second

portion, said third portion having a diameter smaller than the shotgun \bore diameter, said shell de?ning at least one vent opening, communicating laterally with said third portion, and means for selectively closing only a portion of said vent opening.

References Cited by the Examiner UNITED STATES PATENTS

2,191,484 2,306,176 2,322,370 2/1940 12/1942 61/ 1943 Hughes __________ __ 8914.3 Mathis _____________ __ 4279 Lance ____________ __ 8914.3

plane of said shell. 9. The combination de?ned in claim 2 further char acterized by said shell including at least one ?ange surface 45 thereon normal to the axis thereof forwardly adjacent at

least one vent opening, said tvent openings being so dis

posed that gases escaping therefrom impinge upon said ?ange surface.

10. The combination as set forth in claim 3 wherein 50 said means for selectively positioning said collar is a

ball detent mechanism. 11. The combination set forth in claim 3 wherein said means for selectively positioning said collar is provided by said shell having an externally threaded portion and said collar having internal threads cooperating with said

2,453,121 2,484,988

2,484,998

11/1948 10/1949

10/1949

Cutts ____________ __ 4279 X Finlay _____________ __ 4279

Hutchinson _________ __ 4279

2,629,958 2,796,005

2,989,815 3,161,979

3/1953 6/ 1957

6/1961 12/1964

Roper et al. ________ __ 4279 Shapel ___________ __ 8914.3

Hare ______________ __ 4279 Lowe ______________ __ 4279

externally threaded portion for selectively positioning said collar therealong.

12. A choke attachment for a shotgun comprising a 60 BENJAMIN A. BORCHELT, Primary Examiner.

You might also like

- Jan. 4, L 1966 T. W. Spack 3,227,148Document6 pagesJan. 4, L 1966 T. W. Spack 3,227,148MainAvelNo ratings yet

- Siled Sept. 8, 1966: T, N. NccomeDocument5 pagesSiled Sept. 8, 1966: T, N. NccomeliNo ratings yet

- Berthier Us1366863Document9 pagesBerthier Us1366863cll1968No ratings yet

- Foldable Boat FlierDocument5 pagesFoldable Boat FlierRakeshNo ratings yet

- March 8, 1960 Y H. A. Longino 2,927,383: Filed June 3, 1958 2 Sheets-Sheet 1Document5 pagesMarch 8, 1960 Y H. A. Longino 2,927,383: Filed June 3, 1958 2 Sheets-Sheet 1david19775891No ratings yet

- Berthier Us1446635Document12 pagesBerthier Us1446635cll19680% (1)

- Gun Silencer Patent 3Document7 pagesGun Silencer Patent 3Flavio Marçal100% (2)

- United States Patent (191: McguganDocument6 pagesUnited States Patent (191: McguganJamesStenhouseNo ratings yet

- Unlted States Patent (191 1111 3,736,693: Koch 1451 June 5, 1973Document4 pagesUnlted States Patent (191 1111 3,736,693: Koch 1451 June 5, 1973fgrt45No ratings yet

- Byfwf p41 ': March 7, 1961 O. Danyluke 2,973,909Document5 pagesByfwf p41 ': March 7, 1961 O. Danyluke 2,973,909KrozeNo ratings yet

- Us 3690255Document5 pagesUs 3690255wewewewNo ratings yet

- Us 3960084Document3 pagesUs 3960084rte678No ratings yet

- (1966, May 3) US3248803 Rotary Drum Heat ExchangerDocument6 pages(1966, May 3) US3248803 Rotary Drum Heat ExchangeraegosmithNo ratings yet

- ZZ? ??/?? ???P?c222/Z: Filed April 20, 1945Document5 pagesZZ? ??/?? ???P?c222/Z: Filed April 20, 1945Edikan AkpanNo ratings yet

- Us 4037770Document3 pagesUs 4037770ererNo ratings yet

- R.T MM MS: ' Filed July 28, 1965Document6 pagesR.T MM MS: ' Filed July 28, 1965Alexcel CorporalNo ratings yet

- Tube Saport PDFDocument4 pagesTube Saport PDFjr110livecomNo ratings yet

- Umted States Patent (19) (11) Patent Number: 5,642,778: Gentry (45) Date of Patent: Jul. 1, 1997Document15 pagesUmted States Patent (19) (11) Patent Number: 5,642,778: Gentry (45) Date of Patent: Jul. 1, 1997aegosmithNo ratings yet

- United States Patent: Attorney-Pastoriza and KellyDocument4 pagesUnited States Patent: Attorney-Pastoriza and KellyEnrico FermiNo ratings yet

- Us4522105 PDFDocument10 pagesUs4522105 PDFJin SongNo ratings yet

- Us1517483 PDFDocument10 pagesUs1517483 PDFJin SongNo ratings yet

- US5231917 - Wobble PistonDocument5 pagesUS5231917 - Wobble PistondevheadbotNo ratings yet

- Us2960824 PDFDocument5 pagesUs2960824 PDFgrigNo ratings yet

- Us5361479 PDFDocument5 pagesUs5361479 PDFmohammadreza91No ratings yet

- Clem Engine Paper PresentationDocument6 pagesClem Engine Paper PresentationDankamialNo ratings yet

- Limited States Patent: LngramDocument7 pagesLimited States Patent: LngramJin SongNo ratings yet

- 8%, ZGZFMWMD @144': June 4, 1968 R. E. Roy 3,386,336Document9 pages8%, ZGZFMWMD @144': June 4, 1968 R. E. Roy 3,386,336tyrer567899No ratings yet

- Us4252504 PDFDocument7 pagesUs4252504 PDFAhmed EltemsahNo ratings yet

- Umted States Patent (19) (11) Patent Number: 5,671,656: Cyphers Et A) - (45) Date of Patent: Sep. 30, 1997Document6 pagesUmted States Patent (19) (11) Patent Number: 5,671,656: Cyphers Et A) - (45) Date of Patent: Sep. 30, 1997zeichsteinNo ratings yet

- US3404552Document4 pagesUS3404552Prabal JindalNo ratings yet

- Us 3717946Document4 pagesUs 3717946ererNo ratings yet

- Us3771455 PDFDocument3 pagesUs3771455 PDFdgfsduuwioNo ratings yet

- United States Patent (191: SeecampDocument4 pagesUnited States Patent (191: Seecamp9aszerfNo ratings yet

- United States Patent (191 (11) Patent Number: 5 363 542: Sorem Et A1. (45) Date of Patent: Nov. 15, 1994Document6 pagesUnited States Patent (191 (11) Patent Number: 5 363 542: Sorem Et A1. (45) Date of Patent: Nov. 15, 1994mohammadreza91No ratings yet

- O/65ézá / /zzáez: Ozzezz67Document4 pagesO/65ézá / /zzáez: Ozzezz67TECUMCE GOMEZ PEREZNo ratings yet

- United States Patent: Boulogne-sur-Seine, FranceDocument7 pagesUnited States Patent: Boulogne-sur-Seine, FranceRagini SharmaNo ratings yet

- United States Patent (191: Allum Et Al. (11) Patent NumberDocument12 pagesUnited States Patent (191: Allum Et Al. (11) Patent NumberdnddownloaderNo ratings yet

- Mannlicher Us1008162Document6 pagesMannlicher Us1008162cll1968No ratings yet

- Us4540334 PDFDocument9 pagesUs4540334 PDFJigar SutharNo ratings yet

- (12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Document13 pages(12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Selvaraji MuthuNo ratings yet

- Sept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LDocument4 pagesSept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LRakeshNo ratings yet

- United States PatentDocument5 pagesUnited States PatentJagannathan ArumugamNo ratings yet

- SL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296Document7 pagesSL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296lucasmosnaNo ratings yet

- United States Patent: Sultan Et Al. (45) Date of Patent: Apr. 29, 2008Document7 pagesUnited States Patent: Sultan Et Al. (45) Date of Patent: Apr. 29, 2008aqil_shamsiNo ratings yet

- US Patent 4677897Document8 pagesUS Patent 4677897Mosin-NagantNo ratings yet

- Oct. 5, 1965 G. L. Mittelsteadt 3,209,480: Filed Aug. 28, 1964Document5 pagesOct. 5, 1965 G. L. Mittelsteadt 3,209,480: Filed Aug. 28, 1964Юрий РуденкоNo ratings yet

- Cloth Tow Target Sleeve (1935)Document6 pagesCloth Tow Target Sleeve (1935)CAP History LibraryNo ratings yet

- United States Patent (191: Lown (45) Nov. 11, 1980Document4 pagesUnited States Patent (191: Lown (45) Nov. 11, 1980HamedJamshidiNo ratings yet

- Us 1401667Document11 pagesUs 1401667kissaNo ratings yet

- BOΤTLE LABELING MACHINEDocument4 pagesBOΤTLE LABELING MACHINEq12wertyNo ratings yet

- M2 HB Bolt Side Change US2529391Document4 pagesM2 HB Bolt Side Change US2529391apoorva singhNo ratings yet

- April 3, 1962 RAE 3,027,711: Securing Isentropic CompressionDocument4 pagesApril 3, 1962 RAE 3,027,711: Securing Isentropic CompressionDinh LeNo ratings yet

- TEPZZ - 4 885B - T: European Patent SpecificationDocument10 pagesTEPZZ - 4 885B - T: European Patent SpecificationshamsNo ratings yet

- Err-Easels - / ' Ma. Ma @&?7hii?%: March 3, 1936. G, Gimera Et Al 2,032,695Document3 pagesErr-Easels - / ' Ma. Ma @&?7hii?%: March 3, 1936. G, Gimera Et Al 2,032,695RakeshNo ratings yet

- Us 4394836Document4 pagesUs 4394836ererNo ratings yet

- A Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderFrom EverandA Guide to Motor Boat Design and Construction - A Collection of Historical Articles Containing Information on the Methods and Equipment of the Boat BuilderNo ratings yet

- Scientific American Supplement, No. 611, September 17, 1887From EverandScientific American Supplement, No. 611, September 17, 1887No ratings yet

- Fausti: Fine Italian ShotgunsDocument23 pagesFausti: Fine Italian ShotgunsM PovedaNo ratings yet

- Silent Hill 2 (NTSC-U)Document4 pagesSilent Hill 2 (NTSC-U)عمر عمرNo ratings yet

- G0860Document68 pagesG0860Jon MorenoNo ratings yet

- IZHMSH Baikel ManualDocument26 pagesIZHMSH Baikel ManualtiberiansonNo ratings yet

- Gungeoneer ReduxDocument8 pagesGungeoneer ReduxDavid Ash100% (1)

- Ballistics ReaderDocument8 pagesBallistics ReaderDana Althea AlgabreNo ratings yet

- 220 2 .55Document15 pages220 2 .55ol_49erNo ratings yet

- Mc9 T Titanium: Caliber Operating System Firing System Length Height Width WeightDocument40 pagesMc9 T Titanium: Caliber Operating System Firing System Length Height Width WeightStefani CarvalhoNo ratings yet

- DM Screen 1 PDFDocument4 pagesDM Screen 1 PDFmaszerkNo ratings yet

- Yllana Bay View College: Balangasan District Pagadian CityDocument9 pagesYllana Bay View College: Balangasan District Pagadian CityElla BanlasanNo ratings yet

- Marvel d616 RPG Playtest - Update 1.21Document15 pagesMarvel d616 RPG Playtest - Update 1.21taha onurNo ratings yet

- FN-303 Ammo OptionsDocument10 pagesFN-303 Ammo Optionsreeder45960No ratings yet

- Akdal Mka 1919 PDFDocument28 pagesAkdal Mka 1919 PDFSerteco Coleccionista MilitariaNo ratings yet

- Arcane Artillery FirearmsDocument9 pagesArcane Artillery FirearmssomethingNo ratings yet

- Manuel D'utilisation Et Entretien Benelli NovaDocument42 pagesManuel D'utilisation Et Entretien Benelli NovaAlvaro Serrano GómezNo ratings yet

- Confidential Gunsmith Work Suggested Pricing GuideDocument3 pagesConfidential Gunsmith Work Suggested Pricing GuideapostadoNo ratings yet

- Derya Hunting Catalog 2011Document2 pagesDerya Hunting Catalog 2011Mario LopezNo ratings yet

- Dark Streets & Darker Secrets - Plain Text PDFDocument165 pagesDark Streets & Darker Secrets - Plain Text PDFWilliam Henry Caddell100% (2)

- For The Toughest Hunts and The Toughest Hunters, It's Just A Better GunDocument15 pagesFor The Toughest Hunts and The Toughest Hunters, It's Just A Better GunJeremi LeeNo ratings yet

- Manual CatalogDocument31 pagesManual Catalogwddrf100% (1)

- Microlite20 Modern - Pocketmod PDFDocument2 pagesMicrolite20 Modern - Pocketmod PDFTanner YeaNo ratings yet

- Stoeger Over & Under Shotgun Owners ManualDocument6 pagesStoeger Over & Under Shotgun Owners Manualrick55_55100% (1)

- 12 PhenomaDocument42 pages12 PhenomaMarcelo MarquesNo ratings yet

- Tavor Ts12 Shotgun: Operator ManualDocument67 pagesTavor Ts12 Shotgun: Operator ManualRicardo C TorresNo ratings yet

- Rugers 2004 Firearms CatalogDocument52 pagesRugers 2004 Firearms CatalogPlainNormalGuy2No ratings yet

- Guns and Ammo BasicsDocument2 pagesGuns and Ammo Basicswqrew321No ratings yet

- Fosc-Chapter-1-3 4Document10 pagesFosc-Chapter-1-3 4buddy helpsNo ratings yet

- Mothership Hive Mind (Issue 01)Document40 pagesMothership Hive Mind (Issue 01)NAGIRYANo ratings yet

- Manual Boys ScoutDocument170 pagesManual Boys Scoutmatias primeroNo ratings yet

- Myz ArtefatosDocument11 pagesMyz ArtefatosEdu BrunoNo ratings yet