Professional Documents

Culture Documents

WSystem Diagram PDF

Uploaded by

johnstockton9876Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WSystem Diagram PDF

Uploaded by

johnstockton9876Copyright:

Available Formats

SYSTEM DIAGRAMS

September 2012

31

SYSTEM DIAGRAMS

32

September 2012

SYSTEM DIAGRAMS

September 2012

33

SYSTEM DIAGRAMS

34

September 2012

SYSTEM DIAGRAMS

September 2012

35

SYSTEM DIAGRAMS

Return to Outdoor Furnace

Plate Information

The popularity of brazed plate heat exchangers lies in their small size and highly efcient heat transfer surface. Brazed plate heat exchangers begin as stainless steel plates specially embossed to critical tolerances. The embossed surface increases uid turbulence, thereby increasing the heat transfer coefcient and lowering potential fouling. The plates are stacked for maximum use of the surface area and to form two independent circuits running in alternating layers. The two uid circuits are congured to ow in opposite directions (counterow) to further enhance the dissipation of heat. This honeycomb of passages provides high heat transfer, low uid pressure drop and complete separation of the two uids. The assembled units are then brazed in a vacuum furnace for consistent quality. As a nal step, a helium pressure test is used to ensure leak-free performance. The result is a very rugged, highly efcient and reliable heat exchanger, built to last. Brazed plate heat exchangers are available in a variety of sizes and plate congurations (see page 7).

Up to 60-percent smaller than traditional devices. Higher heat transfer coefcients and lower fouling rates. Costs less than traditional devices. Easier to install and connect.

Smaller Size

High Performance

Lower Installation Cost Easy Installation

Smaller size and less weight makes it easier and more inexpensive to transport.

Lower Shipping Cost

36

September 2012

SYSTEM DIAGRAMS

September 2012

37

SYSTEM DIAGRAMS

for E-Classic 1400, E-Classic 1450, E-Classic 2400 and E-Classic 3200

38

September 2012

DIMENSIONS AND MEASUREMENTS

September 2012

39

DIMENSIONS AND MEASUREMENTS

40

September 2012

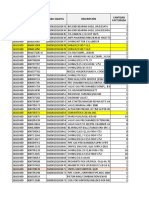

SAMPLE PARTS LIST

NOTE: These lists are intended to be examples only. Actual installations will vary. See your dealer if you have questions concerning your application.

Sample Parts List for Forced-Air Heating System

DESCRIPTION

QTY.

1 1 1 1 1 1 1 1 1 1 1 6 6 6 20 1 1 1 1 1 1 1 1 1 1 2 2

P/N

107 591 2053 326 171 224 588 198 118 296 1330 1333 1334 5978 2441 1302 2443 6593 556 1650 297 299 300 308 1548 6054 3042

Central Boiler Outdoor Wood Furnace Heat Exchanger Coil, 125k Btu Side-Arm Heat Exchanger Kit Fittings Kit Water Heater Mixing Valve, 3/4" Taco 007 Pump Isolation Flange Kit, 3/4" 24-Volt Thermostat Ball Valve, 3/4" Nipple, 3/4" x close Brass Swing Check Valve, 3/4" PEX Adapter, 1" PEX x 3/4" MIP PEX Coupling, 1" PEX 90 Elbow, 1" Central Boiler Clamp, 1" 100' ThermoPEX Pipe, 1" Central PEX 1" Pipe, ve 10' straight sections ThermoPEX Cap, 1" Grounding Rod Kit (supplied standard with E-Classic and Maxim models) Power Supply Cord, 32" Corrosion Inhibitor Plus (amount varies per model; see Owner's Manual) Ashtrol, 6.25 lb Ash Shovel Ash Rake Hoe Thermostatic Valve Fittings Kit, 3/4" Temperature Gauge (optional) Brass Hex Bushing (optional)

QTY.

1 1 1 1 1 1 1 4 8 10 1 1 1 1 1 2 1 1 1 1

323 322 106 171 224 1267 198 1334 1330 5978 199 133 556 296 118 6764 1544 1548 6054 3042

P/N

Sample Parts List for Additional Buildings

Transition Fan Heat Exchanger Coil, 100k Btu Taco 007 Pump Isolation Flange Kit, 3/4" Line Voltage Thermostat Ball Valve, 3/4" PEX 90 Elbow, 1" PEX Adapter, 1" PEX x 3/4" MIP Central Boiler Clamp, 1" Brass Hose Bib, 3/4" MPT Black Tee, 3/4" NPT Power Supply Cord, 32" Brass Swing Check Valve, 3/4" Nipple, 3/4" x close Brass Offset Tee, 4" Thermostatic Valve, 3/4" Thermostatic Valve Fittings Kit, 3/4" Temperature Gauge (optional) Brass Hex Bushing (optional) 41

DESCRIPTION

September 2012

SAMPLE PARTS LIST

Parts List

QTY. P/N DESCRIPTION

42

September 2012

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Traulsen RDT - ADT Refrigerator-FreezerDocument4 pagesTraulsen RDT - ADT Refrigerator-Freezerwsfc-ebayNo ratings yet

- Tornado 1300 GIIIDocument46 pagesTornado 1300 GIIIFeRFer (FeRFEr)No ratings yet

- Saes L 132Document16 pagesSaes L 132Ali Aldubaikhi100% (1)

- Directory of Suppliers To Cement Industry: Product Category-WiseDocument1 pageDirectory of Suppliers To Cement Industry: Product Category-WiseAneeshNo ratings yet

- Crane Parts PDFDocument931 pagesCrane Parts PDFNavarro Nayra100% (1)

- Chapter 2 Poisson's RatioDocument9 pagesChapter 2 Poisson's RatioMalik Umar KhakhNo ratings yet

- Airplane Flight Manual Z 242 LDocument40 pagesAirplane Flight Manual Z 242 LFeksesNo ratings yet

- trsl0261 0510Document2 pagestrsl0261 0510Darrinel Perez CcordovaNo ratings yet

- Hornos Keen OvensDocument8 pagesHornos Keen Ovensjinyuan74No ratings yet

- Safety in Welding and CuttingDocument33 pagesSafety in Welding and CuttingBhavya ShuklaNo ratings yet

- Shear Modulus of GravelDocument9 pagesShear Modulus of GravelSajjadNo ratings yet

- MT4400 Front Brakes (Carlisle)Document15 pagesMT4400 Front Brakes (Carlisle)Brian CareelNo ratings yet

- External FlowsDocument90 pagesExternal FlowsSüleyman BirgiNo ratings yet

- 3tz PDFDocument4 pages3tz PDFWilfredo AchoNo ratings yet

- MGT Turbec t100 CCDocument28 pagesMGT Turbec t100 CCDk DamoNo ratings yet

- Camion Articulado 730C2 Plano HYD 2016 SISDocument2 pagesCamion Articulado 730C2 Plano HYD 2016 SISFabrizio Jesus Morales SalirrosasNo ratings yet

- 1000-0046 - EN Transportation of Type 6Document22 pages1000-0046 - EN Transportation of Type 6AmeerudinSiddiquiNo ratings yet

- NPCP Chapter 6Document6 pagesNPCP Chapter 6Cristian OmacNo ratings yet

- Axial Deformation On FramesDocument31 pagesAxial Deformation On FramesAndy OretaNo ratings yet

- FRP DN 1500 - Google SearchDocument2 pagesFRP DN 1500 - Google SearchThanga PandiNo ratings yet

- Comparativo Llegada Stock de Seguridad 14012023Document6 pagesComparativo Llegada Stock de Seguridad 14012023Jesus Sarmiento VillanuevaNo ratings yet

- BCA Annual Testing Report (Full Load)Document3 pagesBCA Annual Testing Report (Full Load)Shen WeijianNo ratings yet

- Dynamics AssignmentDocument3 pagesDynamics AssignmentSid MenonNo ratings yet

- Chapter 22A - Sound WavesDocument24 pagesChapter 22A - Sound Wavesqwivy.comNo ratings yet

- Ceng60 A2021 Module 1aDocument5 pagesCeng60 A2021 Module 1aKurt Francis AcostaNo ratings yet

- Manual John Deere 244JDocument18 pagesManual John Deere 244JYoriel GuzmanNo ratings yet

- Wear of RailsDocument13 pagesWear of RailsMusanif Ahmed FarooqiNo ratings yet

- 4301 L 2 - 2006Document23 pages4301 L 2 - 2006Indra H BasriNo ratings yet

- UNIT-3 Part-A 1. Write Short Notes On Mixture Requirements of SI EnginesDocument27 pagesUNIT-3 Part-A 1. Write Short Notes On Mixture Requirements of SI EnginesJVCNo ratings yet