Professional Documents

Culture Documents

Royal Belgian Institute of Marine Engineers Basic Ship Propulsion Principles

Uploaded by

papaki2Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Royal Belgian Institute of Marine Engineers Basic Ship Propulsion Principles

Uploaded by

papaki2Copyright:

Available Formats

Royal Belgian Institute of Marine Engineers

Basic Principles of Ship Propulsion

DieselFactspresentsextractsfromanewlyupdatedMANDiesel&Turbotechnicalpaper ThisupdatedpaperhasbeenwrittenbyBirger Jacobsen,SeniorTwoStrokeResearchEngineer, basedinCopenhagen.

HeavyWavesandSeaandWindAgainst

When sailing in heavy seas with much wave resistance, the propeller can be up to 78% heavier running than in calm weather, i.e. at the same propeller power, the rate of revolution may be 7 8%lower. In order to avoid slamming of the ship in bad weather conditions, and thereby damage to the stemandracingofthepropeller,theshipspeedwill normally be reduced by the navigating officer on watch. A valid example for a smaller ship based on calculations is shown in Fig. 1. This example shows Fig.1:Influenceofseamarginonasmallshipsailingat14knots for a given reduced ship speed of 14 knots the influenceofincreasedresistancecausedbyheavyweatherandfoulingexpressedasincreasedseamargin.

StandardEngineLoadDiagram

Definitions Theloaddiagram(Fig.2)definesthepowerandspeedlimitsforthecontinuousaswellasoverloadoperationof aninstalledengine,whichhasaspecifiedMCRpointMthatconformstotheship'sspecification. Normally,pointMisequaltotheMCRpropulsionpointMP,butincaseswhereashaftgeneratorisinstalled, pointMmayincorporatetheenginepowerrequiredforshippropulsionMPandfortheshaftgeneratorSG,if installed.Duringshoptestrunning,theenginewillalwaysoperatealongcurveI,withpointMas100%SMCR.If CPpropellerandconstantspeedoperationisrequired,thedeliverytestmaybefinishedwithaconstantspeed test. LimitstoContinuousOperation The continuous service range is limited by the four lines4,5,7,3and,inextraordinarycases,9.SeeFig. 2. Line3andline9: Line 3:Represents the maximum acceptable speed for continuous operation, i.e. 105% of M. During seatrial conditions the maximum speed may be extended to 107% of M, see line 9. The above limits may, in general, be extended to 105% and, during seatrial conditions, to 107% of the nominal L1 speed of the engine, provided torsional vibration conditionspermit. The overspeed setpoint is 109% of the speed in M, however, it may be moved to 109% of the nominal speed in L1, provided that torsional vibration conditionspermit. Running at low load above 100% of the nominal L1 speed of the engine is, however, to be avoided for extendedperiodsoftime. Line 4: Represents the limit at which an ample air supply is available for combustion and imposes a limitation on the maximum combination of torque andspeed. Line 5: Represents the maximum mean effective pressure level (mep) which can be accepted for continuousoperation. Line 7: Represents the maximum power for Fig.2:Standardengineloaddiagram continuousoperation.

Royal Belgian Institute of Marine Engineers

Line10:Representsthemeaneffectivepressure(mep)lines. Line5isequaltothe100%mepline.Themeplinesarealsoanexpressionofthecorrespondingfuelindexofthe engine. LimitsforOverloadOperation Theoverloadservicerangeislimitedasfollows,seeFig.2.Line8:Representstheoverloadoperationlimitation. Theareabetweenlines4,5,7andthedashedline8inFig.2isavailableforoverloadrunningforlimitedperiods only(1hourper12hours). Recommendation Continuous operation without a time limitation is allowed only within the area limited by lines 4, 5, 7 and 3 of the load diagram. For fixed pitch propeller operation in calm weather with loaded ship and clean hull, the propeller/engine may run along or closetothepropellerdesigncurve6. After some time in operation, the ship's hull and propeller will become fouled, resulting in heavier running of the propeller, i.e. the propeller curve will move to the left from line 6 towards line 2, and extra power will be required for propulsion in order to maintain the ship speed. In calm weather conditions the extent of heavy running of the propeller will indicate the need for cleaning the hull and,possibly,polishingthepropeller. The area between lines 4 and I is available for operation in shallow water, heavy weather and during acceleration, i.e. for nonsteady operation withoutanyactualtimelimitation. The recommended use of a relatively high light running factor for design of the propeller will involve that a relatively higher propeller speed will be used for layout design of the propeller. This, in turn,mayinvolveaminorreductionofthepropeller efficiency, and may possibly cause the propeller manufacturer to abstain from using a large light running margin. However, this reduction of the Fig.3:Extendedloaddiagramforspeedderatedenginewithincreased propellerefficiencycausedbythelargelightrunning lightrunning factor is actually relatively insignificant compared with the improved engine performance obtained whensailinginheavyweatherand/orwithfouled hullandpropeller.

ExtendedEngineLoadDiagram

Whenashipwithfixedpitchpropellerisoperatinginnormalseaservice,itwillingeneralbeoperatingaroundthe designpropellercurve6,asshownonthestandardloaddiagraminFig.2.Sometimes,whenoperatinginheavy weather,thefixedpitchpropellerperformancewillbemoreheavyrunning,i.e.forequalpowerabsorptionofthe propeller,thepropellerspeedwillbelowerandthepropellercurvewillmovetotheleft. Asthetwostrokemainenginesaredirectlycoupledtothepropeller,theenginehastofollowthepropeller performance,i.e.alsoinheavyrunningpropellersituations.Forthistypeofoperation,thereisnormallyenough marginintheloadareabetweenline6andthenormaltorque/speedlimitationline4,seeFig.2.Totheleftofline 4intorquerichoperation,theenginewilllackairfromtheturbochargertothecombustionprocess,i.e.theheat loadlimitsmaybeexceededandbearingloadsmightalsobecometoohigh. Forsomespecialshipsandoperatingconditions,itwouldbeanadvantagewhenoccasionallyneededtobe abletooperatethepropeller/mainengineasmuchaspossibletotheleftofline6,butinsidethetorque/speed limit,line4. Suchcasescouldbefor: shipssailinginareaswithveryheavyweather shipsoperatinginice shipswithtwofixedpitchpropellers/twomainengines,whereonepropeller/oneengineisdeclutched foroneortheotherreason.Thus,measurementsshowanapproximate810%heavyrunningofthe remainingpropellerinoperationforatwinskegship.

Royal Belgian Institute of Marine Engineers

Theincreaseoftheoperatingspeedrangebetweenline6andline 4ofthestandardloaddiagrammaybecarried out as shown in Fig. 3 for the extended load diagram for speed derated engine with increased light running. The maximumspeedlimit(line3)oftheenginesis105%oftheSMCRspeed,asshowninFig.2. However, for speed and, thereby, power derated engines it is possible to extend the maximum speed limit to 105% of the engine's nominal L1 speed, line 3', but only provided that the torsional vibration conditions permit this. Thus, the shafting, with regard to torsional vibrations, has to be approved by the classification society in question,basedontheextendedmaximumspeedlimit. Whenchoosinganincreasedlightrunningtobeusedforthedesignofthepropeller,theloaddiagramareamay beextendedfromline3toline3',asshowninFig.3,andthepropeller/mainengineoperatingcurve6mayhavea correspondinglyincreasedheavyrunningmarginbeforeexceedingthetorque/speedlimit,line4.Acorresponding slightreductionofthepropellerefficiencymaybetheresult,duetothehigherpropellerdesignspeedused.

Constantshipspeedlineforincreasedpropellerdiameter

Thelargerthepropellerdiameter,thehigherthepropellerefficiencyandthelowertheoptimumpropellerspeed. A more technically advanced development drive, therefore, is to optimise the aftbody and hull lines of the ship including bulbous bow, also considering operation in ballast condition making it possible to install propellers withalargerpropellerdiameter. The constant ship speed line a shown in Fig. 4 indicate the power required at various propeller speeds to keep the same ship speed provided that the optimum propeller diameter with an optimum pitch diameter ratio is used at any given speed, taking into consideration the total propulsion efficiency. Normally, for a given ship with the same number of propeller blades, but different propeller diameter, the following relation between necessary powerandpropellerspeedcanbeassumed: P2=P1X(n2/n1) where: P=Propulsionpower n=Propellerspeed,and =theconstantshipspeedcoefficient. Fig.4:Layoutdiagramandconstantshipspeedlines.Examplefora Foranycombinationofpowerandspeed,eachpoint Handymaxtankerwithdifferentpropellerdiameters ontheconstantshipspeedlinegivesthesameship speed. When such a constant ship speed line is drawn into the layout diagram through a specified propulsion MCR point 'Ml', selected in the layout area, another specified propulsion MCR point 'M2' upon this line can be chosen to give the ship the same speed for the new combination of engine powerandspeed. Provided the optimum pitch/diameter ratio is used for a given propeller diameter the following dataapplieswhenchangingthepropellerdiameter: For general cargo, bulk carriers and tankers = 0.250.30,andforreefersandcontainervesselsa =0.150.25. Fig. 4 shows an example of the required power and speed point Ml, through which a constant ship speed curve = 0.28 is drawn, obtaining point M2 with a lower engine power and a lower engine speedbutachievingthesameshipspeed. Fig.5:Selectionofnumberofpropellerbladesforashipwithmainengine Thus, when for a handymax tanker increasing the withSMCR=20,000kWx105rpm propellerdiameter,andgoingforexamplefromthe SMCR propeller speed of nM1 = 127 r/min to nM2 = 100 r/min, the propulsion power needed will be p M2 = p M1 x (100/127)0.28= 0.935 x P M1' i.e. involving a power reduction of about 6.5%. In this example, another main engine has been applied, verifying the fuel savings potential of this ultra low speed type engine. When changing the propellerspeedbychangingthepitchdiameterratio,theconstantwillbedifferent.

Royal Belgian Institute of Marine Engineers

Estimationsofengine/propellerspeedatSMCRfordifferentsingle screwFPpropellerdiametersandnumberofpropellerblades

Based on theory and experience, the connections between main engine SMCR power PM' SMCR speed nM and propeller diameter d = Dprop can as guidance be estimatedasfollows: In the constant C, a light running propeller factor of 45% is included. The aboveformulaisvalidforstandardsinglescrewFPpropellertypes. The constant C is an average value found for existing ships (before 2011) and reflectsthedesignshipspeedappliedinthepast. For lower design ship speed which seems to be the coming tendency due to EEDI (Energy Efficiency Design Index) and fuel costs, the constant C will be higher. For an NPT propeller (New Propeller Technology), the estimated, claimedengine/propellerspeednMmightbeapprox.I0%lower.

Numberofpropellerblades

Propellers can be manufactured with 2, 3, 4, 5 or 6 blades. The fewer the number of blades, the higher the propellerefficiencywillbe.However,forreasonsofstrength,propellerswhicharetobesubjectedtoheavyloads cannotbemanufacturedwithonlytwoorthreeblades. Normally 4, 5 and 6bladed propellers are used on merchant ships. In the future maybe 3bladed propellers may be used due to reduced design ship speed. Ships using the MAN B&W twostroke engines are normally largetype vessels which, so far, use at least 4bladed propellers. Ships with a relatively large power requirement and heavily loaded propellers, e.g. container ships, may need 5 or6bladedpropellers. The optimum propeller speed depends on the number of propeller blades. Thus, for the same propeller diameter, a 6bladed propeller has an about 10% lower optimum propeller speed than a 5 bladed. For vibrational reasons, propellers with Fig.6:Exampleofselectionof4bladedFixedPitchpropellerdiameter(All certain numbers of blades may be avoided in figuressourceMANDiesel&Turbo) individual cases in order not to give rise to the excitation of natural frequencies in either the ship's hulloritssuperstructure. The influence of a selected number of propeller blades is shown as an example in Fig. 5 for a ship installed with a main engine with SMCR = 20,000 kW x 105 r/ min. For each number of propeller blades, the corresponding appliedpropellerdiameteraccordingtothepreviousformulaeisshowntoo. Amorecomprehensivepropellerdiameterexample,basedonthementionedformulae,isshowninFig.6andis validfor4bladedFPpropellertypes.BymeansofagivenpropulsionSMCR(powerandspeed)point,itispossible toestimatethecorrespondingFPpropellerdiameter. However, in the upper power and propeller diameter range, it is, for technical reasons, probably necessary to select a 5bladed or 6bladed propeller type with a reduced propeller diameter and lower pressure pulses (vibrations).Someexamplesofmainenginetypes(layoutdiagrams)tobeselectedareshowntoo. ThetextforthisarticleisbasedonextractsfromthenewlyupdatedMANDiesel&Turbopaper"BasicPrinciplesof ShipPropulsion",writtenbyBirgerJacobsen,SeniorTwoStrokeResearchEngineerinCopenhagen.AnM.Sc. graduateoftheTechnicalUniversityofDenmark,Jacobsenjoinedthecompanybackin1969andsince1979has workedintheMarineInstallationDepartment.Hehassincebecometheprolificauthorofvariedtechnicalpapers onengineapplicationsandpropulsiontrendsindifferentvesselsegments.Theoriginalpaperisfreelyavailablein itsentiretyuponrequestfromMANDiesel&Turbo. Source:DIESELFACTS12012 www.mandieselturbo.com

You might also like

- Prop CurveDocument4 pagesProp CurveArun S100% (1)

- A Study On Torque Rich Phenomena in Ship OperationDocument11 pagesA Study On Torque Rich Phenomena in Ship OperationAnonymous XtvvG80zuNo ratings yet

- Slide Fuel Valves Reduce EmissionsDocument5 pagesSlide Fuel Valves Reduce EmissionsParthiban NagarajanNo ratings yet

- Grone PDFDocument25 pagesGrone PDFthis9999No ratings yet

- Tier III SCR For Large 2-Stroke MAN B&W Diesel EnginesDocument6 pagesTier III SCR For Large 2-Stroke MAN B&W Diesel EnginesWon-young SeoNo ratings yet

- MSC Carina Delivery 6 June 2013: Main Engine MAN 6S60ME-C 8.1 AuxiliariesDocument10 pagesMSC Carina Delivery 6 June 2013: Main Engine MAN 6S60ME-C 8.1 AuxiliariesПетрNo ratings yet

- Safety Margin PropellerDocument2 pagesSafety Margin PropellerJaspal Singh Sahota100% (2)

- Shop TestDocument129 pagesShop TestKatsaras Sotiris100% (1)

- Vit and Super VitDocument6 pagesVit and Super VitRavindar Anandan0% (1)

- DLF (Dynamic Limiter Function) Introduction - FE - Rev1.10Document17 pagesDLF (Dynamic Limiter Function) Introduction - FE - Rev1.10Emrah YesiltasNo ratings yet

- MC Engines Service Experience: Cylinder Condition, Design Updates, and Reliability ImprovementsDocument12 pagesMC Engines Service Experience: Cylinder Condition, Design Updates, and Reliability ImprovementsHarpreet Singh100% (1)

- DieselFacts 2008-1 PDFDocument16 pagesDieselFacts 2008-1 PDFAsh Kai100% (1)

- Cleaning FIVA ValvesDocument5 pagesCleaning FIVA ValvesValeriy DomashenkoNo ratings yet

- How to Check and Adjust Bumping Clearance in Air CompressorsDocument5 pagesHow to Check and Adjust Bumping Clearance in Air CompressorsAnurag KUMAR0% (1)

- Propeller slip calculationDocument7 pagesPropeller slip calculationBorislav PetrovNo ratings yet

- Training Book-CE Aung BaDocument176 pagesTraining Book-CE Aung BaPhyo Thiha KyawNo ratings yet

- SFOC Optimization Methods - For MAN B&W Two-Stroke IMO Tier II EnginesDocument16 pagesSFOC Optimization Methods - For MAN B&W Two-Stroke IMO Tier II EnginesTimmyJuriNo ratings yet

- Examples of HCU Events From ME-ECS Ver 0, Training Material PDFDocument19 pagesExamples of HCU Events From ME-ECS Ver 0, Training Material PDFПетрNo ratings yet

- Main EngineDocument10 pagesMain EngineFe CaprichoNo ratings yet

- Starting - Reversing Problems in Marine EnginesDocument6 pagesStarting - Reversing Problems in Marine EnginesTarek AzizNo ratings yet

- Slide Fuel ValvesDocument2 pagesSlide Fuel ValvesSpasoje100% (1)

- MAN B&W Two-Stroke Service Experience Imabari & Tokyo - November 2014Document69 pagesMAN B&W Two-Stroke Service Experience Imabari & Tokyo - November 2014Joseph AbrahamNo ratings yet

- Lambda Controller and Jet Assist System On ShipsDocument8 pagesLambda Controller and Jet Assist System On ShipsSwarg VibhaNo ratings yet

- Man B&W Cold CorrosionDocument36 pagesMan B&W Cold Corrosionjatin jain100% (1)

- MAN B&W Diesel A/S: Service LetterDocument2 pagesMAN B&W Diesel A/S: Service Letterflorin100% (1)

- S70MC-C8 2 PDFDocument348 pagesS70MC-C8 2 PDFVuich ToanNo ratings yet

- 1 - 50-108 Me-Me-C Operation (D2378a)Document660 pages1 - 50-108 Me-Me-C Operation (D2378a)SimonaMauna100% (3)

- MEO Class I OralsDocument2 pagesMEO Class I OralsGurvindarNo ratings yet

- 1 Eng Performance 2Document17 pages1 Eng Performance 2Virdhaval JadhavNo ratings yet

- Reversing Gears of A Marine Diesel EngineDocument4 pagesReversing Gears of A Marine Diesel Engineashry_tarekNo ratings yet

- Guidance For Sox Emissions Reduction and Fo Change Over ProceduresDocument13 pagesGuidance For Sox Emissions Reduction and Fo Change Over Proceduresnikbatist100% (1)

- Bearing Failure Service LetterDocument7 pagesBearing Failure Service LetterAurvin SinghNo ratings yet

- Man B&W SL2007-479Document7 pagesMan B&W SL2007-479Charalampos BarNo ratings yet

- Maersk - Cylinder ConditionDocument64 pagesMaersk - Cylinder ConditionDondigidonNo ratings yet

- 18 Service Experience Me Gi EnginesDocument61 pages18 Service Experience Me Gi EnginesCharalampos Soultatis100% (2)

- MAN B&W SUPER VIT - Marine InboxDocument9 pagesMAN B&W SUPER VIT - Marine InboxИгорьNo ratings yet

- Mim Wingd x72Document172 pagesMim Wingd x72hihihi100% (1)

- 08 Exhaust Valve System (Maj 2015)Document42 pages08 Exhaust Valve System (Maj 2015)Alexandru AlexNo ratings yet

- Ce Handing OverDocument10 pagesCe Handing OverAkhilvjohnNo ratings yet

- 5510 0101 01ppr - LowDocument30 pages5510 0101 01ppr - LowFuchsbauNo ratings yet

- MAN-PMI Off PDFDocument92 pagesMAN-PMI Off PDFarunNo ratings yet

- HIMSEN Engine Operation With Low Sulphur FuelDocument18 pagesHIMSEN Engine Operation With Low Sulphur FuelPipis FakidomitisNo ratings yet

- Low Load and Low Sulphur Fuel Operation On Two Stroke Diesel EnginesDocument51 pagesLow Load and Low Sulphur Fuel Operation On Two Stroke Diesel EnginesTziouris Vasileios100% (1)

- Five Methods of Putting a Single Cylinder Out of OperationDocument4 pagesFive Methods of Putting a Single Cylinder Out of OperationAnakin SkywalkerNo ratings yet

- Cargo Handling Manual - SOE 12k LEG (01-TECHNICAL - 1304275 - 1 - 01) PDFDocument283 pagesCargo Handling Manual - SOE 12k LEG (01-TECHNICAL - 1304275 - 1 - 01) PDFМаксим Шабатын100% (2)

- Maintenance of Alpha Lubricator SystemDocument6 pagesMaintenance of Alpha Lubricator SystemGeorgios Papakostas100% (1)

- BB. Docking Indent (Repair) Pioneer. 13th Feb.20Document11 pagesBB. Docking Indent (Repair) Pioneer. 13th Feb.20Thiet PhamNo ratings yet

- Cylinder Liner Cold Corrosion ControlDocument8 pagesCylinder Liner Cold Corrosion ControlarunNo ratings yet

- Wislab Excessive Liner WearDocument13 pagesWislab Excessive Liner WearGeorgios PapakostasNo ratings yet

- Performance CurvesDocument4 pagesPerformance Curvessevero97No ratings yet

- ME Engines – The New Generation of Electronically Controlled Diesel EnginesDocument21 pagesME Engines – The New Generation of Electronically Controlled Diesel Enginesiuliiulian100% (1)

- Int Eng Prospects MAN BWDocument19 pagesInt Eng Prospects MAN BWWsm HNNo ratings yet

- Fuel Change Over Procedure-1Document4 pagesFuel Change Over Procedure-1Radu IchimNo ratings yet

- About Me-B - enDocument25 pagesAbout Me-B - enMannMannNo ratings yet

- Stuffing BoxDocument6 pagesStuffing BoxrajishrrrNo ratings yet

- The difference between M.C.R and C.S.R ratingsDocument2 pagesThe difference between M.C.R and C.S.R ratingsRavindra kumarNo ratings yet

- 514 614 L28 32H Fuel Oil SystemDocument30 pages514 614 L28 32H Fuel Oil SystemFlo MarineNo ratings yet

- Marine Combustion Practice: The Commonwealth and International Library: Marine Engineering DivisionFrom EverandMarine Combustion Practice: The Commonwealth and International Library: Marine Engineering DivisionRating: 5 out of 5 stars5/5 (1)

- RT 119Document9 pagesRT 119papaki2No ratings yet

- RT 113 Issue3Document14 pagesRT 113 Issue3papaki2No ratings yet

- RT 110 Issue2Document30 pagesRT 110 Issue2papaki2100% (1)

- Macgregor Gl4028 2 PDFDocument454 pagesMacgregor Gl4028 2 PDFpapaki2100% (6)

- 692D Guidelines Marine DesignersDocument9 pages692D Guidelines Marine Designerspapaki2No ratings yet

- Service Manual Damcos Local Power Unit en 60632 1 PDFDocument144 pagesService Manual Damcos Local Power Unit en 60632 1 PDFpapaki2100% (1)

- General Information: RT-86 Wärtsilä 2-StrokeDocument6 pagesGeneral Information: RT-86 Wärtsilä 2-Strokepapaki2No ratings yet

- AalborgDocument61 pagesAalborgChristopher King50% (2)

- Child Sexual AbuseDocument7 pagesChild Sexual Abusepapaki2No ratings yet

- Macgregor Gl4028 2 PDFDocument454 pagesMacgregor Gl4028 2 PDFpapaki2100% (6)

- Service Experience PDFDocument36 pagesService Experience PDFpapaki2No ratings yet

- ABB Generations - 19 Emma Ship Energy Manager PDFDocument8 pagesABB Generations - 19 Emma Ship Energy Manager PDFpapaki2No ratings yet

- ABB Generations - 19 Emma Ship Energy Manager PDFDocument8 pagesABB Generations - 19 Emma Ship Energy Manager PDFpapaki2No ratings yet

- Technical InformationDocument6 pagesTechnical Informationpapaki2No ratings yet

- Installation Manual for Inmarsat FleetBroadband Satellite Communication TerminalDocument113 pagesInstallation Manual for Inmarsat FleetBroadband Satellite Communication Terminalpapaki2100% (3)

- A Brief Introduction To Ship Performance ManagementDocument44 pagesA Brief Introduction To Ship Performance Managementpapaki2No ratings yet

- Conversion of tankers into heavy lift vesselsDocument26 pagesConversion of tankers into heavy lift vesselspapaki2No ratings yet

- Basic Principle of Ship PropulsionDocument45 pagesBasic Principle of Ship PropulsionShengte Hsu100% (7)

- The Atlas of WaterDocument16 pagesThe Atlas of Waterpapaki2No ratings yet

- Analysis of The Effect of The New EEDI Requirements On Dutch Build and Flagged ShipsDocument46 pagesAnalysis of The Effect of The New EEDI Requirements On Dutch Build and Flagged Shipspapaki2No ratings yet

- STRATFORGreece MonographDocument11 pagesSTRATFORGreece MonographstratilatisNo ratings yet

- F Fa Al LK K ™ ™ Q Qu Ua Ad DR Ri IV Ve e ® ® S SH Ha Af FT T M Mo Ou Un NT Te Ed D D DR Ri IV Ve e ( (E en NG GL Li Is SH H - M Me Et TR Ri Ic C) )Document56 pagesF Fa Al LK K ™ ™ Q Qu Ua Ad DR Ri IV Ve e ® ® S SH Ha Af FT T M Mo Ou Un NT Te Ed D D DR Ri IV Ve e ( (E en NG GL Li Is SH H - M Me Et TR Ri Ic C) )papaki2No ratings yet

- ITTC Trials AnalysisDocument15 pagesITTC Trials Analysispapaki2100% (1)

- The ATLAS of Food.Document16 pagesThe ATLAS of Food.papaki2No ratings yet

- Hall EffectDocument64 pagesHall Effectpapaki2No ratings yet

- Hull Thickness Measurement - Lloyds RegisterDocument66 pagesHull Thickness Measurement - Lloyds RegisterRuano Andreola StumpfNo ratings yet

- News in Focus: US Suspends Risky Disease ResearchDocument2 pagesNews in Focus: US Suspends Risky Disease Researchpapaki2No ratings yet

- Environmental SolutionsDocument16 pagesEnvironmental Solutionspapaki2No ratings yet

- Navigational Infrigement Fine in Geogian Waters 14th November 2014Document1 pageNavigational Infrigement Fine in Geogian Waters 14th November 2014papaki2No ratings yet

- Sony+hvr-Hd1000 Service ManualDocument426 pagesSony+hvr-Hd1000 Service ManualLeandroGoulartNo ratings yet

- WEWW Website User Manual V1.3Document18 pagesWEWW Website User Manual V1.3Digital PineNo ratings yet

- Bizgram Export FileDocument58 pagesBizgram Export FileBizgram Asia0% (1)

- Action Plans and EU Acquis Progress Report 2023 WEBDocument212 pagesAction Plans and EU Acquis Progress Report 2023 WEBRaza KandicNo ratings yet

- Gun PowderDocument20 pagesGun Powderkimberlyn odoñoNo ratings yet

- Customer Portal - User Manual 2021-07Document58 pagesCustomer Portal - User Manual 2021-07Nurul HidayatNo ratings yet

- Biometrically Secured ATM Vigilance SystemDocument4 pagesBiometrically Secured ATM Vigilance SystemSoundaryaNo ratings yet

- Android Studio Cookbook - Sample ChapterDocument21 pagesAndroid Studio Cookbook - Sample ChapterPackt Publishing100% (1)

- CV-JM Van StraatenDocument5 pagesCV-JM Van StraatenJovan Van StraatenNo ratings yet

- Microdis IPC 2.0Document16 pagesMicrodis IPC 2.0jimNo ratings yet

- Chemgineering OGLASDocument2 pagesChemgineering OGLASSrdjanNo ratings yet

- Resume NovemberDocument2 pagesResume Novemberpeter_f_murphyNo ratings yet

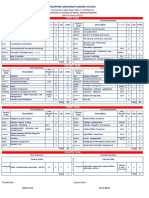

- Philippine Merchant Marine School: First YearDocument5 pagesPhilippine Merchant Marine School: First YearCris Mhar Alejandro100% (1)

- DS-2TD4136-25/50: Thermal & Optical Bi-Spectrum Network Speed DomeDocument5 pagesDS-2TD4136-25/50: Thermal & Optical Bi-Spectrum Network Speed Domeal lakwenaNo ratings yet

- Ge Oil and Gas-Rtpu-8, 9, 60 Tr-prx080Document1 pageGe Oil and Gas-Rtpu-8, 9, 60 Tr-prx080syed mustafa aliNo ratings yet

- Inspection ControlDocument10 pagesInspection ControlIvan D. RiveraNo ratings yet

- 1 Gbps Wireless Link in 5 GHZ Radio Frequency BandDocument4 pages1 Gbps Wireless Link in 5 GHZ Radio Frequency BandAnkan RoyBardhanNo ratings yet

- Piping Speciality ItemDocument29 pagesPiping Speciality Itemshoghi wisesaNo ratings yet

- How To Program by RS232: Projection Display Serial Interface 7-1. RS232 SettingDocument9 pagesHow To Program by RS232: Projection Display Serial Interface 7-1. RS232 SettingShubham PanchalNo ratings yet

- Autonomous Vehicles RRLDocument8 pagesAutonomous Vehicles RRLDominique LopenaNo ratings yet

- Maipu MannualDocument12 pagesMaipu MannualKazi BarakatNo ratings yet

- Manufacturing Process LabDocument9 pagesManufacturing Process LabJing HengNo ratings yet

- Melt Viscometer For PET Testing Intrinsic Viscosity (IV) and Melt Viscosity (MV) MeasurementDocument3 pagesMelt Viscometer For PET Testing Intrinsic Viscosity (IV) and Melt Viscosity (MV) MeasurementAnjum ParkarNo ratings yet

- Assignment 3Document5 pagesAssignment 3kevin0% (2)

- Vivado Basic TutorialDocument30 pagesVivado Basic Tutorial8885684828No ratings yet

- GPS World 2020-01Document54 pagesGPS World 2020-01Diego FrancoNo ratings yet

- Batch Rm111 en PDocument538 pagesBatch Rm111 en PFranky RiveroNo ratings yet

- Precios MayoDocument230 pagesPrecios Mayoeuronet_seNo ratings yet

- Syscomp Circuit Gear MiniDocument62 pagesSyscomp Circuit Gear MinidizpozNo ratings yet

- AVCCDocument3 pagesAVCCTanya WilkersonNo ratings yet