Professional Documents

Culture Documents

Roll Crusher 1 Single

Uploaded by

Bobby A. PalemOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Roll Crusher 1 Single

Uploaded by

Bobby A. PalemCopyright:

Available Formats

GENTLE

SINGLE

CRUSHING

ROLL

CRUSHER

ENGLISH

T H E F I E L D S O F A P P L I C AT I O N Single roll crushers are used for grain size reduction for products ranging from soft to medium-hard.

T H E F E E D M AT E R I A L S Coal, coke, salt, slag, marl, chalk, chemical and similar products.

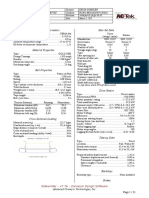

Single roll crusher with V-belt drive, type 2311, size 2311/06-05, featured with crushing ledges.

T H E M O D E O F O P E R AT I O N The single roll crusher reduces the feeding material in a wedge-shaped crushing area by means of pressure and shearing stress. The crushing body is formed by a rotating roll and an adjustable and spring-mounted crushing plate located on the opposite side. The distance between the base of the crushing plate and the tips of the roll crushers teeth forms the adjustable gap width, which can be varied depending on the required final grain size. Any wear and tear which may occur can be adjusted via the crushing plate. Depending on the feeding material and the required final grain, the roll crusher is equipped with either teeth or ledges. The crushing plate is equipped with a replaceable comb plate.

THE SPECIAL CHARACTERISTICS The crushing roll is firmly fixed onto the base frame of the machine. The crushing rings, shells or ledges, made of a special casting, are mounted up or bolted on the body of the roll of welded construction. The crusher shaft, made of high-grade steel, is arranged on amply dimensioned spherical roller bearings. The bearing housings are protected against dust and dirt by means of lubricated labyrinths. To adjust the gap width, the crushing plate is set by using thread spindles. The spring elements provide initial tension for the crushing force and serve simultaneously as overload protection. The machine can either be powered hydraulically, by belt drive or by a slip-on gear motor.

T H E A D VA N TA G E S high and constant capacity low susceptibility to breakdowns long lifetime easy replacement of wear and spare parts wide range of application high crushing grade with a minimum of fine grains

T H E S C O P E O F A P P L I C AT I O N Capacity: Feeding size: Final grain size: up to 400 m 3/h up to approx. 800 mm 15 -150 mm depending on the feed material and its size up to 1 : 6 up to 200 kW

Reduction ratio: Required drive:

AUBEMA MASCHINENFABRIK GMBH KLNER STRASSE 94 D-51702 BERGNEUSTADT TEL.: +49 (0)2261/4094-0 FAX: -325 E- MAIL: INFO@AUBEMA.DE INTERNET: WWW.AUBEMA.COM

You might also like

- Double Roll CrusherDocument3 pagesDouble Roll CrusherjtpmlNo ratings yet

- Double Roll CrusherDocument6 pagesDouble Roll Crusherjaswanth60% (5)

- Roll Crusher BrochureDocument4 pagesRoll Crusher BrochureWaris La Joi Wakatobi100% (1)

- Lecture 7 SlidesDocument59 pagesLecture 7 SlidesHasil SharmaNo ratings yet

- VibratingEquipmentBrochure PDFDocument10 pagesVibratingEquipmentBrochure PDFWilliam VillamizarNo ratings yet

- DFZC 7985 1 91 en - GB 1211Document4 pagesDFZC 7985 1 91 en - GB 1211RogerioNo ratings yet

- Design Hammer Pivoted To RotorDocument5 pagesDesign Hammer Pivoted To RotorsubhendujenaNo ratings yet

- Feeder Breaker 1200mtph Project01!08!08Document3 pagesFeeder Breaker 1200mtph Project01!08!08Herman AbdullahNo ratings yet

- Gundlach Roll Crushers BrochureDocument2 pagesGundlach Roll Crushers Brochurerajeevup2004No ratings yet

- Brochure Hammer Mill Granulex DFZP FB19230 enDocument6 pagesBrochure Hammer Mill Granulex DFZP FB19230 enmuhammadnainNo ratings yet

- Double Roller CrusherDocument14 pagesDouble Roller CrusherFavorSea Industrial Channel LimitedNo ratings yet

- Smalis Radial Stacker ManualDocument61 pagesSmalis Radial Stacker Manualmacross086100% (1)

- 2010 - Telescopic ChuteDocument29 pages2010 - Telescopic ChutesteelageNo ratings yet

- I Feeder Application Design CalculationsDocument2 pagesI Feeder Application Design Calculationsarsaniose100% (1)

- Ypt Paletli Brosur 3 PDFDocument4 pagesYpt Paletli Brosur 3 PDFarsanioseNo ratings yet

- Engineered Steel ChainsDocument140 pagesEngineered Steel ChainsCarlos Castañeda HernándezNo ratings yet

- Smooth Double Roll CrusherDocument4 pagesSmooth Double Roll CrusheradehriyaNo ratings yet

- Pulley CatalogDocument36 pagesPulley CatalogTito FuentesNo ratings yet

- Bearing Centre and Face Width in Conveyor PulleyDocument8 pagesBearing Centre and Face Width in Conveyor PulleyPrashant MishraNo ratings yet

- Telestack Hopper Feeders Brochure 2017Document16 pagesTelestack Hopper Feeders Brochure 2017Alok MehtaNo ratings yet

- Feeder BreakerDocument10 pagesFeeder BreakerAmit BhaduriNo ratings yet

- Chain Drive: NO. of Teeths On Driving Sprocket No. of Teeths On Driven Sprocket Engine Power Service FactorDocument3 pagesChain Drive: NO. of Teeths On Driving Sprocket No. of Teeths On Driven Sprocket Engine Power Service FactorSUMEET SINGHNo ratings yet

- CP6 Chain FeederDocument119 pagesCP6 Chain Feederdeddy ariyantoNo ratings yet

- 50055781Document14 pages50055781Monu SharmaNo ratings yet

- 243 BUI 1047 BCI Conveyor Belt CatalogDocument19 pages243 BUI 1047 BCI Conveyor Belt CatalogBayu SuprayogiNo ratings yet

- Aa Spec 331001Document13 pagesAa Spec 331001Mardi RahardjoNo ratings yet

- Sample - Belt Bucket Elevator DesignDocument7 pagesSample - Belt Bucket Elevator DesignAli DandamunNo ratings yet

- Natural Frequency Vibrating ConveyorsDocument8 pagesNatural Frequency Vibrating ConveyorsZiggy GregoryNo ratings yet

- AF Apron Feeder: Key BenefitsDocument2 pagesAF Apron Feeder: Key BenefitsIle JieNo ratings yet

- TeleStacker® ConveyorDocument4 pagesTeleStacker® ConveyorSuperior IndustriesNo ratings yet

- A Double Roll Crusher AppliedDocument7 pagesA Double Roll Crusher AppliedAnonymous bmFsuvNo ratings yet

- Conveyor BeltsDocument22 pagesConveyor BeltsFavorSea Industrial Channel LimitedNo ratings yet

- Eriez-Vibratory Feeders PDFDocument16 pagesEriez-Vibratory Feeders PDFruben quedo salazarNo ratings yet

- Vibrating ConveyorsDocument28 pagesVibrating ConveyorsMusheer BashaNo ratings yet

- Telestack Tracked Conveyors BrochureDocument4 pagesTelestack Tracked Conveyors BrochureRaghavendra DeshpandeNo ratings yet

- Conveyor Chain Design GuideDocument64 pagesConveyor Chain Design GuideAtacomaNo ratings yet

- Belt Selection Procedure-FENNERDocument12 pagesBelt Selection Procedure-FENNERkmambiNo ratings yet

- Tsubaki Drive Chain SprocketsDocument210 pagesTsubaki Drive Chain SprocketsHendrick Kurniawan100% (1)

- Flexowell - 2013 - EnglischDocument5 pagesFlexowell - 2013 - Englischeduardo_chaban100% (1)

- DFZK FU19210 Hammer Mill enDocument6 pagesDFZK FU19210 Hammer Mill enAntonNo ratings yet

- How To Size A ThickenerDocument7 pagesHow To Size A ThickenerJesus Sing RoblesNo ratings yet

- BHG - Transfer Chute Data SheetDocument2 pagesBHG - Transfer Chute Data Sheetacas35No ratings yet

- Telescopic ChuteDocument2 pagesTelescopic Chutebiswajit sabuiNo ratings yet

- Is 8531 1986Document6 pagesIs 8531 1986Srini KumarNo ratings yet

- Tsubaki ChainDocument8 pagesTsubaki Chainbmihaiela100% (1)

- Crusher SizerDocument4 pagesCrusher SizerZiggy GregoryNo ratings yet

- Apron Feeder Spare Part ListDocument17 pagesApron Feeder Spare Part ListParmeshwar Nath Tripathi100% (1)

- Introduction To Mechanical Size ReductionDocument35 pagesIntroduction To Mechanical Size ReductionFikrie MuhdNo ratings yet

- Heavy Duty Conveyor Pulley CatalogDocument100 pagesHeavy Duty Conveyor Pulley Catalogkosmc123No ratings yet

- FAM Apron Feeders: WWW - Fam.de Förderanlagen MagdeburgDocument4 pagesFAM Apron Feeders: WWW - Fam.de Förderanlagen MagdeburgriteshsamantrayNo ratings yet

- Roll CrusherDocument7 pagesRoll CrusherSudarshan Devarapalli100% (1)

- Filter & Size ReductionDocument20 pagesFilter & Size ReductionMuhammad Putra RamadhanNo ratings yet

- Cone CrusherDocument4 pagesCone CrusherSam ShiddoNo ratings yet

- Single Roll CrushersDocument8 pagesSingle Roll CrushersRinaldi SaputraNo ratings yet

- Single RollDocument8 pagesSingle RolltashdashNo ratings yet

- BCR Singleroll PDFDocument8 pagesBCR Singleroll PDFAneuk Naga BiruNo ratings yet

- Impact Hammer CrusherDocument4 pagesImpact Hammer Crusherdjenan100% (1)

- Vibrating Mill PDFDocument6 pagesVibrating Mill PDFPhanHathamNo ratings yet

- Jaw CrusherDocument5 pagesJaw CrusherHugo Fernandez CeronNo ratings yet

- Alwasy Step Ahead in TechnologyDocument3 pagesAlwasy Step Ahead in TechnologyjtpmlNo ratings yet

- Diagnostic Geas 2016 2ndsemDocument4 pagesDiagnostic Geas 2016 2ndsemjj012586No ratings yet

- LX8000T Preventative Maintenance & DiagnosticsDocument14 pagesLX8000T Preventative Maintenance & Diagnosticsjennifer murrishNo ratings yet

- Machine SafetyDocument33 pagesMachine Safetymarnhy -No ratings yet

- Electric Motors BizHouse - UkDocument3 pagesElectric Motors BizHouse - UkAlex BekeNo ratings yet

- Preventive Maintenance For Bucket ElevatorsDocument4 pagesPreventive Maintenance For Bucket ElevatorsMuhammad Usman AhmadNo ratings yet

- Group 14 Cooling: 1. Cooling System (Flow of Coolant) 2. Thermostat 3. Water PumpDocument21 pagesGroup 14 Cooling: 1. Cooling System (Flow of Coolant) 2. Thermostat 3. Water PumpclaudiosilvahNo ratings yet

- Yb 010Document40 pagesYb 010harshNo ratings yet

- Canon 6112 PCDocument77 pagesCanon 6112 PCVrtec Gabrovka GlasovanjeNo ratings yet

- Automotive PartsDocument9 pagesAutomotive PartsJestoniNo ratings yet

- Westfalia Edible Oil Industry Processing Lines RR 13-08-0033Document32 pagesWestfalia Edible Oil Industry Processing Lines RR 13-08-0033Azmi AhmadNo ratings yet

- CB-300S User ManualDocument25 pagesCB-300S User ManualShadi Salim-Ammon100% (1)

- Creew Diesel 1000Document375 pagesCreew Diesel 1000Erick VELANDIA TELLEZ100% (2)

- Conveyor Belt Construction: Top Cover RubberDocument10 pagesConveyor Belt Construction: Top Cover RubbersanthoshkumarplNo ratings yet

- Powergrip GT3: Expands The Limits of Your Power Transmission SolutionsDocument8 pagesPowergrip GT3: Expands The Limits of Your Power Transmission SolutionsVolodymyrNo ratings yet

- Deep Water - NotesDocument5 pagesDeep Water - NotesPoorvi RaghuvanshiNo ratings yet

- Stylus Pro 7600: (With Supplement For Optional Stand - C844061) Page No.:1Document13 pagesStylus Pro 7600: (With Supplement For Optional Stand - C844061) Page No.:1lftrevNo ratings yet

- BS - 3790 - 2006 PDFDocument37 pagesBS - 3790 - 2006 PDFVijay Balaji75% (4)

- Caya Cayb Cayc 1 6 Tdi CR Engine EngDocument212 pagesCaya Cayb Cayc 1 6 Tdi CR Engine EngLucian CristinaNo ratings yet

- Machine Design BookDocument202 pagesMachine Design BookAhl Francis ReyNo ratings yet

- 22E Backhoe Loader HBEDocument29 pages22E Backhoe Loader HBEhebert trujilloNo ratings yet

- Conveyor Design Information Idler Set Data: Tension SummaryDocument31 pagesConveyor Design Information Idler Set Data: Tension SummaryonuroztkNo ratings yet

- Instruction Manual MC4 - 2 - 14030 - DB - GMT PDFDocument64 pagesInstruction Manual MC4 - 2 - 14030 - DB - GMT PDFPatricio AcuñaNo ratings yet

- Kinds of Conveyor Belts Pipe Conveyor Belt Conveyo 5ad270867f8b9acc4a8b4583Document19 pagesKinds of Conveyor Belts Pipe Conveyor Belt Conveyo 5ad270867f8b9acc4a8b4583nicolasNo ratings yet

- Basics of Balancing 202Document8 pagesBasics of Balancing 202Nigo VillanNo ratings yet

- 02-Engine Mechanical SystemDocument150 pages02-Engine Mechanical SystemDavid VillamarinNo ratings yet

- MP C4500 PDFDocument84 pagesMP C4500 PDFJohn ArtunduagaNo ratings yet

- MSV40 MAX Manual de PartesDocument7 pagesMSV40 MAX Manual de PartesLenny SosaNo ratings yet

- John Deere 5520 Tractor Operator's Manual PDFDocument16 pagesJohn Deere 5520 Tractor Operator's Manual PDFfkskefmmseNo ratings yet

- Owner'S Manual FOR Duoseal® Vacuum Pumps Models: 1400, 1405, 1402, 1376, 1397, 1374, 1399, 1380, 1392Document42 pagesOwner'S Manual FOR Duoseal® Vacuum Pumps Models: 1400, 1405, 1402, 1376, 1397, 1374, 1399, 1380, 1392ckkimbleNo ratings yet

- Mathematical Reasoning - Practice SheetDocument2 pagesMathematical Reasoning - Practice SheetSahilNo ratings yet

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemFrom EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNo ratings yet

- Workbook to Accompany Maintenance & Reliability Best PracticesFrom EverandWorkbook to Accompany Maintenance & Reliability Best PracticesRating: 3.5 out of 5 stars3.5/5 (3)

- Electrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70EFrom EverandElectrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70ERating: 3 out of 5 stars3/5 (6)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- Redefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesFrom EverandRedefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesNo ratings yet

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- Incidents That Define Process SafetyFrom EverandIncidents That Define Process SafetyNo ratings yet

- Fire Protection Engineering in Building DesignFrom EverandFire Protection Engineering in Building DesignRating: 4.5 out of 5 stars4.5/5 (5)

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- What Went Wrong?: Case Histories of Process Plant Disasters and How They Could Have Been AvoidedFrom EverandWhat Went Wrong?: Case Histories of Process Plant Disasters and How They Could Have Been AvoidedRating: 5 out of 5 stars5/5 (2)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- The Invisible Rainbow: A History of Electricity and LifeFrom EverandThe Invisible Rainbow: A History of Electricity and LifeRating: 4.5 out of 5 stars4.5/5 (21)

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Healthy Buildings: How Indoor Spaces Drive Performance and ProductivityFrom EverandHealthy Buildings: How Indoor Spaces Drive Performance and ProductivityRating: 5 out of 5 stars5/5 (2)

- Fire Fighting Pumping Systems at Industrial FacilitiesFrom EverandFire Fighting Pumping Systems at Industrial FacilitiesRating: 4.5 out of 5 stars4.5/5 (3)

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)