Professional Documents

Culture Documents

BAck Seat PDF

Uploaded by

Anil KulkarniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BAck Seat PDF

Uploaded by

Anil KulkarniCopyright:

Available Formats

VALVE INSPECTION AND TESTING 9

6.1.4 When closure testing valves, the valve manufacturers test procedure shall ensure that excessive force is not

used to close the valve. The applied force may be determined from the appropriate figures in MSS SP-91, but in any

case shall not exceed the values published by the valve manufacturer.

6.1.5 The valve shall be visually examined for leakage after it has been fully prepared and is under full test pressure.

6.2 Backseat Test

6.2.1 The backseat test is required for all valves, except for bellows seal valves, that have the backseat feature and

shall be performed by applying pressure inside the assembled valve with the valve ends closed, the valve fully open,

and the packing gland loose or packing not installed. If the backseat test is performed after the shell test, the packing

shall be installed and/or packing glands retightened after the backseat test.

6.2.2 For valves DN 100 (4 in. NPS) and smaller, the backseat test may be combined with the shell test when

volumetric devices are used to monitor leakage from the shell and backseat. When tested by this method, the packing

shall be loose. The manufacturer shall be responsible for demonstrating that the packing will not leak at the valves

rated pressure at 38 C (100 F).

6.2.3 The successful completion of the backseat test shall not be construed as recommendation by the valve

manufacturer that, while the valve is pressurized, the valve may be repacked or packing may be replaced.

6.3 Shell Test

Except as provided in 6.2.2, the shell test shall be made by applying the pressure inside the assembled valve with the

valve ends closed, the valve partially open, and any packing gland tight enough to maintain the test pressure, thereby,

except for bellows seal valves, testing the stuffing box.

6.4 Low-pressure Closure Test

6.4.1 The low-pressure closure test shall be performed with the seat sealing surface interface clean and free from

oil, grease, and sealant. If necessary to prevent galling, the sealing surfaces may be coated with a film of oil that is not

heavier than kerosene. This requirement does not apply to a valve that uses a lubricant as its primary seal (e.g.

lubricated plug valves).

6.4.2 Any leakage at the seat sealing surface interface, behind the seat ring, or through the disk on the open side of

the valve shall be detected when bubbles are observed coming from the closure (disk, seat, and seat ring), covered

with water.

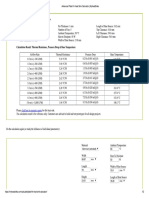

Table 5Duration of Required Test Pressure

Valve Size Minimum Test Duration (Seconds)

a

DN NPS Shell

Backseat

(for Valves

with

Backseat

Feature)

Closure

Check

Valves

(API 594)

Closure

Other Valves

50 (2) 15 15 60 15

65 to 150 (2

1

/2 to 6) 60 60 60 60

200 to 300 (8 to 12) 120 60 120 120

350 (14) 300 60 120 120

a

The test duration is the period of inspection after the valve is fully prepared and is under full

pressure.

Copyright American Petroleum nstitute

Provided by HS under license with AP Licensee=Petrofac nternational Ltd/5954785002

Not for Resale, 12/21/2010 07:48:28 MST No reproduction or networking permitted without license from HS

You might also like

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Notes - API 598 Valve Inspection & TestingDocument5 pagesNotes - API 598 Valve Inspection & TestingM Saad KhanNo ratings yet

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Procedure Manual: Ball Valve Hydro TestDocument5 pagesProcedure Manual: Ball Valve Hydro Testnima_h10No ratings yet

- Hydrostatic Shell TestDocument5 pagesHydrostatic Shell TestsojeckNo ratings yet

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)

- Hydro Test ProceduresDocument10 pagesHydro Test Proceduresazimr157100% (1)

- Gas Well Deliquification: Solutions to Gas Well Liquid Loading ProblemsFrom EverandGas Well Deliquification: Solutions to Gas Well Liquid Loading ProblemsNo ratings yet

- Proposed Hydro Test Procedures For ValvesDocument8 pagesProposed Hydro Test Procedures For ValvesNilesh GhodekarNo ratings yet

- Prosedur Testing Ball Valve KVCDocument4 pagesProsedur Testing Ball Valve KVCAl Hamra Ayashofiya100% (1)

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Assignment 5Document7 pagesAssignment 5Sharizada KanapiyevaNo ratings yet

- Valve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationFrom EverandValve Selection Handbook: Engineering Fundamentals for Selecting the Right Valve Design for Every Industrial Flow ApplicationRating: 4.5 out of 5 stars4.5/5 (21)

- Valve) - 2. End Fittings For ClosureDocument10 pagesValve) - 2. End Fittings For ClosureNaveen Vel100% (1)

- Air Testing TanksDocument2 pagesAir Testing TanksTatiana CruzNo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- What Is Valve Backseat TestDocument2 pagesWhat Is Valve Backseat TestMADHAN RAMAMOORTHYNo ratings yet

- Autoclave Expansion of Portland Cement: Standard Test Method ForDocument3 pagesAutoclave Expansion of Portland Cement: Standard Test Method ForHumberto GutierrezNo ratings yet

- API 598 Testing Procedure-20130720-032647Document2 pagesAPI 598 Testing Procedure-20130720-032647JOMAGUES100% (1)

- Valve TestingDocument6 pagesValve TestingjobertNo ratings yet

- Testing Procedure For Ball Valve MAPDocument16 pagesTesting Procedure For Ball Valve MAPbasuki100% (3)

- SCSSVDocument8 pagesSCSSVSaqxank100% (4)

- Api 576 Q 2Document6 pagesApi 576 Q 2abdoNo ratings yet

- Off-Factory Test Procedure For X-Mas TreesDocument11 pagesOff-Factory Test Procedure For X-Mas Treesomar shadyNo ratings yet

- Maintenance and Testing ManualDocument13 pagesMaintenance and Testing ManualCarlos AcNo ratings yet

- 89 Sub Surface Safety Valves SSSV InstallationDocument16 pages89 Sub Surface Safety Valves SSSV InstallationManuel Coxe100% (1)

- Api 576 Q 1Document10 pagesApi 576 Q 1abdoNo ratings yet

- 4 Litre Closed SamplersDocument4 pages4 Litre Closed SamplersShaifudin MuhammadNo ratings yet

- Wom ValvesDocument11 pagesWom ValvesRio IndokniveziaNo ratings yet

- Valve InspectionDocument6 pagesValve Inspectionrosid_alhusnaNo ratings yet

- Corsbysek PDFDocument16 pagesCorsbysek PDFMargaret DaughertyNo ratings yet

- TBV Series 21 20 Cryogenic Flanged Ball ValveDocument5 pagesTBV Series 21 20 Cryogenic Flanged Ball ValveJosip PobranNo ratings yet

- Ball Valve Testing ProcedureDocument7 pagesBall Valve Testing ProcedureVipul Panchal100% (2)

- ROCEDURE - INSPECTION & TEST ValvesDocument10 pagesROCEDURE - INSPECTION & TEST Valvessabes26No ratings yet

- Valvework Usa. Model M MSGDocument7 pagesValvework Usa. Model M MSGLuis Enrique RicoNo ratings yet

- Awwa C-561Document2 pagesAwwa C-561Leonardo Sierra100% (2)

- API 6D ExtractedDocument3 pagesAPI 6D ExtractedSam JoseNo ratings yet

- Valves Valve LeakageDocument5 pagesValves Valve Leakagearson5646100% (1)

- API 6D Valves - Types, vs. API 598 - QRC ValvesDocument9 pagesAPI 6D Valves - Types, vs. API 598 - QRC ValvesMAHESH CHANDNo ratings yet

- Bladder Accummulators InspectionsDocument7 pagesBladder Accummulators InspectionsJamin S. PanderajaNo ratings yet

- Welded Body Ball ValveDocument20 pagesWelded Body Ball ValveBisoyiNo ratings yet

- Bench Testing of Relief ValvesDocument1 pageBench Testing of Relief ValvesSARATH KRISHNAKUMARNo ratings yet

- Control Valve Test ProcedureDocument5 pagesControl Valve Test ProcedureMark Haizlip100% (2)

- QCP-12 Valve Leak Test Procedure PDFDocument21 pagesQCP-12 Valve Leak Test Procedure PDFIbrahim100% (3)

- EGV ManualDocument15 pagesEGV ManualT.MuthuvijayapandiNo ratings yet

- Casing and Liner Pressure TestingDocument1 pageCasing and Liner Pressure TestingMohd AshrafNo ratings yet

- Casing and Liner Pressure TestingDocument1 pageCasing and Liner Pressure TestingYougchu LuanNo ratings yet

- Valve Leak Test ProcedureDocument4 pagesValve Leak Test ProcedurezaihasrenNo ratings yet

- Gate Valve MaintenanceDocument8 pagesGate Valve Maintenancechar_lynNo ratings yet

- 5 Handling and Storage of Compressed Gas CylinderDocument2 pages5 Handling and Storage of Compressed Gas CylinderFAYAZ HUSSAINNo ratings yet

- Spe 77 - 307Document5 pagesSpe 77 - 307Dunamis Joe100% (1)

- Fsa PSJ 701 06 PDFDocument9 pagesFsa PSJ 701 06 PDFAshitava SenNo ratings yet

- Worcester Large 3-Piece Cryogenic Valves: Installation, Operating & Maintenance InstructionsDocument14 pagesWorcester Large 3-Piece Cryogenic Valves: Installation, Operating & Maintenance Instructionsافضح الكوارثNo ratings yet

- 2.0 Pressure TestingDocument11 pages2.0 Pressure TestingHATEMNo ratings yet

- 11 Installation and Storage CP - ENDocument5 pages11 Installation and Storage CP - ENandersson benito herreraNo ratings yet

- 6 Oil Tanker Operations: 6.1.1 Openings in SuperstructuresDocument76 pages6 Oil Tanker Operations: 6.1.1 Openings in Superstructuressubhenduhati100% (5)

- InterpretationDetail PDFDocument1 pageInterpretationDetail PDFAnil KulkarniNo ratings yet

- Api 520Document1 pageApi 520Anil Kulkarni0% (4)

- FlangesDocument1 pageFlangesAnil KulkarniNo ratings yet

- API 580 Cn1aDocument24 pagesAPI 580 Cn1aAnil KulkarniNo ratings yet

- NDTDocument1 pageNDTAnil KulkarniNo ratings yet

- ME 641 Theory of Elasticity & Plasticity Total No. of Contact Hours/week Course Assessment Theory Lab. Tutorial Total Hours Continuous End SemesterDocument1 pageME 641 Theory of Elasticity & Plasticity Total No. of Contact Hours/week Course Assessment Theory Lab. Tutorial Total Hours Continuous End SemesterAnil KulkarniNo ratings yet

- ME 601 Finite Element Methods Total No. of Contact Hours/week Course Assessment Theory Lab. Tutorial Total Hours Continuous End SemesterDocument1 pageME 601 Finite Element Methods Total No. of Contact Hours/week Course Assessment Theory Lab. Tutorial Total Hours Continuous End SemesterAnil KulkarniNo ratings yet

- DisclaimDocument1 pageDisclaimAnil KulkarniNo ratings yet

- Fir 01Document1 pageFir 01Anil KulkarniNo ratings yet

- M.S. Consultancy Management Course DescriptionsDocument2 pagesM.S. Consultancy Management Course DescriptionsAnil KulkarniNo ratings yet

- Closed Book API 510 Practice Exam ADocument1 pageClosed Book API 510 Practice Exam AAnil KulkarniNo ratings yet

- 2011 ASHRAE Handbook HVAC Applications: I-P Edition SI EditionDocument1 page2011 ASHRAE Handbook HVAC Applications: I-P Edition SI EditionAnil KulkarniNo ratings yet

- CV FormatDocument1 pageCV FormatAnil KulkarniNo ratings yet

- Guideline For IWE and IWT TrainingDocument6 pagesGuideline For IWE and IWT TrainingAnil KulkarniNo ratings yet

- 4.2.16.8 Related Mechanisms: The Welding InstituteDocument1 page4.2.16.8 Related Mechanisms: The Welding InstituteAnil KulkarniNo ratings yet

- Multiquadrant Dynamics in The Speed-Torque PlaneDocument41 pagesMultiquadrant Dynamics in The Speed-Torque PlanethanvandhNo ratings yet

- Ijmemr V3i1 009Document5 pagesIjmemr V3i1 009Sandesh SanNo ratings yet

- Position PaperDocument7 pagesPosition PaperClem CollantesNo ratings yet

- Fandek Evaporative Cooling System: F F F F Fan An An An Andek Dek Dek Dek DekDocument2 pagesFandek Evaporative Cooling System: F F F F Fan An An An Andek Dek Dek Dek DekCH1253No ratings yet

- Lab 11 12 ECA HIGH AND LOW PASSDocument32 pagesLab 11 12 ECA HIGH AND LOW PASSAmna EjazNo ratings yet

- I R Lib ReferenceDocument117 pagesI R Lib Referencebiltou0% (1)

- 475英文说明书Document33 pages475英文说明书Jon Aldwin CamachoNo ratings yet

- Samtec ASP 134488 01 DatasheetDocument4 pagesSamtec ASP 134488 01 DatasheetamiteshtripathiNo ratings yet

- Sensible HeatDocument31 pagesSensible Heat12001301100% (2)

- What Is NoSQLDocument4 pagesWhat Is NoSQLDulari Bosamiya BhattNo ratings yet

- TCAD Workshop Volume IDocument69 pagesTCAD Workshop Volume IVipan SharmaNo ratings yet

- Kuhlmann DigiTherm Digital Controller Manual ENDocument12 pagesKuhlmann DigiTherm Digital Controller Manual ENLuis SantosNo ratings yet

- Karcher Quotation List - 2023Document12 pagesKarcher Quotation List - 2023veereshmyb28No ratings yet

- Computer Science - Paper 1 - Mock 1Document10 pagesComputer Science - Paper 1 - Mock 1uththaramala calderaNo ratings yet

- BBRAUNDocument9 pagesBBRAUNLuis RosasNo ratings yet

- Colebrook EquationDocument3 pagesColebrook EquationMuhammad Ghufran KhanNo ratings yet

- Anu Tandon Resignation As DirectorDocument3 pagesAnu Tandon Resignation As DirectorjaychandonkakhulasaNo ratings yet

- Ds Lm5006 en Co 79839 Float Level SwitchDocument7 pagesDs Lm5006 en Co 79839 Float Level SwitchRiski AdiNo ratings yet

- MKDM Gyan KoshDocument17 pagesMKDM Gyan KoshSatwik PandaNo ratings yet

- Template Extended-AbstractDocument3 pagesTemplate Extended-AbstractGraita PurwitasariNo ratings yet

- Orkot® TLM & TXM Marine Bearings: Trelleborg Se Aling SolutionsDocument7 pagesOrkot® TLM & TXM Marine Bearings: Trelleborg Se Aling Solutionsprodn123No ratings yet

- Advanced Plate Fin Heat Sink Calculator - MyHeatSinksDocument2 pagesAdvanced Plate Fin Heat Sink Calculator - MyHeatSinksHarsh BhardwajNo ratings yet

- Item 3 Ips C441u c441r Ieb Main ListDocument488 pagesItem 3 Ips C441u c441r Ieb Main Listcristian De la OssaNo ratings yet

- Boeing Defence Australia LimitedDocument16 pagesBoeing Defence Australia LimitedMitchNo ratings yet

- Heavy Industry Taxila ReportDocument25 pagesHeavy Industry Taxila ReportMuhammad UmairNo ratings yet

- Bubble Point Temperature - Ideal Gas - Ideal Liquid: TrialDocument4 pagesBubble Point Temperature - Ideal Gas - Ideal Liquid: TrialNur Dewi PusporiniNo ratings yet

- Mohiuddin Ahmad and Rafiqul Tarefder Department of Civil Engineering, University of New MexicoDocument1 pageMohiuddin Ahmad and Rafiqul Tarefder Department of Civil Engineering, University of New MexicoMohiuddin AhmadNo ratings yet

- BAERD GEN-007 Rev CDocument27 pagesBAERD GEN-007 Rev CPaulNo ratings yet

- Module 3 Lesson 1 Edited For CBL Lesson ContentDocument3 pagesModule 3 Lesson 1 Edited For CBL Lesson ContentMariecris BatasNo ratings yet

- GETDIL Annual Report 2016 17Document172 pagesGETDIL Annual Report 2016 17kmnNo ratings yet

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Real Life: Construction Management Guide from A-ZFrom EverandReal Life: Construction Management Guide from A-ZRating: 4.5 out of 5 stars4.5/5 (4)

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (242)

- The Aqua Group Guide to Procurement, Tendering and Contract AdministrationFrom EverandThe Aqua Group Guide to Procurement, Tendering and Contract AdministrationMark HackettRating: 4 out of 5 stars4/5 (1)

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyFrom EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyRating: 4 out of 5 stars4/5 (1)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Woodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsFrom EverandWoodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsRating: 1 out of 5 stars1/5 (4)

- Well Integrity for Workovers and RecompletionsFrom EverandWell Integrity for Workovers and RecompletionsRating: 5 out of 5 stars5/5 (3)

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesFrom EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Civil Engineer's Handbook of Professional PracticeFrom EverandCivil Engineer's Handbook of Professional PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsFrom EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsRating: 4.5 out of 5 stars4.5/5 (6)

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)

- Sustainable Design and Build: Building, Energy, Roads, Bridges, Water and Sewer SystemsFrom EverandSustainable Design and Build: Building, Energy, Roads, Bridges, Water and Sewer SystemsNo ratings yet

- Estimating Construction Profitably: Developing a System for Residential EstimatingFrom EverandEstimating Construction Profitably: Developing a System for Residential EstimatingNo ratings yet

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyFrom EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyRating: 4 out of 5 stars4/5 (1)

- Piping Engineering Leadership for Process Plant ProjectsFrom EverandPiping Engineering Leadership for Process Plant ProjectsRating: 5 out of 5 stars5/5 (1)

- Starting Your Career as a Contractor: How to Build and Run a Construction BusinessFrom EverandStarting Your Career as a Contractor: How to Build and Run a Construction BusinessRating: 5 out of 5 stars5/5 (3)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)