Professional Documents

Culture Documents

ASEAN Food Journal 15 (1) : 73-78 (2008) Biochemical Studies On

Uploaded by

aditiagrawal2009Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASEAN Food Journal 15 (1) : 73-78 (2008) Biochemical Studies On

Uploaded by

aditiagrawal2009Copyright:

Available Formats

ASEAN Food Journal 15

Biochemical (1): 73-78

Studies on the(2008)

Immobilization of the Enzyme Invertase (EC.3.2.1.26) in Alginate Gel and its Kinetics 73

Biochemical Studies on the Immobilization of the Enzyme

Invertase (EC.3.2.1.26) in Alginate Gel and its Kinetics

*Vu, T. K. H. and Le, V. V. M.

Department of Food Technology, Ho Chi Minh City University of Technology,

268 Ly Thuong Kiet, District 10, Ho Chi Minh City, Vietnam

Abstract: The biochemical properties of invertase entrapped in alginate gel were studied. The

kinetic parameters were determined for immobilized and free invertase. The value of Michaelis

constant Km of the immobilized invertase (139.19 mM) was greater than that of the free invertase

(93.19 mM), whereas, Vmax was smaller for the immobilized enzyme. Immobilization impressively

improved the thermal and storage stability of invertase. The half-life values of the immobilized

and free enzymes at 60oC were 28 min and 8 min, respectively. In 0.1M acetate buffer (pH 4.5) at

2 - 4oC, the immobilized invertase activity was found to be quite stable after 40 days.

Keywords: Calcium alginate, enzyme immobilization, entrapment, invertase, sucrose hydrolysis

INTRODUCTION active, (2) immobilization protects the activity

of the enzyme from unfavourable conditions,

Invertase, also known as β-fructofuranoside (3) the separation and recovery of enzyme is

fructohydrolase (EC 3.2.1.26) is a catalyst for easy and convenient, (4) it can be used in a

sucrose hydrolysis yielding invert sugar. Invert continuous system for the production of invert

sugar has been used to a great extent in the syr up from sucrose solution, (5) the

food industr y such as in beverage and application of immobilized enzyme provides

confectionery products. Invert sugar can be considerable reduction in the operating costs

produced by a chemical process (using acid (Bayramolu et al., 2003). Many studies were

as a catalyst) or biochemical process (using focused on the support for immobilization of

invertase as a catalyst). Nowadays, the invertase in different aspects namely

biochemical process is preferred as the polyvinylalcohol (Agkol et al., 2001),

resulting product contains less coloured by- polyacrylamide (Abdellah et al., 1992; Mansour

product and salt (Bergamasco et al., 2000; and Dawoud, 2003), chitosan (Hseih et al.,

Akgol et al., 2001; Bayramolu et al., 2003). 2000), hen-egg white and diethylaminoethyl-

Moreover, this process requires less energy cellulose (Abdellah et al., 1992).

than the chemical process. In this investigation, calcium alginate gel

However, the enzymatic process is more was chosen as a carrier for the enzyme

expensive than acid hydrolysis, due to the entrapment due to its non-toxicity, high

relatively high cost of invertase. To reduce the mechanical stability, high porosity for substrate

cost of the final product, the application of and product diffusion and above all the simple

immobilized invertase has been considered an procedural requirements for immobilization

appropriate solution. This immobilized (Bucke, 1987). Some properties of

enzyme has many advantages because (1) it immobilized invertase in alginate gel like

can be re-used many times and still remains kinetics, thermal and storage stability were

investigated.

*Corresponding author.

E-mail: vukimhanh@hcmut.edu.vn

ASEAN Food Journal Vol. 15, 73-78

74 Vu, T. K. H. and Le, V. V. M.

MATERIALS AND METHODS hydrolyse 1.0 mmol sucrose per minute under

the assay conditions. The reducing sugars

Materials produced by sucrose hydrolysis were measured

Commercial invertase (b-D-fructofuranoside by spectrophotometric method using 3,5

fructohydrolase, E 3.2.1.26) produced from dinitrosalicylic acid reagent (Miller, 1959).

baker’s yeast, Saccharomces cerevisiae, was

obtained from Sigma Chemical Company Determination of Invertase Immobilization Yield

(USA). The yield of invertase immobilization Y was

Alginate from Sargassum was procured calculated by the following equation (Abdellah

from Biotechnology Center – Nha Trang et al., 1992).

University of Marine Products. Powder alginate

contains 21.88% moisture with a viscosity Y = [(A – B)/A] x 100, where:

(1.5% (w/v) alginate solution): 720 cp.

Saccharose was purchased from Bienhoa A is the total amount of enzyme (mg)

Sugar Company. It contained 99.8% (db) added to the immobilization solution.

sucrose. It has 0.05% moisture and 0.03%

reducing sugar. Other analytical chemicals B is the amount of residual enzyme in the

were obtained from Merck AG (Germany) and CaCl2 solution and in the washing solution

Shantou Xilong Chemical Factory Guangdong of the gel beads in the immobilization

(China). procedure.

Procedure of Invertase Immobilization in Alginate Both A and B were evaluated from the

Gel amount of reducing sugars produced

Sodium alginate solution 2.5% (w/v) and enzymatically in the corresponding solutions.

invertase solution 1.33% (w/v) were mixed in

the ratio of 1:1 (v/v) to homogenization. The Determination of Kinetic Parameters

mixture was passed drop wise into 2% (w/v) Km and Vmax values of the free and immobilized

CaCl 2 solution. The formed beads were invertase were determined by Lineweaver-Burk

retained in the stirred CaCl2 solution (using a method using various substrate concentrations

magnetic stirrer) at least for 2 hours for gel (0.029-0.29 M) in acetate buffer (0.1 M, pH

hardening. The invertase-alginate beads had 4.5) at 55oC.

3-4 mm in diameter. Finally, the beads were

separated and washed with distilled water 3 Thermal Stability of the Free and Immobilized

times. Before using, the beads were immersed Invertase

in 0.1 M acetate buffer of pH 4.5 (Le et al., The thermal stability of the free and

2003). immobilized invertase were determined by

measuring the residual activity of the enzyme

Activity Assays of Free and Immobilized Invertase exposed to three different temperatures (50,

The invertase activity was assayed as follows: 55 and 60oC) in acetate buffer (0.1 M, pH 4.5)

Ten cm3 of immobilized invertase beads or 5 for 160 min. After every 20 minutes, a sample

ml free invertase solution (1.005% (w/v)) was was taken and assayed for enzymatic activity.

added to 100 ml sucrose solution (200 g/L in The inactivation rate constants, k, and the half-

acetate buffer, pH 4.5) and incubated for 15 life, t1/2 , were calculated with the following

min at 50 oC. The enzymatic reaction was equation (Bailey et al., 1986; Bayramolu et al.,

stopped by crossing out immobilized invertase 2003).

or boiling the solution at 100oC for 5 min. One [A] = [Ao] .e-kt

international unit (IU) of activity was defined k: Inactivation rate constants (min-1).

as the amount of enzyme that is required to

ASEAN Food Journal Vol. 15, 73-78

Biochemical Studies on the Immobilization of the Enzyme Invertase (EC.3.2.1.26) in Alginate Gel and its Kinetics 75

Ao: The initial activity (U/mg protein

enzyme).

Initial Vo (mM-min-1)

A: The activity after a time t (U/mg

protein enzyme).

Storage Stability of the Free and Immobilized

Invertase

This experiment was conducted to determine

the stability of the free and immobilized

invertase during storage in distilled water and

acetate buffer (0.1 M, pH 4.5) at 2 - 4oC for 40

days. The residual activities were measured by

the assay procedure described earlier. The

activity of the free and immobilized enzymes

was expressed as a percentage of its residual Figure 1: Michaelis-Menten plots of the free and

activity compared to the initial activity. The immobilized invertase. (I) free invertase, (N)

inactivation rate constants k and the half-life immobilized invertase in alginate gel

t1/2 were also calculated as described earlier.

RESULTS AND DISCUSSION

Initial Vo (mM-min-1)

Yield of Invertase Immobilization

The results show that the yield of invertase

immobilization in alginate gel was 79.34 ±

3.48%. This means that the enzymes used in

immobilization was not completely included

in the gel matrix. Some invertase molecules

distributed on the surface of alginate beads

diffused into the CaCl2 solution during the gel

beads formation. This obser vation was in

accordance with earlier reported studies where

the yield of enzyme immobilization in alginate

gel varied from 50 to 85%. (Das et al., 1998;

Figure 2: Lineweaver-Burk plots of the free and

Arruda et al., 1999; Le et al., 2004).

immobilized invertase. (I) free invertase, (N)

immobilized invertase in alginate gel

Kinetic Parameters

The kinetic parameters of the hydrolytic

reaction of sucrose using the free and min -1, respectively. Therefore, K m of the

immobilized invertase were determined. immobilized invertase was approximately 1.5-

Figure 1 presents the relation between initial fold higher than that of the free invertase,

rate and substrate concentration for the free while Vmax was 6-fold lower. When an enzyme

and immobilized invertase. Using Lineweaver- was immobilized in gel matrix such as alginate

Burk method (Figure 2), the apparent gel, the Km of immobilized enzyme increased,

Michaelis constants Km and Vmax of the free while Vmax decreased. This means that the

invertase were 93.19 mM and 35.84 mM min-1, affinity of the enzyme for its substrate and the

respectively. For the immobilized invertase in velocity of enzymatic reaction decreased. This

alginate gel, the apparent Michaelis constants, was due to the lower accessibility of the

Km and Vmax, were 139.19 mM and 5.97 mM substrate to the active site of the immobilized

ASEAN Food Journal Vol. 15, 73-78

76 Vu, T. K. H. and Le, V. V. M.

invertase and lower transporting of the

Inventase activity (% of initial activity)

substrate and products into and out the gel

beads (Bailey et al., 1986; Akgol et al., 2001;

Bayramolu et al., 2003).

Thermal Stability of the Free and Immobilized

Invertase

The free and immobilized enzymes were

incubated in the absence of substrate at three

different temperatures (50, 55 and 60oC).

Figure 3 shows the heat inactivation curves of

the free and immobilized invertase. At 50oC,

the activity of the immobilized invertase and

free enzyme retained their activities about 90

and 75%, respectively after 160 min for the

same incubation period. At 55oC, the activities

of the immobilized and free enzymes were Figure 3: Influence of temperature on the

retained at levels of 93 and 45%, respectively. stability of the free and immobilized invertase. —

The immobilized form was inactivated at a Immobilized invertase, .... Free invertase, (N)

50oC, (L) 55oC, (I) 60oC

much slower rate than the native form. At

60oC, the free enzyme lost their initial activity

after 120 min while the immobilized enzyme during storage in distilled water and acetate

retained its activity about 25% after 160 min. buffer (0.1 M, pH 4.5) at 2 - 4oC. After 40 days,

The half-life values and thermal inactivation in acetate buffer, the immobilized enzyme

rate constants for the free and immobilized preserved their activity, while, the free enzymes

enzymes are presented in Table 1. The higher retained its initial activity at a level of 69%. In

the temperature, the lower the half-life value, distilled water, the immobilized and free

t1/2, and the higher the thermal inactivation enzyme retained 90% and 59% of their initial

rate constant k for both the immobilized and activities, respectively. The half-life values and

free invertase. However, at the same the inactivation rate constants for the free and

temperature, the half-life value, t1/2, of the fixed immobilized enzymes are shown in Table 2.

enzyme was much higher than that of the free During storage in distilled water or in acetate

enzyme. The thermal stability of immobilized buffer, the half-life values of immobilized

invertase increased considerably as a result of invertase are 5 or 10-fold higher than those of

immobilization in alginate gel. Enzyme the free enzyme, respectively; and the

stabilization by immobilization may also be inactivation rate constants are also 5 or 10-fold

caused by the existance of a local environment lower, respectively. On the other hand, the

for the immobilized enzymes which is less results in Table 2 also show that the storage

damaging than bulk solution conditions stability of immobilized invertase when stored

(Bailey et al., 1986). in acetate buffer was 3-fold higher than when

stored in distilled water. Amaya et al. (2006)

Storage Stability of the Free and Immobilized reported similar conclusions in their

Invertase investigation about invertase immobilized on

In general, the enzymes are not stable during nylon-6 microbeads.

storage in solution and their activities are In general, these results reveal that enzyme

gradually reduced or lost through time. Figure immobilization in alginate gel can reduce

4 indicates the activity evolution of the free enzyme deactivation. First, by holding the

and immobilized invertases in alginate gel enzyme in relatively fixed position,

ASEAN Food Journal Vol. 15, 73-78

Biochemical Studies on the Immobilization of the Enzyme Invertase (EC.3.2.1.26) in Alginate Gel and its Kinetics 77

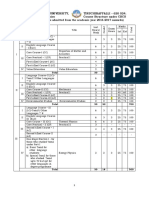

Table 1

Half-lives (t1/2) and inactivation rate constant (k) of the free and immobilized invertase

in alginate gel at three different temperatures

Immobilized invertase Free invertase

Temperature (oC)

t1/2 (min) k (min-1) t1/2 (min) k (min-1)

50 1168 0,6.10-3 403 1,8.10-3

55 323 2,0.10-3 143 4,1.10-3

60 28 7,1.10-3 8 3,2.10-2

Table 2

Half-lives (t1/2) and inactivation rate constant (k) of the free and immobilized invertase in alginate

gel during the storaged in distilled water and acetate buffer (0.1 M, pH 4.5) at 2 - 4oC

Immobilized invertase Free invertase

Storage solution

t1/2 (days) k (day-1) t1/2 (days) k (day-1)

Distilled water 272 2,5.10-3 59 1,3.10-2

Acetate buffer 767 9.10-4 70 1,1.10-2

immobilization reduces interaction between

Inventase activity (% of initial activity)

enzyme molecules which contributes to

deactivation by aggregation and to autolysis by

proteolytic enzymes. Second, dramatic stability

enhancements have been reported based on

this strategy in which gel entrapment was

applied to attempt to form a local support

microstructure complementar y to enzyme

surface. Similarly, deactivation caused by

dissociation of oligomeric proteins such as

invertase may be reduced by immobilization

which stabilised the active, multiunit structure

(Bailey et al., 1986; Esmon et al., 1987;

Bayramolu et al., 2003). In summary, alginate

gel provided a stable environment and

prevented the loss of activity during the storage

Figure 4: Storage stability of the free and the of the enzyme in solution.

immobilized invertase. (N) Immobilized

invertase – Stored in acetate buffer, (L) CONCLUSION

Immobilized invertase – Stored in distilled water,

(I Free invertase–– Stored in acetate buffer, (G) In this study, the alginate was used as a support

Free invertase – Stored in distilled water for invertase immobilization. Generally, the

immobilization of invertase in alginate gel

ASEAN Food Journal Vol. 15, 73-78

78 Vu, T. K. H. and Le, V. V. M.

showed a marked increase in Km and a sharp Bayramolu, G., Akgol, S., Bulut, A., Denizli, A. and

decrease in Vmax. However, the thermal stability Yakup, A.M. 2003. Covalent immobilization of

of the immobilized invertase was much higher inverase onto a reactive film composed of 2-

hydroxyethyl methacr ylate and glycidyl

than that of the free enzyme. The rate of

methacrylate: properties and application in a

thermal inactivation of the immobilized continous flow system. Biochemical

enzyme decreased due to entrapment in gel Engineering Journal, 14: 117-126.

matrix. In addition, the activity of the

immobilized invertase was more stable in Bergamasco, R., Bassetti, F.J., Moraes, F.F. and

retention than that of the free enzyme during Zanin, G.M. 2000. Characterization of free and

immobilized invertase regarding activity and

the storage in solution. Even though the

energy of activation. Brazilian Journal of

activity of the immobilized enzyme was lower Chemical Engineering, 17: 873-880.

in comparison with the free enzyme, the

enhancement of thermal and storage stability Bucke, C. 1987. Cell immobilization in calcium

highlights the value of alginate gel as a support alginate. Methods in Enzymology, 135: 175-189.

for enzyme immobilization. A stable

immobilized system and long storage life are Das, N., Kayastha, A.M. and Malhotra, O.P. 1998.

Immobilization of urease from piggeonpea

convenient for applications that would not be

(Cajanus cajan L.) in polyacrylamide gels and

feasible with a soluble enzyme system. For calcium alginate beads. Biotechnology and

instance, immobilized invertase can be used Applied Biochemistry, 27: 25-29.

successfully in a continuous system for the

production of invert syrup from sucrose Esmon, P.C., Esmon, B.E., Schauer, I.E., Taylor, A.

solution. and Schekman R. 1987. Structure, assembly,

and secretion of octameric invertase. The

Journal of Biological Chemistry, 262: 4387-

REFERENCES 4394.

Abdellah, H.A., Baker, T.M. Abou, S.L.A. and El- Hsieh, H.J., Liu, P.C. and Liao, W.J. 2000.

Iraqi, S.M. 1992. Characteristics of invertase Immobilization of invertase via carbohydrate

immobilized on three different types of moiety on chitosan to enhance its thermal

supports. Food Chemistry, 43: 369-375. stability. Biotechnology Letters, 22: 459-464.

Akgol, S., Kaçar, Y., Denizli, A. and Arica, M.Y. 2001. Le, V.V.M. and Duong, T.T. 2003. Application of

Hydrolysis of sucrose by invertase immobilized immobilized invertase in invert syrup

onto novel magnetic polyvinylalcohol processing from sucrose. Proceedings of the 8th

microspheres. Food Chemistry, 74: 281-288. Asean Food Conference, pp. 435-439. Hanoi.

Amaya, D.L., Hidalgo, L.M.E. and Montes, H.M.C. Le, C.T., Mathieu, M., Monique, L. and Mircea,

2006. Hydrolysis of sucrose by invertase A.M. 2004. Modified alginate matrices for the

immobilized on nylon-6 microbeads. Food immobilization of bioactive agents.

Chemistry, 99: 299-304. Biotechnology and Applied Biochemistry, 39:

189-198.

Ar r uda, L.M.O. and Vitolo, M. 1999.

Characterization of invertase entrapped into Mansour, E.H. and Dawoud, F.M. 2003.

calcium alginate beads. Applied Biochemistry Immobilization of invertase on celite and on

and Biotechnology, 81: 23-34. polyacrylamide by an absorption procedure.

Journal of the Science of Food and Agriculture,

Bailey, J.E. and Ollis, D.F. 1986. Biochemical 83: 446-450.

engineering fundamentals. 2nd edn. United

States of America: McGraw-Hill Book Company. Miller, G.L. 1959. Use of dinitrosalicylic acid

reagent for determination of reducing sugar.

Analytical Chemistry, 31: 426-429.

ASEAN Food Journal Vol. 15, 73-78

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Simplified MELC Based BOL in Science 3 FINALDocument8 pagesSimplified MELC Based BOL in Science 3 FINALFranz Evhanne50% (2)

- Pauli Exclusion PrincipleDocument66 pagesPauli Exclusion PrincipleAtul SinghNo ratings yet

- FHGGHDocument3 pagesFHGGHsangeethaNo ratings yet

- Compositional and Structural Characterization of Waxes Isolated From BitumensDocument8 pagesCompositional and Structural Characterization of Waxes Isolated From BitumensMa JamieNo ratings yet

- Determining Molar Mass Using CryosDocument6 pagesDetermining Molar Mass Using CryosValentin-AngeloUzunovNo ratings yet

- Lecture 7 (MT Resistances in Immobilized Enzyme)Document21 pagesLecture 7 (MT Resistances in Immobilized Enzyme)sanyukta sinha100% (1)

- 11th Chemistry Chapter 4 PDF Notes - Unlocked - OCRDocument27 pages11th Chemistry Chapter 4 PDF Notes - Unlocked - OCRamirbadshahNo ratings yet

- Quantitative Determination of Total Hardness of WaterDocument11 pagesQuantitative Determination of Total Hardness of WaterJoshua Oliveros50% (2)

- Nature and Properties of LightDocument16 pagesNature and Properties of LightCarl Daniel FandiñoNo ratings yet

- Waste Heat RecoveryDocument12 pagesWaste Heat RecoveryJafarNo ratings yet

- Ol 48 3311 Tanjaya Thermo Optical Measurements Using Quantitative Phase MicrosDocument4 pagesOl 48 3311 Tanjaya Thermo Optical Measurements Using Quantitative Phase MicrosJean-Charles CotteverteNo ratings yet

- Ionization Potential of MercuryDocument7 pagesIonization Potential of Mercurylucy lucy100% (8)

- Chemical Engineering Thermodynamics Problem Set 1: Bicol UniversityDocument5 pagesChemical Engineering Thermodynamics Problem Set 1: Bicol UniversityJohn Patrick Sanay NunezNo ratings yet

- 10 1016@j Mineng 2020 106456Document10 pages10 1016@j Mineng 2020 106456faouzi rachidNo ratings yet

- Bioencap Innov 2013 03Document28 pagesBioencap Innov 2013 03yuziyuzi hanNo ratings yet

- Mechanism and Kinecs of The Metal-Catalyzed Synthesis of Methylchlorosilanes - 1Document12 pagesMechanism and Kinecs of The Metal-Catalyzed Synthesis of Methylchlorosilanes - 1Bruna PlentzNo ratings yet

- Thesis On Zns NanoparticlesDocument7 pagesThesis On Zns Nanoparticlesjenniferalexanderfortlauderdale100% (2)

- Alternative Cycles Based On Carbon Dioxide For Central Receiver Solar Power PlantsDocument13 pagesAlternative Cycles Based On Carbon Dioxide For Central Receiver Solar Power PlantsfaizaNo ratings yet

- Corrosion of Constructional Steels in Marine and Industrial Environment - 2013Document188 pagesCorrosion of Constructional Steels in Marine and Industrial Environment - 2013lei huangNo ratings yet

- Tutorium Refrigeration SolutionDocument20 pagesTutorium Refrigeration SolutionwanpudinNo ratings yet

- Jee Main 2021 Mar 18 First Shift PaperDocument15 pagesJee Main 2021 Mar 18 First Shift Papershivam singhNo ratings yet

- G GN 180Document34 pagesG GN 180reza329329No ratings yet

- Bharathidasan University, Tiruchirappalli - 620 024. B.Sc. Physics Course Structure Under CBCSDocument27 pagesBharathidasan University, Tiruchirappalli - 620 024. B.Sc. Physics Course Structure Under CBCSSarjithNo ratings yet

- MI - 1748 Rev FDocument21 pagesMI - 1748 Rev FSudarshan Dhumal100% (2)

- Experiment 5 Chem 26.1Document2 pagesExperiment 5 Chem 26.1Collin Reyes HuelgasNo ratings yet

- Irreversible ThermodynamicsDocument2 pagesIrreversible ThermodynamicsManoj PrakashNo ratings yet

- Propertiesof Glass MaterialsDocument13 pagesPropertiesof Glass MaterialsElva Diany SyamsudinNo ratings yet

- Class XI Chemistry Support Material (Term-2)Document191 pagesClass XI Chemistry Support Material (Term-2)Sharma AdityaNo ratings yet

- The Corrosion Behaviour of Aisi 304 Stainless Steel in Methanol H2SO4 MixturesDocument11 pagesThe Corrosion Behaviour of Aisi 304 Stainless Steel in Methanol H2SO4 MixturesnicusebpNo ratings yet

- A Study of Corrosion Initiation On Polyi PDFDocument24 pagesA Study of Corrosion Initiation On Polyi PDFrasnaNo ratings yet