Professional Documents

Culture Documents

Manufacturing Process Overview

Uploaded by

Gaurav Crimson AroraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manufacturing Process Overview

Uploaded by

Gaurav Crimson AroraCopyright:

Available Formats

Manufacturing Process (Overview) Manufacturing is the use of machines, tools and labor to produce goods for use or sale.

The term may refer to a range of human activity, from handicraft to high tech, but is most commonly applied to industrial production, in which raw materials are transformed into finished goods on a large scale. Such finished goods may be used for manufacturing other, more complex products, such as aircraft, household appliances or automobiles, or sold to wholesalers, who in turn sell them to retailers, who then sell them to end users the "consumers".

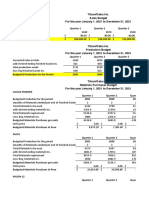

Fig. Manufacturing Cycle Manufacturing of products is an important activity historically, technologically, and economically. The products that are available to us or alternatively, the benefits of civilization which we enjoy today, are necessarily due to the improvement in their quality.

This improvement is possible with proper design, which ta es into consideration the functional requirement as well as its manufacturing aspects. This ma es a better product available at an economical cost. !ll this is possible with the availability and adoption of a variety of new techniques and process replacement and improvement of prevailing processes or techni"ues that include better and more compact design, efficient and appropriate methods of production, mechanization, automation and numerical control and optimal output. #resently there have been increasing demands on the performance of the product by way of desirable characteristics such as resistance to elevated temperatures, higher operating speeds and ability to carry extra loads . ! variety of raw materials and its associated processing would be re"uired for this purpose. Just li e technology that can be defined as the application of science to provide society and its members with those items! things! products that are desired", so is the manufacturing processes. The manufacturing process forms a vital ingredient for various products such as plant and machinery that is needed in various disciplines of engineering. ! detailed nowledge of the manufacturing processes is thus essential for every engineer. $e will be able to appreciate the process capabilities, advantages and limitations. This in turn would help him in the proper design of the product as per demand in the mar et. %urther, he would be able to assess the feasibility of manufacturing the re"uisite design, select the appropriate process requiring minimum manufacturing cost and of the desired quality from the different! alternative techniques or processes available. Definition of Manufacturing Manufacturing can be defined in two ways in the modern context i.e. technological and economic. Technologically, manufacturing is the application of physical and chemical processes for changing the geometry, characteristics and! or appearance of a given input material to produce parts or products , the assembly involving many parts to ma e products is also included in manufacturing.

The processes to accomplish manufacturing involve a combination of machines! tools, man power, power! energy and methods as represented in %ig.

#conomically, manufacturing means the transformation of materials into items! goods of greater value by way of one or more processing and! or assembly operations as shown in %ig. The meaning of greater value is that manufacturing adds value to the material by altering its shape or characteristics . $he material has been made more valuable by virtue of the manufacturing operations performed on it.

Manufacturing Industries and Products Manufacturing is an important activity, but it is performed by various enterprises& organizations as a commercial activity for the purpose of financial gains and customer satisfaction. %ndustry means enterprises and organizations that are able to produce or supply goods& products and services. The final products made by manufacturing industries are termed as manufactured products. These can be divided into &onsumer 'roducts and &apital goods. Manufacturing Processes %or every engineer a through nowledge of the manufacturing processes is essential. This would help him to appreciate the advantages, limitations and capabilities of the process.

'ith such nowledge, he would be able to assess the feasibility of manufacturing a particular product from the designs. %urther, he would be able to select proper processes, which would re"uire the lowest manufacturing cost and would manufacture the product of re"uisite "uality. Classification of Manufacturing Processes Manufacturing processes can be classified in six groups. They are( ). 'rimary (haping or )orming 'rocesses #rimary shaping or forming is manufacturing of a solid body from a molten or gaseous state or from an amorphous material. Some of the important primary shaping processes is( * &asting* 'owder Metallurgy* 'lastic technology. +. +eforming 'rocesses ,eforming processes ma e use of suitable stresses li e compression, tension, shear or combined stresses to cause plastic deformation of the materials to produce re"uired shapes without changing its mass or material composition. Some of the forming processes are( * )orging* #xtrusion* ,olling* (heet metal wor ing* etc. -. Machining/Removing Processes The principle used in all machining processes is to generate the surface re"uired by providing suitable relative motions between the wor piece and the tool. Some of the machining processes are( * $urning* +rilling Milling* -rinding* (haping* etc. .. Joining processes /n this process one or more pieces of metal parts are united together to ma e sub*assembly or final product. Some of the important joining processes are( * 'ressure welding* +iffusion welding* brazing* ,esistance welding* soldering* etc. 0. Surface Finishing Processes These processes are utilized to provide intended surface finish on the metal surface of a job. Some of the important surface finishing processes are( * 'lastic coating* Metallic coating* #lectroplating* etc . 1. Material Properties Modification Processes /n this type of process, material properties of a wor piece is changed in order to achieve desired characteristics without changing the shape. Some of the processes are( * .eat and surface treatment* /nnealing* (tress relieving .

!pes of Production S!stems Types of production and choice of production type dictates the machine re"uirements, organizational system and to a large extent, layout, planning and inventory sub*systems. There are three main types of production, namely, job, batch and flow or process production. Plant "a!out #lant layout is the arrangement of the physical element of facilities 2or machines& e"uipment3 which ma e the product or service. Thus facilities layout is the overall arrangement of machines, men, material handling, service facilities, and passage re"uired to facilitate efficient operation of production system. The primary goal of plant layout is to maximize profit by the arrangement of all plant facilities to the best advantage of the 4manufacturing equation5 men, material, machines, and money in fulfilling this goal. The pattern by which departments and facilities within departments are arranged may be viewed either in terms of wor flow or the function of the productive system. !ccording to wor flow pattern, four basic types are used in manufacturing operations. These are( * %ixed position layout * #roduct or line layout * #rocess or functional layout * 6roup layout.

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- LexAndYaccTutorial PDFDocument41 pagesLexAndYaccTutorial PDFHarsha MadhwaniNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Einstein and The Theory of EverythingDocument13 pagesEinstein and The Theory of EverythingGaurav Crimson AroraNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Microwave ExperimentDocument37 pagesMicrowave Experimentsufiyan aliNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Solar PowerDocument13 pagesSolar PowerGaurav Crimson AroraNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Kosaraju AlgorithmDocument1 pageKosaraju AlgorithmGaurav Crimson AroraNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- 4D2-5&6 Hashing Techniques v1.02Document9 pages4D2-5&6 Hashing Techniques v1.02pirjade_harunNo ratings yet

- 303 IT Microprocessors SyllabusDocument3 pages303 IT Microprocessors SyllabusGaurav Crimson AroraNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Macro Solutions 4-5 2010 PDFDocument9 pagesMacro Solutions 4-5 2010 PDFADITYANo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Experiment No:-10 Shortest Seek-Time First Disk Scheduling Algorithm Source CodeDocument6 pagesExperiment No:-10 Shortest Seek-Time First Disk Scheduling Algorithm Source CodeGaurav Crimson AroraNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Software+Development+Engineer+I JDDocument2 pagesSoftware+Development+Engineer+I JDGaurav Crimson AroraNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Airline Reservation System SRSDocument29 pagesAirline Reservation System SRSAshhad Faqeem80% (65)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- ERD ExamplesDocument8 pagesERD Examplesnisay_life2255No ratings yet

- Telugu Folk Additions To Maha Bharatha: Bangalore UniversityDocument8 pagesTelugu Folk Additions To Maha Bharatha: Bangalore UniversityGaurav Crimson Arora100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Cigarette Smokers ProblemDocument2 pagesCigarette Smokers ProblemGaurav Crimson AroraNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Burn It UpDocument2 pagesBurn It UpGaurav Crimson AroraNo ratings yet

- Communication and Network ConceptsDocument15 pagesCommunication and Network ConceptsGaurav Crimson AroraNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Front Office ManagementDocument3 pagesFront Office ManagementLu XiyunNo ratings yet

- Design and Implementation of Real Processing in Accounting Information SystemDocument66 pagesDesign and Implementation of Real Processing in Accounting Information Systemenbassey100% (2)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Jis B 1196Document19 pagesJis B 1196indeceNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ConWay Stewart Pen Catalogue 2012Document76 pagesConWay Stewart Pen Catalogue 2012MarcM77100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Hire Purchase SystemDocument13 pagesHire Purchase SystemDeepak Dhingra100% (1)

- Construction International Innovation Ability - The Mode of Huawei Abstract After Reviewing Huawei's Twenty Years of Innovation andDocument1 pageConstruction International Innovation Ability - The Mode of Huawei Abstract After Reviewing Huawei's Twenty Years of Innovation andDwitya AribawaNo ratings yet

- Chap - 33 Aggregate Demand & Aggregate SupplyDocument28 pagesChap - 33 Aggregate Demand & Aggregate SupplyUdevir SinghNo ratings yet

- 1 Zong Net Package PDFDocument8 pages1 Zong Net Package PDFHafiz Abid Malik0% (1)

- She Bsa 4-2Document7 pagesShe Bsa 4-2Justine GuilingNo ratings yet

- Significance of Cross Elasticity of DemandDocument4 pagesSignificance of Cross Elasticity of Demandvijay vijNo ratings yet

- Products Services FCPO EnglishDocument16 pagesProducts Services FCPO EnglishKhairul AdhaNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Swot Analysis of BSNLDocument2 pagesSwot Analysis of BSNLNiharika SinghNo ratings yet

- Mid Term Exam 1 - Fall 2018-799Document3 pagesMid Term Exam 1 - Fall 2018-799abdirahmanNo ratings yet

- FEB 599 CAT 2015-2016 First SemesterDocument2 pagesFEB 599 CAT 2015-2016 First SemesterlucyNo ratings yet

- Royal Laundry ServicesDocument34 pagesRoyal Laundry ServicesRian Atienza EclarNo ratings yet

- ABS Summary TextDocument12 pagesABS Summary TextjesusmemNo ratings yet

- MBA Course StructureDocument2 pagesMBA Course StructureAnupama JampaniNo ratings yet

- DH Fire Training Schedule Jan 26-29, 2021Document15 pagesDH Fire Training Schedule Jan 26-29, 2021Noushin ShaikNo ratings yet

- Bookkeeping Problems Batch 1Document2 pagesBookkeeping Problems Batch 1lanz kristoff racho100% (1)

- Price and Return ModelsDocument38 pagesPrice and Return Modelsnoir_weizzNo ratings yet

- Share Holders Right To Participate in The Management of The CompanyDocument3 pagesShare Holders Right To Participate in The Management of The CompanyVishnu PathakNo ratings yet

- Acctg 202 Di Pa FinalDocument10 pagesAcctg 202 Di Pa FinalJoshua CabinasNo ratings yet

- B2B E-Marketplace Adoption in Agriculture: Zheng XiaopingDocument8 pagesB2B E-Marketplace Adoption in Agriculture: Zheng XiaopingNikhil MalhotraNo ratings yet

- Biz - Quatitative - Managment.Method Chapter.07Document27 pagesBiz - Quatitative - Managment.Method Chapter.07phannarithNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Analysis On Apollo Tyres LTDDocument43 pagesAnalysis On Apollo Tyres LTDCHAITANYA ANNENo ratings yet

- Objectives For Chapter 9: Business Cycle, Inflation and UnemploymentDocument19 pagesObjectives For Chapter 9: Business Cycle, Inflation and UnemploymentAnonymous BBs1xxk96VNo ratings yet

- Amount of Investment Bonus Method: Than Investment Greater Than InvestmentDocument14 pagesAmount of Investment Bonus Method: Than Investment Greater Than InvestmentElla Mae Clavano NuicaNo ratings yet

- Roles & Responsibilities of A Maintenance Engineer - LinkedInDocument4 pagesRoles & Responsibilities of A Maintenance Engineer - LinkedInEslam MansourNo ratings yet

- Not Include Customs Duties, Taxes, Brokerage Fees or Any Other Charges That May Be Incurred. They Are The Responsibility of The Recipient/consigneeDocument2 pagesNot Include Customs Duties, Taxes, Brokerage Fees or Any Other Charges That May Be Incurred. They Are The Responsibility of The Recipient/consigneeALIZON JAZMIN OROSCO QUISPENo ratings yet

- Example of RFP For Credit ScoringDocument4 pagesExample of RFP For Credit ScoringadaquilaNo ratings yet

- Algorithms to Live By: The Computer Science of Human DecisionsFrom EverandAlgorithms to Live By: The Computer Science of Human DecisionsRating: 4.5 out of 5 stars4.5/5 (722)

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveFrom EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveNo ratings yet