Professional Documents

Culture Documents

Tamol850 960 731A PDF

Uploaded by

dalton2003Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tamol850 960 731A PDF

Uploaded by

dalton2003Copyright:

Available Formats

TAMOL

SCALE INHIBITORS

TAMOL 850 TAMOL 960 TAMOL 731A

SCALE INHIBITORS In aqueous systems, such as boiler feed water and recirculated cooling water, dissolved salts and solid particles are present, which can form harmful scale deposits on equipment surfaces. Prevention of these deposits is essential for efcient equipment operation. Scale inhibition can be accomplished effectively with the use of synthetic polymers. Highly carboxyl-functional polymers such as TAMOL 850, TAMOL 960 and TAMOL 731A scale inhibitors can be used in various aqueous systems over a wide temperature range. FEATURES AND BENEFITS Inhibit scale deposits on equipment surfaces Promote efcient heat transfer Inhibit corrosion Decrease equipment damage Used over a wide range of temperatures MECHANISM FOR SCALE INHIBITION Polymeric scale inhibitors like TAMOL 850, TAMOL 960 and TAMOL 731A have several functions. The specic conditions in the aqueous system give predominance to one or more functions: Anti-precipitant action: Adsorption on the active sites of the crystal nuclei delays crystal growth and precipitation. Adsorption on positive sites of growing crystals forms crystals of distorted structure that are weak and less adherent to surfaces. Dispersant action by adsorption increases the negative charge on the sludge particles, reduces their tendency to agglomerate, and inhibits scale formation by keeping them suspended.

Rohm and Haas Company, 1999

TABLE I TYPICAL PHYSICAL PROPERTIES (these do not constitute specications)

Product 5000 Clear, pale yellow liquid Clear, pale yellow liquid Clear, pale yellow liquid 24-26 9.2 29-31 9.9 9.0-10.8 39-41 10.6 8-9

Type

Molecular Weight Mw1 Appearance % Total Solids pH

Density 25C lbs/gal

Brookeld Viscosity 25C, cps 300-800

Spindle/Speed #2 @ 30

TAMOL 960

Na Salt of PMAA

TAMOL 850

Na Salt of PMAA

30000

125-325

#2 @ 60

2 15000 15000 White to tan freeowing powder 91 min.

TAMOL 731A

Na Salt of a maleic anhydride copolymer

9.5-10.53

19-182

#2 @ 60

TAMOL 731 SD

Na Salt of a maleic anhydride copolymer

262

9.3-10.53

1Weight

average molecular weight determined by aqueous GPC.

2Average

bulk density of Tamol 731 SD is expressed in units of lbs/ft3.

3Measured

on a 10% aqueous solution.

THERMAL STABILITY High-temperature stability is an important requirement in most water treatment applications and is a fundamental requirement for polymers used in internal boiler-water treatment. Thermogravimetric analysis is often used to rank polymers in order of their thermal stability. This is done by comparing polymer weight loss vs. temperature. In Table II the decomposition temperature is the temperature at which the onset of signicant polymer weight loss occurs.

TABLE II THERMOGRAVIMETRIC ANALYSIS OF TAMOL POLYMERS Polymer Decomposition Temperature (in air, C) 450 425 365

TAMOL 850 TAMOL 960 TAMOL 731A

As the data in Table II indicate, TAMOL 850 and TAMOL 960 are stable to temperatures above the critical point of water (375C): this suggests that these polymers have potential as sludge scale inhibitors even in high-pressure boiler-water treatment. DISPERSANT ACTIVITY The dispersant activity of carboxyl-functional polymers is an important element of their ability to inhibit scale formation. The effectiveness of a polymeric dispersant is dependent on the particle to be dispersed, the medium in which it is being dispersed, and the chemical structure of

the dispersant. A determination of Fluidity Point gives a general indication of the dispersant activity of a polymer. The Fluidity Point is determined by a titration method and is dened as the concentration of dispersant needed to achieve uidity in a mass of particles in an aqueous system. The Fluidity Point is the minimum amount of dispersant that must be used to deocculate the particles in the system. The data in Table III illustrate that TAMOL 850, TAMOL 960 and TAMOL 731A exhibit good dispersant activity, an important function for effective scale inhibition.

TABLE III FLUIDITY POINT % Polymer Solids Based on Dispersed Solids Compound Calcium Phosphate Calcium Carbonate Magnesium Oxide Iron Oxide TAMOL 850 0.05 0.04 1.01 0.13 TAMOL 960 0.07 0.04 0.90 0.13 TAMOL 731A 0.09 0.05 1.08 0.15

TAMOL 731A dispersant is exceptionally effective for stabilizing dilute iron oxide suspensions, as Table IV shows. In this study, a suspension containing 700 ppm of iron oxide (pH 7.5) was allowed to settle four hours. The turbidity of the uppermost layer was measured in a nephelome-

ter. The higher the turbidity value, the greater the stability of the suspension and the more effective the dispersant. The result suggests that TAMOL 731A dispersant should greatly reduce the tendency of iron oxide to form deposits from recirculated cooling and boiler feed waters.

TABLE IV TURBIDITY OF IRON OXIDE SUSPENSIONS Dispersant None TAMOL 731A (3 ppm) Polyacrylate (3 ppm) Phosphonate (3 ppm) Turbidity Units 77 860 100 60

VISCOSITY CHARACTERISTICS TAMOL 850, TAMOL 960, and TAMOL 731A have low viscosity at temperatures as low as 5C and should present no handling problems at temperatures above freezing, as indicated in Table V.

TABLE V VISCOSITY VS. TEMPERATURE Viscosity (cps), 12 rpm TAMOL 850 30% 470 250 TAMOL 960 40% 2,300 500 TAMOL 731A 25% 150 70

Temperature, C 5 25

SURFACE-ACTIVE AND FOAMING PROPERTIES TAMOL 850 and TAMOL 960 exhibit very little surface activity and are essentially non-foaming. TAMOL 731A is weakly surface-active and produces somewhat more foam than the other polymers; however, at low use levels, TAMOL 731A should present no foaming problem. Table VI illustrates the effect of these polymers on the sur-

face tension and the interfacial tension between water and a highly rened mineral oil. The properties of Triton X-1001, a commonly used surfactant, are included for comparison. Values were obtained by ASTM Method D 1331-56, using a du Nouy Tensiometer. Table VII gives the foam heights for several concentrations of the TAMOL polymers.

1Triton

is a registered trademark of Union Carbide Corp.

TABLE VI SURFACE-ACTIVE PROPERTIES OF TAMOL POLYMERS AT 25C Surface Tension (dynes/cm) 1.0% 71 63 36 30 72 0.1% 64 29 Interfacial Tension of Acroprime 90 vs. water (dynes/cm) 1.0% 51 42 15 1 52 0.1% 40 5

Product Active Ingredient, % TAMOL 850 TAMOL 960 TAMOL 731A Triton X-100 None

TABLE VII FOAM HEIGHT OF TAMOL POLYMERS (Hamilton Beach Test, 25C, cm) Polymer Active Ingredient 5 seconds 15 seconds 30 seconds TAMOL 850 0.1% 0.6 0.2 0.2 TAMOL 960 0.1% 0.2 0.2 0.1 TAMOL 731A 0.1% 4.4 4.0 3.3 0.01% 0.6 0.4 0.3

FDA CLEARANCE TAMOL 850, TAMOL 960, and TAMOL 731A conform with the FDA regulations indicated Regulation Title or Application Boiler-water additives Adhesives

below, provided that the nal formulation meets any extractives limitations and other conditions prescribed by the regulation: TAMOL 850 TAMOL 960 X X X X1 X X X

Number 21CFR173.310 21CFR175.105 21CFR175.300 21CFR176.170 21CFR176.180

TAMOL 731A

Resinous and polymeric coatings Components of paper, paperboard in contact with aqueous and fatty food Components of paper, paperboard in contact with dry food

1TAMOL

850 may be used as a coating adjuvant for controlling viscosity when used at a level not to exceed 0.3% by weight of coating solids. TAMOL 960 may be used as a coating adjuvant for controlling viscosity when used at a level not to exceed 0.1% by weight of coating solids.

ISO 9002-CERTIFIED These products are manufctured in an ISO 9002certied facility. SAFE HANDLING INFORMATION CAUTION: CONTACT CAUSES IRRITATION OF THE EYES AND SKIN. Vapors may irritate the eyes and respiratory tract, especially in poorly ventilated areas. Avoid breathing the vapors. KEEP OUT OF THE REACH OF CHILDREN FIRST AID MEASURES In case of contact, ush the eyes immediately with plenty of water for at least 15 minutes; call a physician. Wash the skin thoroughly with soap and water. If clothing is drenched with the liquid products, remove and launder them before rewearing. If swallowed and victim is conscious, dilute by giving two glasses of water to drink and call a physician immediately. Never give anything by mouth to an unconscious person. If overcome by vapors, remove victim to fresh air. Administer oxygen or articial respiration if victim shows difculty in breathing.

TOXICITY Toxicity screening tests have shown that the acute oral toxicity (LD50) in rabbits is greater than 5 g/kg for all of these materials. The acute dermal toxicity (LD50) in rabbits is greater than 2 g/kg for TAMOL 850 and TAMOL 731A. The TAMOLbrand products contain a low level of formaldehyde preservative (except TAMOL 731A). TAMOL 850 and TAMOL 960 contain a low level (below 0.1%) of residual monomer. Inhaling vapors of these materials may irritate the eyes and respiratory tract and may cause headache and nausea, especially in poorly ventilated workplace areas. Direct contact with the liquid grades or TAMOL 731 SD irritates the eyes and prolonged or repeated contact with the skin may be irritating and produce rashes. GENERAL HANDLING INFORMATION Provide adequate ventilation in the workplace or storage areas to remove irritating vapors and dusts. In storing the liquid grades, keep from freezing. Wastes can be directed to a sewage treatment plant. The biological oxygen demand of these materials is low; the value for TAMOL 850, for example, is about 3,100 ppm.

MATERIAL SAFETY DATA SHEETS Rohm and Haas Company maintains Material Safety Data Sheets (MSDS) on all of its products. These contain important information that you may need to protect your employees and customers against any known health and safety hazards associated with our products. We recommend you obtain copies of MSDS for our products from your local Rohm and Haas technical representative or the Rohm and Haas Company. In addition, we recommend you obtain copies of MSDS from your suppliers of other raw materials used with our products. Under the OSHA Hazard Communication Standard, workers must have access to and

understand MSDS on all hazardous substances to which they are exposed. Thus, it is important that appropriate training and information be provided to all employees and that MSDS be available on any hazardous products in their workplace. Rohm and Haas Company sends MSDS on nonOSHA-hazardous as well as OSHA-hazardous products to both bill-to and ship-to locations of all our customers upon initial shipment (including samples) of all of our products. Updated MSDS are sent upon revision to all customers of record. In addition, MSDS are sent annually to all customers of record.

For additional information, a sample, a Material Safety Data Sheet or to have a technical representative call for the nearest Rohm and Haas Ofce. THE AMERICAS Corporate Headquarters Rohm and Haas Company 100 Independence Mall West Philadelphia, PA 19106 Phone:1-800-223-3897 Fax: 610-437-5212 Canada Phone: 416-284-4711 Fax: 416-284-2982 Brazil Phone: 55-11-5185-9000 Fax: 55-11-5182-5110 Mexico Phone: 525-728-6666 Fax: 525-728-6653 EUROPE France, Paris Phone: 33-1-40-02-50-00 Fax: 331-43-45-28-19 Germany Phone: 49-69-78996-0 Fax: 49-69-7895356 Italy Phone: 39-02-95250-1 Fax: 39-02-95250399 Japan Phone: 81-3-5488 3100 Fax: 81-3-5488 3179 Philippines Phone: 63-2-8925091/98 Fax: 63-2-8183908 Singapore/Malaysia Indonesia Phone: 65-7350855 Fax:65-7350877 Taiwan Phone: 886-2-2718-7090 Fax: 886-2-2713-3857 Thailand Phone: 66-2-6791030 Fax: 66-2-6791039

ASIA/ PACIFIC Australia/ New Zealand Phone: 61-3-92724222 Fax: 61-3-92724211 China, North Phone: 86-10-6464-3450-60 Fax: 86-10-6464-3466 China, South Phone: 86-757-3363-3708 Fax: 86-757-336-5478 India Phone: 91-11-464 7570 Fax: 91-11- 464 7683

Internet Address: http://www.rohmhaas.com

TAMOL is a registered trademark of Rohm and Haas Company or of its subsidiaries or afliates, and is intended to designate goods marketed in North and South America; the same goods may be marketed in other countries, generally under other Company designations.

These suggestions and data are based on information we believe to be reliable.They are offered in good faith, but without guarantee, as conditions and methods of use of our products are beyond our control.We recommend that the prospective user determine the suitability of our materials and suggestions before adopting them on a commercial scale. Suggestions for uses of our products or the inclusion of descriptive material from patents and the citation of specic patents in this publication should not be understood as recommending the use of our products in violation of any patent or as permission or license to use any patents of the Rohm and Haas Company.

FC-127f

August 1999

Printed in U.S.A.

You might also like

- Reichhold: Coating Resins CatalogDocument35 pagesReichhold: Coating Resins CatalogAPEX SON100% (1)

- Specialty Additives and Solvents: For Coatings FormulationsDocument24 pagesSpecialty Additives and Solvents: For Coatings FormulationsManoj Lalita GoswamiNo ratings yet

- Diagram 1: Gibbs Equation On ElasticityDocument8 pagesDiagram 1: Gibbs Equation On ElasticityManoj Lalita GoswamiNo ratings yet

- Oxylink - Technical Product Information: Additive For Waterborne Resin SystemsDocument32 pagesOxylink - Technical Product Information: Additive For Waterborne Resin SystemsAPEX SONNo ratings yet

- LUBRIZOL General BrochureDocument20 pagesLUBRIZOL General BrochureMuhammad Ali100% (1)

- Clariant Brochure Emulsion Polymerization Portfolio 2017 EN PDFDocument4 pagesClariant Brochure Emulsion Polymerization Portfolio 2017 EN PDF幸福100% (1)

- AkzoNobel Paint Eng Tcm54-18194Document20 pagesAkzoNobel Paint Eng Tcm54-18194a2009sNo ratings yet

- LoVOCoat - For Low VOC High Performance Solvent Borne CoatingsDocument4 pagesLoVOCoat - For Low VOC High Performance Solvent Borne CoatingskarlaNo ratings yet

- Additives For Solvent-Free Epoxy Floor CoatingsDocument6 pagesAdditives For Solvent-Free Epoxy Floor CoatingscockeiserNo ratings yet

- Polymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3From EverandPolymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3No ratings yet

- Antifoam PresentationDocument15 pagesAntifoam PresentationAnonymous qLk7qDHfK100% (2)

- Acrysol rm-8w 3Document4 pagesAcrysol rm-8w 3Forever0% (1)

- Redispersible Powders - DOWDocument4 pagesRedispersible Powders - DOWAnonymous Cf3oL4x4No ratings yet

- Eo Po Block Co PolymersDocument29 pagesEo Po Block Co PolymersUtpalNo ratings yet

- Croda How To LoVOCoatDocument6 pagesCroda How To LoVOCoatkarla100% (1)

- Anionic Surfactant BrochureDocument6 pagesAnionic Surfactant BrochureKarolina SaavedraNo ratings yet

- Pergut EDocument17 pagesPergut ECesar MartinezNo ratings yet

- Defoamers: TEGO® FoamexDocument10 pagesDefoamers: TEGO® FoamexAbhinav TayadeNo ratings yet

- Jo GradeDocument40 pagesJo GradeEvonne TanNo ratings yet

- Paint Additives: Product Guide L-G 1Document16 pagesPaint Additives: Product Guide L-G 1محمد عزتNo ratings yet

- Automotive Coatings Product Guide: Resins, Polymers, Dispersants & AdditivesDocument7 pagesAutomotive Coatings Product Guide: Resins, Polymers, Dispersants & AdditivesAmado ElzNo ratings yet

- Rhoplex Ac 3001Document12 pagesRhoplex Ac 3001hongducxxxNo ratings yet

- Guide To Surfactant ChemistryCMT1!20!12Document12 pagesGuide To Surfactant ChemistryCMT1!20!12jeremykramerNo ratings yet

- Rheology ModifiersDocument35 pagesRheology Modifierssbttbs67% (3)

- Sulphonation Technology in The Detergent IndustryDocument5 pagesSulphonation Technology in The Detergent IndustryСергей КубахNo ratings yet

- Resins For: Vehicle Refinish & Commercial Transportation CoatingsDocument6 pagesResins For: Vehicle Refinish & Commercial Transportation CoatingsEmilio HipolaNo ratings yet

- Additives FOR Specialty Chemistry Formulations pER Function: Product ListDocument16 pagesAdditives FOR Specialty Chemistry Formulations pER Function: Product ListAPEX SONNo ratings yet

- Safety Data Sheet: Glutaraldehyde 50% Solution Low MethanolDocument13 pagesSafety Data Sheet: Glutaraldehyde 50% Solution Low MethanolAdi Wahyu Mancunian Arzanto100% (1)

- Technical Data Sheet: Latex Emulsion PaintsDocument2 pagesTechnical Data Sheet: Latex Emulsion PaintsAaron Chris Gonzales100% (1)

- EDM - 012 Additives For Wood and Furniture Coatings PDFDocument8 pagesEDM - 012 Additives For Wood and Furniture Coatings PDFEugene PaiNo ratings yet

- Supreme: Premium Opacifying Mineral For Titanium Dioxide ExtensionDocument2 pagesSupreme: Premium Opacifying Mineral For Titanium Dioxide Extensionkensley oliveiraNo ratings yet

- The Big TEGO. Products Services Data Sheets-75-150!1!15Document15 pagesThe Big TEGO. Products Services Data Sheets-75-150!1!15DWI RAHMASARI FATMAWATINo ratings yet

- Paten US8957127 - Liquid Glue Formulated With Acrylic Emulsions - Google PatenDocument4 pagesPaten US8957127 - Liquid Glue Formulated With Acrylic Emulsions - Google PatenSepvan ValeriNo ratings yet

- Soyol Polyol FormulationsDocument3 pagesSoyol Polyol FormulationsurethanNo ratings yet

- Resin Solubility ChartDocument7 pagesResin Solubility ChartLaboratorio InkctechNo ratings yet

- UCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex D 161Document4 pagesUCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex D 161sriatul2006No ratings yet

- 20 - Alkyd Emulsifier - ES 4045 - 2019 EditionDocument4 pages20 - Alkyd Emulsifier - ES 4045 - 2019 Editionumar buttNo ratings yet

- Incozol 2 DataDocument2 pagesIncozol 2 DataJeffrey Bempong100% (1)

- Paint BrochureDocument8 pagesPaint BrochureDharmendra B MistryNo ratings yet

- Akzonobel Formulation 2C 75 01Document1 pageAkzonobel Formulation 2C 75 01culiniNo ratings yet

- FoamStar ST 2412 August 2018 R3 ED2Document2 pagesFoamStar ST 2412 August 2018 R3 ED2APEX SONNo ratings yet

- Surfactant AnalysisDocument5 pagesSurfactant Analysisjuli_radNo ratings yet

- Rhodoline Ote 500Document2 pagesRhodoline Ote 500ReginaldojoaquimNo ratings yet

- ECOSURF LiteratureDocument16 pagesECOSURF LiteratureTrev GlasbeyNo ratings yet

- Crayamid 115X - 70%Document2 pagesCrayamid 115X - 70%WALTER KLISSMANNo ratings yet

- Eastman Coatings: Formulating Solutions: Meeting VOC Regulations With CoalescentsDocument4 pagesEastman Coatings: Formulating Solutions: Meeting VOC Regulations With Coalescentsvijay662No ratings yet

- Maxfloc - TDocument3 pagesMaxfloc - TChoice OrganoNo ratings yet

- Dow-Espesantes ACRYSOLES PDFDocument12 pagesDow-Espesantes ACRYSOLES PDFAntonio Benitez MendozaNo ratings yet

- Economic Paint RedaDocument1 pageEconomic Paint RedaForeverNo ratings yet

- Brochure Alcohol Ethox StepanDocument24 pagesBrochure Alcohol Ethox StepanMiguel Angel Diaz100% (2)

- Long Durability Exterior CoatingDocument1 pageLong Durability Exterior CoatingAmit BholaNo ratings yet

- Floor CareDocument11 pagesFloor CareShravan DurgaNo ratings yet

- 07 Hungary Interior VINNAPAS VAE Dispersions 2018e KotschiDocument62 pages07 Hungary Interior VINNAPAS VAE Dispersions 2018e KotschiForeverNo ratings yet

- Optifilm Enhancer 300: A Low Odour, Non-VOC Coalescent For Dispersion PaintDocument16 pagesOptifilm Enhancer 300: A Low Odour, Non-VOC Coalescent For Dispersion PaintAPEX SONNo ratings yet

- Primal Ac 369sDocument20 pagesPrimal Ac 369shongducxxx100% (1)

- FORM 07-1018A Semi Gloss Deeptone Paint Formula Af Xls 500 and Nhs 300 PDFDocument1 pageFORM 07-1018A Semi Gloss Deeptone Paint Formula Af Xls 500 and Nhs 300 PDFelgendawyNo ratings yet

- TAMOL™ 960 Tamol 731A: Scale InhibitorsDocument4 pagesTAMOL™ 960 Tamol 731A: Scale InhibitorsErick FaundezNo ratings yet

- BT 35 PDFDocument6 pagesBT 35 PDFdalton2003No ratings yet

- BT 25Document8 pagesBT 25dalton2003No ratings yet

- PBDocument6 pagesPBdalton2003100% (1)

- Am Fsropro e Cell enDocument2 pagesAm Fsropro e Cell endalton2003No ratings yet

- PBDocument6 pagesPBdalton2003100% (1)

- BT 58Document7 pagesBT 58dalton2003No ratings yet

- Owner/Operator Seminar Tuesday, February 7, 10:00a - 2:00p (Lunch Will Be Included)Document1 pageOwner/Operator Seminar Tuesday, February 7, 10:00a - 2:00p (Lunch Will Be Included)dalton2003No ratings yet

- BT 31Document9 pagesBT 31dalton2003No ratings yet

- Flocon 285Document2 pagesFlocon 285dalton2003No ratings yet

- Water Treating Panel Discussion Monday, February 4, 2008 2:00p To 3:45pDocument4 pagesWater Treating Panel Discussion Monday, February 4, 2008 2:00p To 3:45pdalton2003No ratings yet

- Table To Play OutDocument1 pageTable To Play Outdalton2003No ratings yet

- 2011 Seminar EducationDocument1 page2011 Seminar Educationdalton2003No ratings yet

- 2006 Winter WT MinutesDocument2 pages2006 Winter WT Minutesdalton2003No ratings yet

- Appendix: Ionization of CO Solutions As Function of TH PH at 25 CDocument1 pageAppendix: Ionization of CO Solutions As Function of TH PH at 25 Cdalton2003No ratings yet

- CTSM 2 MSDS 1Document2 pagesCTSM 2 MSDS 1dalton2003No ratings yet

- Forugh Farrokhzad 2012 3Document71 pagesForugh Farrokhzad 2012 3Eliana Galanda100% (1)

- Stabrom 909 MSDSDocument6 pagesStabrom 909 MSDSdalton2003No ratings yet

- Material Safety Data Sheet: U.S. Department of LaborDocument2 pagesMaterial Safety Data Sheet: U.S. Department of Labordalton2003No ratings yet

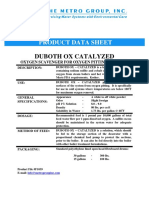

- Duboth OX Catalyzed - Product DataDocument1 pageDuboth OX Catalyzed - Product Datadalton2003No ratings yet

- BWA Belcor 575 Replaces Molybdate USA WF 0Document2 pagesBWA Belcor 575 Replaces Molybdate USA WF 0dalton2003No ratings yet

- EDTMP Na5Document1 pageEDTMP Na5dalton2003No ratings yet

- 1st Announcement 66th COE - IOA, Banjarmasin, 9-12 May 2018Document15 pages1st Announcement 66th COE - IOA, Banjarmasin, 9-12 May 2018Masda Kamarullah Ribas100% (1)

- Study On Consumer Behavior For Pest Control Management Services in LucknowDocument45 pagesStudy On Consumer Behavior For Pest Control Management Services in LucknowavnishNo ratings yet

- Voice Over Script For Pilot TestingDocument2 pagesVoice Over Script For Pilot TestingRichelle Anne Tecson ApitanNo ratings yet

- Material Safety Data Sheet: Liquefied Petroleum GasDocument1 pageMaterial Safety Data Sheet: Liquefied Petroleum GasardhanhendroNo ratings yet

- Citations Issued Due To COVID-19Document726 pagesCitations Issued Due To COVID-19Maritza NunezNo ratings yet

- Understanding Desistance From Crime Laub and SampsonDocument70 pagesUnderstanding Desistance From Crime Laub and Sampsonchrisgoss1No ratings yet

- Mental Health in The Time of Pandemic Ma. Grace Baquiran-Sison, MD, DpcomDocument32 pagesMental Health in The Time of Pandemic Ma. Grace Baquiran-Sison, MD, Dpcomcelica juabanNo ratings yet

- Cleaning Reusable Medical DevicesDocument12 pagesCleaning Reusable Medical DevicesDavid Olamendi ColinNo ratings yet

- Kraniotomi DekompresiDocument17 pagesKraniotomi DekompresianamselNo ratings yet

- Pe2 Lasw11w12Document4 pagesPe2 Lasw11w12christine mae picocNo ratings yet

- TES Harian: Bahasa InggrisDocument3 pagesTES Harian: Bahasa InggrisAlfiya HasnaNo ratings yet

- Dental Juris and Practice MGT Board 2008Document14 pagesDental Juris and Practice MGT Board 2008Anonymous FwwfR650% (2)

- Ada 2018Document174 pagesAda 2018CarlosChávezNo ratings yet

- Biodata Format FinalDocument5 pagesBiodata Format FinalCharles Saurus PacomaNo ratings yet

- Msds Uq160 enDocument5 pagesMsds Uq160 enAnnalisa GiammòNo ratings yet

- Becks Depression Inventory BDI IIDocument4 pagesBecks Depression Inventory BDI IIAnalyn GalwardoNo ratings yet

- EffectiveTeaching Full ManualDocument340 pagesEffectiveTeaching Full ManualHabtamu AdimasuNo ratings yet

- Lesson 2 Prepare Cereal and StarchDocument25 pagesLesson 2 Prepare Cereal and StarchLieybeem Vergara50% (2)

- Code of Conduct Shell Vs PetronasDocument4 pagesCode of Conduct Shell Vs PetronasSharulNizamAkilayni100% (1)

- Planning PlaygroundDocument16 pagesPlanning PlaygroundAdnan AliNo ratings yet

- SDS N 7330 NorwayDocument15 pagesSDS N 7330 NorwaytimbulNo ratings yet

- Recall GuidelinesDocument31 pagesRecall GuidelinesSandy PiccoloNo ratings yet

- Dental Trauma - An Overview of Its Influence On The Management of Orthodontic Treatment - Part 1.Document11 pagesDental Trauma - An Overview of Its Influence On The Management of Orthodontic Treatment - Part 1.Djoka DjordjevicNo ratings yet

- Altius Annual Leave Policy Wef 1st January 2012 Ver 1.1Document11 pagesAltius Annual Leave Policy Wef 1st January 2012 Ver 1.1Mudassar HakimNo ratings yet

- Sps8 Q1mod1 Skill Related Parameters Noel Rullan Bgo v2Document20 pagesSps8 Q1mod1 Skill Related Parameters Noel Rullan Bgo v2RandyNo ratings yet

- Intro To EugenicsDocument16 pagesIntro To EugenicsJesus LivesNo ratings yet

- Analytical Customer UpdationDocument16 pagesAnalytical Customer UpdationSathish SmartNo ratings yet

- HACCP in Milk Industry: Ankara University, Faculty of Veterinary Medicine Department of Food Hygiene and TechnologyDocument18 pagesHACCP in Milk Industry: Ankara University, Faculty of Veterinary Medicine Department of Food Hygiene and TechnologyGeorgette RepunteNo ratings yet

- Revised Week 3Document61 pagesRevised Week 3John Teo DalisaymoNo ratings yet

- REFERENCES in APA Style 7th EditionDocument2 pagesREFERENCES in APA Style 7th EditionReabels FranciscoNo ratings yet