Professional Documents

Culture Documents

API - Centrifugal Pump (Section 1,2,3) PDF

Uploaded by

Imtiaz Ali0 ratings0% found this document useful (0 votes)

2K views128 pagesit contains basic knowledge regarding pump..

Original Title

API - Centrifugal Pump [Section 1,2,3].pdf

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentit contains basic knowledge regarding pump..

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2K views128 pagesAPI - Centrifugal Pump (Section 1,2,3) PDF

Uploaded by

Imtiaz Aliit contains basic knowledge regarding pump..

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 128

Training For Professional Performance

This manual is one of a seri es for

your use in learning more about equipment

that you work with in the oilfield. Its

purpose is to assist in developing your

knowledge and skills to the point that you

can perform your work in a more

professional manner.

The manual was prepared so t hat you

can learn its contents on your own time,

without the assistance of an instructor or

classroom discussion. Educators refer to

learning by self -study as Programmed

Learning. It is a method widely used in all

industries as a means of trai ning employees

to do their job properly and teach them

how to perform higher rated jobs.

You can demonstrate your desire to

be a professional by taking a positive

attitude toward learning the contents of

this manual and others that are applicable

to your job.

The au thor of tliis manual has years

of experience in operating petroleum

equipment. He also has t he technical

knowledge of how and why petroleum

equipment functions. The text was written

_ . for use by personnel with little or no

? previous experience with petroleum equip-

ment. Consequently, some of the mate rial

may be familiar to you if you have

experience with oilfield equipment. From

such experience, you have observed the

effect of making operating changes. The

manual will help explain why the changes

occurred that you observed. It will also

teach you how and why equipment

functions.

In order for you to learn the contents

of the manual, you must dig out the perti-

nent facts and relate them to the subject.

Simply reading the material and answering

the questions is not enough. The more

effort you make to learn the material the

more you will learn from the manual.

Teaching yourself requires seif-

discipline and hard work. In order to pre-

pare yourself for the sacrifice you will have

to make, you should set goals for yourself.

Your ultimate goal is to perform your work

in a more professional manner. Training is

one step in reaching tha t goal. Application

of what you learn- is another. Seeking

answers to questions is a third.

Once you have established your final

goal, you must determine the means for

reaching that goal. You may decide, for

example, that you must complete a series of

10 or 15 manuals. to get the basic knowledge

and skills you need. After you decide which

training material is required, you should set

a time table for completing each section of

the material.

Achieving your final goal may take

more than a year, and will require hours of

hard work on your part. You will know you

have achieved your goal when you under-

stand how and why to operate oilfield equip-

ment in order to obtain the maximum pro-

duct at the lowest cost. Your sacrifice will

have been worth-while from the satisfaction

of knowi ng that you can perform your job in

a methodical professional manner, instead of

a trial-and-error-approach.

Instructions For Using This Manual

This is your manual. You should write

your name on the cover. Upon complet ion you

will find it helpful to keep it in an accesslble

place for future reference.

Problems may be included throughout

the text. The solutions to the problems are

given at the end of the book.

The manual is used in traini ng programs

all over the world. In some countries, English

of measurement such as feet, gallons,

etc., are used. In other countries

Systems Internationale (SI) or Metric units,

such as meters, liters, kilograms, etc., are

used. In order for the manual to be of

maximum use, both SI and English units are

shown.

The SI unit always appears first, and the

English unit follows in brackets []. Example:

the temperature is 25'C [77'F], The

English equivalent of the SI Unit will be

rounded off to the nearest whol e number to

. plify the text and examples. A distance of

m may be shown as 33 ft when the exact

equi valent is 32.81 f1.

If you are working in English umts, you

may find it helpful to mark out the parts that

are in SI units, and vice versa.

Some of the Figures have units of

In such cases, two Figures are

included. The first one has Sl units, and the

Figure number is followed by the .letter A

(Example: Figure lA). The second Flgure wllI

be on the next page and will have English

units. It will be the same number as the first

one but it will be followed by the leiter 8

(Figure 18). If you use SI units, be sure to

refer to Figures followed by the letter A; lf

you use English units, refer to Figures

followed by the letter 8.

The following general procedure is rec-

ommended for using thi s manual :

1. Turn to Page 1. Read the material

until you come to the first problem

or question.

2. Work the first problem or answer the

question and enter the answer in the

proper space in ink. If the probl em

or question i s shown in both SI and

English units of measurement, answer

only t he part in units of measurement

tha t you use.

3. Compare your answer with that

shown at the end of the book; be sure

to use solut ions to the probl ems in

the units you are working in.

If your answer is correct, conti nue

reading unti 1 you come to the next

problem and work it. If not, restudy

the manual until you understand the

reason for your error. Rework the

problem if necessary. Leave your

wrong answer and note the correct

one. This will keep you from making

the same mistake later on.

4. Proceed stepwise as shown above

until you have completed the text.

The above approach will require

thought, making mistakes, and ret hinking the

situati on. Concentrate on two things - the how

and the why. Do not cheat yoursel f by taking

shor t-cuts or looking up the answers m

advance. It saves time and errors but pro-

duces no real understanding. Your future

depends on how efficlentl y you perform your

job and not on how rapidly you proceed

t hrough this manual. Since this is your

manual, any errors you make are private.

Abbrevjations Used

In This Manual

SI UNIT ABBREVIATIONS

s, min second, minute time

h, d hour, day time

mm millimeter length

cm centi meter length

m meter length

km kilometer length

2

square meter m area

m' cubic meter volume

m'ld cubic meters per day volume rat e

L li ter volume

g gram weight

kg kilogram weight

kPa kilopascal pressure

MPa megapascal pressure

kPa(a) ki l opascal absolute pressure

bar bar (1 bar = 100 kPa) pressure

kJ k i l o j o l ~ heat, work

MJ megajoul e heat, work

W, kW watt, kil owatt power

M meta million

ENGLISH UNIT ABBREVIATIONS

s, min second, minute time

h, d hour, dgy t ime

in, ft inch, foot length

sq in square inch area

sq ft square foot area

cu ft cubic foot volume

gal gallon volume

bbl bal'rel (42 US gal) volume

BPD barr el s per day volume rate

Ib pound weight

psi Ibs per square inch pressure

psia Ibs per sq in absolute pressure

Btu British thermal unit heat

MBtu thousands of Btu heat

MMBtu millions of Btu heat

IV , kIV wat t , kilowatt power

hp horsepower power

d i d cubic feet per day gas flow ra te

Md/d thousands of cfl d gas flow ra te

MMcf/ d millions of cfl d gas flow rate

M thousand

MM million

Units Of Measurement

SI UNITS OF MEASUREMENT

Most of the SI units of measurement used in

the oilfield are traditional metric units. The

exceptions we are concerned wi th are pressure

and heat units, which differ as follows:

METRIC SI UNIT CONVERSION

UNIT

Pressure bar ki lopascal, kPa

kPa

bar = IOU

Heat kil ocal kilojoul e, kJ

kJ

kcal =[2

STANDARD CONDITIONS FOR GAS VOLUME

Measurement units for gas volume are cubic

met ers (m ' ) or cubic feet (cf). The lett ers st

or s are someti mes used with t he units to

designate volume at standard temperature and

pressure: m' (51) or scf . In thi s manual, st an-

dard volumes are corrected to a temperature

of 15 C and a pl'essure of 101. 325 kPa(a), or

GO F and 14.7 psia.

To si mplify the text, the letters st and

s are omitted However, aU gas volumes

shown are at st andard conditions unless

specifi cally stated otherwise.

HEAT CAPACITY AND RELATIVE DENSITY

Specific heat and specific gravity are tradi-

ti onal t erms that have been used in both

Metri c and Engl ish uni ts for many years.

These names are being I'eplaced with the

words: heat capacity and relative densi ty.

The new names are used i n thi s manual. When

you see the term heat capeci ty (Ht Cap), it

will have the same meaning as specific

heat; and relati ve density (ReI Dens )

means specific gravity.

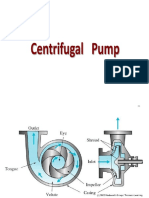

CENTRIFUGAL PUMPS

TABLE OF CONTENTS

INTRODUCTION ...... . ......... . ... ... . . .... .. .. . . . ... . ..... . ...... I

I. DESCRIPTION OF CENTRIFUGAL PUMPS... . . .. . . ... . . . . .. . .. . . .. 2

A. Basic Pump Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1. Case . ... ... . .... . ... ... .... . ... . . . .. . . .. . ... .... . . . . . . 2

2. Impell er. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3. Shaft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

4. Bearings . ..... . . _ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

5. Seal or Packing . .... . .... . ............... . ... .. . .. . . ... . 3

B. Couplings ... . ....... . . . ... .... .. .... . .. ... .. .... . . . .. . .... 4

C. Types of Cent rifgual Pumps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6

D. Alternate Sealing Systems . .............. . . . .. . . . .. .. ... .. .. 10

II . PRINCIPLES OF CENTRIFUGAL PUMPS . . .. .................... 14

A. Flow Through Pumps ............ . . .. . . .... ... .. ... . .. . ... ... 14

B. Centrifuga l Force ... ... . .... ....... . ................ . .... . 14

C. Head Pressure . ....... . ... . ..... .. ....... . ............ .. ... 16

D Cavitation and Vapor Lock .. . . . . ... ............. . . . ........ . 17

E Performance Curves . . . . . .. .... . ..... . ... .... . ... .... .. .. ... 19

F. Pump Efficiency ... . . .. . ... . ... . ..... ... ... . ....... . .. . ... 21

G. Driver Power .... .. ...... . ....... ... . . . ..... .. .. . . . ...... . . 24

H. Liquid Suction Head ............ .. . ... . ... . .. ......... . . .... 25

I. Thrust . . ... .. . . . ... .. .. . . " ... ... .. . . . ..... .. ... . .... .. . . . 27

J . Pump Curve Appli cation .. ... . .... .. .... . .... . .. .. .. ... . . . . 29

III. OPERATION .... . ... . .. .. . .... . .... .. ... ... . ... . . . ... . . .. .. .. .. 35

A. Start-up Procedure . .... . . .. .. . . . ..... . . . . .. . .. .... . . . . .. .. 35

B. Control of Pump Flow Rate . . . . . . ... ... ... .. .. .. . .. .. . ... .. .. 36

C. Shutdown Procedure ............ . ... ... .. .. ... ... .. . ........ 40

D. Routine Operating Checks .. . .... . .... . . ... .. ... . .. . . .. . .. .. 41

IV. TROUBLESHOOTING .. . . .... . .. . ......... . ...... . . . ...... . ..... 42

A. Troubleshooting Procedure for Vapor Lock . .. . . . . . . . . . .. . .... 42

B. Troubleshooting Procedure for Low Flow Rate .. . .............. 43

VALIDATION, SI UNITS .... . ... . .......... ......... . .. . . . ... . .. .. ... 45

SOLUTIONS TO PROBLEMS, SI UNITS . . .... . .... ... ... . . . . . .. . .. . ... 46

VALIDATION, ENGLISH UNITS ........ .. ... .. . . . . ... . . . . . . .. . . ... . .. 47

SOLUTIONS TO PROBLEMS, ENGLISH UNITS ............ . ........ ... . 48

LIST OF DRAWINGS, GRAPHS AND ILLUSTRATIONS

Impellers ..... ... .............. . .. ......... ... .. ..... . .. ........

Cut-away Picture of Pump

2

3

Packing and Seals .. ....... .. .... .. .. ....... . .. .. ... . ............. . 4

Couplings .... .. . ... ... .... ... .. ... . ........ ..... . .. . ............ 6

Pump with 2 Seals . . .................. ... ... . .. ... .... .. . ...... .. . 10

Seal Oil Pots . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . .. . . . . . . . . . .. 11

Circulating Seal Oil System 13

Flow Through P-ump ... .... . . ......... .. .... .. .... .. . . . .... ...... ... 14

Head Pressure . .. . .......... . . ..... ..... .. . .. . ........ . . . ..... ... 17

Procedure to Clear Vapor Lock 18

Pump Performance Curves . . ... .. .. . .. .. . . ..... . ... . .... . 20, 22, 23

Liquid Suction Head ........ .. . .... . . .... ... .... ....... . . . .. ... 26

Thrust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 27, 28

Balance Piston . . ... . .... .. ................ . .. .... .. .......... . ... 28

Design Conditions for Stabilizer Feed Pump .. . .. . .. .... . ............ 29

Performance Curves for Stabil izer Feed Pump ...... . . .. ....... . 30, 31

Start-up Procedure .............. .... .. ........ . .............. . 35

Flow Control with Control Valve in Discharge Line . .. ... .. .. .. .. .. . .. 36

Regulated with Level Controller

Flow Control with Control Valve in Discharge Line .. ... ........ . .. .. , 37

RJ',!/ulated with Pressure Controller

Low Flow Recycle .. ........ .. ... .... .. . ........ . ...... ... . .. 38

Flow Contl'ol By Changing Driver Speed ... ........ .. . . .. . ....... 39

Effect of Pump Speed on Capacity, Pressure Head and Power . .. ... .... 40

CENTRJFUGAL PUMPS

INTRODUCTION

Pumps are used to force a liquid to flow from a point of low preso,;;ure to one of

highcr p,c,-,u,e.

Ther Are two general cia ifieutions of pumps:

l. Positive Displuc mcnt Pumps

2. Centrifugal Pumps

In thi., manual we will di ... cuss the Ccnl r'ifugal Pump. Posi tive Displacement Pumps

are discussed in Manual -17.

NOTE: Thi s manual includes bot h SI and Engli sh Units of measurement. I f you

use English Unit ... , disl'egard the i\ ietl'ic Units, and vice versa. Refer to

the instruc t ion page at the front of the manual.

.

. .

CENTRIFUGAL PUMPS

2 I. DESCRIPTION OF CENTRIFUGAL PUMPS

A. Basic Pump Parts

A t ypical Centnfugal Pump is shown on the opposi t e page, It has fi ve basic parts

which arc deseribed below:

l. Case - The pump ease 01' casing is the visible part of the pump, Most of the

othel' par'ls arc enclosed within it. It is usuAlly made of case iron or steel, plHStiC, or

other special mAteJ'ials. 1n the oilfield, casings on pumps operating at 8 pl'essure below

1000 kPa'[150 psiJ usually arc made of cast Iron, Pumps opel'ating at highel' pressu]' e

generally will have casing made of steel.

2, Impeller - The Impelle]' is the part of t he pump that causes the liquid pl'essul'e to

rise, It is fu'mly attached to the shaft with a key and/or pI'essed on the shaft, It rotat es

inside the case at the speed of the shaft.

l'he Impeller on most oilfield pumps is made of cast iron. However', stainl ess steel,

p l ~ l l c l or oUler' special mater ialS can be used for corrosive or chemical service. 'J'h!'c

are two gener.1 types of Impeller's; the open vane and the closed vane, The closed vane

develops a higher pressure, but has a lower capaci ty.

CLOSED VANE IMPELLER OPEN VANE IMPELLER

3, Shaft - The shaft I'otates inside the case at the speed of the dl'iver, It usually is

made of .teel. The portion or shaft exposed to the seal 01' packing may have a sleeve

made of some hard metal, such as tungston carbide, to resist corrosion or WeBI' at tl1a t

point.

-t. Bearings - Bearings serve two functions on a pump:

a, To hold the shaft so that it does not wobble inside the pump easing,

b, To prevent lateral movement or the shaft so that the rotating par ts do not touch

the pump casing, Th,'ust forces, developed as the impeller I'otates, are the main

PUMP PARTS 3

- Bearings

-

-.

Case

Shaft

Seal

PARTS OF CENTRIFUGAL PUMP

cause of lateral shaft movement. One or more of the bearings must be designed to

withst and the thrust forces .

On small process pumps, the bearings may be contained in the pump casing. On

larger pumps, the bearings are contained in housings located on one or both ends of the

shaft.

The bearings reqUIre lubrication. The bearing housing shown above is partially

filled with oil for lubricatrion. A sight glass indicates the level of oil in the housing. The

bearings shown on the end of eacll shaft on Page 5 are a grease lubricated type.

5. Seal or Packing - The seal or packing is used to prevent liquid under pressure

inside the pump from leaking out the pump.

The mechanical seal is used in most oilfield cen t rifugal pumps. It has two basic

components:

4 PUMP PARTS

PACKING RINGS

a. 1\ statiooary ring thll t is secured in the seal gland.

Sea l

Gland

Stationary

Seal Ri ng

Rotating

Ring

," Shaft

MECHANICAL SEAL

b. A rotating "i ng that is part of tile seal element attached to the shaft.

One of the seal ri ngs is made of cal'bonj the other is made of hardened steel,

ceramic Ot' other speci al non-cor r'osive material. Some seal manufacturers use a carbon

stati onary ring and other's a cHrbon "otating ring.

Packing often is used in low pressUl'e service, or in pumps handling abrasive liquids

such as mud or s]urr'y.

is composed of a series of pliable ri ngs contained in a packing gland. The

.. ings arc compressed by tightening the gland nuts. This squeezes the dngs aga inst the

shaft and p,'events liquid from leaking out,

"'Iecilanical seals generall y require much less maintenance than packing, so they are

used whenever poss ibl e. When they are used, liquid must be free of sand, dirt, or other

solid particles that CUll scratch the seal faces and cause leakage.

B. Couplings

The pump shaft connects to the driver with a coupling.

Couplings trans mit ,'otation from the dri ver shaft to the pump shaft. If a gearbox is

between the drive,' and the pump, a coupling attaches the dr ive,' shaft to the inlet gearbox

silaft. alld another coupling attaches the outlet bearbox shaft to the pump shaf t.

COUPLINGS 5

Bearings

Coupling

The couplings ill il st be able to withstand the shock of a sudden change in pump load,

0 1' stoppage of t he dr ivel' . They must be flexible enough to t,' ansmit power from the

dri ver to t he pump at high speed when the two shafts al'e not pcl'fectly al igncd, In fact, it

is almost impossible to perfectly align the two shafts, because the operati ng tempel'ature

diffel'ence between the d,' i ver and pump resul ts i n one expanding slightly more than the

otehr. The coupling must be able 10 1wobble' enough to overcome the misalignment.

Some of the more com man types of coupli ngs are shown on Page 6. In each type,

the drivel' shaft attaches t o one half or hub of the coupling, and the pump shaft att aches

to the other. The shafts al'e usually keyed to the coupling hubs.

Pl'oblem 1

Match each itcm in the column on the right with one on t he left.

Impell er a, Prevents liquid inside pump f rom leaking out.

Case b, Prevent shaft movement.

Seal c, Connects pump and dr iver,

Shaft d. Open or closed vane,

Bear ings e, Rotates inside pump.

__ Couplings f, Enclosure for rotating pump par t s.

Ii

CR It) COU,'UNG

Hubs art" ;'".hed with

serpent I '" ,, ;"lng that

fils il' In each hub.

c . Types of Cent r ifugal Pumps

PUMP TYPES

Hub

Sleeve

FLEXlflU DISC COUI'UNG

\ lubs attach to compo-

sitIOn di:.;cs that arc

casily replacl:d.

GEAR COUPLING

Hubs with gear t eeth

mesh with sl eeves

having rnatching t eeth.

(\,'Iltl'igu: d pumps can eithC'1' be hOl'jzontaJ or vCl'ti('ul. Tht' hOl'i7Clnla L pump I'l'quircs

l: 'olillda li on ror its mounti ng. the vertical pumr Can he nttaeilcd to the

l-.ilil 0 mi nimum of support bcnenth the pump. The horizontal pump is 11 more

P1lillp wl1i(' 11 will any vibration present.

V('I'll(,'al pump" are commonly used in process ph-Jots i n IOt'ations where vibrution is

:!I)t "pf'Obknt. I\nolilel' advantage or the vel' tical pump i s thul the ulignlTlent bf'twcen the

!110({'I[' lind Dump j -; much easier to maintain than that of the horizontal pump.

PUMP TYPES 7

HORIZONTAL PUMP

VERTICAL PUMP

1. Mul tistage Pumps

As we win learn later, there will be occasions when 2 or more impellers are needed

for the pump to delivel' the required presslIre. Pumps with more than one impeller are

called multistage pumps. Each impellel' is referred 10 as a stage. A pump with 5

impellers is a 5-slage pump.

There are three common types of mul li-slage pumps;

1. Submersible

2. Can

3. HOl'izontal

The submersible pump is an integral pump-motOJ' uni t in a sealed enclosure. In a

well, Ihe pump is insert ed inside the casing. An electric cable runs from Ihe surface to

tile motor. These pumps are used for lifting watel' OJ' oil from any depth. The pump

capacity is limited by the size of the casing. For example, a submel'sible pump which will

fit inside a 20 cm [8 i nch J casing will deliver a maximum now rate of about 68 m 3/d

[300 gplll J. An electr ic power source is required to operate the pumps.

8

PUMP TYPES

CAN TYPE:

SUBMERSIBLE PUMP

VERTICAL PUMP

PUMP TYPES 9

HORIZONTAL MUL TlST AGE PUMP

Can-type Pumps are used to 1 ift liquids from storage tanks or sub-sur race sources.

The pump driver is l ocated at 01' above the li quid surface, and the shaft extends f rom the

driver to the pump, which may be located some dist ance bel ow the liquid sUt'face, Thi s

type is used f requently on offshore pl stfol'ms to provide an emergency f irewatel' suppl y,

Both the can and submersible pumps can have up to 60 stages or impell el's,

depending upon the depth at which thc pump is set. [f one impell er developes a pressure

rise of 1300 kPa [43,5 psi], and a total pressure rise of 9000 kPa [1305 psi J is I'equired to

lift the liquid to the surface, then the number of st ages wi ll equal:

SI UNITS ENGLISH UNITS

Total P['essure Required 9000 kPa 1305 psi

Pl'es;ure rise pel' stage 360 kPa 43,S psi

Number of stages

9000 = 30

300

1305 = 30

43.5

Horizontal multistage pumps are used i n process plants and oil pi pelines where the

pump must raise the liqui d pressure seve!'al thousand kPa [sevel'81 hundred psi]. Thel'e is

no lheoreticallimit to the numbel' of impeJlers in 8 hori zonta l pump, but more than 8 are

seldom used,

10 SEAL SYSTEMS

D. Alternate Seal Systems

A pump handl ing liquid hydrocarbon can cause a hazardous situat ion if hydrocarbon

leaks out the pump seal to t he surrounding atmosphere.

One way to avoid this is to install two seals on the pump wi th a pressure guage

between the two. When the inner seal starts leaking, pressure will rise between the two

seals and it can be observed on the pressure gauge. In some cases, a pressure swi tch is

provided between the two seals so that a rise in pressure trips the switch and signals an

alal'm or may even shut down the pump.

Impeller

Inner Seal

Rise in pressure between

seals indicates leaking

inner seal.

Outer Seal

PUMP WITH TWO SEALS

Shaft

Anot her way to prevent liquid inside the pump from leaking to the atmosphere is

that of using a seal oil system, which also has two seals.

A simple seal oil system is shown opposite. There are two seal oil pots with water in

lhe bottom of lhem. Pump discharge liquid fills one pot above waler level; the other pot

is filled above lhe waler level with seal oiL The seal oil is piped to the space between the

two seals on lhe pump. Water in the bottom of the pots prevents pump discharge liquid

from mixing with the seal oil. Since pump discharge pressure is imposed on the seal oil

pots, the pressure in the pump seal oil chamber (bel ween the two seals) is pump discharge

pressure.

The purpose of the bypass line is to allow liquid on l he pump side of the inner seal to

flow inlo the suction side. This will hold the presure on the pump side of the inner seal at

suction pressure. Pressure on the other side of lhe inner seal is pump discharge pressure.

Wilh this arrangement, a leaking seal will resull in seal oil leaking into the pump, becau e

BypllSil

Used for IiqllLd CW"I In! PlIrT"9

side 01 the inoel Jeal 10 flow

to the aoction tide of the

pump, This Jowerl press"re on

pump .ide of IlYler IIIal to

lion prfllllUtt.

SEAL SYSTEMS

Pump LIquid At

Dllctl.rge Pre"ure

I

SEAL OIL POTS

___ . .bd-- .. __ .. -. ---.

Inner Seal Seal Oil Chamber

ll;!akirw:l see! will

result in Ioeel oil

lellking into pump.

SIMPLE SEAL OIL SYSTEM

PUMP WITH SEAL OIL POTS

l eaking aeal wlU Te...,lt in

luI oil leelcing into lilt

atmosphere.

11

J

seal oi l pressure is higher than pressure on the pump side of the seal. The outer seal is

provided to prevent seal oil from leaki ng to the atmosphere.

The seal oil pots are used on small process pumps - usually less than 35 kw [50 hp J.

The effectiveness of the system is limi t ed by the volume of seal oil contained in t he

system. If a large leak occurs in the inner seal, pump discharge liquid will eventually

displace seal oi l in the pots, and the liquid between the two seals will be pump liquid. In

th is sit uat ion, failure of the out er seal will result in pump liquid leaking to the surrounding

atmosphere and crea te a hazard.

Lal'ge pumps handling volatile or hazardous liquids are oft en equipped with a

circulat irg seal oil system as shown on page 13. This system has two pump seals just as

the seal oil pot system did. The primary difference is that seal oi l is cont inuously pumped

through the seal chamber at a pressure higher than the pressure inside the pump, A

pressure controUer in the seal oi l outlet line is set to hold this desired press ure.

12 SEAL SYSTEMS

The drawing on the opposite page shows a mult i -stage pump with a bal ance piston

used to offset thrust for ces in t he pump. Pressure on the outboard side of the balance

piston is held at suction pressure by allowing liquid that leaks across the balance piston t o

flow back to the suction side of the pump t hrough t he balance line. This particular pump

has scals at each end of the shaft. The bal ance line holds suct ion pressure on the pump

side of both seal s. Consequently, as long as the sea l oil pressure is above pump suction

pressure, leaking seals will result in seal oil leaking into the pump rathel' than pump liquid

leaking to the seal oil system.

Seal oil is a non-volatile liquid that docs not contaminate the l iquid inside the pump

when it leaks into it. Some fOI'm of lubricating oil is often used for seal oil in hydrocarbon

pumps.

PI'oblem 2

List th type of pump and seal to use in the following services:

Service

a. Process pump used in gasoline plant

b. Pump water from a well

c. High pressure cI'ude oil pipel ine pump

located in an enclosed building

d. Fire water pump on offshore platform

Pump Type Seal

CENTRFUGAL PUMPS

USED IN ffiACTIDNA TlNG

SECTION 0; REFINERY

SEAL SYSTEMS

l

SEAl.. OIL COOLER

WATER

flL TERS

SEAl OL TAN< F'l.MP

SEAL OIL SYSTEM

1

t

PRESSURE

CONTROLLER

DISCHARGE

13

14 D. PRINCIPLES OF CENTRIFUGAL PUMPS

A. Flow Through Pump

Liquid ent ers the pump at the eenter or eye of the impeller. In most process pumps,

the impeller rotates at a speed of 1200 to 36.00 revolutions per minut e. At this speed, the

liquid enters the center of the impeller and is thrown into an enlarged chamber called the

volute. Liquid flows around the volute and exits in the outlet nozzle.

Liquid

Outlet .

Liquid

Inlet b=l,,';

-n'f----Volute------+_

UQUJD FLOW IN CENTRIFUGAL PUMP

B. Centrifugal Force

Suppose you take a bucket that is almost completely filled with water and swing it

in a circular motion around your body. If you swing it very slowly, some of the water will

spill out of the bucket. However, if you swing it fast enough, none of the water will spill

out of the bucket. The centrifugal force generated by swinging the bucket pushes the

water against the bottom of the bucket so that it does not spill out.

Now suppose we have a small hole in the bottom of the bucket. As you swing the

bucket, water will come out of the hole. The faster you swing the bucket, the farther the

water will travel that leaves the bucket.

This is the principle of centrifugal action. When you move the bucket fast, you use

more energy. The distance that the water travels from the hole in the bucket will depend

upon the amount of energy that you use in spinning the bucket.

Before we attempt to understand the principle of centrifugal pumping, let us look at

the pump unit first. It includes a driver and a pump. The energy used by the driver -

CENTRIFUGAL FORCE 15

motor, turbine, or engine - is transferred to liquid in the pump in the form of pl'essure by

the pump. In other words, a pump is a device for transfer ring energy from the driver to

t he liquid. It is important that we recognize that energy is enter'ing the liquid in order to

under'stand pumping.

El ectri c energy used by a motor-driven pump is transferred to liquid by the pump in

t he form of pressure.

Another thing we need to realize is that ener'gy can exit i n sever al forms. A ri fle

shell contains ener gy in the form of powder . When t he shell is fired, energy of the

burning powder transfer s to the bullet in the form of velocity. That energy converts to

pressure when t he bull et strikes an obj ect and l oses its velocity. Vel ocity energy is

convert ed to pressur'e energy,

A centrifugal pump uses the same velocit y-pressure concept to mise liquid pressure.

Liquid enters an impeller at the eye. The speed of the impell er' Cl'eates a cen t rifugal .

16 HEAD PRESSURE

force that throws the liquid to the outer edge at a high velocity. It leaves t he i ~ p e l l e r at

high velocity and enters the volute, which is an enlarged chamber where the velocity is

quickl y reduced. This veloci ty reduction results in a pressure i ncrease.

The liquid flow can be compared to that of the moving bullet . The now i n the

impeller at a high velocity cor responds to the movement of a bullet through the air. The

liquid slowing down in the volute with a resultant pressure ri se is comparable to the force

of a bu ll et striking an object.

The amount of pressure an impeller will develop depends upon its diameter and the

speed at which i t rotates. A large di ameter impeller operat ing at a high a speed will

develop t he highest pressure. The p"essure developed by the impell er is l imited by the

materials of which the impeller is made. It is subject to the same centrifugal force as the

liquid and will fly apart if the centr igual force is excessi ve.

If a si ngle impell er will not develop thc p" essure requi"ed, two or more impellers can

be inst alled in ser ies to increase the pressure rise across the pump. A pump with three

impellers can be compared wit h t hree pumps which operate in series. Discharge liquid

from the f irst pump enter s the second one, and liquid from t he second pump flows to the

third one.

There is no theoretical limit to the number of i mpell ers which can be instaUed in a

pump. However, horizontal pumps seldom have more than eight impeUers in one casing.

If thi s is not enough to produce the desired pressure, a second pump will be used.

Submersi ble or can pumps can have 50 or more impell ers.

Vertical pumps are usually bui lt i n segments, so t hat there is no theoretical

mechanical limit to the number of impellers which can be installed.

C. Head Pressure

The purpose of a pump is to rai se the pressure of liquid. The amount of pressure rise

is called the head pressure, or si mply head It equals the di scharge pressure minus the

suct ion pressure. The pressure developed by the pump - head pressure - will be constant

fOl' any sucti on pressure. In other words, a pump that develops a head pressure of 300 kPa

[45 psi], wi ll have a discharge pressure that is 300 kPa [45 psi] more than the suction

pressure, regardless of what the suct ion pressure is. Obviously, the pump casing must be

designed to withstand t he highest discharge pressure expected in the servi ce for which i t

is used.

CAVITATION AND VAPOR LOCK 17

,

It is important that you remember

frequently in the following discussions.

the t er m head pressure, as it will be used

Suction

Pressure

Sue t i on

Liquid

DIScharge

Pressure

1

1IIIII1II!1IIII1III1IIIII1IIIl1IIIII1IIIII-. Discharge

Liquid

CENTRIFUGAL PUMP

HEAl) PRESSURE = DISCHARGE PRESSURE - SUCTION PRESSURE

Problem 3

The discharge pressure gauge on a pump reads 1000 kPa [145 .psi J. . Suclio.n pressule .

is 400 k.Pa [58 psi J. The head pressure developed by the pump is

___ kPa [psi J.

D. Cavitation and Vapor Lock

Cavitation and vapor lock are ter[lls often used interchangeably to describe pump

failure due to the presence of vapor in it. Although caviation and vapor lock, both occur

when gas is present in a pump, they each have different effects on the operation of the

pump.

Cavitation occurs when the liquid entering a pump contains a few bubbl es of gas.

The gas flows through the impeller with the liquid and as its pressure is increased in the

pump, some or all of tti", gas liquifies (the vapor ' bubble.s collapse.) A high centripetal -

force results from this collapse and. may ;cause severe vibration and poss ible pump

damage. The pump will continue to pump liquid, but it will be noisy and may vibrate.

Vapor lock occurs when gas. enters the pump with liquid and separates from the

liquid inside the pump and fills all ar a part of the pump. The pump will compress the gas

a slight amount, but not nearly enough for tlie gas to flow out the. discharge line. The

gas prevents liquid tram entering .the pump. The effect is that no liquid flows

through the pu mp.

18 VAPOR LOCK

When a pump vapor locks, the discharge pressure gauge reads about the same as

suction pressure while the pump is running. In order to clear the conditi on, the vapor

must be removed from the pump. In some cases, this can be done by opening a vent valve

while the pump is r unning. Quite often, the pump must be shutdown and the casing vented

unti l liquid flows out the vent line. At this point, the pump is restarted.

Some pumps are more prone to vapor lock t han others. A procedure for starting

these pumps is:

1. Close a val ve in the dischalge line. Suction valve is open.

2. Open the casing vent valve until a steady stream of liquid comes out. Partiall y

close the vent valve, but keep a steady steam of liquid flowing.

3. Start the pump and observe the discharge plessure. It should rapidl y increase

and then level off.

4. Slowly open the valve in the discharge line.

5. Close the valve in the vent line.

Observe the disoharge pressure during Step 4. If i I drops to suction pr essure, the

pump has vapor locked again, and you will have to shut it down and start over.

cP Sto" d,I .. ,

r.M.l

SUCTION

8

1

1-------'

Open .... 1 .... in IlUCtion line

) Open "eot ",lve uotU 1[811dy

.tream of liquid come. out.

5 Quer ... e dllch8rqe preMUU!.

ahoi,Jld rill! rapidly and then

level off. Slowly open .... I ... e

In dischllrge line.

PROCEDlRE TO START - UP AFTER CA VIT AnON

Cavitation or vapor l ock occur when gas is present in the pump. A few gas bubbles

will cause cavitation. More will cause vapor l ock. Both are prevented by preventing gas

from entering a pump. This can be done by raising the suction pressure to the pump, or

raising the l evel of liquid in the vessel that is being pumped.

PERFORMANCE CURVES 19

E. Performance Curves

It will help us in operating our centr ifugal pumps i f we understand how pumps are

sel ected i n the fi r st place, and what thei r operati ng limitations are.

Suppose have need for a centrigual pump that will operate at the following

conditions:

Flow Rate:

Head Press ure:

Relat ive Densit y of Liquid:

Maximum Discharge Pre!)'Sure:

40 m J I hr [ 175 gpm]

600 kPa [ 87 psi]

0. 80

3450 kPa [500 psi]

We gi ve thi s informat ion to a pump manufacturer and t ell him to supply us with a

pump driven by an electric mot or. The manufacturer has a number of st andard size pump

casi ngs and impell cls. He must sel ec t the standard unit that will fit our design conditions

and operate at a hi gh efficiency so that we don't wast e a lot of electricity in dri ving the

motor. We wi ll discuss efficiency later.

The pump manufact urer has pel'formance curves fOi' cach standard si ze pump that he

makes. These curves show the relation bet ween flow rat e and head pressure f or di fferent

size impellel's operating at different speeds that can be used in the same pump casing.

Typical cUI'ves for a pump operati ng at 3500 rpm are shown on the following page. The

top curve is for the largest diameter impell er that can be used in that pump casing. It has

the hi ghest head pl'essure of any of the impellers. It also requires the largest driver. The

bottom cur ve shows t he smallest diamet er impell er which can be used in t hat pump

casmg. In our application, a 200 mm [8 in] diamet er impeller will deliver the head

pressure at t he flow rate we have speci fi ed. This will be the size impeller that the

manufacturer wiU use in our pump.

The pump curves show the head pressure t hat different sizes of impell ers will

develop at various flow I'ates at a 3peed of 3500 Ipm. A di ffer ent set of curves for the

same casing and impellers wi ll apply at a speed other than 3500 rpm. As t he speed is

reduced, the head pressure at a given flow rat e will be less. We will discuss the effects of

speed later. For the time being, we wi ll confi ne our discussion to pumps operat ing at a

const ant speed.

The pump manufacturer uses the pump curves to select the pump casi ng, impell er

size, and speed that will sat isfy our process requi rements at the lowest power consump-

tion by the driver.

20

800

500

4 00

0

110

100

7

60

0

, ..

10

,.

..

, .

PERFORMANCE CURVES

51 UNITS

,

230 Iotl.OJA",'r,, '

. _ _ _ , '" IMPELLER

, "

215 lotH

t . ,

,.

OES TG

POINT'

-

, ,

., , 1

- ..! -

. ,

I - , :

20 30 4 0

PU-1P CAPACITY, M I /Kt

ENGLISH UNITS

T

. 71. S I GN-

"1 '\ INC"

' ,. I",

.. PO I NT

, -

i

,

"t

, .

., .

' T

_. 3500 RPH

t

50 100 150 200 250

'00

CAPACITY CLRVES FOR VARIOUS DIAMETER

IMPELLERS IN Sf ANOARD PUMP CASING

AT ) 500 RPM

350

PERFORMANCE CURVES 21

The pump cUi'ves also t ell us somethi ng else: that the pump will deliver the flow

rate and head press ure shown on the curve. In the example we have cited, we selected a

200 mm [8 i n] impeller whi ch will deliver head presure of 600 kPa at a flow rate of 40

m '/hr [head pl'essure of 87 psi at a flow rate of 175 gpm] .

Suppose when we start to o"perate the pump that we r equire a head pressure of only

550 kPa [80 psi] at the design flow ra teo I f we look at tile 200 mm [8 in] diameter pump

curve, at 500 kPa [80 psi ] the flow rate through the pump wi 11 be 56 m '/hr [ 25 0 gpm ].

In othel' words, the pump is goi ng to deli ver a flow rate and head pressure along its

operating curve. Even though we do not need as much head pressure as it will develop, we

cannot reduce the flow rate without i ncreasing the head pressure.

What this means from an operati ng standpoint is thi s: if a constant speed pump

develops more head pl'essure than we need, we must have a pressure reducing device on

the pump discharge that wi ll take up t he excess head pressure that t he pump develops.

Using a pressure reducing device is wasting the energy t hat was used by the pump dr iver

to put up the pressure drop we are taking across tile pressure reducing device.

We can save t hat wasted energy by installi ng a small er impeller in the pump. Look

at t he pump curves again. At our operating flow rate of 40 m '/hr [175 gpm] and

operat ing head pressure 550 kPa [80 psi ], we need an impell er having a diameter of 195

mm [7-3/4 in]. We can purchase t his size impeller from the pump manufacturer. When

we put the smaller diameter impeller i n the pump, we will have a new curve shown in the

dotted lines of the pump curves. This is our new per formance curve. It will allow us to

run the pump at our actual operating conditions wihtout wasting POWI' in the driver.

We purchase the pump with a 200 mm [8 i n] diameter impeller to give some excess

capacity. The manufacturer suppli es us wi t h performanc.e curves for that pump as shown

on the next pages. The top curve is the same as th'e 200 mm [ 8 in ] diameter impeller on

Page 20. It shows the pressure head at di fferent flow rates. The maximum head pressure

the pump will develop 650 kPa [93.5 psi]. This head is developed with no flow through

the pump. In other words, i f we turn the pump on and close the discharge valve, the

pressure gauge on the dischar ge will read 650 kPa [ 93.5 psi] more than the suction

pressure gauge. If the occasi on should arise t hat we want to increase the flow rate

through this pump f rom 40 m '/hr to 60 m '/hr [175 gpm to 265 gpm J, the head pressure

developed by the pump will drop to 540 kPa [77.5 psi].

22

It is important to rec-

ogni ze that a pump will oper-

ate at some ' pressure and

flow rate on or near its oper-

PUMP EFFICIENCY

-. ...:.. '

.; >

"

. _1

SILNTS

-

" ,

.... " _ I ..

<

aling curve. Large multi- 600 , .

: - .....

' r- . - .. ....

; - DESIGN '

- : .- - -

.. _ . i

stage pumps

slightly from

may deviate

the opera Ii ng

curve. As a pump wears and

clearances increase, some in-

ternal leakage from the dis-

charge back to the suction

occurs, and the opera ting

curve moves downward to a

line parallel wit h the original

curve. This is a way of

troubleshoot ing pump

problems. We observe the

head pressure and flow rate

through the pump and com-

pare it to the operating

curve. If it is too far below

the curve, it may be time to

repair the pump. Otherwise,

we are wast ing energy

driving the pump.

F. Pump Efficiency

Centrifugal pumps are

not high effi ciency energy

transfer devices. In other

, "

-.. POINT

-"- '... ' ....

. - .. -

- .. ..;. -,

550

.! .

" '

,- _ . ,

500

' I .

60

oj

_. . .,.- ..,

. - . . ; ! . , . I i -!

,:

"

T-- ..... '-

. - .'

. - I.. . . , _.

.. - - -... .., .. ;. , .. :- ,-..

-' -- ". '" .-

, -1 , -J. t ;" .

, ,

20 ,

, : - ,- .-

.0

- ..... -,

"

. ., .. ,

is

2

10

, ,

1"- - -..,

I . - .,.

K

o

- r - .

- "

.. - ",.-

I , .. :

f

o

I -. ,

1 T :

.- . -

". ' ". 'i

" ' - a

.. .;:. = .1 :

.. "'

; , i ..... -

: -"

t _ .

., B

, i ' "

. , .; .:. I .;

..

, , .

.... "f OO:J

o 60

, "

,- .!. .

20 40 10

Pl..M' CAPACITY. M J I'rfl

PERFORMANCE CURVES FOR PUMP

WITH ioo MM IMPEl.LER AT }500 RPM

wordS, only part of the energy used by the driver is actually transferred by the pump into

pressure. The pump efficiency is the percentage of energy that transfers from the driver

to the liquid in the form of presure. The efficiency curve for the pump we selected

indicates the maximum efficiency for this particular pump is about 63%.

This is the highest effi-

ciency we can get for this

pump. At our design flow

rate of 40 m 3/ hr [175 gpm 1,

the pump efficiency is about

61%. The efficiency drops off

rapidly as the flow rate re-

duces.

PUMP EFFICIENCY

- ,- ,

~

i

t . ~

~ 80

70

. -. -. .-t-r-

- - .. r

,- -

-, -

, I

ecuSHl.NTS

"DESICN

- POI NT

- ,

,-

, -

23

-r

I. _._

-. ,

60

.:.. 40

-,

L

The energy suppl ied by

the driver which does not

transfer into pressure energy

inside the pump has to go

somewhere. Part of it goes

to friction; part of it makes

up for internal leakage; the

remainder enters the liquid in

the pump in the form of heat.

As long as the pu mp is opera-

ting at an efficiency of 30%

or more, the heat energy that

transfers from the driver to

the liquid in the pump will

cause only a degree or two

rise in the liquid tempera-

ture.

o "

20 ~

~ d _.

~

- (AD '

, . ' ClIONt-i

_ . _ .. \QllID SU 10 S

- .,

~

Q

o '"

100 150 200 250

o

300

However, at low pump-

PUMP CAPACITY I GPM

PERHRMANCE CURVES FOR PUMP

WITH B N::H IMPELLER AT J500 RPM

ing rates, the efficiency may drop as low as 10-20%, which means that a larger percentage

of the driver energy is entering liquid in the pump in the form of heat. In this situation,

the temperature rise may be several degrees, which may vaporize part of the liquid or

expand the internal parts of the pump to the point that damage may occur.

Problem 4

What is the head pressure and efficiency at a flow rate of 50 m 3/ hr (220 gpm J?

24 DRIVER POWER

A pump having several impell ers will have a temperature ri se ac,'oss each impeller.

In some instances, this limits the number of impellers tha-t can be installed in a pump

case.

G. Driver Power

The power required

to drive the pump is indi-

ca ted on the curve. The

power increases as the

flow rate increases. The

power curve is used for se-

l ect ing the driver for the

pump. In this particular

case, the power required at

design flow rate of 40

m' / hr [175 gpm J is 12 kW

[16 hp J. However, since

the pump is capable of

operating at a higher flow

rate, we size the driver for

the maximum flow rate,

which requires a 14 kW [20

hp J motor.

The pump perform-

ance curves are fot' a pump

speed of 3500 revolutions

per minutes (rpm). This is

a com mon motor speed.

The same pump with

a different speed motor (or

,J

65.

600

55.

>0.

20

, "

<

. - ,

-

"

"

"

,

,

-

,

, ..

51 LNT5

, ' ,

! --

. I . j.

DESIGN

POINT .. . -,

, . I' ...

, '

'1,

- I. .

- ,

, "

,. I

..

;

"

1 '

T ' -'

, ,

- ,

, .

1

.... . ,..".

. , "-," , I.",,,

, .. ,

'. . -. !-.

r . . , . . . . f. -, .-

, ."' 1 __

r 1 , , '

L ,"

,

- ." l . r- ..... __ ..... ..,.

- ;- . . ,. '"

-I" - , -- '" t

r

-! . ,

I ' " I

90 ...

'! - "

I .

I - -

t , ."

, '

.. ,

. .

-,

... _ ..

. _ .... , . .. ; I , , , ,

.,... - t I "T" .j .

1;; . _ ' -' -.

.r-110l'1 H(.AO

" ,

"-

I . I . 1 .. ,

10 20 40

"

PUMPCAPAOrv, "'-/Hit

PERFORMANCE CURVES FOR PUMP

WITH 200 MM IMPELLER AT }500 RPM

40

speed cont rol) would have a different set of performance curves. If we have a centrifugal

pump driven with a variable speed .engine or turbine, it will have pel'formance curves at

each different speed. The effect of speed on the head pressure developed by the pump is

a square l'OOt function. Cut the speed in half and the head pressure developed will be one

fourth the original.

LIQUID SUCTION HEAD 25

H. Liquid Suction Head

The impell er on a centrifugal pump pulls liquid into it from the suct ion line t o the

pump. Liquid moves at a high velocity from the point that it enters the pump to the eye

of the impeller. This dis-

tance may be only a few em

signi f i cant pressul'e drop in-

side the pu mp. This pressure

drop that occurs within the

pump can cause some of t he

liqui d t o vapor ize in the suc-

ti on chamber of t he pump.

When t his occurs, t he pump

will ""vitate or vapor leek.

We normally prevent

locating the pump far enough

below the vessel we

pumpi ng out of, so that the

pressure head

height of the

due to the

liquid in t he

vessel is mor e t han the pres-

sure dl'op i nside the pu mp and

connecting piping. The pres-

sure drop inside the pump i s

expressed as height of liquid

required at the suction l ine

to t he pump. It will var y

with flow to the pump as

shown by the cur ves.

l

P\..Np CAPACITY, GPM

PERFORMANCE CURVES FOR PUMP

WITH 8 INCH IMPELLER AT J500 RPM

i

The liqui d suct i on head represents a pressure drop as l iquid Dows from the pump

inlet fl ange to the impeller. We normally add about 10% to the liqui d head to allow for

pressure drop in piping between the vessel we are pumping out of and the pump. In other

words, the height of the liquid in the vessel above the pump will be 110% of the height

26 UQUID SUCTION HEAD

LIQUID

SUCTION

HEAD

LIQUID

t.:::::.::> PUMP

shown on the suction head curve, If the pump is loca ted some distance from the tank or

vessel it is pumpi ng out of, we will calculate the press ure drop in the piping and add it to

the liquid suct ion head to get the total pressure drop, and then adjust the level in our

separa tor so that we have enough liquid head p,'essure to ove,' come pressure drop in the

piping and in the pump, If we allow the level to drop below this point, vapor will form in

the pump and it will cavi tate a" vapor lock,

Since piping pressure drop depends on size, it is important tha t the suction line be

la"ge enough, [n cases where adj ustments in level cannot prevent cavitat ion, a larger

suction line may be needed,

Example

At a {low ra te of 40 m' /hr [ 175 gpm], the suction head required at the

pump is 340 cm [ 11 feet], We determine t he pressure d,'op in the piping

between the seporator and the pump is 100 cm [ 3,3 fee t], Thi s must be added

to the head taken f rom the curve in orde,' to get the total height of liquid

above the suction to the pump, When the two are added, we get Q liquid head

requirement of 440 cm [ 14,3 ftl. If the level in the separat or fall s below thi s

paint, the pump will vapor l ock and stop pumping, If a valve in the pump

suction line is not complet ely open, it can cause Q pressure drop which will

reduce t he suction head to t he pump to the point that vapor lock will occur,

The suct ion head is referred t o as NPSH by engineers, an abbreviation for Net

Positive Suct ion Head, It is particularly important when pumping volat ile li quids, such as

ethane, propane, or unstabi lized crude Oil; or if the pump is located some distance from

t he vessel cont aining liqui d, On offsho,'e producti on platforms, crude oil pipeline pumps

often are located some distance from the separa t ors or tanks, A booster pump is oft en

THRUST 27

used to pump li qui d from the separat or into the pipeline pumps. The purpose of the

booster pump is simply to maintain suction head to the pipeline pumps so they will not

vapot l ock.

Pump cavitation and vapor lock are major operating probl ems of centri f ugal pumps.

As we mentioned earlier, when a pump vapor locks it simply stops pumping liquid. The

pump will continue to run. If the problem is not co,,ected, the pump will overheat

because no li quid is circulati ng through it to cool it. In this case, the pump is transfe,,ing

some of the energy from the driver in the form of heat, because no li qui d is flowing

through the pump to remove energy in t he form of pressure.

The impor t ant thing to remember about suction head is that it increases as the flow

rate inc,cases through the pump.

Suppose we are operating the pump with the. curves shown on pages 24 and 25. It

was sized f or a flow r at e of 40 m J Ihr [175 gpm]. The sucti on head required is 340 cm

[ 11 ft J. I f the fiow rate to the pump increases to 60 m J Ihr [ 265 gpm J, the liquid suct ion

head must be 585 cm [19.2 ft J or the pump will cavitate. If we design the elevation of

our separator for a 340 cm [ Jl ft J suction head, we will not abe able to operat e the pump

above 40 m J Ihr [175 gpm J unless we raise the level of liquid in our separator. Remember

that the suct ion head is the pressure drop inside the pump, and we must add about 10% t o

it to allow for presure drop in piping bet ween the separator and the pump.

Problem 5

Wha t liquid suction head is required at 50 m J Ihr [ 220 gpm J?

I. Thrust

As a pump impeller rotates, a thrust force

develops which is transmitted through t he pump

shaft. The force is simil ar to that of an airplane

propell er which pulls the airplane through the air.

The for ce developed in si ngl e impell er

pumps i s relatively low, and can be overcome with

th,ust bearings locat ed on the pump shaf t as

shown in the phot ograph on Page 3.

t

SUCTION ....-.

PRESStJRt. I

fLOW

SHAFT

+

DIRECTION

Of THRUST

...

I

/

.... OISCHARCE

.,. PRESSURE

SINCLE It.flEl...LER EXER 15

n ..fUJST TOWARD !iJCTD-I EN)

28

Thrust forces in multistage

pumps are compounded at each im-

peller. Special design considera-

tions are required to contain these

forces. One way of neutralizing

two forces is to install some of the

impellers in opposite direction to

others, so the thrust forces equal-

ize one another. This design does

not totally balance thrust forces,

but it reduces them enough so that

small thrust bear ings can be used.

THRUST

FLOW

SHAFT

+

DIRECTION

Of THRUST

t

j

Tl-RUST NElJlRAUZED

WITH

OPPOSING IMPELLERS

DIRECTION

Of'THHUST

Some multi- stage pumps have all impellers facing the same direction. This

arrangement results in the maximum thrust force. It can be neutralized by installing a

balance pi ston on the high pressure end of the shaft. Pump discharge pressure is imposed

on one face of the piston. A small amount of discharge liquid leaks around the piston to

the outer face, and flows to the suction of the pump. This results in a pressure on the

outer face of the piston of suction pressure. The force exerted on the inner side of the

piston will equal discharge pressure times the area. The piston is sized so that the net

force resulting from the piston is approximately equal to, and in the opposite direction of,

thrust force from the impellers. This arrangement minimizes the size of thrust bearings

required.

Selection of a multi-stage untt having opposed impellers, or having in-line impellers

SUCTION DISCHARCE

,--BALA>CE PISTON

-THllUST BEAR..,

7 STADE PUMP WITH BAlAf'CE PISTON

\

PUMP CURVE APPLI CATION 29

with a bal ance piston, depends upon the pump service and the cost of the two units. The

balance piston is att ached to the pump shaft and rotat es in the casing. The clearance

between the piston and the casing must be very low to prevent excessive di scharge liquid

from leaking around the piston. This requires a clean liquid inside the pump so that dirt

does not get between the blance piston and the casing and wear one or the other parts.

Multi-stage pumps having opposed impell ers require special passageways through the

casing for liquid to flow from t he fi nal stage of the first set of impellers to the first stage

of t he opposi ng set of impellers. This adds considerabl e cost to t he casing.

J. Pump Curve Applicati on

Now let us apply what we have learned to an operati ng situation. Liquid from a

sevarator must be pumped into a st abil izer. Operating conditions of pressure and flow are

as shown below. The pump selected for this service has performance curves as shown on

the following pages. The basic design point is for a flow rate of 68 m 3/hr [300 gpm J and

a head pressure of 345 kPa [50 psi J. At these conditions the pump efficiency i s 73%, and

the dr iver requires a horsepower of 12 kW [ 16 hpj. A 15 kW [20 hpj motor was provided

wi th the pump.

690 kPa

[100 k P ~

",""p

] } ~ kPa

[1$0 p1i]

-

1

STABIUZER

DESIGN COI'VmONS FOR ST ABIllZER FEED PUMP

First of all, look at t he power curves to deter mine what maximum continuous flow

rate can be maintained in the pump without overloading the motor. The maximum power

required by the pump, is 15. 8 kw [21 hp J, which is 5% above the power of the motor. We

can safely operate at 105% motor load for extended periods, so we can say that the motor

does not Ii mit the flow t hrough the pu mp.

Let's get back to the design point on our pump. Checking the effici ency at the

30

des ign flow rate of 68

m ' l hr [300 gpm I we find

that it is 73% efficient at

that point. This means that

73% of the electrici ty used

in driving the motor is con-

verted into pressure energy

inside the pu mp. The other

27% is lost to frict ion, to

internal leakage in the

pump, and to temperature

rise in the liquid.

Refer to the suct ion

head curve. It shows that at

the design flow ra te of 68

m ' l hr [300 gpm 1, a suction

head of 270 cm [9 ftl is

required at the pump. This

means that the level in the

separator must be at least

this distance above the

pump. We normally add 10%

for pressure drop in piping

between the separator and

the pump, so the level in the

separator must be 297 cm

[ 9.9 ft I above the pump.

PUMP CURVE APPLICATION

LoT 300

200

,

o

, ,

, .

...

...

20

"

I

SI LNTS

I '

'. ,

.. ,

, , '

,

t ,

t "

. ,

. ,

- . , , ' .. iJ'

4 .' I,

f

f I

, .... !

t - t -

I' "

, , ..

, ,

I

I' .-....Il-IE,o.O

, ,

, ,

<

I SUC1\U"

lJ(JJ\O . .. I

, i

I' I, ...

'0

. ,

60

,

80

. ,

, .

,

I ,

, ,

,

, ' .. ,

,

t

I

,

I

... , ,

"

,

,

,

,

"

80

70

, .0

t

'00 3

.

i .. ..l-

r

. ,

I .. , , .

200

100 120

PERFCRMANCE CURVES FCR STABlllZER FEED PUMP

51 UNTS

Look at the suction head curve at a flow rate of 114 m 'lhr [500 gpm I. It shows

that the liquid head to the pump ' must be at least 455 cm [15 ft). If we add 10% for

pressure drop in piping to the pump, we get a height of about 500 cm [16.5 ft I.

Suppose the maximum level we can maintain in the separator is 455 cm [15 ft I

above the pump. We deduct 10% to allow for pressure drop in piping, which leaves 410 cm

[13.5 ft I of suction head. At this height the maximum flow rate the pump will deliver

PUMP CURVE APPLICATION

without vapor locking is about

108 m 3/hr [470 gpm).

Assume we learn that the

flow to the separator and

through the pump will increase

to 102 m 3/hr [450 gpm J. Also

assume that the pump discharge

pressure must be 1035 kPa [ 150

psi) in order to pump liquid

into the stabilizer.

Refer to the head curve

at 102 m 3/hr [450 gpm) : the

pump will deliver a head pres-

Sure of 300 kPa [43 psi). If we

deduct this from the discharge

pressure, we get a suction pres-

Sure of 737 kPa [107 psi ). This

is the pressure we will have to

hold on the separator at a flow

rate of 102 m 3/hr [450 gpm).

Now look at the liquid suction

head curve at 102 m 3/hr [450

gpm). It shows that the level

of liquid must be at least 380

cm [12.5 ft) above the pu mp.

Adding 10% for safety gives us a

total liquid height of 418 cm

, ,

OGJSH \..NITS

,

400

PUMP CAPACITY. GPM

CURVES FOR

STABIUZER FEED PUNP

ENGUSH LNlTS

31

!

t

[13.75 ft J. We will have to raise the level in the separator to this height above the pump,

and hold the separator pressure at 735 kPa [107 psi) in order for the pump to deliver 102

m 3/

hr

[45 gpm) at a discharge pressure of 1034 kPa [150 psi).

Suppose the pump has been in service for a few years, and we are checking its

capacity against the design curve. We have a flow meter in the line which shows 79.5

m 3/

hr

[350 gpm J. Pressure gauge at the pump discharge reads 1035 kPa [ 150 psi),

"

,.

-,'>',

3Q.'

a. line

_t <", . " ,,_ . . .. _

ga).!ge

.. : . -.,.

,.' Ttw '

"

. ,', .. '"

"

,'.

.: ' I ' j

;'

.r. :: ..., ,; ' J'.

t.wl) is

,3,Hi kPa [45 psi j whi"h

. : , J '-.'

'" ,

; is .. put

,

', up,,by: th:' pump.

, 'We, ta'k,r this",ilatli

.'

" - ',19,:'5 ,m '/1ir and

" r, . ... .

". , . ". . ....

hea,d [,35'0

gpm and .45 psi: head

c' am'd , com-

. ", . ',.

':p,are :.-it, wiW

"'f-ot:rn'arr<:e ' CJirv'e for' our

We find ' fliat at 1 __

, 7:9.5 fu 3

/hr

[35,OgPTQ \;

shbuld"delivllF

33-5 kP'a j of

, ,

pres.sure, .. , S;rice ii

" , ..... ' . "

',QnIy<i6Hver<l 310 'kPa

[ 45 t'>sfj,ii is. lik,eli

i

:

,w<Jrn, ' or, that clear-

anMs :jnsi<i\l ,ihe

.,' J ':.-r",., .. "

.. due:. fo

. . .. "'" ... ., ,

": wea!i,

..

, ,

' I

. J ' . : .': . , :.,p

'., --, .. ,

f ",

, , ,

I' "I' '\ ;, ' i .

. J ,

(0 ,r-r::_.: .. I , ' :'? __ ".' . .. ;i:,:, .. ,' ; .. "1

:"':' ,:; - :-I" ", . ;" : .. ,' . . j. . I , -

'. .;.- -0 ' ', ' -- - t'

" , ,;- , \ -': .' " .' 1-1 :. ' ! _, .; !. ' I ) i ' . ..

ffi "', -''''-'; ... ':. :

' i < . :: ",' '. i:

0 " 5 " ,': -.... ...

;

:t:::ti't:

1

'. '1 ,.':,- - '1- r".1; I

.",' ! L. __ . , ' .... ,.,- :. _ .. ,.'.!,.: .. .:' t'

..,-- . ,

- I , .. '" ! l' _: " :

. :.. ' ,- . . .

: 1 ' ." -j ; '" '. . : ;., t ,t -

" ',.!. ' 1-: '-, . ! . _ . -', _., '. . ".'.. _ I

1 - ' . '. ,- ':lQ'Or""L

.j, " .. ... J -:,< - '. .. , ,. ' .. . . '.' ,

-': : " " ;,'

.. ' I ' ,-::, J" . ' :, ", .": , .. ' - ... .-' I , " 1

. '."H :: ', . .. .. :.r.' 1;' ., ''- ,> - , ' : I - I T

- f '" I , . , 't I j , ; ! l ' _I

,200

20, -10 : 6IJ - SO . , 1;,00: 12,2 '

o

.

"

.

.

l

, ,

,

, As long as, the; pu'mij iii,1I conlinue to' liquid 1 wtlich in the" ,.

'. -.,.' .. , ..... - - ., ' ';' '; > ' " ' , ' " := '- ,. -

pnopab;i, is i'o ,\Ic>wmr, ,

. ',-

' fhe p,eriorll)a;r:tee ;per)pdjf1!t1,ly.,jn: 6I;lI"t to see 'if .J he ,condition' g,grs woi'st;, ' "

T. J" ... ' "".,

.wea.r!kgtns: , !t e;((eet 'if,

,

"

:, Each centrifugal has ,,",r,ves 'sjm ilar to the .. we:'Jilive'

:discussed. The only differeli'ee b'etw,fen 'ihe pe'rforman'ce OJ1r,ves;, Pr\)v,td,i d," ;,the;

.. arid ,we have ,is ,

t , ,r "..

, , '

PUMP CURVE APPLICATION 33

performance curve is given in meters [ feet J of liquid rather than kPa [psi J. The he ight

of liquid is conver ted to pressure by the following equations:

SI UNITS, kPa ENGLISH UNITS, PSI

LIQUID HEAD PRESSURE = (Height,m) (Rei Dens) x 9.8 = (Height,ft) (Rei Dens) x 0.43

The term relative density used in the head pressure equation is the new term in Sl

nomenclature that replaces the traditional term specific gravity. Both mean

the same thing and are found by LNJTS

dividing the density of liquid by the : ,I I I

density of water at the same

conditions.

The performance of each pu mp

should be checked at 3 to 6 month

intervals to see if the pump is opera-

ting near its curve. When the head

pressure drops below the curve, per-

formances should be checked more

frequently so that the point at which

the pump will fail to deliver the

required flow rate can be ant icipated

and repairs made before this occurs.

In checking the suction and dis-

charge pressures of the pump, it is

best to use the same pressure gauge, ffi

or use two gauges that have been

recently calibrated. Use of the same

5

gauge is preferred as it will give

more accurate readings. Our primary

concern is that of pressure difference

and not the actual pressure readings.

Two different gauges may each be

slightly in error so that the

difference in readings of the gauges

will not be accura teo

300 400

P\..Jt.ofI CAPACITY, GPM

PERfeRMANCE CLRVES FeR

Sf ABIUZER FEED PUMP

EU;USHLNTS

I

34

PUMP CURVE APPLI CATION

Another use of t he performance curves is that of estimating the fl ow rat e through a

pump. This can be done vel'y easily by measuri ng the curr ent and voltage to a motor

dr iven pump. Power equations for 3-phase alternati ng current motors are:

MOTOR POWER: KW = Volts x Amps x 0.00l5 HP = Vol ts x Amps x 0. 002

Example

The st abilizer (eed pump with curves shown on pages 32 and 33 is driven

with an AC motor that has 440 volts and 20 amps. Calculate t he Power and

(low rate through the pump.

SI UNITS ENG LISH UNITS

POWel' Equa tion

Motor s volts

Volts x Amps x 0. 0015

440

Volts x Amps x 0.002

440

20 20 Motor amps

Substitute in equation

= 13.2 kW

440 x 20 x 0.0015

= 17.6 hP

440 x 20 x 0.0002

From pump curve, jlow

rate at above power

Problem 6

76 m '/hr 335 gpm

Refer to the stabilizer feed pump curves on Pages 32 and 33 and answer the

following:

A. Flow rate is 80 m' Ihr [ 350 gpm )

Head pressure is

Effi ciency is

Dr iver power is

Liquid Suction Head is

B. The current to t he driver is 10. 6

amps and voltage is 660 v.

Driver power is

Fl ow rat e is

Head pressur e is

C. We are checking the per formance of

t he pump after 2 years of operation.

Fl ow Rat e: 75 m' Ihr [330 gpm )

Discharge Pressure: 1070 kPa [155 psi)

Suction Pressure : 740 kPa [107 psi J

Head Pressure is

Flow ra te should be __ _

D. We are having difficulty with the

pump vapor locking at flow of

gOm '/hr. [400 gpm J

Height of liquid in separat or must be

ID. OPERATION 35

A. Start-Up Procedure

1. Check for bearing lubrication - observe oil l evel In bearing housing or other

form of lubrication.

2. Open valves in the suction piping between the pump and the vessel containing

liquid to be pumped.

3. If the pump is to be started with no pressure at the discharge si de, cl ose the

discharge valve. If there is normal pressure on the discharge side of the pump, the

dischal'ge valve can be left open during start -up if a check valve is included in the

discharge piping.

4. Vent vapol's from the pump casing until a continuous liquid st r eam nows from

the vent valve.

5. Start the motor or d,iver.

?

drlwer

,

Open "'Ilve III

IUCt U)rl p.plng.

SUCTION

Open ... ent .... 1". U'llil t tuOy strum

of liquid come. ouL Then clo-e

Is";J

o '

TA :

11-_ Cibtetyt dllcn,rge pre.ure. II it i.

,

7 NfTlC .. '\oICUOIl j)l1!aute, PUI'l'll ".,

... eper locked.. Shutoown end repel!

,. Slep II.

r DISCHARCE

(0 Cheek l or bearing

V l<bricltion.

DRAIN

J "there ill pl1! .. ure In db

chMge pipifl9, open '1.1" ..

o Check lor nol.e or IIlb,.lIoo.

V Shutdown If either i, noted.

LOW FLOW RECYCLE

6. Observe the pu mp for unusual noise or vibration. I f either occurs, shut down

the pump immediately.

7. Observe the pressUl'e gauge on the discharge side of the pu mp. If it is below

normal , the pump has probably vapor locked. Shut it down and repeat Step No.4.

8. It is not unusual fOi' a pump seal to leak some when a pump starts, particularly

if it is a new seal. Leakage should top within a few minutes.

If a pump has been sitting in the sun before it is started, its temperature may be

36 CONTROL OF PUMP FLOW RATE

above that of the liquid being pumped. As soon as the liquid enters the pump, its

temperature rises and some liquid fl ashes. The pump will immediately vapor lock when

vapors are present in it. Consequently, it will be necessary to vent the pump until the

liquid from the vessel has cooled the pump to the same temperatul'e as that of the liquid.

B. Control of Pump Flow Rate

The pump curves we discussed in the previous section applied to pumps operating at

a constant speed. The flow rate through the pump is determined by the pressure head

developed by the pump. A control valve in the pump discharge line is often used to

control the flow I'ate through the pump. One such type of flow control is shown below.

PRESSURE

CeNTROl

rr===* GAS

"")INloj)(:.iiiiiiiioi)<. DISCKARGE LIQUID

lEVEL

CONTROL

VALVE

FLOW CONTROL USIt-13 CONTROL VALVE IN DISCHARGE LINE

REGULA TED WITH LEVEL CONTROLLER

In the above drawing, liquid is pumped out of a separator which has a st ream of

liquid and gas enteri ng it, Gas flow leaving the top of the vessel is regulated with a

pressure control system that holds a constant p,'essure on the separator.

Liquid is pu mped out of the vessel to its final destinati on. A level control system

regulates the flow rate through the pump. A level controller mounted on the separator

senses the level inside the vessel. [f the level rises, the controller signals the level

control valve to open. This lowers t he pump discharge pressure and also lowers the head

\

CONTROL OF PUMP FLOW RATE 37

pressure developed by the pump. The effect is to incr ease the flow I'ate t hrough t he pump

because the head pressure was loweled.

Conversely, if t he l evel in t he separator fall s, t he level controller will signal t he

control valve to close. This increases the pump discharge pressure, and the head pressure,

which reduces the flow through t he pump.

Another type of flow control through a pump is shown bel ow. A pressure controll er

on the discharge line of the pump is used to I'egulate the fl ow of l iquid pu mped from the

storage tank. This type of control is used on LACT units. The pressure controll er is set

at the desired discharge pressure, and it signals a cont rol valve to open or close as

r equired to maintain a const ant discharge pressure. If the pressure rises, t he contr oller

will signal t he cont l'ol valve to open, whi ch lowers the pressure (and head pressur e) and

i ncreases fl ow t hrough the pump, and vi ce versa.

STORAGE T Ai'<

PRESSURE

CONTROLLER

1 : : ; ; ; ~ OISCHARGE

;><. LI QUID

PRESSURE

CONTROL

VALVE

FLOW CONTROL WITH CONTRQ VALVE IN DISCHARGE

LINE REGUlATED WITH PRESSlRE CONTROLLER

Use of a control val ve in the pump discharge l ine to regulate flow t hrough t he pump

is undesirable for t wo reasons:

1. The control valve has a pressure drop across it, whi ch represents a

wast e of energy used by the pump dr iver.

2. PI'ocess conditions regulati ng the control val ve i n the pump dischar ge

line may be such that at ti mes t he pump operates at a fracti on of i ts

design flow ra teo

In t he second situat ion, t he pump effi ciency at low fl ow rat e may be 10-20%, and

some of t he lost dr ivel' energy ent ers t he li quid in t he pump in t he for m of heat . Heati ng

liqui d in the pump may cause some of it to boil and for m vapor, whi ch wi ll result in a